Biomass Briquette Boiler is a kind of biomass boiler burning biomass particles forming fuel. Biomass briquette fuel features the following characteristics:

(1) High volatile matter and low fixed carbon, easy to ignite and burn.

(2) High hydrogen and oxygen content, conducive to combustion.

(3) Low ash content for woody biomass fuel, only about 2%.

(4) Low sulfur content, beneficial to environmental protection.

(5) Dense and regular shaped briquette fuel convenient for storage and short distance transportation.

(6) Improved energy density beneficial to automatic use.

(7) Standardized fuel lay foundation for biomass briquette boiler design standardization.

Biomass Briquette Boiler Design Analysis

Biomass briquette fuel is rod-shaped, block-shaped or granular fuel formed by extrusion, whose density is much greater than before.

The effusion rate of volatile matter and heat transfer rate are greatly reduced. The combustion includes: precipitation of water, precipitation and combustion of volatiles, and combustion of fixed carbon. In order to improve the combustion and boiler efficiency, take the following measures in the biomass briquette boiler design:

(1) The reciprocating grate with an inclination angle of 6°, not only reducing the overall height but ensuring the smooth movement.

(2) The grate reduction box adopts stepless speed control, which can accurately adjust the speed according to fuel combustion condition.

(3) The feedstock adopts variable frequency screw feeder plus distributor, ensuring accurate feeding and evenly distribution of fuel on the grate.

(4) Reasonable furnace height of biomass pellet boiler ensures lower furnace volume heat release rate.

(5) Reasonable height of secondary air ensures secondary air volume and outlet speed, and strengthens the combustion of volatile matter.

(6) Secondary air pipe is on the fire barrier, prolonging flue gas residence time and promoting the settlement of fly ash.

(7) Spirally corrugated tube has a flue gas velocity of 21m/s, preventing fly ash deposition and ensuring high heat exchange efficiency.

Biomass Briquette Boiler Structure

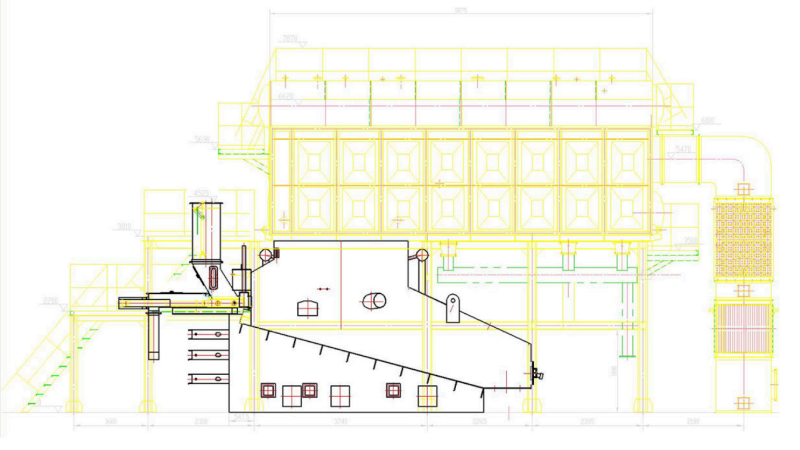

The biomass fuel boiler is double drum, longitudinal layout, reciprocating grate steam boiler. It includes two parts: upper boiler body and lower combustion equipment.

Upper boiler body includes drum, spirally corrugated tube, upper and lower headers, and water wall tube. The inner side is furnace wall, front and rear arches, fire barrier and flue duct. The outer side is steel frame and outer cover, and the middle is aluminum silicate insulation material.

Lower combustion equipment is 6° reciprocating grate, considering pushing and moving of fuel on grate and overall height limit.

The secondary air volume accounts for 25% of total air volume, and air speed is about 50m/s. The volatile matter of biomass briquette fuel is up to 70%. The design of secondary air is particularly important for ensuring the combustion of volatile matter and efficiency of boiler.