What Are the Different Types of Industrial Biomass Boilers?

As industries move toward renewable energy and carbon reduction, industrial biomass boilers have become a key solution for sustainable steam and heat generation. However, biomass fuels vary widely in form, moisture, and combustion behavior, and not all biomass boilers are the same. Choosing the wrong boiler type can result in low efficiency, fuel handling issues, and high maintenance costs. Understanding the different types of industrial biomass boilers is essential for selecting the right technology for your application.

Industrial biomass boilers can be broadly classified based on their combustion method and fuel adaptability, including grate-fired biomass boilers, fluidized bed biomass boilers (BFB/CFB), suspension-fired boilers, and gasification-based biomass boilers. Each type is designed to handle specific biomass fuels—such as wood chips, pellets, agricultural residues, or waste biomass—while balancing efficiency, emissions, and operational flexibility.

Knowing the differences between these boiler types helps industries optimize fuel utilization, improve efficiency, and ensure stable long-term operation.

Understanding the main biomass boiler technologies will guide you toward the most suitable solution for your fuel supply, capacity needs, and environmental requirements.

What Is a Grate-Fired Industrial Biomass Boiler and Where Is It Best Applied?

In many industrial facilities seeking to reduce fuel costs and carbon emissions, biomass energy appears attractive—but confusion quickly arises around boiler technology selection. The pain point for decision-makers is clear: biomass fuels are diverse, inconsistent, and operationally challenging, and choosing the wrong boiler design can lead to low efficiency, frequent shutdowns, and excessive maintenance. The consequence of a poor match between fuel and technology is not only higher operating cost but also loss of confidence in biomass as a viable energy solution. The solution lies in understanding what a grate-fired industrial biomass boiler is, how it works, and where it delivers the greatest practical and economic value.

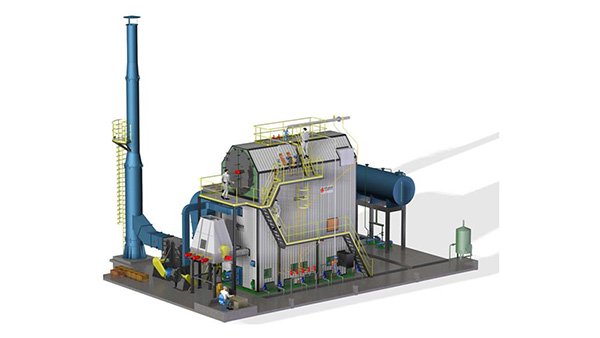

A grate-fired industrial biomass boiler is a solid-fuel steam boiler that burns biomass fuels on a fixed or moving grate, making it best suited for industries with stable heat demand, access to coarse or variable biomass fuels, and a need for robust, proven combustion technology.

This technology has become one of the most widely adopted biomass boiler solutions worldwide due to its fuel flexibility and operational reliability.

Grate-fired biomass boilers can only burn uniform, high-quality biomass pellets.False

Grate-fired boilers are specifically designed to handle coarse, heterogeneous, and variable biomass fuels.

Grate-fired biomass boilers are well suited for continuous industrial steam production.True

Their robust combustion process and stable operation make them ideal for continuous-duty industrial applications.

What Is a Grate-Fired Industrial Biomass Boiler?

From a professional manufacturer’s and supplier’s perspective, a grate-fired industrial biomass boiler is a combustion system in which solid biomass fuel is fed onto a grate where it burns in stages as it moves through the furnace. The grate supports the fuel bed, allows controlled air distribution from below, and enables ash to be discharged continuously.

Unlike suspension-fired or fluidized-bed systems, grate-fired boilers rely on a solid fuel bed. This makes them mechanically simpler and more tolerant of fuel variability. Typical grate designs include fixed grates, reciprocating grates, and moving or traveling grates, each selected based on fuel characteristics and capacity requirements.

In industrial steam applications, grate-fired boilers are commonly integrated with water-tube boiler structures to handle medium to large steam outputs reliably.

How the Grate-Firing Process Works

The combustion process in a grate-fired biomass boiler occurs in distinct zones along the grate. Fresh biomass is fed at one end, where drying and devolatilization begin. As the fuel progresses, volatile gases burn above the fuel bed while fixed carbon burns on the grate surface. Finally, residual ash is discharged at the end of the grate.

Primary air is supplied from beneath the grate to support solid fuel combustion, while secondary air is injected above the fuel bed to complete gas-phase combustion. This staged process ensures stable flame formation and accommodates fuels with varying moisture content and particle size.

From an operational standpoint, this gradual, controlled combustion is the key reason grate-fired boilers are so forgiving compared with more sensitive biomass technologies.

Types of Biomass Fuels Suitable for Grate-Fired Boilers

One of the defining advantages of grate-fired biomass boilers is fuel flexibility. They can handle a wide range of biomass fuels that would be problematic for other combustion systems.

| Biomass Fuel Type | Suitability for Grate-Firing |

|---|---|

| Wood chips | Excellent |

| Wood bark | Excellent |

| Sawdust | Good |

| Agricultural residues | Good–excellent |

| Biomass briquettes | Good |

| High-moisture fuels | Acceptable with design adaptation |

This flexibility allows facilities to use locally available or low-cost biomass, significantly improving long-term fuel economics.

Why Grate-Fired Boilers Are Industrially Robust

From an engineering perspective, grate-fired biomass boilers are valued for their mechanical robustness. The combustion process is slow and stable, reducing sensitivity to fuel fluctuations. Grate systems are designed for continuous ash removal, minimizing clinker buildup and reducing manual intervention.

Maintenance requirements, while higher than gas-fired systems, are predictable and manageable. Components are accessible, wear patterns are well understood, and spare parts are readily available. This predictability is crucial for industrial users who prioritize uptime and cost control.

Best Industrial Applications for Grate-Fired Biomass Boilers

Grate-fired biomass boilers are not universal solutions; they excel in specific application contexts. Their best applications share common characteristics related to fuel availability, load profile, and operational philosophy.

Wood Processing and Forest Products Industry

The wood processing industry is the most natural fit for grate-fired biomass boilers. Sawmills, panel manufacturers, and pulp and paper plants generate large quantities of wood waste such as bark, chips, and sawdust. Using these residues as boiler fuel converts waste into energy.

Steam is often required continuously for drying, pressing, and process heating. Grate-fired boilers match this demand profile well, delivering stable steam while consuming internally generated biomass fuel at low marginal cost.

Pulp and Paper Industry

In pulp and paper facilities, steam demand is high and continuous, and fuel streams are often heterogeneous. Grate-fired biomass boilers provide the robustness required to burn mixed biomass fuels reliably while supporting base-load steam generation.

From a lifecycle cost perspective, these boilers enable fuel self-sufficiency and reduce exposure to fossil fuel price volatility, making them economically attractive despite higher capital investment.

Agricultural and Agro-Processing Facilities

Agricultural processing plants often produce residues such as straw, husks, shells, and other by-products. Grate-fired biomass boilers can be adapted to burn these fuels effectively, provided proper fuel preparation and feeding systems are in place.

These facilities typically have seasonal but predictable operating patterns, making grate-fired systems suitable for long operating campaigns with planned maintenance intervals.

District Heating and Industrial Energy Centers

Grate-fired biomass boilers are widely used in district heating and centralized energy plants serving industrial parks. Their ability to operate continuously at stable load makes them ideal for base-load heat and steam generation.

From an economic standpoint, centralized grate-fired biomass systems benefit from scale, fuel aggregation, and professional operation, improving reliability and cost-effectiveness.

Where Grate-Fired Biomass Boilers Are Less Suitable

Despite their strengths, grate-fired biomass boilers are not ideal for every application. They are less suited to facilities with highly intermittent demand, limited space for fuel storage, or access only to very fine or uniform fuels where alternative technologies may offer higher efficiency.

Additionally, applications requiring extremely rapid load changes may find grate systems less responsive than gas-fired boilers.

Comparison With Other Biomass Boiler Technologies

The table below highlights how grate-fired boilers compare with other common biomass combustion technologies.

| Technology | Fuel Flexibility | Complexity | Typical Application |

|---|---|---|---|

| Grate-fired | Very high | Moderate | Industrial base-load |

| Fluidized bed | High | High | Large-scale plants |

| Suspension-fired | Low–medium | Low | Uniform fuels |

From a supplier’s perspective, grate-fired boilers occupy the optimal middle ground between flexibility and complexity.

Environmental and Economic Considerations

Grate-fired biomass boilers support renewable energy goals and can significantly reduce net CO₂ emissions when sustainably sourced biomass is used. However, they require proper emissions control systems to manage particulates and other pollutants.

Economically, their long-term value depends heavily on fuel cost and availability. Where low-cost biomass is accessible, grate-fired boilers often deliver excellent lifecycle economics despite higher initial capital cost compared with fossil-fuel systems.

Case Example: Practical Application Success

A wood panel manufacturing plant installed a grate-fired biomass steam boiler fueled by internal wood waste. The boiler operated continuously, supplying process steam while eliminating disposal costs for residues. Over time, fuel savings and avoided waste handling costs justified the investment, and the system became a core component of the plant’s energy strategy. This example illustrates how application alignment determines success.

Strategic Perspective From a Manufacturer

From a professional manufacturer’s and supplier’s standpoint, grate-fired biomass boilers represent a mature, proven technology that delivers reliability and fuel flexibility when properly applied. They are best suited for industrial users who view biomass not as an experimental fuel but as a long-term energy resource integrated into their production ecosystem.

In conclusion, a grate-fired industrial biomass boiler is a solid-fuel boiler that burns biomass on a grate, offering high fuel flexibility, stable operation, and industrial robustness. It is best applied in industries with continuous steam demand, access to coarse or variable biomass fuels, and a long-term commitment to renewable energy—such as wood processing, pulp and paper, agricultural processing, and district heating. When matched correctly to application conditions, grate-fired biomass boilers deliver reliable performance and strong long-term economics.

How Do Bubbling Fluidized Bed (BFB) Biomass Boilers Differ From Grate Boilers?

For industrial users investing in biomass energy, one of the most common and consequential dilemmas is choosing between a bubbling fluidized bed (BFB) biomass boiler and a traditional grate-fired boiler. The pain point is uncertainty: both technologies are proven, both can generate reliable steam, yet they differ fundamentally in combustion behavior, fuel tolerance, operating complexity, and long-term cost structure. Choosing the wrong technology can result in unstable combustion, excessive maintenance, or fuel limitations that undermine the entire biomass strategy. The consequence is not merely inefficiency, but operational frustration and lost economic value. The solution is a clear, engineering-based understanding of how BFB biomass boilers differ from grate boilers and where each technology delivers its strongest advantages.

Bubbling fluidized bed (BFB) biomass boilers differ from grate boilers primarily in combustion mechanism, fuel particle size requirements, efficiency, emission control capability, and operational complexity, making BFB systems better suited for fine, low-quality fuels and stricter emission demands, while grate boilers excel in simplicity and coarse fuel handling.

This distinction is critical for aligning boiler technology with fuel characteristics and long-term operational goals.

BFB biomass boilers require higher fuel quality than grate-fired boilers.False

BFB boilers can handle low-grade and high-ash fuels, but require smaller and more uniform particle size.

Grate boilers are mechanically simpler than BFB boilers.True

Grate boilers rely on solid fuel beds and fewer auxiliary systems, resulting in simpler operation and maintenance.

Fundamental Combustion Principle Differences

From a professional manufacturer’s and supplier’s perspective, the most important difference between BFB biomass boilers and grate boilers lies in how fuel is burned. Grate boilers burn biomass on a solid fuel bed supported by a fixed or moving grate. Combustion progresses slowly as the fuel dries, ignites, and burns out along the grate length.

In contrast, BFB boilers suspend biomass fuel in a hot, bubbling bed of inert material—typically sand—using upward-flowing air. The fuel particles behave almost like a fluid, mixing intensely with the bed material. This fluidization creates uniform temperature distribution and highly efficient heat transfer.

This fundamental difference drives nearly every other operational and economic distinction between the two technologies.

Fuel Size and Preparation Requirements

Fuel preparation is one of the most decisive factors in technology selection. Grate-fired boilers are extremely tolerant of fuel size variability. They can handle large, coarse, irregular biomass such as wood chips, bark, and agricultural residues with minimal preprocessing. This makes them ideal where fuel preparation infrastructure is limited or fuel streams are heterogeneous.

BFB boilers, while tolerant of low fuel quality in terms of ash and moisture, require smaller and more uniform particle sizes. Oversized fuel can disrupt fluidization and cause defluidization zones. As a result, BFB systems typically require shredding, screening, or milling equipment upstream, increasing capital and operational costs.

| Parameter | Grate Boiler | BFB Boiler |

|---|---|---|

| Fuel particle size | Large, coarse | Small, uniform |

| Fuel preparation | Minimal | Moderate–high |

| Tolerance to variability | Very high | High (size-dependent) |

From a supplier’s standpoint, fuel logistics often determine feasibility more than combustion efficiency.

Combustion Efficiency and Temperature Control

BFB boilers offer superior combustion efficiency due to intense mixing and uniform temperature distribution. The bubbling bed maintains stable combustion even with low-calorific-value fuels. Heat transfer is highly efficient, allowing for compact furnace designs and improved steam generation efficiency.

Grate boilers, while reliable, experience temperature gradients along the grate. Combustion efficiency depends heavily on fuel distribution and grate speed. Although modern grate designs have improved performance significantly, they generally cannot match the combustion uniformity of BFB systems.

However, higher efficiency comes at the cost of increased operational complexity, which must be justified by fuel and emission requirements.

Emissions Performance and Control

From an environmental compliance perspective, BFB boilers offer clear advantages. Lower and more uniform combustion temperatures reduce NOₓ formation. The intense mixing promotes complete burnout of fuel, lowering CO and unburned carbon emissions. In-bed additives can also be introduced to capture sulfur and other contaminants directly during combustion.

Grate boilers typically require downstream emission control systems to achieve similar performance. While fully compliant systems are achievable, they often involve additional equipment and operating cost.

| Emission Aspect | Grate Boiler | BFB Boiler |

|---|---|---|

| NOₓ formation | Moderate | Low |

| CO emissions | Moderate | Low |

| In-bed emission control | Limited | Excellent |

For facilities operating under strict environmental regulations, this difference has major long-term economic implications.

Operational Complexity and Maintenance

Grate boilers are widely regarded as the most straightforward biomass combustion technology. Operators can visually assess combustion behavior, and mechanical systems are relatively simple. Maintenance focuses on grate components, ash handling, and refractory inspection.

BFB boilers, while highly efficient, are more complex. They require careful control of bed temperature, air distribution, and bed material inventory. Bed material must be replenished and managed to avoid agglomeration. Instrumentation and automation requirements are higher, and operator skill levels must be correspondingly greater.

From a lifecycle cost perspective, this complexity increases both training and maintenance demands, which must be offset by efficiency and emission benefits.

Load Flexibility and Response

BFB boilers generally offer superior load flexibility compared with grate boilers. The fluidized bed responds quickly to changes in fuel input and air flow, allowing faster load ramping and better turndown capability. This makes BFB systems suitable for applications with variable steam demand.

Grate boilers respond more slowly due to the inertia of the solid fuel bed. While adequate for base-load operation, they are less ideal for applications requiring rapid load changes.

| Load Characteristic | Grate Boiler | BFB Boiler |

|---|---|---|

| Load ramp rate | Moderate | Fast |

| Turndown ratio | Limited | Wide |

| Best operation mode | Base load | Variable load |

Capital and Operating Cost Implications

From a professional supplier’s standpoint, capital cost comparisons are nuanced. BFB boilers typically require higher initial investment due to additional systems for fuel preparation, bed material handling, and advanced controls. Installation complexity is also higher.

Grate boilers usually offer lower capital cost and simpler project execution. However, operating costs can vary depending on fuel quality and emission control requirements. In regions with stringent emission standards, the long-term compliance cost of grate boilers may narrow the capital cost advantage.

Best Application Scenarios for Each Technology

Grate-fired biomass boilers are best applied where fuel is coarse, variable, and locally available, and where steady base-load steam demand exists. Industries such as wood processing, pulp and paper, and agro-processing commonly favor grate systems due to their robustness and simplicity.

BFB biomass boilers are best suited for applications requiring high efficiency, low emissions, and fuel flexibility in terms of ash and moisture—but with controlled particle size. Large industrial plants, power generation facilities, and sites facing strict environmental regulations often prefer BFB technology despite higher complexity.

Case Comparison: Practical Decision-Making

A forestry-based manufacturing plant evaluated both technologies. Its fuel consisted of large bark pieces and mixed wood residues with minimal preprocessing. A grate boiler delivered reliable combustion with low preparation cost. In contrast, a chemical plant using agricultural waste fines selected a BFB boiler to achieve emission targets and handle high-ash fuel efficiently. These contrasting outcomes highlight that neither technology is universally superior—application context is decisive.

Strategic Perspective From a Manufacturer

From a professional manufacturer’s and supplier’s perspective, the choice between BFB and grate boilers should be driven by fuel characteristics first, regulatory requirements second, and operational philosophy third. Grate boilers prioritize simplicity and fuel size tolerance. BFB boilers prioritize efficiency, emissions performance, and load flexibility.

Selecting the wrong technology often leads to higher long-term cost than any initial capital savings.

In conclusion, bubbling fluidized bed (BFB) biomass boilers differ from grate boilers in combustion mechanism, fuel size requirements, efficiency, emissions performance, and operational complexity. BFB boilers excel in high-efficiency, low-emission, variable-load applications with prepared fuels, while grate boilers remain the most robust and economical solution for coarse, heterogeneous biomass and steady industrial steam demand. Understanding these differences is essential for making a technically sound and economically sustainable biomass boiler investment.

What Advantages Do Circulating Fluidized Bed (CFB) Biomass Boilers Offer?

As industries pursue lower-carbon energy and long-term fuel cost stability, biomass boilers are increasingly seen as strategic assets rather than auxiliary equipment. However, many decision-makers encounter a serious pain point when scaling up biomass utilization: conventional grate or bubbling fluidized bed systems begin to struggle with fuel diversity, emission limits, and efficiency targets at larger capacities. The consequence is often higher operating cost, compliance risk, or limited future expansion. The solution lies in advanced combustion technology—specifically, understanding the advantages that circulating fluidized bed (CFB) biomass boilers offer and why they are widely adopted for large, demanding industrial applications.

Circulating fluidized bed (CFB) biomass boilers offer superior fuel flexibility, high combustion efficiency, low emissions, excellent load flexibility, and strong scalability, making them ideal for large-scale, continuous industrial steam and power generation.

These advantages position CFB technology as the most versatile and future-proof biomass boiler solution available today.

CFB biomass boilers can only operate efficiently with high-quality, uniform biomass fuels.False

CFB boilers are specifically designed to handle a wide range of low-quality, high-ash, and variable biomass fuels.

CFB biomass boilers provide lower emissions than traditional grate-fired biomass boilers.True

Uniform combustion temperature and in-bed emission control significantly reduce NOₓ, SO₂, and CO emissions.

What Is a Circulating Fluidized Bed (CFB) Biomass Boiler?

From a professional manufacturer’s and supplier’s perspective, a CFB biomass boiler is an advanced fluidized combustion system in which biomass fuel particles are suspended in a high-velocity upward airflow, circulating continuously between the furnace and a cyclone separator. Unlike bubbling fluidized bed (BFB) systems, where solids remain mostly within the furnace, CFB systems intentionally entrain fuel and bed material and recirculate them for extended residence time.

This circulation ensures nearly complete fuel burnout, uniform temperature distribution, and exceptional fuel flexibility. CFB boilers are typically used in medium- to large-capacity installations where performance, emissions, and scalability are critical.

Exceptional Fuel Flexibility: A Core Advantage

Fuel flexibility is one of the most significant advantages of CFB biomass boilers. These systems can burn a wide variety of biomass fuels, including those with high ash content, variable moisture, and inconsistent calorific value. The long residence time and intense mixing allow complete combustion even for difficult fuels.

| Biomass Fuel Type | CFB Suitability |

|---|---|

| Wood chips and bark | Excellent |

| Agricultural residues | Excellent |

| Energy crops | Excellent |

| High-ash biomass | Very good |

| Mixed biomass streams | Excellent |

From an economic standpoint, this flexibility allows operators to source the lowest-cost available biomass without being constrained by strict fuel specifications, significantly improving long-term fuel economics.

High Combustion Efficiency and Stable Performance

CFB boilers achieve high combustion efficiency due to uniform temperature distribution and extended fuel residence time. Fuel particles circulate multiple times through the combustion zone, ensuring near-complete burnout. This minimizes unburned carbon losses and improves overall thermal efficiency.

Unlike grate-based systems, which experience temperature gradients, CFB systems maintain stable combustion across the entire furnace. This stability translates into consistent steam output, reduced thermal stress on boiler components, and predictable long-term performance.

Low Emissions by Design

Environmental performance is a defining advantage of CFB biomass boilers. Combustion temperatures in CFB systems are lower and more uniform than in traditional furnaces, significantly reducing thermal NOₓ formation. Additionally, in-bed additives such as limestone can be introduced to capture sulfur directly during combustion, reducing SO₂ emissions without extensive downstream treatment.

The table below highlights typical emission performance advantages.

| Emission Parameter | Grate Boiler | CFB Boiler |

|---|---|---|

| NOₓ | Medium | Low |

| SO₂ | Medium–high | Low |

| CO | Medium | Low |

From a compliance perspective, these inherent advantages reduce reliance on expensive end-of-pipe emission control systems and lower long-term regulatory risk.

Superior Load Flexibility and Turndown Capability

CFB biomass boilers excel in applications with variable load demand. The circulating bed responds quickly to changes in fuel and air input, allowing rapid load adjustments and wide turndown ratios. This makes CFB systems suitable not only for base-load operation but also for facilities with fluctuating steam or power demand.

In contrast, grate boilers are better suited to steady operation and may struggle with frequent load changes. For industrial plants with dynamic production schedules, the flexibility of CFB technology delivers tangible operational and economic benefits.

Scalability for Large Industrial Applications

From a manufacturer’s standpoint, CFB biomass boilers offer unmatched scalability. They are commonly applied in large industrial plants and combined heat and power (CHP) systems where steam and electricity demand is substantial. CFB technology scales efficiently to higher capacities without sacrificing combustion quality or emission performance.

This scalability future-proofs energy infrastructure, allowing facilities to expand production or integrate additional biomass streams without replacing the core boiler technology.

Ability to Co-Fire Multiple Fuels

Another key advantage of CFB biomass boilers is their ability to co-fire biomass with other fuels, such as coal, lignite, or refuse-derived fuel. This capability provides operational flexibility during fuel supply disruptions or transitional energy strategies.

From an economic and strategic perspective, co-firing allows gradual decarbonization while maintaining energy security, making CFB boilers attractive for industries transitioning away from fossil fuels.

Reduced Sensitivity to Fuel Moisture and Ash

CFB systems tolerate high-moisture and high-ash fuels better than most other biomass boiler types. The circulating bed material absorbs heat and stabilizes combustion, preventing flame quenching and slagging. Ash is continuously removed with circulating solids, reducing fouling and clinker formation.

This tolerance reduces fuel preprocessing requirements and lowers maintenance costs associated with slagging and fouling, contributing to long-term reliability.

Capital and Operational Trade-Offs

While CFB biomass boilers offer numerous advantages, they also involve higher capital investment and operational complexity compared with grate or BFB systems. Additional components such as cyclones, recirculation loops, and advanced control systems increase project cost and require skilled operation.

However, from a lifecycle cost perspective, these higher upfront costs are often offset by fuel savings, lower emission compliance expenses, and improved operational flexibility—particularly in large-scale, long-term installations.

Best Industrial Applications for CFB Biomass Boilers

CFB biomass boilers are best applied in industries with high and continuous energy demand, diverse biomass fuel availability, and strict environmental requirements. Typical applications include pulp and paper mills, large chemical plants, industrial CHP facilities, and district heating systems.

These environments fully leverage the strengths of CFB technology, maximizing return on investment over decades of operation.

Case Example: Large-Scale Biomass Success

A large industrial CHP plant adopted a CFB biomass boiler to utilize mixed agricultural residues and wood waste. The system achieved stable operation despite fuel variability, met stringent emission standards without extensive downstream treatment, and supported flexible power and steam generation. Over time, fuel cost savings and compliance stability justified the higher initial investment, demonstrating the long-term economic value of CFB technology.

Strategic Perspective From a Manufacturer

From a professional manufacturer’s and supplier’s perspective, CFB biomass boilers represent the most advanced and adaptable biomass combustion technology available. They are particularly well suited for industrial users who prioritize fuel flexibility, emissions resilience, scalability, and long-term energy strategy alignment over minimum upfront cost.

Selecting CFB technology is often a strategic decision aimed at decades of reliable, compliant operation rather than short-term savings.

In conclusion, circulating fluidized bed (CFB) biomass boilers offer significant advantages, including exceptional fuel flexibility, high combustion efficiency, low emissions, superior load flexibility, and strong scalability. These characteristics make them ideal for large-scale, continuous industrial steam and power generation using diverse biomass fuels. While capital cost and complexity are higher, the long-term economic and operational benefits position CFB biomass boilers as a future-proof solution for industrial energy systems.

What Is a Suspension-Fired Biomass Boiler and Which Fuels Does It Use?

As industries explore biomass as a cleaner and more sustainable energy source, one recurring pain point is confusion around combustion technologies. Many decision-makers assume that all biomass boilers behave similarly, only to encounter performance issues when fuel characteristics do not match boiler design. Suspension-fired biomass boilers, in particular, are often misunderstood—leading to improper fuel selection, unstable combustion, or disappointing efficiency. The consequence is not only higher operating cost, but also skepticism toward biomass solutions as a whole. The solution lies in clearly understanding what a suspension-fired biomass boiler is, how it operates, and which fuels it is truly designed to use.

A suspension-fired biomass boiler is a boiler that burns finely prepared biomass fuel while it is suspended in the combustion air stream, making it best suited for dry, finely sized, and homogeneous biomass fuels such as wood powder, sawdust, and agricultural fines.

This technology delivers fast combustion, high efficiency, and excellent load response—but only when paired with the right fuel types.

Suspension-fired biomass boilers can efficiently burn large wood chips and coarse biomass.False

Suspension-fired systems require finely sized fuels that can remain airborne during combustion.

Suspension-fired biomass boilers offer fast load response compared with grate-fired boilers.True

Combustion occurs almost instantly as fuel particles burn in suspension, enabling rapid output changes.

What Is a Suspension-Fired Biomass Boiler?

From a professional manufacturer’s and supplier’s perspective, a suspension-fired biomass boiler is a combustion system in which finely divided biomass fuel is injected into the furnace with air and burned while suspended in the flame zone. Unlike grate-fired or fluidized-bed boilers, there is no solid fuel bed supporting combustion. Instead, fuel particles burn completely while airborne, similar to pulverized coal combustion.

Suspension-fired biomass boilers are typically water-tube boilers equipped with specialized burners, mills or shredders, and precise fuel-air control systems. Because combustion occurs rapidly and uniformly, these boilers can achieve high thermal efficiency and excellent controllability—provided the fuel meets strict preparation requirements.

How Suspension Combustion Works

The suspension-firing process begins with intensive fuel preparation. Biomass is dried, milled, or finely shredded to achieve a narrow particle size distribution. The prepared fuel is then conveyed pneumatically into the furnace, where it mixes with combustion air and ignites almost immediately.

Combustion takes place entirely in the furnace volume. Volatile gases burn rapidly, and fine char particles complete burnout before reaching the furnace exit. Ash is carried with flue gas and captured downstream by particulate control systems.

This rapid combustion mechanism is fundamentally different from the slow, staged combustion on a grate or within a fluidized bed.

Key Design Characteristics of Suspension-Fired Boilers

From an engineering standpoint, suspension-fired biomass boilers are characterized by compact furnace design, high flame temperatures, and sophisticated control systems. Because there is no fuel bed to buffer fluctuations, precise control of fuel feed rate, air distribution, and combustion conditions is essential.

| Design Aspect | Suspension-Fired Boiler |

|---|---|

| Fuel combustion | In-flight, airborne |

| Fuel residence time | Very short |

| Furnace size | Compact |

| Control requirement | High |

These characteristics make suspension-fired boilers highly responsive but also more sensitive to fuel quality variations.

Biomass Fuels Suitable for Suspension-Firing

Fuel selection is the single most critical factor in the success of a suspension-fired biomass boiler. Only fuels that can be finely processed and remain airborne during combustion are suitable.

Wood-Based Fuels

Wood-derived fuels are the most common choice for suspension-fired biomass boilers due to their favorable combustion properties. Suitable wood fuels include:

– Wood powder

– Fine sawdust

– Wood flour

– Dry wood milling residues

These fuels have low ash content, good grindability, and predictable combustion behavior, making them ideal for suspension firing.

Agricultural Biomass Fines

Certain agricultural residues can also be used if properly prepared. Examples include:

– Straw fines

– Husk powder

– Ground agricultural residues

However, these fuels often have higher ash content and more variable chemistry, requiring careful design and emission control.

| Fuel Type | Suitability for Suspension-Firing |

|---|---|

| Wood powder | Excellent |

| Fine sawdust | Excellent |

| Wood pellets (milled) | Good |

| Agricultural fines | Moderate |

| Coarse biomass | Not suitable |

From a supplier’s standpoint, consistent fuel quality is more important than fuel price in suspension-fired systems.

Fuels That Are Not Suitable

Suspension-fired biomass boilers are not designed to handle coarse, wet, or heterogeneous fuels. Large wood chips, bark, high-moisture biomass, and mixed residues cannot remain airborne long enough for complete combustion. Attempting to use such fuels leads to incomplete burnout, slagging, and unstable operation.

This limitation differentiates suspension-fired boilers sharply from grate-fired and fluidized-bed technologies, which are intentionally designed for fuel flexibility.

Efficiency and Performance Advantages

When paired with appropriate fuels, suspension-fired biomass boilers offer excellent thermal efficiency. Rapid and complete combustion minimizes unburned carbon losses. The compact furnace design enhances heat transfer, allowing high steam output from a relatively small footprint.

From an operational perspective, these boilers provide fast startup and rapid load response. This makes them suitable for applications with fluctuating steam demand or where precise process control is required.

Emissions Characteristics

Suspension-fired biomass boilers can achieve low CO and unburned hydrocarbon emissions due to complete combustion. However, higher flame temperatures may result in increased NOₓ formation compared with fluidized-bed systems.

To manage emissions, advanced combustion control, staged air injection, and downstream flue gas treatment are commonly employed. From a compliance standpoint, suspension-fired systems perform well when properly engineered but require careful emission management.

Typical Industrial Applications

Suspension-fired biomass boilers are best applied in industries where suitable fine biomass fuels are readily available and process control requirements are high.

Wood Products and Panel Manufacturing

Facilities producing wood powder or fine sawdust as by-products are ideal candidates. Suspension-fired boilers allow direct utilization of these residues with minimal additional processing.

Industrial CHP and Process Steam Plants

Where fast load response and compact design are important, suspension-fired biomass boilers offer economic and operational advantages, particularly in combined heat and power applications.

Retrofit Applications

Suspension-fired biomass boilers are sometimes used to retrofit pulverized coal boilers for biomass firing, leveraging existing infrastructure while reducing carbon emissions.

Comparison With Other Biomass Boiler Technologies

| Technology | Fuel Flexibility | Efficiency | Complexity |

|---|---|---|---|

| Suspension-fired | Low (fuel-specific) | High | High |

| Grate-fired | Very high | Medium | Low |

| BFB | High | High | Medium |

| CFB | Very high | Very high | High |

From a manufacturer’s perspective, suspension firing is a high-performance but fuel-sensitive solution.

Economic and Operational Trade-Offs

While suspension-fired biomass boilers often have lower furnace volume and high efficiency, their reliance on intensive fuel preparation increases both capital and operating cost. Milling, drying, and pneumatic conveying systems add complexity and energy consumption.

As a result, suspension-fired technology is most economical when suitable fine fuels are already available as by-products, minimizing additional preprocessing investment.

Case Example: Successful Suspension-Firing Application

A wood-based panel manufacturer installed a suspension-fired biomass boiler using internally generated wood powder. The system delivered rapid load response, high efficiency, and reliable steam supply. Because the fuel required minimal additional processing, lifecycle costs were competitive with other biomass technologies. This case highlights the importance of fuel-technology alignment.

Strategic Perspective From a Manufacturer

From a professional manufacturer’s and supplier’s standpoint, suspension-fired biomass boilers are specialized tools rather than universal solutions. They excel when fuel quality is controlled and consistent, and when operational responsiveness is a priority. When fuel conditions cannot be guaranteed, more forgiving technologies such as grate or fluidized-bed boilers offer better long-term reliability.

In conclusion, a suspension-fired biomass boiler is a system that burns finely prepared biomass while it is suspended in the combustion air stream. It is best suited for dry, homogeneous, finely sized fuels such as wood powder, fine sawdust, and milled biomass residues. When matched with the right fuel supply, suspension-fired boilers deliver high efficiency, fast load response, and compact design. When mismatched, however, they quickly lose economic and operational viability. Understanding fuel compatibility is therefore essential to successful application.

How Do Biomass Gasification Boilers Work in Industrial Applications?

-scaled.jpg)

Industrial users exploring biomass solutions often encounter a major pain point: conventional biomass boilers burn solid fuel directly, yet still struggle with efficiency limits, emission control, and fuel variability. As energy costs rise and environmental regulations tighten, many facilities find that traditional combustion technology alone cannot meet long-term economic and compliance goals. The consequence is higher operating cost, unstable performance, or restricted fuel choices that undermine the promise of renewable energy. The solution increasingly lies in biomass gasification boilers—a technology that separates fuel conversion from heat generation to unlock higher efficiency and cleaner operation in industrial applications.

Biomass gasification boilers work by converting solid biomass into a combustible synthesis gas (syngas) under controlled oxygen conditions, then burning this gas in a separate boiler or combustion chamber to produce high-efficiency industrial steam with lower emissions and improved controllability.

This two-stage process fundamentally differentiates gasification boilers from direct-fired biomass systems.

Biomass gasification boilers burn solid biomass directly like grate-fired boilers.False

Gasification boilers first convert biomass into syngas, which is then combusted separately.

Gasification allows better emission control compared with direct biomass combustion.True

Separating gas production from combustion enables cleaner, more controlled burning of the fuel gas.

What Is Biomass Gasification in an Industrial Context?

From a professional manufacturer’s and supplier’s perspective, biomass gasification is a thermochemical process that converts solid biomass into a combustible gas mixture—commonly called syngas—using limited oxygen or air at high temperature. Unlike full combustion, gasification intentionally restricts oxygen to prevent the biomass from burning completely.

In industrial applications, this syngas is cleaned and then burned in a boiler, furnace, or thermal oxidizer to generate steam or heat. The separation of fuel conversion and heat generation enables higher efficiency, cleaner combustion, and improved operational control compared with direct solid-fuel firing.

Step-by-Step Working Principle of Biomass Gasification Boilers

The operation of an industrial biomass gasification boiler can be divided into several tightly integrated stages.

First, prepared biomass fuel—such as wood chips, pellets, or agricultural residues—is fed into the gasifier. Inside the gasifier, the fuel is exposed to high temperatures with limited oxygen. Drying, pyrolysis, oxidation, and reduction reactions occur sequentially, converting solid biomass into syngas composed mainly of carbon monoxide, hydrogen, methane, and light hydrocarbons.

Second, the produced syngas exits the gasifier and passes through gas cleaning systems. These may include cyclones, filters, or scrubbers to remove particulates, tars, and contaminants. Gas quality control is essential for stable downstream combustion.

Third, the cleaned syngas is burned in a dedicated combustion chamber or boiler furnace. Because syngas behaves similarly to gaseous fuel, combustion is highly controllable, allowing precise air–fuel mixing and stable flame characteristics.

Finally, heat released from syngas combustion is transferred to water or steam circuits in the boiler, producing industrial steam for process use, power generation, or combined heat and power (CHP) systems.

Key Components of an Industrial Biomass Gasification Boiler System

From an engineering standpoint, gasification boiler systems are modular and more complex than direct-fired boilers.

| System Component | Function |

|---|---|

| Biomass gasifier | Converts solid biomass into syngas |

| Gas cooling & cleaning | Removes particulates and tars |

| Syngas combustion chamber | Burns gas cleanly and controllably |

| Steam boiler heat exchanger | Generates steam |

| Control system | Coordinates gasification and combustion |

This modular structure allows optimization of each stage independently, which is a major advantage in industrial operation.

Fuels Used in Biomass Gasification Boilers

Fuel selection strongly influences gasification performance. Biomass gasification boilers typically require reasonably dry and consistent fuels to maintain stable gas production.

Common fuels include:

– Wood chips and wood pellets

– Forestry residues

– Agricultural biomass with controlled moisture

– Energy crops

Compared with grate or fluidized-bed boilers, gasification systems are less tolerant of extreme fuel variability, but they reward good fuel preparation with superior performance and emissions.

Efficiency Advantages in Industrial Applications

Gasification improves efficiency by enabling more complete and controlled combustion. Syngas burns uniformly and quickly, reducing unburned carbon losses. Heat transfer surfaces are exposed to cleaner flue gas, lowering fouling and maintaining efficiency over time.

From a lifecycle perspective, efficiency stability is a major economic advantage. Many industrial users find that gasification boilers maintain near-design efficiency for longer periods compared with direct-fired biomass systems, reducing fuel consumption year after year.

Emission Reduction and Compliance Benefits

One of the strongest advantages of biomass gasification boilers is emission performance. Because syngas combustion resembles gas firing, particulate emissions, CO, and unburned hydrocarbons are significantly reduced. NOₓ formation can also be controlled more effectively through staged combustion.

This inherent cleanliness reduces reliance on complex downstream emission control equipment. For facilities operating under strict environmental regulations, this translates into lower compliance cost and reduced regulatory risk.

Operational Control and Load Flexibility

Gasification boilers offer excellent controllability in industrial settings. Syngas flow can be adjusted rapidly, enabling fast load response similar to gas-fired boilers. This makes gasification suitable for applications with variable steam demand or frequent load changes.

Compared with grate-fired systems, which rely on slow-moving fuel beds, gasification boilers decouple fuel conversion from steam demand, improving responsiveness and process integration.

Typical Industrial Applications of Biomass Gasification Boilers

Biomass gasification boilers are best applied where efficiency, emission control, and operational flexibility are high priorities.

Common applications include:

– Industrial CHP plants

– Food and beverage processing

– Chemical and pharmaceutical manufacturing

– District heating with strict emission limits

These industries benefit from clean steam, predictable operation, and the ability to integrate biomass into modern energy systems.

Comparison With Other Biomass Boiler Technologies

| Technology | Efficiency | Emissions | Fuel Flexibility | Complexity |

|---|---|---|---|---|

| Grate-fired | Medium | Medium | Very high | Low |

| BFB | High | Low | High | Medium |

| CFB | Very high | Very low | Very high | High |

| Gasification | High–very high | Very low | Medium | High |

From a supplier’s perspective, gasification offers gas-like performance using solid renewable fuel.

Economic Trade-Offs and Challenges

Despite its advantages, biomass gasification boilers involve higher capital cost and greater system complexity. Fuel preparation, gas cleaning, and advanced controls increase investment and require skilled operation.

However, in applications where emission compliance, efficiency, and flexibility have high economic value, these costs are often offset by fuel savings, regulatory stability, and improved reliability.

Case Example: Industrial Gasification Success

An industrial CHP facility installed a biomass gasification boiler using locally sourced wood chips. The system achieved stable syngas production, low emissions, and fast load response. Over time, reduced fuel consumption and avoided emission control upgrades justified the higher initial investment, demonstrating strong long-term economics.

Strategic Perspective From a Manufacturer

From a professional manufacturer’s and supplier’s standpoint, biomass gasification boilers represent a bridge between traditional solid-fuel systems and modern gas-fired technology. They are best suited for industrial users who value clean operation, controllability, and future-ready energy infrastructure and who can support consistent fuel preparation and skilled operation.

In conclusion, biomass gasification boilers work by converting solid biomass into syngas under controlled conditions and then burning that gas to generate industrial steam. This two-stage process delivers higher efficiency, lower emissions, and superior operational control compared with direct biomass combustion. While system complexity and fuel requirements are higher, gasification boilers offer compelling advantages for industrial applications where environmental compliance, efficiency stability, and flexibility are central to long-term economic success.

How Should Fuel Type and Capacity Requirements Guide Biomass Boiler Selection?

For many industrial users, choosing a biomass boiler is far more complex than simply “going renewable.” A common pain point arises when companies invest heavily in biomass equipment only to discover that the selected boiler does not match their actual fuel characteristics or steam demand. The consequences can be severe: unstable combustion, excessive maintenance, rising operating costs, fuel supply bottlenecks, or even regulatory non-compliance. In most failed biomass projects, the root cause is not the technology itself—but a mismatch between fuel type, capacity requirements, and boiler design. The solution is a disciplined selection approach where fuel characteristics and required capacity jointly drive the biomass boiler choice from the very beginning.

Fuel type determines the appropriate combustion technology, while capacity requirements define the boiler scale and configuration; together, they are the two most critical factors guiding the selection of a reliable, efficient, and cost-effective biomass boiler.

Understanding this relationship is essential for long-term technical and economic success.

Any biomass boiler can efficiently burn all types of biomass fuels.False

Different biomass fuels require specific combustion technologies to ensure stable operation and acceptable emissions.

Matching boiler capacity to real steam demand improves efficiency and reduces lifecycle cost.True

Oversized or undersized boilers operate inefficiently and increase fuel and maintenance costs.

Fuel type and capacity are not independent variables; they interact directly with combustion stability, efficiency, emissions, capital cost, and future scalability. The following sections explain how industrial users should evaluate both factors together to make the right biomass boiler selection.

Why Fuel Type Is the Primary Selection Driver

From a professional manufacturer’s and supplier’s perspective, fuel type is the foundation of any biomass boiler project. Biomass fuels differ dramatically in particle size, moisture content, ash composition, bulk density, and calorific value. These characteristics directly dictate which combustion technologies can operate reliably.

A boiler designed for uniform wood pellets will fail quickly if fed wet agricultural residues, while a system optimized for coarse wood chips will be inefficient and overbuilt for fine biomass powders. Therefore, fuel analysis must precede technology selection.

Key fuel parameters that influence boiler choice include:

– Moisture content

– Particle size distribution

– Ash content and ash melting temperature

– Fuel variability and supply consistency

Matching Fuel Types to Biomass Boiler Technologies

Different biomass boiler technologies exist precisely because no single design can efficiently handle all fuels. The table below illustrates the relationship between common fuel types and suitable boiler technologies.

| Fuel Type | Grate-Fired | BFB | CFB | Suspension-Fired | Gasification |

|---|---|---|---|---|---|

| Wood chips | Excellent | Excellent | Excellent | Poor | Good |

| Wood pellets | Good | Good | Very good | Good | Very good |

| Agricultural residues | Very good | Excellent | Excellent | Poor | Moderate |

| High-ash biomass | Good | Very good | Excellent | Poor | Poor |

| Fine biomass powders | Poor | Moderate | Moderate | Excellent | Good |

From a supplier’s standpoint, selecting a boiler that tolerates expected fuel variability is often more important than optimizing for peak efficiency.

Fuel Flexibility vs Fuel Efficiency Trade-Off

Highly flexible technologies such as circulating fluidized bed (CFB) boilers can burn a wide range of fuels with stable performance. However, this flexibility comes at the cost of higher capital investment and system complexity. Conversely, suspension-fired and gasification boilers deliver very high efficiency but require tightly controlled fuel quality.

Industrial users must decide whether fuel cost savings from flexibility outweigh the higher initial investment, or whether consistent high-quality fuel justifies a more specialized, high-efficiency boiler.

Understanding Capacity Requirements Beyond Nameplate Output

Capacity is often misunderstood as simply the maximum steam output of the boiler. In reality, capacity selection must reflect actual operating profiles, not theoretical peaks.

From an engineering perspective, the following capacity-related factors must be evaluated:

– Average steam demand

– Peak load frequency and duration

– Load variability and ramp rates

– Planned future expansion

Oversizing a biomass boiler leads to low-load operation, poor combustion, and higher emissions. Undersizing results in production constraints and excessive cycling, shortening equipment life.

Typical Capacity Ranges and Suitable Technologies

Biomass boiler technologies naturally align with certain capacity ranges due to combustion physics and economic scaling.

| Capacity Range (Steam) | Recommended Technologies |

|---|---|

| Small (<10 t/h) | Grate-fired, Gasification |

| Medium (10–50 t/h) | Grate-fired, BFB |

| Large (50–200+ t/h) | BFB, CFB |

CFB boilers, for example, become economically attractive only at larger capacities where their superior performance offsets higher capital cost.

Capacity and Load Flexibility Considerations

Capacity selection must also consider load flexibility. Industrial plants rarely operate at constant load. Processes start, stop, and fluctuate, placing dynamic demands on the boiler.

Grate-fired boilers tolerate steady operation well but respond slowly to load changes. Fluidized-bed and gasification systems offer better turndown and faster response, making them suitable for variable-demand environments.

Matching boiler responsiveness to process requirements prevents inefficiency and operational stress.

Integrating Fuel Supply Capacity With Boiler Size

Another common mistake is selecting boiler capacity without verifying fuel supply capability. Biomass fuel logistics—harvesting, processing, storage, and transportation—must support the required thermal input.

A larger boiler consuming low-calorific, high-moisture fuel may require impractically large fuel volumes. In such cases, either fuel upgrading or capacity reduction may be necessary.

From a project feasibility standpoint, fuel supply capacity often becomes the limiting factor rather than boiler technology.

Emissions and Capacity Scaling

Environmental compliance becomes more complex as boiler capacity increases. Larger biomass boilers face stricter emission limits and often require more sophisticated control systems.

CFB and gasification boilers offer inherent emission advantages at scale, while smaller grate-fired systems may rely more heavily on downstream emission controls. Capacity selection must therefore align with regulatory strategy and permitting constraints.

Lifecycle Economics: Fuel and Capacity Together

From a lifecycle cost perspective, fuel type and capacity jointly determine:

– Capital investment

– Fuel consumption rate

– Maintenance intensity

– Emission control costs

– Operational staffing requirements

A well-matched system minimizes total cost of ownership, not just initial purchase price. In many successful projects, a slightly higher upfront investment delivers substantial long-term savings by reducing fuel waste and downtime.

Case Example: Correcting a Fuel–Capacity Mismatch

An industrial facility initially selected a large grate-fired boiler based solely on peak steam demand. However, its fuel supply consisted of highly variable agricultural residues. The system suffered from slagging and low efficiency. After reassessment, the facility replaced the unit with a BFB boiler sized closer to average demand. Fuel utilization improved, emissions stabilized, and lifecycle cost dropped significantly, illustrating the importance of aligning fuel type and capacity.

Strategic Manufacturer Perspective

From a professional manufacturer’s and supplier’s standpoint, successful biomass boiler projects always start with fuel and capacity analysis—not with boiler selection. Technology should be chosen to serve fuel reality and production demand, not the other way around. When fuel type and capacity requirements are properly aligned, biomass boilers deliver decades of reliable, economical, and compliant operation.

In conclusion, fuel type and capacity requirements should be the primary drivers of biomass boiler selection. Fuel characteristics determine which combustion technologies can operate reliably, while capacity requirements define boiler scale, responsiveness, and economic viability. Selecting a boiler without fully integrating these two factors leads to inefficiency, instability, and unnecessary cost. A fuel-first, capacity-matched approach ensures that the chosen biomass boiler delivers optimal performance across its entire service life.

🔍 Conclusion

Industrial biomass boilers come in multiple designs to match different fuels, capacities, and operating conditions. From simple grate-fired systems to advanced fluidized bed and gasification technologies, selecting the right type is crucial for achieving high efficiency, low emissions, and reliable performance. A well-matched biomass boiler not only supports sustainability goals but also delivers strong long-term economic benefits.

🔹 Contact us today to find the most suitable biomass boiler technology for your fuel and production needs. 🌿🔥🏭✅

FAQ

Q1: What are the main types of industrial biomass boilers?

A1: Industrial biomass boilers are categorized based on combustion technology and fuel handling capability. The main types include grate-fired biomass boilers, fluidized bed biomass boilers, biomass pellet boilers, and biomass gasification boilers. Each type is designed to handle specific fuel characteristics, capacity ranges, and efficiency requirements. Choosing the right type depends on factors such as fuel availability, moisture content, ash level, load flexibility, and emission regulations.

Q2: How do grate-fired biomass boilers work and where are they used?

A2: Grate-fired biomass boilers burn solid biomass fuels on a moving or fixed grate, where fuel passes through drying, ignition, combustion, and burnout zones. They are well-suited for fuels like wood chips, bark, agricultural residues, and bagasse with varying moisture content. These boilers are widely used in food processing, pulp and paper, wood industries, and district heating due to their robust design, simple operation, and ability to handle coarse and heterogeneous fuels. While efficiency is slightly lower than fluidized bed systems, their reliability and lower capital cost make them a popular choice.

Q3: What are fluidized bed biomass boilers and their advantages?

A3: Fluidized bed biomass boilers, including bubbling fluidized bed (BFB) and circulating fluidized bed (CFB) boilers, use air to suspend fuel particles in a fluid-like state, ensuring uniform temperature and excellent mixing. These boilers offer high combustion efficiency, low emissions, and exceptional fuel flexibility, capable of burning low-grade biomass with high ash or moisture content. CFB boilers, in particular, are preferred for large-scale industrial and power generation applications, while BFB boilers are common in medium-capacity plants.

Q4: What are biomass pellet boilers and when are they most suitable?

A4: Biomass pellet boilers are designed to burn densified biomass pellets, which offer consistent size, low moisture, and high energy density. These boilers provide high efficiency, automated operation, and low emissions, making them suitable for clean industrial processes, commercial buildings, and smaller industrial facilities. Although pellet fuel costs are generally higher than raw biomass, reduced storage space, stable combustion, and lower maintenance requirements make pellet boilers attractive where fuel quality consistency is critical.

Q5: What is a biomass gasification boiler and how does it differ from direct combustion systems?

A5: A biomass gasification boiler converts solid biomass into producer gas (syngas) through partial combustion at high temperatures. The syngas is then burned in a secondary chamber to generate heat or steam. This two-stage process allows for higher efficiency, lower particulate emissions, and better combustion control compared to direct combustion boilers. Biomass gasification boilers are often used in high-efficiency industrial heating, CHP systems, and specialized applications, though they require higher capital investment and stricter fuel quality control.

References

- International Energy Agency (IEA) – Bioenergy and Biomass Boilers – https://www.iea.org/ – IEA

- U.S. Department of Energy – Biomass Combustion Technologies – https://www.energy.gov/ – DOE

- International Renewable Energy Agency (IRENA) – Biomass Power and Heat – https://www.irena.org/ – IRENA

- ASME – Boiler and Pressure Vessel Code (BPVC) – https://www.asme.org/ – ASME

- Valmet – Biomass Boiler Technologies – https://www.valmet.com/ – Valmet

- GE Steam Power – Biomass and Waste-Fired Boilers – https://www.ge.com/steam-power/ – GE Steam Power

- Engineering Toolbox – Biomass Boiler Types and Efficiency – https://www.engineeringtoolbox.com/ – Engineering Toolbox

- ScienceDirect – Review of Biomass Boiler Technologies – https://www.sciencedirect.com/ – ScienceDirect

- World Bioenergy Association – Biomass Heating Systems – https://www.worldbioenergy.org/ – World Bioenergy Association

- European Commission – Renewable Heating Technologies – https://energy.ec.europa.eu/ – European Commission

What Are the Different Types of Industrial Biomass Boilers? Read More »

-1024x768.jpg)