How to Choose a Reliable Industrial Biomass Boiler Manufacturer

Selecting a reliable industrial biomass boiler manufacturer is critical for ensuring long-term system efficiency, environmental compliance, and return on investment. Biomass boilers involve complex combustion processes, variable fuel types, and stricter emissions control—making manufacturer experience and engineering expertise essential. Choosing the wrong supplier can result in frequent operational issues, inefficient fuel usage, and costly retrofits.

To choose a reliable industrial biomass boiler manufacturer, evaluate their experience with multi-fuel systems, biomass combustion technologies, compliance with international standards (e.g., ASME, CE, ISO), and track record of installations in your industry. Prioritize manufacturers that offer in-house engineering, custom system design, emissions control integration, and robust after-sales support. Request real-world performance data, references from similar projects, and guarantees on efficiency and emissions.

Here’s a checklist of the most important criteria to guide your decision.

What Technical Expertise Should a Biomass Boiler Manufacturer Demonstrate?

Ensuring optimal performance, emissions compliance, and long-term reliability in biomass boiler projects hinges on selecting a manufacturer with deep technical capabilities. 🛠️ Biomass boilers face challenges such as feedstock variability, combustion stability, ash behavior, and control integration. Without proven expertise, facilities risk inefficient operation, high maintenance costs, and regulatory issues. This article outlines the essential technical areas a biomass boiler manufacturer must master to deliver reliable, efficient, and compliant systems.

A qualified biomass boiler manufacturer must demonstrate expertise in feedstock testing, combustion design, ash handling systems, corrosion-resistant materials, emissions control, thermal efficiency optimization, and full-spectrum engineering support—from site assessment to commissioning. These competencies ensure performance tailored to your fuel type, capacity, and environmental constraints.

Let’s explore what sets a capable supplier apart.

🔍 Core Competencies Required

| Technical Area | Details | Why It Matters |

|---|---|---|

| Feedstock Analysis | Testing moisture, ash content, particle size | Enables custom furnace design for specific biomass types |

| Combustion System Design | Fluidized bed or grate technology; air staging | Ensures stable combustion, efficiency, and emissions control |

| Ash & Slag Management | Automated removal, ash cooling systems | Prevents fouling, reduces unplanned downtime |

| Materials & Corrosion Protection | High-temp alloys, refractory linings | Essential for resistance to biomass-related corrosion |

| Heat Transfer Optimization | Economizers, superheaters, H‑exchangers | Maximizes thermal efficiency, reduces fuel demand |

| Emissions Control | Cyclones, fabric filters, low-NOx burners | Meets PM, NOx, and organics regulations |

| Control & Automation | DCS/PLC for combustion, feed, and safety | Enables consistent performance with minimal supervision |

| Site Engineering & Integration | Layout, structural, DOE compliance | Ensures smooth fit into existing plant systems |

A manufacturer lacking these core areas risks producing boilers that don’t work efficiently with local biomass or meet regulatory standards.

🔍 Detailed Technical Focus

Feedstock Testing & Adaptation

Moisture tolerance up to 50%: Requires pre-drying or adaptable furnace design

Diverse fuels: Chips, pellets, bagasse, agri residues

Testing lab access: Fuel testing during design phase ensures right configuration

Combustion Technology

Fixed grate: Ideal for coarse, low-grade fuels

Fluidized bed: Handles fine, variable feedstock; offers cleaner burn

Staged combustion: Reduces unburnt carbon and NOx

Corrosion & Material Failures

Species like alkali salts and chlorine cause accelerated wear

Use of Grade 316L steel, Inconel, or ceramic coatings extends component life

Ash System Design

Specifications for ash melting point, slagging, stickiness

Self-cleaning cyclones, vibratory ash removal, ash coolers minimize downtime

🔍 Emissions & Thermal Performance

| Component | Purpose | Typical Metrics |

|---|---|---|

| Cyclonic separator | Coarse PM removal | >85% removal |

| Fabric filter | Fine particle control | <15 mg/Nm³ |

| Low-NOx burner | NOx emission control | <200 mg/Nm³ |

| Economizer | Preheat feedwater | +3–5% efficiency |

| Superheater | Deliver high-pressure steam | Avoids wet steam |

Engineers must supply third-party emissions test reports and thermal efficiency data validated by field trials.

🔍 Engineering Support & Lifecycle Services

| Project Phase | Manufacturer’s Role |

|---|---|

| Feasibility Study | Fuel testing, load analysis, ROI modeling |

| Detailed Design | 3D layout, pipe routing, foundation loading |

| Fabrication & Quality | ISO 9001facility, welding inspection, material traceability |

| Installation | Field supervision, erection support |

| Commissioning | First fire, tuning, ramp-up protocols |

| Training & O&M | Manuals, spare‑parts, service agreements |

| Performance Warranty | Covers output, emissions, and uptime |

High-performing manufacturers offer turnkey solutions rather than simply supplying components.

Summary

In biomass boiler investments, technical expertise is not optional—it defines success. Manufacturers must prove their competence in fuel testing, combustion system design, ash handling, corrosion resilience, emissions control, and full-engineering lifecycle support. Choosing a partner with these capabilities ensures your facility will run efficiently, meet environmental standards, and enjoy reliable steam generation for years. Demand concrete evidence—field trial data, lab reports, site visit references—to secure a resilient biomass boiler investment.

Why Are Multi-Fuel Capability and Fuel Flexibility Important in Biomass Boiler Design?

Many biomass boiler investments fall short of their full potential—not due to poor engineering or low-quality fuel, but because the system was designed to handle only a single feedstock type. 🔍 When fuel prices fluctuate, or local availability changes, a rigid combustion system leads to underperformance, higher operating costs, and regulatory risk. Multi-fuel capability and true fuel flexibility solve this problem by enabling boilers to process various biomass types efficiently and cleanly—ensuring reliable steam supply, cost control, and sustainability across changing fuel markets.

Multi-fuel capability and fuel flexibility are crucial in biomass boiler design because they allow the system to operate efficiently and within emissions limits across a range of biomass fuels, such as wood chips, pellets, agricultural waste, RDF, and even co-fired materials. This adaptability ensures uninterrupted operations despite feedstock changes, lowers operating costs by enabling use of locally available or cheaper fuels, and supports compliance with evolving environmental regulations.

If your biomass boiler can’t handle a range of fuels, you may find yourself stuck with costly redesigns or unreliable operation.

Designing for fuel flexibility ensures you’re investing in a system that’s built to last—technically, financially, and environmentally. Let’s explore how multi-fuel capability adds value at every stage of your biomass boiler lifecycle.

Biomass boilers only operate efficiently when burning one specific type of fuel.False

Modern biomass boilers are designed to operate efficiently with a range of biomass fuels, including mixed-feed scenarios, thanks to advanced combustion control and adaptable design.

🔍 Feedstock Variability Is the Norm in Biomass Markets

Unlike natural gas or oil, biomass fuel characteristics vary widely:

| Property | Wood Chips | Pellets | Agri-Waste | RDF |

|---|---|---|---|---|

| Moisture Content (%) | 20–50 | 5–10 | 30–60 | 10–30 |

| Ash Content (%) | 0.5–2 | <1 | 5–15 | 10–20 |

| Bulk Density (kg/m³) | 250–400 | 650 | 150–300 | 300–500 |

| Heating Value (MJ/kg) | 14–18 | 18–20 | 12–15 | 15–22 |

This variability demands a boiler design that adjusts combustion parameters dynamically and handles changes in flow, burn rate, and emissions without manual intervention.

🔍 Benefits of Multi-Fuel Biomass Boiler Systems

| Benefit | Description |

|---|---|

| Fuel Price Arbitrage | Facilities can shift to cheaper or more available fuels when markets change. |

| Supply Chain Resilience | Avoids shutdowns due to local unavailability of a specific biomass source. |

| Regulatory Compliance | Systems can be tuned for emissions performance depending on the feedstock. |

| Sustainability Optimization | Enables co-firing with waste or recycled biomass, reducing carbon footprint. |

| Eligible for Broader Incentives | Projects with fuel flexibility often qualify for more grants or carbon credits. |

A flexible boiler becomes a strategic asset in a volatile fuel market.

🔍 Engineering Considerations for Fuel Flexibility

For true multi-fuel operation, the manufacturer must integrate:

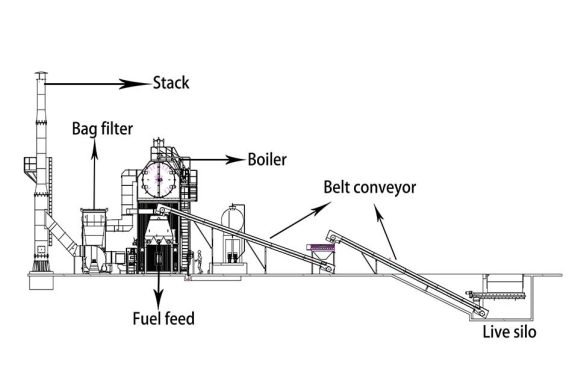

Advanced combustion technology: Fluidized bed combustion (FBC), sloped moving grates, or hybrid systems.

Dynamic air-fuel control: Automated O₂ trim and modulation based on heat load and fuel properties.

Fuel feeding systems: Adjustable augers, screw conveyors, and hoppers designed for varied density and flowability.

High-durability materials: Alloy steel and corrosion-resistant linings that withstand fuel-borne chemical stress.

Ash management systems: Rotary or reciprocating ash removal systems that prevent clinker formation or fouling.

Emission control modules: Cyclone separators, bag filters, and lime injection systems tuned per fuel ash chemistry.

🔍 Real-World Case Study: Co-Firing Wood and Rice Husk

A 30 TPH biomass boiler designed for a cement plant in Southeast Asia was commissioned to run on 50% wood chips and 50% rice husk.

The system utilized a fluidized bed combustor with high turndown flexibility.

Engineers incorporated dual feed-inlet systems with variable-speed drives.

Emission control modules included a bag filter system rated for 15 mg/Nm³ dust output.

Outcome: The plant achieved 87% efficiency and reduced fuel cost by 21% compared to a mono-fuel boiler, with seamless fuel switching based on seasonal pricing.

🔍 Key Performance Metrics for Multi-Fuel Boilers

| Parameter | Flexible Design Target |

|---|---|

| Fuel Moisture Tolerance | 10–55% |

| Ash Handling Capacity | ≥15% ash fuels |

| Combustion Efficiency | ≥85% across all fuel types |

| NOx Emissions | <150 mg/Nm³ (with staged air or FGR) |

| PM Emissions | <20 mg/Nm³ (with cyclone or bag filter) |

These benchmarks demonstrate the value of engineering for versatility—not just initial efficiency.

🔍 Future-Proofing Your Biomass Boiler Investment

Fuel policies, carbon pricing, and sustainability demands are all evolving. A fixed-fuel boiler may not meet tomorrow’s:

Emissions caps on PM, SO₂, and NOx

Fuel mandates (e.g., biogenic carbon share)

ESG or green bond standards requiring cleaner combustion

Regional biomass availability changes (e.g., pellet export trends)

Fuel flexibility improves long-term resilience and operational cost control for biomass boiler projects.True

By adapting to different fuels, operators can switch to cheaper or more sustainable options without re-engineering the boiler.

Summary

Fuel flexibility is not a luxury—it’s a necessity in modern biomass boiler design. Systems built for multi-fuel use provide critical advantages in fuel sourcing, emissions management, cost control, and long-term compliance. Whether your facility relies on wood chips today or wants to co-fire agri-waste tomorrow, a flexible boiler design ensures you’re ready. When evaluating boiler suppliers, demand data and references that prove their multi-fuel capability. It’s the only way to ensure your investment pays dividends across every operational and market condition.

How Do Certifications and Compliance Standards (ASME, CE, ISO) Ensure Quality and Safety?

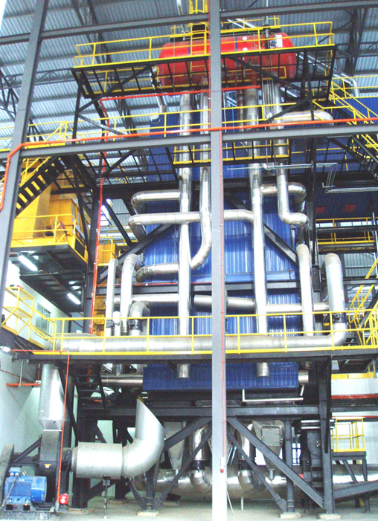

Industrial biomass boilers operate under extreme conditions—high temperatures, pressure, corrosive ash content—and any failure can lead to safety hazards, unscheduled downtime, environmental violations, or financial loss. 🔒 International standards and certifications like ASME, CE, and ISO play a crucial role by enforcing rigorous design, manufacture, inspection, documentation, and lifecycle quality management. Here’s how they safeguard the integrity and reliability of biomass boiler systems.

Certifications such as ASME (BPVC), CE (PED), and ISO 9001/14001/45001 are critical for biomass boiler quality and safety. They ensure pressure vessel integrity, material traceability, welding accuracy, manufacturing process control, emissions compliance, environmental stewardship, and worker safety—resulting in safer operations, regulatory acceptance, and consistent performance.

💡 ASME Certification – Boiler & Pressure Vessel Code

ASME BPVC Section I and VIII cover pressure components of biomass boilers. Key requirements include:

Design Calculations & Stress Analysis: Ensures vessel can withstand operational pressure and thermal expansion.

Material Traceability: Mill Test Reports verify material properties, reducing risk of failure.

Welding Procedures (WPS/PQR): Certified welders and weld profiles guarantee strong joints.

Non-Destructive Testing (NDT): Radiographic, ultrasonic, or dye-penetrant inspections detect hidden flaws.

Hydrostatic Testing: Pressure-tested at ≥1.5× the design rating before first fire.

Achieving ASME stamp “I” confirms compliance with recognized pressure safety protocols—essential for legal operation and insurance.

⚙️ CE Marking – Pressure Equipment Directive (PED)

For equipment sold in the EU, CE compliance ensures:

Risk-Based Assessment: Notified body reviews critical parts like boiler drum or superheater.

Material and Manufacturing Oversight: Must meet EN standards with documented production history.

Final Pressure Test: CE-stamped hydrotest confirms structural integrity.

Technical Dossier: Contains design notes, test records, and compliance evidence—retained for at least 10 years.

Declaration of Conformity: Manufacturer commits in writing to EDT standards and operates a retrieval system.

The CE mark ensures cross-border acceptance and streamlined regulatory checks.

🔧 ISO 9001 – Quality Management System

ISO 9001:2015 certification guarantees consistent and auditable business practices:

Document Control: Engineering drawings, revisions, and approvals are traceable.

Production Quality: Supplier approval, inspection checkpoints, and defect tracking reduce defects.

Customer Satisfaction: Feedback mechanisms ensure service responsiveness.

Internal Auditing: Regular reviews drive continuous improvement.

Certification builds confidence in both the product and the process.

🌱 ISO 14001 & ISO 45001 – Environmental and Occupational Health

Supplementary ISO standards demonstrate responsible operations:

ISO 14001 (Environmental): Requires management of emissions, waste handling, and legal compliance.

ISO 45001 (Health & Safety): Emphasizes risk assessment, emergency procedures, staff training, and incident investigation.

Together, they reduce plant risk, promote worker safety, and support green credentials.

🧩 Integrated Impact: Certifications Work Together

| Standard | Focus Area | Assurance Provided |

|---|---|---|

| ASME | Pressure design & safety | Prevents catastrophic failures |

| CE | European regulatory compliance | Ensures acceptance and legal operation |

| ISO 9001 | Quality systems and traceability | Prevents production errors |

| ISO 14001 | Environmental responsibility | Reduces pollution and compliance risk |

| ISO 45001 | Workplace health & safety | Minimizes accidents and downtime |

📌 Without these certifications, boilers may face insurance restrictions, import/export hurdles, legal penalties, or unsafe reliability.

Summary

Certifications and compliance standards are not optional—especially for industrial biomass boilers. ASME and CE ensure mechanical safety under pressure and thermal strain, while ISO frameworks guarantee production quality, environmental stewardship, and workplace safety. These endorsements allow manufacturers to deliver reliable equipment that meets regulatory requirements, protects staff and infrastructure, and supports long-term operational performance. Demand certified systems to minimize risk and maximize return on your biomass boiler investment.

What Role Do Case Studies, References, and Customer Success Stories Play in the Selection Process?

In the high-stakes environment of industrial biomass boiler procurement, choosing the wrong manufacturer can lead to catastrophic inefficiencies, compliance failures, or long-term reliability issues. Technical specs and pricing are essential, but they don’t always reflect how a boiler will perform under real-world conditions. 📂 This is where case studies, client references, and customer success stories become critical. They provide verifiable proof of past performance, helping decision-makers assess whether a manufacturer can truly meet their unique project requirements.

Case studies, client references, and customer success stories play a pivotal role in the selection process for industrial biomass boilers by offering evidence of real-world performance, emissions compliance, installation timelines, after-sales service, and long-term operational stability. These resources validate a manufacturer’s claims, reduce perceived risk, and offer insights into system behavior under comparable operating conditions.

Let’s explore how these tools help facility owners, engineers, and procurement leaders make better, safer investment decisions.

📌 Why Project Experience Is More Important Than Brochures

While brochures describe what a manufacturer claims to do, case studies and references show what they’ve actually done.

| Evaluation Factor | What to Look for |

|---|---|

| Industry Match | Boilers installed in cement, paper, textile, food, etc. |

| Fuel Type Handling | Experience with wood chips, pellets, bagasse, RDF, agri-waste |

| Regional Operation | Cold climate? Altitude? High-humidity zones? |

| Emissions Compliance | Documented proof of NOx, SO₂, PM within limits |

| Thermal Output & Load | Systems that match your steam or power profile |

Success stories offer context—not just numbers—so you can judge relevance and replicability.

📊 Key Elements of an Effective Case Study

| Case Study Component | Why It Matters |

|---|---|

| Client Name/Industry | Provides authenticity and shows industry relevance |

| Boiler Specifications | Validates capacity, pressure, temperature ranges |

| Fuel Description | Confirms combustion system is fuel-flexible or fuel-specific |

| Project Scope | EPC turnkey? Equipment supply only? Retrofit? |

| Performance Metrics | Efficiency achieved, emissions, uptime, payback period |

| Photos & Data | Visual proof of installation quality and M&V compliance |

| Challenges Overcome | Insights into how manufacturer handles complexity |

| Client Testimonial | Confirms satisfaction, support responsiveness, and value delivery |

Look for boiler vendors with a library of documented, verifiable case studies, not vague one-line project lists.

📞 Client References: What to Ask

Client references allow you to speak directly with past customers. Important questions include:

Was the boiler delivered and commissioned on time?

How did the manufacturer handle unexpected changes?

What was the post-installation support experience?

Has the boiler met or exceeded performance guarantees?

Would you work with this manufacturer again?

🧠 Pro tip: Always request at least 3 references across different fuel types, industries, or geographies.

Customer references are only necessary for large-scale utility boiler projects.False

Even mid-sized industrial biomass boiler projects benefit greatly from references, as they provide insights into performance and reliability across sectors.

🔍 Customer Success Stories: Marketing or Management Tool?

Beyond sales value, these stories reflect how well the manufacturer aligns with customer goals:

Highlight fuel cost reductions, emissions compliance, or automation gains

Include photos of installed equipment, dashboards, or O&M activity

Identify key project milestones and how they were achieved

Success stories humanize the experience, showing the journey—not just the destination—and often reveal intangibles like collaboration quality or technical creativity.

📈 Real-World Example: Biomass Boiler Case Study Table

| Project | Industry | Fuel | Capacity | Result |

|---|---|---|---|---|

| Vietnam | Pulp & Paper | Rice husk + wood chips | 30 TPH | Met 86.5% efficiency, NOx < 150 mg/Nm³ |

| Germany | Food Processing | Wood pellets | 10 MW | Delivered 24/7 operation, 97% uptime |

| India | Cement | RDF + bagasse | 35 TPH | Reduced fuel cost by 28%, 18-month ROI |

These snapshots help decision-makers match project conditions to their own needs.

🎯 Final Checklist: Choosing a Proven Manufacturer

Ensure your selected supplier provides:

5–10 recent case studies with metrics and photos

3+ active references for live conversation

Documented success with similar fuels and loads

Performance test reports and emissions verification

A client base with repeat projects

These prove that the manufacturer isn’t just selling boilers—they’re solving problems.

Summary

Case studies, references, and customer success stories are essential tools in selecting a biomass boiler manufacturer. They bridge the gap between theoretical capability and proven performance, giving buyers the confidence to move forward with a high-stakes investment. From thermal performance to emissions control and after-sales support, only real-world examples can reveal whether a vendor can deliver. Always demand data-backed documentation—not just glossy marketing—before making your final decision.

How Important Is After-Sales Support, Spare Parts Availability, and Remote Diagnostics?

Investing in an industrial biomass boiler is not a one-time event—it’s a long-term operational commitment. The initial purchase is only the beginning; the true test of value emerges in day-to-day operations, efficiency consistency, and how quickly problems are resolved. 🚨 That’s why after-sales support, spare parts availability, and remote diagnostics are mission-critical. Without these, even the most advanced biomass boiler can become a costly liability rather than a productive asset.

After-sales support, spare parts availability, and remote diagnostics are critical for ensuring the operational reliability, uptime, and efficiency of industrial biomass boilers. These services reduce unplanned downtime, extend equipment life, support emissions compliance, and enable rapid troubleshooting. A manufacturer’s support ecosystem can significantly influence total cost of ownership and long-term satisfaction.

Here’s what facility owners, maintenance managers, and procurement teams must understand about these often-overlooked factors.

After-Sales Support: The Backbone of Long-Term Reliability

A boiler may be perfectly engineered, but it will require maintenance, performance tuning, and service intervention over its lifetime. Robust after-sales support ensures:

Rapid technical assistance: Access to certified service engineers who understand your fuel and process requirements.

Scheduled maintenance contracts: Preventive maintenance routines to reduce breakdown risk and maintain efficiency.

Training & onboarding: Operator education ensures safe and efficient day-to-day management.

Warranty compliance: Scheduled inspections are often required to maintain manufacturer guarantees.

On-site and remote field support: Capable partners offer both types, shortening response time.

Lack of post-commissioning engagement can result in early wear, costly shutdowns, and non-compliance with safety standards.

Spare Parts Availability: The Key to Minimizing Downtime

Downtime in an industrial biomass boiler facility can cost thousands—or millions—depending on production value. Immediate access to spare parts prevents prolonged outages.

| Spare Part Type | Importance |

|---|---|

| Critical spares (burners, controllers, valves) | Immediate availability is essential to avoid emergency stops |

| Wear parts (grates, refractory, fans) | Need periodic replacement based on ash content and combustion temperature |

| Instrumentation (thermocouples, sensors) | Supports automation and safety functions |

| OEM certified components | Ensure compatibility and avoid warranty voiding |

Look for manufacturers that offer:

Local warehousing or regional partners

Consignment stocking agreements

Digital spare part catalogs with part numbers and specifications

Fast-track logistics for emergency parts

Without strong parts logistics, even a minor fault can become a production crisis.

Remote Diagnostics: The Smart Boiler’s Guardian

Modern biomass boilers equipped with digital controls allow for remote monitoring, fault diagnosis, and predictive maintenance:

Real-time performance analytics: Efficiency, emissions, feed rate, and thermal output tracking.

Early fault detection: Identify issues such as incomplete combustion, draft instability, or sensor errors.

Software updates & parameter tuning: Engineers can modify combustion air settings or fuel feed rates remotely.

Event log analysis: Historical data enables root-cause failure analysis.

Remote diagnostics dramatically improve response time, reduce the need for on-site visits, and provide data for continuous improvement. Many systems also integrate with SCADA or ERP platforms for plant-wide visibility.

Remote diagnostics are unnecessary for biomass boiler systems since everything can be handled manually.False

Remote diagnostics allow real-time fault detection, performance optimization, and faster support—reducing downtime and improving operational efficiency.

Real-World Example: Boiler Recovery Case Study

A biomass power plant in Eastern Europe using wood chips and RDF faced frequent slagging and temperature drops. Thanks to remote access, the manufacturer’s service team:

Identified inconsistent air-fuel ratio due to a failing flow sensor.

Adjusted oxygen trim parameters remotely.

Dispatched a technician with the correct part within 24 hours.

Result: The boiler returned to 95% capacity within 36 hours with minimal fuel loss and no production delay.

What to Look for in a Support-Ready Manufacturer

| Feature | Why It Matters |

|---|---|

| Global service footprint | Enables faster on-site support and local technician access |

| Dedicated customer portal | Simplifies issue logging, spares ordering, and ticket tracking |

| Annual support plan options | Ensures predictable service costs and preventive visits |

| Remote monitoring dashboard | Increases visibility for plant and OEM |

| Integrated documentation tools | Allows online access to manuals, diagrams, and M&V data |

A service ecosystem isn’t an extra—it’s a core part of a modern boiler solution.

Summary

After-sales support, spare parts logistics, and remote diagnostics are essential pillars of an effective biomass boiler operation. Beyond the engineering, these services ensure operational uptime, fuel efficiency, compliance, and lifecycle cost control. Choosing a manufacturer with proven infrastructure, trained support teams, and real-time monitoring capabilities safeguards your investment against unexpected failures and inefficiencies. In today’s competitive, high-regulation industrial environment, service is just as important as steam.

What Performance Guarantees, Emissions Compliance, and Warranties Should Be Requested?

Investing in an industrial biomass boiler isn’t just about acquiring equipment—it’s about securing long-term performance, regulatory compliance, and operational predictability. 📜 That’s why requesting specific performance guarantees, emissions compliance assurances, and comprehensive warranties is crucial. These contractual components not only define technical expectations but also protect your capital investment against underperformance, inefficiency, and potential fines.

Industrial biomass boiler purchasers should request written guarantees for steam output, combustion efficiency, fuel consumption rates, emissions limits (NOx, SO₂, PM), system uptime, and part durability. These should be backed by third-party test protocols, clear warranty terms (typically 12–24 months), and emissions compliance certifications aligned with local environmental laws.

Here’s what a robust guarantee and warranty package should include—and how to make sure it’s enforceable.

Steam Output & Combustion Efficiency Guarantees

Output and efficiency are the backbone of any boiler project’s ROI. Key metrics to guarantee:

| Parameter | Typical Benchmark |

|---|---|

| Rated Steam Output | ±2–3% of design TPH |

| Combustion Efficiency | ≥85% for most biomass types; ≥88% for pellets |

| Boiler Thermal Efficiency | ≥80% gross, ≥84% net |

| Turn-down Ratio | 3:1 minimum (load variability) |

Vendors should define how these values are verified—typically using ASME PTC 4, ISO 23167, or equivalent standards. Test conditions (fuel spec, ambient temp, pressure) must also be disclosed.

Boiler output guarantees can be waived if the vendor provides general specifications.False

Guarantees must be performance-tested and contractually defined to ensure accountability and enforceability.

Emissions Compliance Assurance

Biomass combustion can generate particulate matter (PM), NOx, SO₂, VOCs, and CO. A trustworthy vendor should provide:

Emission rate guarantees in mg/Nm³ at 6% O₂, dry basis:

NOx: ≤200 mg/Nm³

PM: ≤20 mg/Nm³

SO₂: ≤150 mg/Nm³ (with scrubber or limestone dosing)

Stack test reports from certified agencies (TÜV, SGS, etc.)

Continuous Emissions Monitoring System (CEMS) readiness

Fuel-specific modeling to anticipate variation in emissions output

Ensure the vendor understands and references local environmental standards (e.g., EU IED, USEPA, CPCB India, GB 13223-2025 China).

System Uptime and Availability Guarantees

Downtime affects production continuity and financial performance. Look for:

| Uptime Target | Description |

|---|---|

| ≥95% annual uptime | Based on 8,000+ operating hours/year |

| MTBF targets | Mean Time Between Failures for fans, feeders, and blowers |

| Response Time | On-site support or remote assistance within 24–72 hours |

Vendors should also provide preventive maintenance schedules and parts replacement intervals as part of the performance framework.

Fuel Consumption & Flexibility Commitments

Since biomass varies in calorific value, moisture, and ash content, fuel efficiency guarantees must be fuel-specific:

Fuel Input Guarantee: e.g., ≤1.1 kg biomass/kg steam (dry basis)

Fuel Flexibility Clause: Defines acceptable range of fuel properties:

Moisture: 10–55%

Ash: 0.5–15%

LHV: 12–20 MJ/kg

Manufacturers should test and document boiler behavior across these ranges using real-world fuels.

Warranty Terms & Conditions

A comprehensive warranty protects you from manufacturing or installation flaws. A strong warranty should include:

| Component | Typical Coverage |

|---|---|

| Pressure Parts | 18–24 months from commissioning |

| Non-Pressure Parts | 12–18 months |

| Electrical & Automation | 12 months (sensors, PLCs) |

| Refractory | 6–12 months |

| Auxiliary Equipment | 12 months (fans, feeders, dampers) |

Look for clauses that specify:

Exclusions (e.g., operator error, unapproved spares)

Response time for claims

Service obligations during the warranty period

Penalty or replacement clause for repeat defects

A biomass boiler’s refractory lining is usually not covered under warranty.False

Most warranties include refractory coverage, typically 6–12 months, as it's subject to early wear during startup and tuning.

Support Documentation to Demand

Factory Acceptance Test (FAT) report

Performance test protocol and results

Emissions test certificate

Inspection & test plan (ITP)

Warranty certificate

Spare parts & consumables list

Maintenance manual with service intervals

Training documentation and commissioning reports

These materials protect your interests and enable successful audits or funding compliance reviews.

Summary

Performance guarantees, emissions compliance, and robust warranties are non-negotiable when procuring an industrial biomass boiler. They define output reliability, regulatory readiness, and lifecycle protection. From fuel-specific combustion guarantees to emissions limits and uptime commitments, these contract clauses ensure your investment delivers as promised. Always work with manufacturers willing to back their claims with data, test reports, and enforceable service obligations. It’s not just about buying a boiler—it’s about securing sustainable performance and operational peace of mind.

🔍 Conclusion

Choosing a trusted industrial biomass boiler manufacturer goes beyond price—it’s about partnering with a technology provider that ensures sustainable, efficient, and regulation-compliant energy generation. By carefully evaluating technical capabilities, references, service offerings, and system performance, you can ensure your biomass boiler investment delivers long-term operational and financial success.

📞 Contact Us

💡 Need help selecting the right biomass boiler manufacturer? We offer independent consulting, system specification support, and sourcing assistance for high-performance biomass boiler systems.

🔹 Let us connect you with a manufacturer that delivers biomass boiler reliability, flexibility, and compliance—without compromise. 🌱🔥🏭

FAQ

What certifications should a biomass boiler manufacturer have?

Choose a manufacturer with industry-standard certifications such as:

ASME Boiler & Pressure Vessel Code compliance

ISO 9001/14001 for quality and environmental standards

CE certification for European markets

Biomass fuel compliance certifications (e.g., ENplus, BSL)

These ensure safety, efficiency, and eligibility for renewable energy incentives.

Why is experience and technical specialization important?

A reliable manufacturer should have:

10+ years of experience designing biomass boiler systems

Proven installations in sectors like textile, food, chemicals, or energy

Expertise in handling various biomass fuels (wood chips, pellets, agri-waste, RDF)

Successful integration of emissions control and heat recovery systems

A strong track record reduces the risk of system failures and ensures operational efficiency.

What design features indicate a high-quality biomass boiler?

Look for:

High combustion efficiency (≥85%)

Fully automated feeding and ash handling systems

Moisture and fuel type flexibility

Emission controls (cyclone, baghouse filters)

Durable construction and high-quality refractory

Advanced features lower O&M costs and improve long-term ROI.

What level of after-sales service should you expect?

A trusted manufacturer should provide:

On-site commissioning and operator training

24/7 support and remote diagnostics

Spare parts availability for 10–15 years

Preventive maintenance contracts

Access to local service technicians or global service hubs

How can I evaluate a manufacturer’s credibility before purchase?

Request case studies, efficiency data, and emissions performance reports

Visit existing installations or request a factory tour

Review customer references and repeat clients

Examine warranty coverage, third-party audits, and financial backing

References

ASME Boiler Certification Program – https://www.asme.org

ISO 9001 Certified Biomass Manufacturers – https://www.iso.org

Biomass Boiler Technology Overview – IEA Bioenergy – https://www.ieabioenergy.com

Renewable Heat and Biomass Boiler Standards – https://www.epa.gov

Biomass Fuel Standards and Certification – https://www.enplus-pellets.eu

Industrial Biomass Case Studies – https://www.researchgate.net

Boiler Vendor Comparison and Equipment Reviews – https://www.energystar.gov

Biomass Emissions Control Guidelines – https://www.bioenergyconsult.com

Customer Ratings and Testimonials – https://www.trustpilot.com

Industrial Boiler Support and Warranty Benchmarks – https://www.automation.com