How to Optimize Industrial Biomass Boiler Performance for Lower Operating Costs

Industrial biomass boilers offer a sustainable alternative to fossil-fuel-based systems, but to be economically viable, they must be optimized for maximum efficiency and minimum operational expense. Poor fuel quality, improper combustion control, and inadequate maintenance can result in unnecessary fuel waste, unplanned downtime, and increased emissions. With rising energy costs and tighter environmental regulations, achieving optimal boiler performance is essential for long-term profitability and sustainability.

To optimize industrial biomass boiler performance for lower operating costs, focus on key strategies such as using consistent, high-quality biomass fuel, maintaining proper combustion air control, minimizing heat losses, cleaning heat exchanger surfaces regularly, and utilizing automation and monitoring systems. Improvements in fuel handling, ash management, and flue gas heat recovery can significantly enhance boiler efficiency and reduce fuel consumption. Preventive maintenance and real-time performance monitoring further ensure stable operation and cost control.

Here’s a practical guide to key areas where performance improvements can lead to tangible savings.

How Does Biomass Fuel Quality and Moisture Content Affect Combustion and Fuel Costs?

Biomass energy systems offer a renewable alternative to fossil fuels, but their performance is highly sensitive to the quality and moisture content of the fuel. When biomass has high moisture levels or inconsistent quality, combustion becomes inefficient, emissions rise, and operating costs increase dramatically. These challenges not only reduce energy output per ton of fuel but also cause mechanical problems such as slagging, fouling, and corrosion in the combustion system. In contrast, using high-quality, low-moisture biomass ensures stable flame characteristics, cleaner burning, and lower fuel consumption per unit of energy produced.

Biomass fuel quality and moisture content significantly affect combustion efficiency and fuel costs because wet or poor-quality fuel requires more energy to evaporate water before combustion can occur. High moisture reduces flame temperature, causes incomplete combustion, increases emissions, and reduces boiler efficiency. As a result, more fuel is needed to produce the same amount of heat, increasing operational costs. Consistent, low-moisture, high-density biomass improves fuel economy, combustion stability, and overall plant performance.

Whether you’re operating a small biomass boiler or a utility-scale bioenergy plant, controlling fuel quality is key to maintaining economic and environmental efficiency. Below, we explore the critical relationship between biomass properties and system performance.

Biomass fuel with high moisture content increases energy output during combustion.False

High moisture biomass absorbs energy for water evaporation before combustion occurs, reducing the net energy output and efficiency.

🌲 Understanding Biomass Fuel Properties

Biomass fuel can include wood chips, pellets, agricultural waste, or energy crops. The properties that most affect combustion are:

| Property | Ideal Range | Effect on Combustion |

|---|---|---|

| Moisture Content | 10–20% (by weight) | Higher values reduce net calorific value |

| Ash Content | <2% for wood, <6% for agri-fuels | High ash causes slagging and fouling |

| Volatile Matter | 70–80% | Affects ignition and flame quality |

| Bulk Density | 600–750 kg/m³ for pellets | Influences feeding and storage |

| Particle Size | 5–50 mm (for most systems) | Affects combustion rate and uniformity |

High moisture content is the most critical issue because it reduces the net calorific value (NCV)—the actual usable heat from the fuel after accounting for the energy lost in evaporating water.

📉 How Moisture Content Reduces Combustion Efficiency

Every kilogram of water in biomass fuel must be evaporated before the fuel can burn. This consumes energy that would otherwise be used for heating.

| Moisture Content (%) | Net Calorific Value (MJ/kg) | Boiler Efficiency (%) | Fuel Usage Increase (%) |

|---|---|---|---|

| 10 | 16.5 | 85 | Baseline |

| 25 | 13.2 | 78 | +20% |

| 40 | 10.1 | 69 | +39% |

| 50 | 8.2 | 60 | +60% |

A biomass boiler burning wood chips with 50% moisture will need up to 60% more fuel to generate the same heat output compared to burning chips at 10–15% moisture.

Low-moisture biomass fuels result in higher combustion temperatures and better efficiency.True

Drier fuels burn more easily and produce higher flame temperatures, improving heat transfer and reducing excess air requirements.

🔥 Combustion Challenges with Wet Biomass

High moisture affects combustion in multiple ways:

Lower Flame Temperature: Reduces heat transfer rate and slows combustion reactions.

Incomplete Combustion: Wet fuel can lead to higher CO and unburned hydrocarbons.

Slagging & Corrosion: Low combustion temperatures encourage deposition and acid formation.

Delayed Ignition: Especially in systems with batch-fed or fixed-grate combustors.

Increased Particulate Emissions: Due to poor burnout and unstable combustion zones.

Systems designed for dry pellets may not tolerate moisture well. In contrast, fluidized bed combustors and rotary kilns can better handle variable moisture but still suffer efficiency loss.

💸 Economic Impacts of Poor Fuel Quality

High moisture biomass directly raises fuel costs in two ways:

More fuel per unit energy: You burn more material to achieve the same thermal output.

Higher auxiliary energy consumption: Fans, conveyors, and dryers must work harder.

Cost Example:

| Biomass Type | Moisture (%) | Required Fuel (tons/day for 10 MW output) | Estimated Daily Fuel Cost ($) |

|---|---|---|---|

| Wood Pellets | 10% | 45 | $4,500 |

| Wood Chips (25%) | 25% | 62 | $5,580 |

| Green Wood (50%) | 50% | 83 | $7,050 |

Over a year, switching from 10% to 50% moisture fuel could increase operating costs by $900,000 or more for a medium-scale plant.

🔍 Fuel Quality Control and Best Practices

| Practice | Purpose | Tools/Methods |

|---|---|---|

| On-Site Moisture Testing | Validate fuel before feeding | Moisture analyzers, drying ovens |

| Fuel Storage Management | Prevent re-wetting from rain or humidity | Covered silos, dry storage sheds |

| Fuel Drying Systems | Reduce moisture to optimal range | Belt dryers, rotary drum dryers |

| Supplier Quality Agreements | Enforce fuel specs | Moisture/ash/particle size contracts |

| Fuel Blending Strategies | Mix wet and dry fuels for consistency | Real-time mixing conveyors or feed hoppers |

In biomass CHP (combined heat and power) plants, using sensors and AI-driven control systems helps adjust air-fuel ratios dynamically to account for real-time fuel moisture changes, improving combustion stability.

Biomass fuels should always be used as-received to minimize processing costs.False

Processing such as drying and screening improves combustion efficiency and reduces operational costs in the long term.

🧪 Case Study: Biomass District Heating Plant

A 5 MW district heating system in Northern Europe initially burned fresh wood chips with 40% moisture content. Combustion was unstable, with visible smoke and high flue gas temperatures (~220°C). After installing a fuel dryer to reduce moisture to 15%, results included:

Boiler efficiency increase: from 69% to 87%

Flue gas temperature drop: from 220°C to 145°C

Fuel use reduction: ~38%

Payback period for dryer investment: 18 months

This example underscores the economic and operational importance of moisture control.

Summary

Biomass fuel quality and especially moisture content play a critical role in combustion efficiency, system reliability, and fuel cost. High-moisture fuel absorbs energy needed for water evaporation before burning can begin, lowering flame temperatures and increasing the amount of biomass required. In contrast, low-moisture, clean, and uniform biomass ensures efficient heat transfer, complete combustion, and lower emissions. For any biomass energy system to perform optimally, fuel quality must be actively monitored and managed—not just accepted.

Why Is Combustion Air Management Critical for Reducing Excess Air and Improving Efficiency?

Industrial boilers and combustion systems are often less efficient than they could be—not due to poor fuel or burner design—but because of ineffective combustion air management. Without careful control of air supply, too much air (excess air) can enter the system, cooling the flame, wasting energy, and increasing stack losses. Conversely, too little air results in incomplete combustion, producing carbon monoxide, soot, and other pollutants. Effective combustion air management is the key to striking the right balance, achieving complete combustion with minimal waste and maximum efficiency.

Combustion air management is critical because it directly controls the amount of excess air entering a combustion system. Proper management ensures just enough oxygen for complete combustion, avoiding energy losses from overheating unnecessary air and reducing stack losses. When excess air is minimized without compromising combustion quality, flame temperatures rise, fuel use decreases, and emissions are reduced. Tools like oxygen trim controls, variable speed drives, and dampers help fine-tune air flow in real time, boosting boiler or furnace efficiency by 5% to 15%.

Mastering this balance between fuel and air is one of the most powerful—and cost-effective—ways to improve thermal system performance.

Excess air above optimal levels increases combustion efficiency by enhancing oxygen availability.False

While a small amount of excess air is needed, too much cools the flame and increases heat loss through the exhaust, reducing efficiency.

🌬️ What Is Excess Air and Why Does It Matter?

Excess air is the additional air supplied beyond the theoretical stoichiometric requirement for complete combustion.

Key Definitions:

| Term | Definition |

|---|---|

| Stoichiometric Air | The exact amount of air needed for complete combustion |

| Excess Air (%) | Extra air above stoichiometric (usually 10–25%) |

| O₂ in Flue Gas (%) | Used as an indicator of excess air |

For most combustion systems, the target is to keep excess air between 10–20%, which corresponds to 2–4% O₂ in flue gas. Higher levels result in:

Lower flame temperatures

Increased heat losses through stack gases

Higher fuel consumption

📉 The Efficiency Cost of Too Much Air

| Excess Air (%) | Flue Gas O₂ (%) | Stack Heat Loss (%) | Estimated Boiler Efficiency (%) |

|---|---|---|---|

| 5 | 1.1 | 15.2 | 86.5 |

| 15 | 3.0 | 17.5 | 84.0 |

| 30 | 6.2 | 21.5 | 80.0 |

| 50 | 9.5 | 25.0 | 76.0 |

Every 10% increase in excess air can reduce combustion efficiency by 1% to 2%, depending on the system. Over time, this can amount to tens or hundreds of thousands of dollars in fuel costs for large facilities.

Flue gas oxygen content is used to estimate the level of excess air in combustion systems.True

Measuring O₂ in flue gas provides a reliable way to calculate how much excess air is being supplied to the combustion process.

🔧 Tools and Techniques for Air Management

Modern air management systems combine sensors, actuators, and intelligent controllers to continuously optimize combustion conditions.

Components of an Efficient Air Management System:

| Component | Function |

|---|---|

| O₂ Sensors | Monitor oxygen in flue gas to determine excess air |

| Oxygen Trim Controllers | Adjust dampers or fan speeds to maintain target O₂ |

| Variable Speed Fans | Modulate combustion air delivery based on demand |

| Damper Positioners | Adjust air flow to burners precisely |

| Burner Control Systems | Integrate fuel and air controls for optimal stoichiometry |

By automatically adjusting air inputs based on real-time feedback, these systems maintain optimal combustion conditions even as fuel quality, load demand, or environmental conditions change.

🧪 Practical Effects of Poor Air Management

Poor combustion air management results in:

Excess fuel consumption: Due to flame cooling and incomplete heat transfer

High stack temperatures: Indicating wasted heat energy

CO formation and visible smoke: Caused by too little air or poor mixing

NOx spikes: From hot spots caused by uneven or fluctuating air supply

Increased maintenance: From soot buildup and corrosion

For example, a paper mill that installed an oxygen trim system on its biomass boiler saw:

Fuel use reduction: 6.8%

Boiler efficiency gain: From 80.2% to 86.1%

Return on investment: Achieved within 14 months

Oxygen trim systems reduce combustion efficiency when installed.False

Oxygen trim systems improve combustion efficiency by adjusting air flow based on flue gas oxygen levels to maintain optimal excess air.

📋 Best Practices for Combustion Air Optimization

| Practice | Purpose |

|---|---|

| Calibrate O₂ sensors regularly | Ensure accurate air adjustments |

| Clean burner and air paths | Remove obstructions that skew air-fuel ratios |

| Set air-fuel ratio by load | Customize ratios for low, medium, and high loads |

| Install parallel positioning systems | Match air/fuel valves separately for precision |

| Use flue gas analyzers for tuning | Confirm combustion health and optimize system setup |

These methods ensure that combustion remains efficient and compliant across all operational conditions.

🔍 Case Study: Hospital Boiler Retrofit

A large metropolitan hospital relied on a 6 MMBtu/h gas-fired boiler that operated year-round with load swings of 30–90%. Before optimization:

Excess air: 40–50%

O₂ levels: >7%

Stack temp: 260°C

Combustion efficiency: ~77%

After installing a variable-speed combustion air fan, oxygen trim system, and new burner controls:

Excess air reduced to 15%

O₂ levels held at 3%

Stack temp dropped to 185°C

Efficiency rose to 85.5%

Annual gas savings: ~$48,000

This demonstrates how even moderate improvements in air management can yield substantial cost and performance gains.

Summary

Combustion air management is at the heart of efficient and clean-burning systems. Controlling excess air through real-time measurement and adjustment ensures the right balance for complete combustion without wasting energy. Whether through basic damper control or advanced oxygen trim systems, managing air intelligently improves thermal efficiency, reduces fuel use, and enhances emissions compliance. In every combustion process, air is free—but mismanaging it can be very expensive.

How Does Cleaning Soot and Ash from Heat Transfer Surfaces Impact Fuel Consumption?

In thermal systems like boilers, furnaces, and heat exchangers, energy efficiency is all about transferring heat effectively. But over time, soot and ash deposits form on heat transfer surfaces, creating a thick, insulating barrier between the flame and the process fluid. This fouling doesn’t just look bad—it blocks heat, forces longer burner operation, and consumes more fuel to meet the same energy demand. Without regular cleaning, these layers can cost facilities thousands of dollars annually in wasted fuel and maintenance downtime.

Cleaning soot and ash from heat transfer surfaces significantly reduces fuel consumption by restoring the system’s ability to transfer heat efficiently. Soot and ash act as insulators that block thermal energy from reaching the working fluid, causing longer burner run-times and increased flue gas temperatures. Even a thin layer of soot (as little as 1 mm) can reduce heat transfer efficiency by up to 10%, which forces the system to burn more fuel to achieve the same output. Regular cleaning can improve boiler efficiency by 5–15%, lowering fuel costs and emissions.

Whether your system runs on coal, oil, biomass, or gas, soot and ash removal is one of the simplest and most cost-effective ways to improve thermal performance.

Soot and ash deposits increase the heat transfer rate in boilers.False

These deposits act as thermal insulators, preventing efficient heat transfer and reducing system performance.

🔍 Why Do Soot and Ash Form?

Soot and ash are combustion byproducts:

Soot is made of unburned carbon particles and hydrocarbons.

Ash comes from mineral content in solid fuels like coal, wood, and biomass.

These particles settle on fire-side surfaces like:

Boiler fire tubes

Economizer tubes

Superheaters

Air preheaters

They cling tightly to metal and form a crust that traps heat inside the flue gases instead of passing it to water or steam.

📉 Impact on Fuel Consumption and Efficiency

Even small deposits can cause big losses. Here’s a breakdown:

| Deposit Thickness | Efficiency Drop | Extra Fuel Use (%) | Flue Gas Temp Rise |

|---|---|---|---|

| 0.5 mm | 2–4% | +3–5% | +15–25°C |

| 1.0 mm | 7–10% | +8–10% | +35–50°C |

| 2.0 mm | 12–15% | +15–18% | +60–80°C |

These figures are based on real-world combustion systems. In one large boiler burning heavy oil, just 1 mm of soot increased fuel consumption by 9%, raising operating costs by over $90,000 per year.

Removing soot from boiler tubes has no effect on fuel economy.False

Soot insulates the heat exchange surfaces, and its removal significantly improves thermal conductivity and reduces fuel use.

🔧 Cleaning Methods and Maintenance Frequency

Common Soot and Ash Removal Techniques:

| Method | Description | Best For |

|---|---|---|

| Soot Blowers | Steam or compressed air jets clean tubes | Large coal or biomass boilers |

| Manual Brushing | Technicians scrub tubes during maintenance | Fire-tube boilers, economizers |

| Rotary Cleaners | Motorized brushes for internal tube cleaning | Shell-and-tube exchangers |

| High-Pressure Washing | Water or solvent jets remove sticky ash | Biomass and waste-fired units |

| Chemical Cleaning | Solvents dissolve hard deposits and corrosion | Oil-fired systems |

📋 Recommended Cleaning Intervals

| Fuel Type | Cleaning Interval | Notes |

|---|---|---|

| Natural Gas | Annually | Less soot, but still subject to fouling |

| Heavy Oil | Monthly to Quarterly | High soot generation |

| Biomass (wood) | Weekly to Monthly | Ash content and variability require frequent checks |

| Coal | Weekly to Bi-weekly | Heavy slagging potential |

In plants with online soot blowing systems, cleanings may occur several times per day automatically to prevent buildup.

🧪 Real-World Example: Biomass Boiler Case Study

A biomass boiler in a European district heating plant experienced:

Flue gas temps rising from 160°C to 235°C over two months

Combustion air fans running at 25% higher capacity

Boiler efficiency dropping from 84% to 75%

Increased fuel usage: 1.2 extra tons/day

After manual soot and ash cleaning:

Flue gas temperature dropped by 60°C

Fan power consumption normalized

Fuel savings of $45,000/year realized

The cleaning took just two days and paid back in less than two weeks.

Ash from biomass combustion can stick to heat exchanger surfaces and lower efficiency.True

Ash in biomass contains sticky components like potassium that bond to surfaces and form insulating layers, requiring frequent cleaning.

📈 Monitoring and Detection of Fouling

To optimize cleaning schedules and detect soot/ash buildup early, use:

| Tool | Function |

|---|---|

| Flue Gas Thermometers | Monitor for rising exhaust temperatures |

| Infrared Cameras | Detect hot spots and heat transfer inefficiencies |

| Draft Pressure Sensors | Indicate buildup via air resistance changes |

| Combustion Analyzers | Check for declining efficiency and CO levels |

| AI Performance Models | Predict fouling trends from operational data |

A sudden increase in flue gas temperature without increased load usually signals that heat transfer surfaces need attention.

Summary

Cleaning soot and ash from heat transfer surfaces is one of the most effective and low-cost methods to reduce fuel consumption and restore boiler performance. These deposits act as insulation, preventing the efficient transfer of heat to the working fluid. Regular cleaning lowers stack temperatures, shortens burner run time, reduces emissions, and improves thermal efficiency—often by 5% to 15%. Whether manual, automated, or predictive, maintenance that targets fouling delivers rapid payback and sustained energy savings across all combustion-based systems.

What Role Do Economizers and Heat Recovery Systems Play in Cutting Energy Waste?

Every unit of heat lost up the stack is money wasted—and in industrial systems, that can mean millions of dollars annually. Boilers and thermal plants typically discharge flue gases at temperatures between 160°C and 300°C. Without any recovery, this energy exits unused. Economizers and heat recovery systems are designed to reclaim that lost heat and redirect it into the process, boosting overall system efficiency and dramatically reducing energy waste. These devices represent one of the most cost-effective strategies for improving fuel economy and sustainability in any thermal system.

Economizers and heat recovery systems reduce energy waste by capturing residual heat from flue gases or exhaust air and transferring it to incoming feedwater, combustion air, or process fluids. This reuse of energy lowers the required fuel input for steam or heat generation, improving overall efficiency by 5% to 20%. The result is reduced fuel costs, lower emissions, and extended equipment life. Economizers are especially impactful in high-temperature operations where flue gas heat would otherwise be lost.

In industries with thermal loads—power generation, food processing, chemicals, paper—heat recovery systems are a cornerstone of energy optimization and emissions control.

Economizers work by cooling the flue gas to below its dew point to recover energy.True

Condensing economizers cool the flue gas enough to recover both sensible and latent heat, increasing energy recovery efficiency.

🔁 What Is an Economizer?

An economizer is a heat exchanger that recovers waste heat from boiler flue gas and uses it to preheat:

Boiler feedwater

Combustion air

Process fluids in thermal systems

There are two main types:

| Type | Heat Recovery Mechanism | Efficiency Gain | Application |

|---|---|---|---|

| Non-Condensing | Recovers sensible heat above dew point | 4–7% | Natural gas, light oil boilers |

| Condensing | Recovers sensible + latent heat by cooling below dew point | 10–15% | Gas-fired systems with low return water temperature |

Condensing systems are more efficient but require corrosion-resistant materials due to the acidic condensate formed from flue gas moisture.

📈 Energy Savings From Heat Recovery

| Flue Gas Temp Before Economizer (°C) | After Economizer (°C) | Feedwater Temp Increase (°C) | Fuel Savings (%) |

|---|---|---|---|

| 220 | 130 | +40 | 8–10 |

| 180 | 95 | +50 | 10–12 |

| 160 | 85 | +60 | 12–15 |

| 140 (condensing) | 55 | +70 | 16–20 |

These savings depend on system load, burner design, and economizer size. For example, in a 10 MW boiler running 8,000 hours/year, improving efficiency by 8% could save $180,000–$240,000 annually in natural gas costs.

Economizers reduce the required fuel input by using waste heat to preheat boiler feedwater.True

By raising the temperature of feedwater before it enters the boiler, economizers reduce the energy required to generate steam.

🔧 Heat Recovery System Components

A heat recovery system may consist of:

| Component | Function |

|---|---|

| Economizer coil/tubes | Transfer heat from flue gas to water |

| Flue gas bypass damper | Allows temperature control and protection during startup/shutdown |

| Condensate drain | Handles acidic liquid in condensing economizers |

| Air preheater | Transfers flue gas heat to combustion air |

| Heat recovery steam generator (HRSG) | Captures exhaust from turbines or engines to produce steam |

These components are engineered to withstand high temperatures, pressure cycles, and corrosive environments. Stainless steel, inconel, and finned tubes are commonly used for durability and heat transfer efficiency.

📋 Additional Benefits Beyond Fuel Savings

| Benefit | Explanation |

|---|---|

| Reduced Flue Gas Temperature | Lowers stack loss and environmental heat discharge |

| Lower Emissions | Reduced CO₂, NOx, and particulate matter |

| Shorter Warm-Up Times | Preheated water or air speeds startup |

| Improved Steam Quality | Stable heat input results in better temperature control |

| Smaller Boiler Sizing | Reduced fuel demand enables downsizing |

For combined heat and power (CHP) systems, heat recovery increases total system efficiency from 35–40% (electricity only) to over 75–85% when thermal energy is captured.

🧪 Real-World Case Study: Food Processing Plant

A food processor installed a condensing economizer on a 15 MMBtu/hr boiler. Baseline flue gas temperature was 205°C, and return feedwater was 60°C. After installation:

Flue gas temperature dropped to 85°C

Feedwater temperature rose to 95°C

Annual gas savings: $210,000

Efficiency improvement: 13.2%

Payback period: 18 months

Maintenance was simplified by adding self-cleaning features and stainless steel construction to handle wet flue gases.

Air preheaters in heat recovery systems improve efficiency by pre-warming combustion air.True

Preheated combustion air supports better flame stability, faster ignition, and more complete combustion, reducing fuel use.

📊 Comparative Table: Heat Recovery Methods and Impact

| System Type | Recovery Target | Typical Efficiency Gain | Best Use Case |

|---|---|---|---|

| Feedwater Economizer | Flue gas → feedwater | 5–10% | Boilers with high feedwater volume |

| Condensing Economizer | Flue gas → feedwater + condensate | 10–15% | Gas-fired low-temp return systems |

| Air Preheater | Flue gas → combustion air | 3–5% | Oil/gas-fired high-capacity systems |

| HRSG (Steam Generator) | Turbine exhaust → steam | 20–40% | CHP and gas turbine systems |

These methods are often combined for cumulative benefits, especially in large, multi-unit operations.

Summary

Economizers and heat recovery systems are essential tools for cutting energy waste in industrial combustion systems. By capturing heat that would otherwise escape through the exhaust stack, these systems preheat incoming water or air, significantly reducing the fuel required to generate heat or steam. The result is a measurable improvement in efficiency—often between 5% and 20%—with additional benefits in emissions, startup speed, and system lifespan. For any facility seeking cost-effective energy savings, heat recovery isn’t just an upgrade—it’s a necessity.

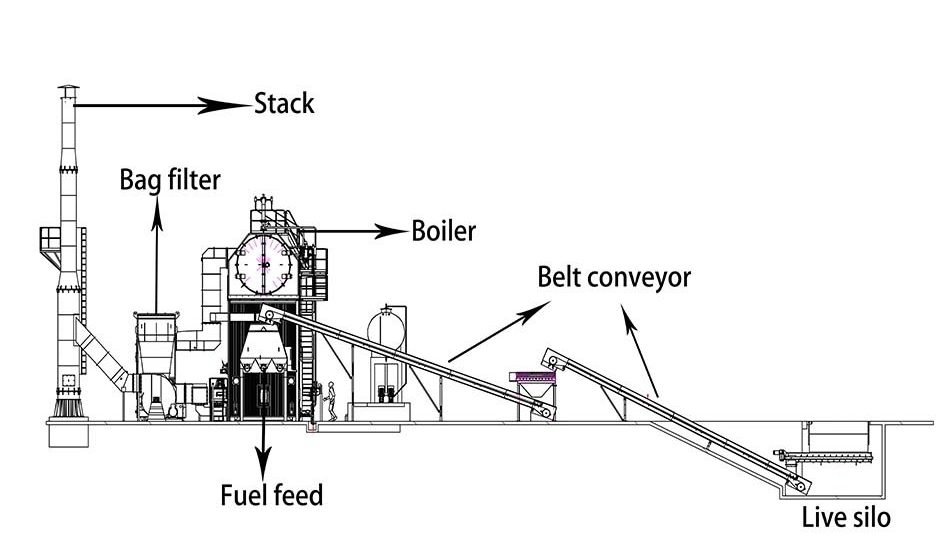

How Can Fuel Feeding Systems and Ash Handling Be Optimized for Smooth Operation?

In biomass and solid fuel combustion systems, two seemingly simple processes—feeding the fuel in and getting the ash out—can be the biggest sources of breakdowns, inefficiency, and operating headaches. When fuel isn’t fed evenly or ash removal is inconsistent, the boiler can’t maintain stable combustion. This leads to energy losses, high emissions, clogs, corrosion, and unplanned downtime. Optimizing these systems is essential not only for reliability but also for ensuring combustion efficiency, reducing maintenance costs, and increasing equipment lifespan.

Fuel feeding systems and ash handling processes can be optimized through proper design, automation, real-time monitoring, and preventive maintenance. Smooth fuel feeding ensures a consistent and controllable burn, which improves combustion stability and efficiency. Meanwhile, reliable ash removal prevents blockages, pressure buildup, and equipment wear. Using technologies like variable-speed feeders, level sensors, automated rotary valves, and continuous ash conveyors helps synchronize fuel input and waste output, ensuring seamless boiler operation.

For operators of biomass plants, solid fuel boilers, or waste-to-energy systems, mastering fuel delivery and ash disposal is a key to consistent performance and reduced operating costs.

Uneven biomass fuel feeding can cause fluctuations in flame stability and combustion temperature.True

Inconsistent feed rates lead to unstable combustion zones, resulting in incomplete combustion, emissions spikes, and thermal cycling.

🔄 Understanding Fuel Feeding Systems: Components and Functions

Fuel feeding systems are responsible for transporting solid fuels—wood chips, pellets, RDF, coal—from storage to the combustion chamber.

Key Components:

| Component | Function | Optimization Tips |

|---|---|---|

| Fuel Hoppers | Store and buffer fuel | Use anti-bridging devices to prevent blockages |

| Screw Feeders | Meter and transport fuel | Apply variable speed control for flow adjustment |

| Rotary Valves | Seal combustion chamber and meter feed | Ensure wear-resistant sealing surfaces |

| Fuel Conveyors | Move bulk material from silo to feeder | Enclose to minimize dust and moisture |

| Level Sensors | Monitor hopper fuel levels | Use radar or ultrasonic for continuous accuracy |

A well-designed feeding system ensures:

Constant fuel flow

Uniform particle distribution

Reduced air leakage into combustion chamber

Minimized mechanical wear

Inconsistent fuel feeding causes air-to-fuel ratio fluctuations, which disrupt combustion and reduce thermal efficiency.

📉 Fuel Feeding Problems and Their Consequences

| Problem | Cause | Consequence |

|---|---|---|

| Fuel Bridging | High moisture or improper particle size | Interrupts flow, flame instability |

| Overfeeding | Lack of feedback control | Overheating, emissions, unburned fuel |

| Underfeeding | Mechanical blockages or misalignment | Incomplete combustion, low output |

| Dust Leakage | Worn seals or open conveyors | Dust accumulation, fire hazard |

Fuel overfeeding improves combustion efficiency by providing more energy.False

Overfeeding leads to excess fuel in the chamber without enough oxygen, causing incomplete combustion and energy loss.

🔧 Optimizing Fuel Feeding: Practical Approaches

Install Variable Speed Drives (VSDs): Match feed rate to boiler load in real time.

Automate Based on Flue Gas Sensors: Adjust fuel flow in response to O₂ or CO levels.

Use Dual Screw Feeders: Prevent bridging and ensure redundancy in case of failure.

Control Fuel Moisture: Install inline moisture sensors or fuel dryers upstream.

Regularly Calibrate Load Cells and Flowmeters: Ensure accurate mass flow control.

A paper mill that installed a sensor-based VSD-controlled screw feeder cut fuel consumption by 7% and reduced O₂ spikes by 45%, improving boiler stability.

🔥 Ash Handling Systems: Types and Challenges

Ash is the incombustible residue left after combustion. It must be efficiently collected and removed to prevent accumulation and equipment damage.

Ash Types:

| Type | Description | Source |

|---|---|---|

| Bottom Ash | Coarse ash collected below the furnace | Grate or stoker-fired boilers |

| Fly Ash | Fine particles carried in flue gas | Cyclone or baghouse captured |

| Clinker | Hardened ash from high-temp fusion | Poor-quality fuels or hot zones |

Common Ash Handling Systems:

| System Type | Method | Suitable For |

|---|---|---|

| Screw Conveyors | Rotating blades move ash mechanically | Medium to large boilers |

| Pneumatic Systems | Use air to transport fly ash | High-volume, dry fly ash |

| Drag Chain Conveyors | Slow-moving chain drags ash forward | Coarse or sticky ash |

| Wet Ash Hoppers | Quenches and collects bottom ash | Biomass and coal plants |

Continuous ash removal systems reduce equipment wear compared to batch dumping.True

Continuous removal prevents buildup that can overheat and damage grates, tubes, and refractory linings.

⚙️ Ash Handling Optimization Techniques

| Optimization Practice | Benefit |

|---|---|

| Automated Ash Level Monitoring | Prevents overfilling and system blockage |

| Sealed Ash Discharge Valves | Prevents air ingress and pressure loss |

| Moisture-Controlled Ash Quenching | Reduces dust and slag formation |

| Vibratory Ash Conveyors | Reduces maintenance and handles varied particle sizes |

| Ash Cooling Systems | Prevents thermal damage to mechanical parts |

🧪 Case Study: Biomass CHP Plant Optimization

A combined heat and power (CHP) plant burning wood chips experienced frequent grate blockages and flame instability. Investigations revealed:

Uneven fuel feeding due to bridging in the hopper

Ash build-up under grates from infrequent removal

Manual ash dumping led to hot spots and slag

Optimizations included:

Dual auger feeders with bridging breakers

Real-time moisture sensors for fuel drying control

Continuous drag-chain ash removal system

Results:

13% increase in combustion stability

9.5% reduction in unburned carbon

$62,000 annual savings on maintenance and fuel losses

Manual ash dumping provides more reliability than automated continuous ash systems.False

Manual dumping is labor-intensive, less consistent, and allows ash to accumulate, increasing risk of overheating and system inefficiencies.

📈 Optimization Tools and Monitoring Technologies

| Tool | Function | Role in Optimization |

|---|---|---|

| SCADA Integration | Real-time monitoring of feeds and ash | Enables remote diagnostics and alerts |

| Load Cell Feed Monitoring | Measures live weight of fuel hopper | Prevents bridging and overfeeding |

| Infrared Flame Cameras | Detect combustion anomalies | Links feeding rate to flame performance |

| Ash Sensor Probes | Track buildup in real-time | Automates ash removal scheduling |

| AI-Based Fuel Flow Control | Adjusts feeding dynamically | Learns patterns to optimize feed/combustion |

Summary

Efficient fuel feeding and ash handling are essential for the reliable and economical operation of biomass and solid fuel combustion systems. When these subsystems are optimized with the right technology and design, combustion becomes stable, fuel use drops, emissions are minimized, and system maintenance is reduced. Automated, sensor-driven, and intelligently controlled systems outperform manual or outdated approaches, delivering smooth operation and long-term cost savings. In any solid-fuel-based energy system, the path to peak efficiency begins at the hopper—and ends with clean, continuous ash removal.

How Does Automation and Performance Monitoring Reduce Downtime and Maintenance Costs?

In industrial thermal systems—whether in power plants, biomass boilers, or chemical processing—unscheduled downtime and reactive maintenance are costly and disruptive. Equipment failures not only interrupt production but also increase safety risks, shorten component lifespan, and waste energy. Traditionally, maintenance was scheduled by calendar or triggered only after a breakdown. Today, automation and real-time performance monitoring enable smarter maintenance by detecting issues early, minimizing failures, and optimizing system efficiency. These technologies transform boiler rooms from reactive to predictive operations, where downtime is rare and performance is maximized.

Automation and performance monitoring reduce downtime and maintenance costs by continuously analyzing key operating data to detect abnormalities before they cause failures. Automated systems adjust parameters in real time to maintain optimal efficiency, while condition-based monitoring identifies wear, fouling, and performance drift. This proactive approach reduces emergency repairs, extends equipment life, and enables predictive maintenance scheduling. Facilities using advanced monitoring systems report up to 50% reductions in unplanned downtime and 20–40% lower maintenance costs.

For any energy-intensive facility, integrating automation and monitoring tools isn’t just an upgrade—it’s a foundational strategy for cost control and operational reliability.

Automation helps reduce downtime by enabling early detection and real-time adjustments to system parameters.True

By analyzing sensor inputs, automated systems can detect deviations from optimal conditions and make corrections before failures occur.

🤖 Key Automation Technologies for Thermal Systems

| Technology | Function | Benefit |

|---|---|---|

| PLC/SCADA Systems | Real-time control and data acquisition | Enables auto-adjustments and remote monitoring |

| Oxygen Trim Systems | Adjust air flow based on flue gas oxygen levels | Maintains combustion efficiency |

| VFDs (Variable Frequency Drives) | Control motor speeds for fans, pumps | Match output to load, reduce energy use |

| Burner Management Systems (BMS) | Sequence startup, shutdown, and safety interlocks | Prevent unsafe conditions and reduce manual errors |

| Control Valves with Positioners | Adjust steam or fuel flow precisely | Maintains stable output and reduces strain |

By automating these subsystems, plants reduce the likelihood of human error, improve consistency, and respond instantly to changing load conditions.

📊 Performance Monitoring: What Should Be Tracked?

| Parameter | What It Indicates | Action Triggered by Deviation |

|---|---|---|

| Flue Gas Temperature | Heat transfer efficiency, fouling | Clean heat surfaces or inspect exchangers |

| O₂ and CO Levels | Combustion quality | Adjust air-fuel ratio or tune burners |

| Steam Pressure/Temperature | Process stability | Adjust feedwater or firing rate |

| Fuel Flow Rate | Fuel economy and system loading | Tune feed systems or correct flow imbalance |

| Blower and Pump Vibration | Mechanical health of motors and bearings | Schedule maintenance before failure |

Advanced monitoring platforms integrate these variables into a dashboard, allowing operators to visualize system health and efficiency in real time.

Manual-only performance monitoring reduces unnecessary maintenance costs compared to automated monitoring.False

Manual systems rely on periodic checks, which can miss emerging issues. Automated monitoring provides continuous visibility and early warnings.

🔧 From Reactive to Predictive Maintenance

Maintenance Strategy Comparison:

| Strategy Type | Trigger | Pros | Cons |

|---|---|---|---|

| Reactive | Failure occurs | Low upfront cost | High repair cost, unscheduled downtime |

| Preventive | Time-based schedules | Reduces major breakdowns | Can lead to unnecessary maintenance |

| Predictive | Based on actual equipment condition | Optimized scheduling, lower costs | Requires sensors and analytics setup |

Predictive maintenance, enabled by automation and monitoring, uses real-time data to forecast when maintenance is needed. For example, detecting a gradual increase in pump vibration may indicate bearing wear—allowing repairs before failure.

A manufacturing facility using predictive analytics reduced unplanned downtime by 47% and maintenance costs by 28% within the first year.

🧪 Case Study: Power Boiler Optimization

A 100 MW power boiler in a paper mill struggled with:

Unexpected shutdowns (~3 times/month)

High stack temperatures (>250°C)

Frequent burner maintenance

Upgrades Included:

SCADA-based burner and airflow control

Real-time monitoring of O₂, CO, and temperature

Integration of AI model for predicting fouling buildup

Results:

Reduced shutdowns from 3/month to <1/quarter

Flue gas temp reduced by 60°C

Maintenance labor hours cut by 35%

Fuel consumption reduced by 6.2%

Boiler systems using real-time monitoring can detect fouling before efficiency is affected.True

Monitoring trends in flue gas temperature and pressure drop helps identify fouling early, enabling timely cleaning.

⚙️ Automation-Driven Efficiency Improvements

| System Function | Manual Operation Result | Automated Control Result |

|---|---|---|

| Combustion Control | Fluctuating flame and air mix | Stable flame, low emissions |

| Feedwater Flow Management | Over/under supply | Real-time matching to demand |

| Burner Cycling | Frequent start-stops | Load-based modulation |

| Soot Blowing | On fixed schedule | Triggered by actual fouling |

| Alarm Management | Delayed response | Instant alerts and diagnostics |

Automated systems adapt to process dynamics instantly, improving safety and minimizing process variability.

🧠 Emerging Technologies in Performance Monitoring

| Technology | Role in Maintenance Optimization |

|---|---|

| AI/ML Predictive Models | Learn from operational data to predict faults and inefficiencies |

| Digital Twins | Virtual replica of boiler to test control strategies |

| Cloud Analytics | Centralized, remote monitoring of multi-site operations |

| Infrared Thermography | Detects heat losses and insulation issues |

| Ultrasound and Vibration Sensors | Detect mechanical wear and misalignment early |

These innovations help shift from calendar-based inspections to data-driven decision-making, reducing unnecessary downtime and improving asset utilization.

Summary

Automation and performance monitoring are essential tools for modern thermal systems aiming to reduce downtime and control maintenance costs. By enabling real-time adjustments, early detection of wear or inefficiencies, and condition-based scheduling, these technologies transform maintenance from a reactive burden into a strategic advantage. With reduced breakdowns, optimized fuel use, and longer equipment lifespan, facilities equipped with advanced monitoring and control systems experience measurable gains in reliability, safety, and operational efficiency. In the competitive world of energy and process industries, automation isn’t optional—it’s the backbone of sustainable performance.

🔍 Conclusion

Lowering the operating costs of an industrial biomass boiler involves more than just using renewable fuel—it requires strategic control of combustion, heat transfer, fuel handling, and maintenance. By fine-tuning these systems, facilities can reduce fuel consumption, prevent performance losses, and extend equipment life. A well-optimized biomass boiler becomes not only a green investment but also a competitive, cost-saving asset.

📞 Contact Us

💡 Want to maximize the efficiency and ROI of your biomass boiler? Our team offers combustion tuning, fuel analysis, heat recovery integration, and maintenance support tailored to your biomass system.

🔹 Let’s help you run a cleaner, more cost-efficient biomass boiler system—built for performance and savings. 🌿🔥📉

FAQ

What are the best ways to optimize biomass boiler performance?

Key strategies include:

Using consistent, low-moisture biomass fuel

Optimizing air-to-fuel ratios for clean, complete combustion

Maintaining clean heat exchange surfaces

Using flue gas recirculation or oxygen trim controls

Monitoring real-time boiler data for performance tuning

How does fuel quality impact biomass boiler efficiency?

Moisture content, particle size, and calorific value all affect combustion. High-moisture fuels reduce flame temperature and increase flue gas losses, while inconsistent fuel size leads to incomplete burn and ash buildup. Aim for <20% moisture and uniform particle size.

What role does maintenance play in reducing operating costs?

Regular cleaning of ash, soot, and deposits from heat exchanger surfaces

Inspection and replacement of worn grates, sensors, and blowers

Checking for air leaks or insulation degradation

Proper maintenance extends equipment life, improves heat transfer, and reduces fuel use.

How can combustion be controlled for better efficiency?

Install automated air-fuel controls like oxygen trim systems or variable-speed blowers. These dynamically adjust combustion air supply, ensuring optimal efficiency under varying loads and fuel conditions.

Can heat recovery systems lower biomass boiler fuel costs?

Yes. Installing an economizer to preheat feedwater or an air preheater to warm combustion air using exhaust gases can improve overall thermal efficiency by 5–10%, directly reducing biomass fuel demand.

References

Biomass Boiler Performance Optimization Guide – https://www.energy.gov

Fuel Quality and Moisture Content Effects – https://www.sciencedirect.com

Industrial Biomass Boiler Maintenance Practices – https://www.researchgate.net

Combustion Control in Biomass Systems – https://www.epa.gov

Using Oxygen Trim and FGR in Biomass Boilers – https://www.bioenergyconsult.com

Boiler Heat Recovery and Economizer Systems – https://www.mdpi.com

Real-Time Boiler Monitoring Technologies – https://www.automation.com

Energy Efficiency in Biomass Heating Plants – https://www.iea.org

Industrial Boiler System Optimization – https://www.energysavingtrust.org.uk

Thermal Efficiency Standards and Trends – https://www.asme.org