Cold wave invasion: How are the heating projects progressing for Taishan Group?

- Date

With the arrival of winter, a cold wave has swept in. Recently, the China Meteorological Administration issued an important weather forecast for November 19th to 22nd. A strong cold air mass will affect nearly 80% of China’s territory from west to east, causing temperatures to drop by 6°C to 10°C in most areas, locally exceeding 12°C!

There’s a kind of cold that makes mothers think you should wear long johns; there’s a kind of chill that renders long johns ineffective. But for kids in the north, there’s a kind of happiness called “finally, the heating is on.”

So, as a leading enterprise in the Chinese industrial boiler industry, how are the heating projects of Taishan Group progressing? Let’s explore it together…

On-Time Heating: Warmth Spreading to Every Home

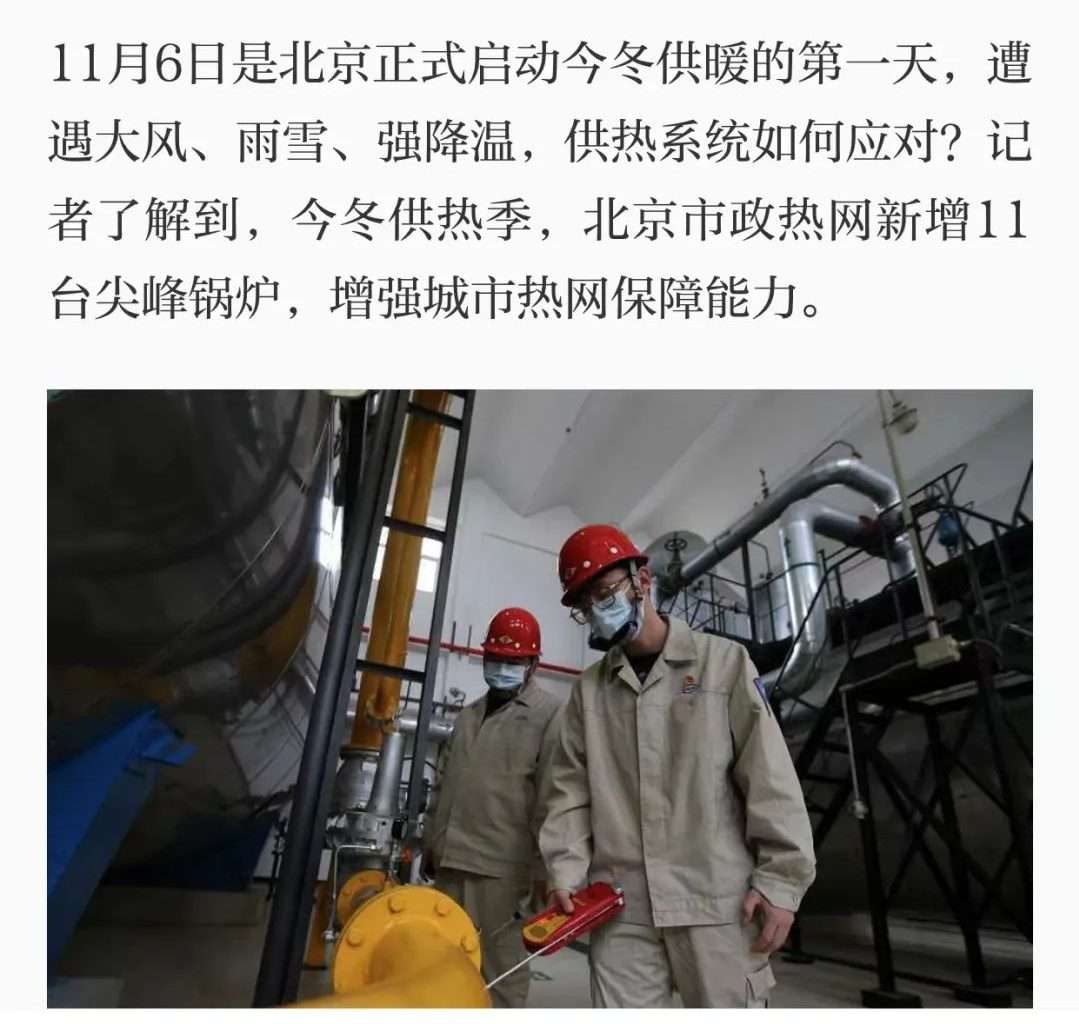

All 11 new peak boilers added in Beijing this winter are “Taishan boiler.”

The site of the 58MW peak boiler project in Beijing.

The site of two QXS116-1.6/130/70-Q gas-fired hot water boilers in Shandong Xingyang.

The site of three QXS58-1.6/130/70-AIII coal powder hot water boilers in Jiuquan Changheng, Gansu.

“Here comes the heating! The radiators at home are warming up!” On October 25th, the heating season officially started in the urban area of Jiuquan, Gansu. This marked the full operation of three QXS58-1.6/130/70-AIII coal powder hot water boilers developed, manufactured, and installed by Taishan Group. At the same time, projects such as Shandong Xingyang Heat, Xinjiang Aksu Sunshine Heat, and Tianjin Xuyang Heat have also successfully started heating on schedule.

To ensure the timely commissioning of projects, Taishan Group cooperated fully with customers in various pre-heating tasks. The sales system tracked the whole process with proactive services; the technical system implemented project responsibility, ensuring the coherence of the product design process; the production system formulated three-level production plans (factory, workshop, team) based on sales orders and production tasks; the energy engineering company deployed personnel reasonably, meticulously arranged project schedules, and responded promptly at all levels. This effectively ensured the smooth progress of the projects. At this moment, the boilers are burning vigorously, and warm currents are flowing into thousands of households.

The site of two QXF116-1.6/130/70-AIII circulating fluidized bed boilers in Aksu, Xinjiang.

The site of three 70MW boilers in Tianjin Xuyang Heat.

Full Effort: Accelerating Project Construction

The site of the SZS58-1.6/130/70-Q project in Zhangjiakou Dongyang Heat, Beijing, fully ensuring the Beijing Winter Olympics.

The site of the 80t/h boiler coal-to-gas project in Fohai Clean Energy Renovation, Xianyang, Shaanxi.

At other project construction sites, workers are installing bridge frames, performing paired welding, and installing pipelines. Working overtime and working hard, they are fully committed to meeting deadlines. Excavators, tower cranes, and other large machinery swing their “iron arms,” and everything is busy in an intense yet orderly manner.

Project managers are always on-site, reasonably allocating manpower and equipment according to the project schedule. They continuously optimize project construction plans, strive to make up for time lost due to objective factors such as the pandemic, and ensure that projects pass acceptance smoothly, laying a solid foundation for on-time completion next year.

The site of the TG45-1.6-M project in Liupanshan, Longde, Ningxia.

The site of the relocation and expansion project of the heating boiler room in Jingyuan, Ningxia.

Technical Optimization: Dedicated to Safeguarding “Heating Blue”

Although it is currently the heating season, the blue sky continues to be “online,” and everyone enjoys the “double benefits” of clear outdoor skies and indoor warmth, thanks to the continuous implementation of measures such as clean heating and environmental supervision.

To meet customer requirements, the company has strengthened cooperation with various universities and research institutes at the technical level. It has optimized core components such as furnace, economizer, and water-cooled wall, using flue gas desulfurization and denitrification technology. This continuously improves the combustion efficiency and thermal efficiency of the boiler, achieves emissions of pollutants such as NOx and SO₂ that comply with or even exceed national environmental requirements, and contributes to the battle for achieving peak carbon and green transformation.

Now, let’s have a wave of on-site project pictures with no beauty filters:

Assisting in clean and efficient heating, dedicated to safeguarding clear waters and blue skies. Taishan Group will continue to prioritize customer needs, enhance service quality and efficiency, continuously optimize design levels, achieve clean, efficient, and high-quality heating, and wholeheartedly safeguard the warmth and blue skies of winter!