Industrial Boiler Cloud Data Platform

- Date

Encountering issues during the operation of industrial boilers?

In the past, even for minor problems, technicians had to make special trips to the project site, causing delays and wasting manpower, resources, and finances.

Now, you can solve small problems “without leaving your home” through the “Industrial Boiler Cloud Data Platform” by checking relevant data, identifying and analyzing the causes of problems, remotely debugging control system code, modifying parameters, and guiding on-site personnel. This cloud-based solution significantly improves the response speed and efficiency of after-sales services.

What is the “Industrial Boiler Cloud Data Platform”?

What role does it play?

What sparks can “Internet + Boiler” generate?

Now, let me provide you with a detailed explanation.

What is the Industrial Boiler Cloud Data Platform?

Ankang, Deputy General Manager of the Combustion Control Company of Taishan Group:

The Industrial Boiler Cloud Data Platform mentioned here is an intelligent data platform developed independently by the Combustion Control Company of Taishan Group based on technologies such as the Internet of Things, cloud computing, and sensors. It consists of three parts: the front-end system, the transmission system, and the user terminal. It can automatically collect boiler room data and upload it to the cloud server’s dedicated database, serving as a comprehensive information management system that integrates data collection, display, diagnosis, analysis, and recommendations.

Driven by Internet technology, the Combustion Control Company of Taishan Group has kept pace with the development trends of the times. At the end of 2018, it officially built and put into use this platform, extending its service tentacles to project sites, achieving remote monitoring of boiler data, and becoming one of the early enterprises in the boiler industry to embrace the Internet.

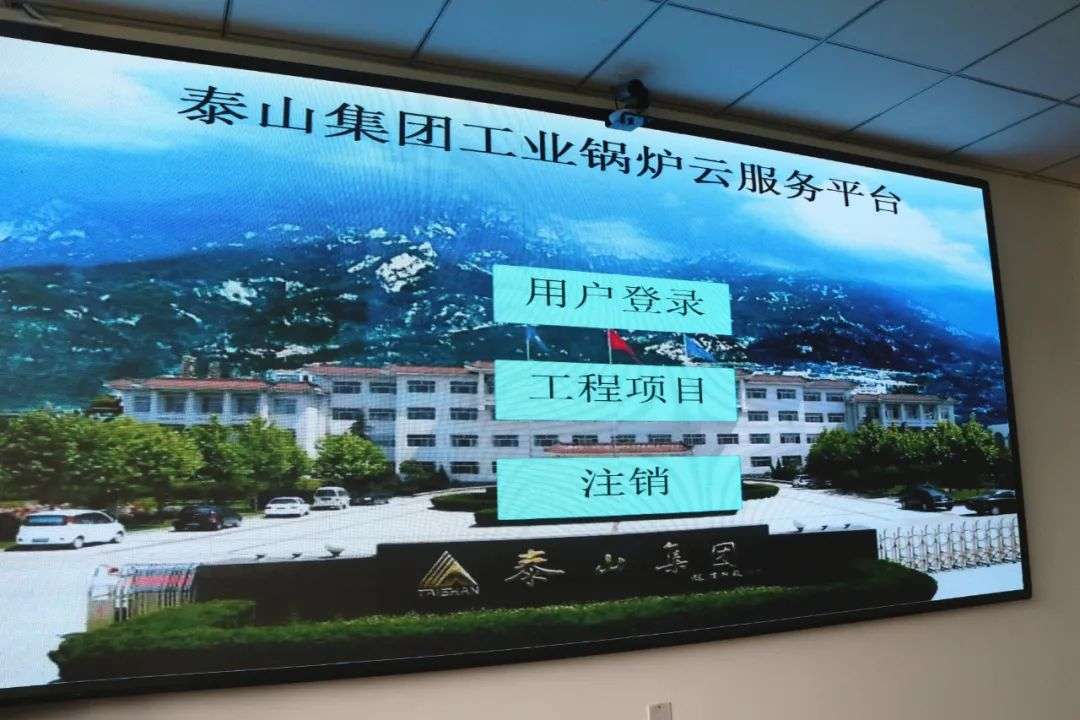

(Interface of the “Industrial Boiler Cloud Data Platform”)

What role can the Industrial Boiler Cloud Data Platform play?

Furnace outlet flue gas temperature 687.5℃/662.6℃, normal; drum pressure 1.1Mpa, normal; economizer outlet water temperature 133.3℃, normal; boiler drum liquid level electrode 50.3%, normal; boiler #1 return water pressure, normal…

On the big screen in the control room of the Boiler Company’s cloud data platform, various screens and data from the DCS system of the platform project are displayed in real time and at a glance. At the same time, all information from projects connected to the “Industrial Boiler Cloud Data Platform” can be freely switched and viewed, achieving centralized and information-based management of the boiler room.

Yue Lei, a technician from the Combustion Control Company of Taishan Group:

“Viewing data is not the ultimate goal of developing this platform but achieving early warning through real-time monitoring of data. This platform has shifted from passive service to active service and from remediation after the fact to proactive warning.”

“When there are sudden situations such as high furnace, steam drum temperatures, excessive or insufficient water flow from the outlet valve, the platform’s alarm system will be triggered. Users at various terminals will quickly receive information such as alarm time, event time, variables, alarm type, alarm level, alarm value, limit value, and recovery value.”

‘’This real-time monitoring of abnormal data serves as an early warning, allowing the analysis of the causes based on real-time and historical data, dealing with issues early on, nipping the problem in the bud, and preventing the occurrence of safety accidents.”

“In addition, one of the advantages of the cloud data platform is convenient access via mobile phones. Both we and our clients can log in, and it supports simultaneous login from multiple devices, with one person able to log in to multiple accounts.”

(Login interface of the “Industrial Boiler Cloud Data Platform”)

“As long as you input the account and password for a project from the mobile app, you enter the “Cloud Data Platform” system for that project, where various screens and data are displayed in real-time sync. Even if you are not on-site, clients can view real-time operational data of boilers anytime, anywhere and receive alarm messages promptly.”

Yue Lei, a technician from the Combustion Control Company of Taishan Group:

“To ensure the security of data, we have also implemented “private customization” for individual projects, assigning exclusive permissions to each project so that only relevant personnel have viewing rights, making it convenient, secure, and efficient.”

“At the same time, the company can use this platform to conduct comprehensive analysis and calculations of on-site data based on mathematical models and algorithms established by the intelligent analysis layer. According to the results of data processing and analysis, it can call up information from the expert database and provide optimization or rectification suggestions for user boiler operations, assisting management personnel in making decisions quickly and accurately.”

Platform Optimization Direction

Ankang, Deputy General Manager of the Combustion Control Company of Taishan Group:

“Since the platform went online, some projects have actively connected and achieved some results. However, overall, customers have a low understanding of the cloud platform, and the company’s promotion efforts are not sufficient. The advantages of the cloud platform have not been fully realized.”

In the upsurge of “Internet +,” the boiler industry is bound to undergo transformation and upgrade. Now, we have taken the first step toward “Internet + Industrial Boiler” and stepped to the forefront of the industry. In the future, we will further enhance platform functions, integrate big data analysis, and provide more powerful support for equipment operation and maintenance, after-sales service, equipment upgrades, fault troubleshooting, etc. We will transform and upgrade from traditional, extensive services to intelligent, refined services, move from manufacturing to “smart manufacturing,” dispel customer concerns with practical services, and turn the cloud data platform into a “trump card” for Taishan Group to seize the market in the era of “Internet +.”