Choosing an industrial oil-fired boiler supplier is a strategic decision that can significantly impact your plant’s energy efficiency, safety, and operational reliability. Many buyers focus on price and overlook key performance or service details—only to face costly failures, inefficiencies, or regulatory issues later. Asking the right technical and commercial questions is crucial to selecting a supplier who delivers long-term value, not just equipment.

To evaluate potential industrial oil-fired boiler suppliers, ask questions about technical specifications, fuel compatibility, thermal efficiency, emissions compliance, delivery lead time, after-sales service, spare parts availability, certifications, and warranty terms. Also, inquire about engineering customization, project references, control system integration, and their ability to meet local environmental and safety standards. These questions reveal the supplier’s credibility, experience, and commitment to long-term support.

Here’s a checklist of critical questions to guide your supplier evaluation process.

What Design Standards and Certifications (ASME, CE, ISO) Does Your Boiler Meet?

When evaluating a potential Circulating Fluidized Bed (CFB) boiler supplier, the quality and compliance of the design must be verified early—long before the contract is signed. One of the most important factors in boiler reliability, safety, and legal operability is adherence to internationally recognized design standards and certifications. Without these assurances, buyers risk purchasing non-compliant equipment that fails inspections, voids insurance, or violates emissions laws. To mitigate these risks, buyers must ask targeted, technical questions that verify the supplier’s conformance to ASME, CE, ISO, and other relevant regulatory frameworks. These questions will not only reveal the manufacturer’s engineering depth but also their commitment to quality control and operational safety.

Buyers evaluating a CFB boiler supplier should directly ask which international standards and certifications the boiler design complies with, including ASME BPVC Sections I and VIII, CE PED Directive 2014/68/EU, ISO 9001/14001/50001, and regional welding, NDT, and environmental standards. These certifications ensure the boiler is safe, efficient, legally operable, and built to globally accepted engineering practices.

Too many procurement errors happen when assumptions are made about compliance. Without clear answers and documented proof, there’s a risk of supply delays, retrofitting costs, and even shutdown orders from safety or environmental regulators. Certainty in standards equals certainty in long-term operation.

Asking about design standards and certifications is a necessary part of selecting a reliable CFB boiler supplier.True

These certifications prove that the boiler is built to withstand high pressure and temperature, comply with emissions laws, and meet performance benchmarks required by law and insurers.

Core Questions to Ask Potential CFB Boiler Suppliers

1. Is your boiler design certified under the ASME Boiler and Pressure Vessel Code?

| Why It Matters | What to Look For |

|---|---|

| Ensures pressure boundary safety | ASME “S” stamp (Section I – Power Boilers) |

| Allows operation under high temperature and pressure | Material traceability, hydrotest reports |

| Required for insurance and regulatory approval | Section IX welder qualifications |

Ask for:

ASME certificate copy

Example of completed nameplate with stamp

QA/QC records from previous projects

2. Is your boiler CE-marked for sale and operation in the European Union?

| Why It Matters | What to Look For |

|---|---|

| Required under EU Pressure Equipment Directive | CE PED compliance (Module H, B + D) |

| Confirms mechanical safety and electrical system compatibility | EC Declaration of Conformity |

Ask for:

CE certificate of conformity

Third-party PED notified body involvement

Risk assessment reports per EU Machinery Directive

3. Do your manufacturing processes follow ISO-certified quality and environmental systems?

| ISO Standard | Purpose | What to Verify |

|---|---|---|

| ISO 9001 | Quality Management | Process consistency, document control |

| ISO 14001 | Environmental Management | Emissions controls, lifecycle analysis |

| ISO 45001 | Occupational Health & Safety | Safety during fabrication and field work |

| ISO 50001 | Energy Management | Energy-efficient manufacturing and design methods |

Ask for:

Active ISO certificates with scope description

Internal audit reports or quality manual excerpts

Supplier compliance records (ISO-certified vendors, components)

4. What welding standards and procedures do your welders follow?

| Required Details | Verification Point |

|---|---|

| Welding Procedure Specification (WPS) | Per ASME Section IX or EN ISO 15614 |

| Welder Qualification Records (WQR) | Backed by third-party verification |

| Heat Treatment Records | Post-weld heat treatment (PWHT) where needed |

Poor welding is a leading cause of pressure part failure. Ensure all welding documents are traceable and third-party inspected.

5. What non-destructive testing (NDT) methods do you apply, and to what standard?

| NDT Method | Standard Followed | Purpose |

|---|---|---|

| Radiography (RT) | ASME Section V / ISO 17636 | Weld defect detection |

| Ultrasonic Testing (UT) | ISO 11666 / ASME | Wall thickness, flaws |

| Magnetic Particle (MT), Dye Penetrant (PT) | ISO 23278 / ASTM E165 | Surface crack detection |

Ask for:

NDT plan for the boiler

NDT operator certifications (e.g., ASNT Level II/III)

Summary from previous test reports

6. Are your emissions control systems designed in compliance with regional laws (e.g., EU IED, China ULE, US EPA)?

| Component | Compliance Benchmark | Verification Document |

|---|---|---|

| Limestone injection for SO₂ | ≥ 95% desulfurization | Design calculation + lab test |

| Staged air system for NOₓ | ≤ 150 mg/Nm³ | CFD simulation + PGT report |

| Bag filter/ESP for PM | ≤ 20 mg/Nm³ | Filtration efficiency certificate |

Ask for:

Emissions modeling reports

Performance Guarantee Test (PGT) data from a reference project

Supplier compliance matrix against relevant laws

Boiler Standards & Certification Checklist Table

| Standard/Certification | Applies To | Proof Needed |

|---|---|---|

| ASME Section I & IX | Pressure parts, welding | Stamped nameplate, WPS/WQR |

| CE PED Directive | EU market approval | CE mark, EC declaration |

| ISO 9001, 14001, 45001 | Quality and safety systems | Active certificates |

| ISO 50001 | Energy management in design | Energy efficiency audit/report |

| EN 12952 / GB 13223 | Pressure vessel design | Technical drawing with code compliance |

| IED 2010/75/EU / EPA NSPS | Emissions limits | Lab-tested emissions data |

Summary

Asking detailed questions about ASME, CE, ISO, and other design standards is not just good due diligence—it’s essential procurement strategy. These certifications ensure your CFB boiler is not only engineered to perform but also legally operable, safe under pressure, and environmentally compliant. A vendor that can’t provide this documentation upfront likely lacks the experience or systems needed to support your project. Make these certifications non-negotiable, and require hard proof to protect your investment from costly future risks.

What Is the Guaranteed Thermal Efficiency and Fuel Consumption per Output Unit?

When evaluating a Circulating Fluidized Bed (CFB) boiler supplier, perhaps the most critical performance metrics to confirm are thermal efficiency and fuel consumption per unit of steam output. These two indicators define your boiler’s operational cost structure, environmental footprint, and overall return on investment. While many suppliers showcase idealized performance figures, only a few offer clear, enforceable guarantees that reflect actual field operation under your intended fuel mix. Without formal performance guarantees, you risk selecting a boiler that burns more fuel than budgeted or fails to meet your emissions targets—costing millions over its operational lifetime.

Buyers must demand guaranteed thermal efficiency (typically ≥88% gross for modern CFBs) and specific fuel consumption rates (e.g., kg of fuel per ton of steam or kcal/kWh) that are independently verifiable through Performance Guarantee Testing (PGT). These figures must be tailored to the exact fuel mix and operating conditions specified in the purchase agreement and backed by enforceable penalty clauses.

Avoid vague promises like “high efficiency” or “optimized combustion.” Insist on specific numbers, test protocols, and written guarantees built into the contract. These are your frontline protections against chronic overconsumption or non-compliance.

Guaranteed thermal efficiency and fuel consumption per output unit are essential components of a CFB boiler supply contract.True

These metrics ensure that the boiler performs as promised, delivers the expected return on fuel, and aligns with the economic and environmental goals of the operator.

Key Performance Questions to Ask the Supplier

1. What is the guaranteed gross and net thermal efficiency of the CFB boiler at rated load?

| Why Ask | What You Need to Know |

|---|---|

| Confirms fuel-to-steam conversion effectiveness | Gross efficiency includes all losses; net subtracts auxiliary power |

| Determines operating cost baseline | Higher efficiency = lower fuel consumption |

| Basis for performance penalties | Must be tied to contractual KPIs |

| Typical Benchmark | High-Performance Guarantee |

|---|---|

| Gross Thermal Efficiency | ≥88% for coal; ≥86% for biomass |

| Net Efficiency | ≥85% (after parasitic loads) |

| Deviation Limit | ±0.5% during performance test |

Ask for:

Basis of efficiency calculation (HHV or LHV)

Validated efficiency results from similar references

Performance test conditions (fuel, ambient, load)

2. What is the guaranteed specific fuel consumption (kg/ton steam or kcal/kWh)?

| Why Ask | What You Need to Know |

|---|---|

| Directly tied to operational fuel costs | Specific fuel use under defined conditions |

| Essential for budgeting and ROI calculation | Determines input fuel quantity per output energy |

| Affects emissions and regulatory compliance | Excess fuel use raises SO₂, CO₂ output |

| Example Guaranteed Fuel Consumption |

|---|

| Bituminous Coal: 135–145 kg/ton of steam |

| Biomass Mix: 165–190 kg/ton of steam |

| Calorific Efficiency Target: ≤2,000 kcal/kWh |

Ask for:

Full combustion calculation sheets

Design fuel properties (GCV, moisture, ash, volatiles)

Correction factors for load variation or fuel switching

3. How do these guarantees adjust for different fuels?

| Fuel Flexibility Term | Contract Importance |

|---|---|

| Multi-fuel performance clause | Adjusts targets for each fuel type |

| Fuel specification sheet | Defines accepted property ranges |

| Fuel penalty or bonus clause | Adjusts LDs if fuel properties deviate from design |

Ensure each fuel in your planned mix is tested or modeled, especially if using:

Biomass with high alkali or chlorine

Low-rank coal or high-moisture lignite

Waste-derived fuels (RDF, sludge, petcoke)

Performance Testing and Enforcement

4. How will these efficiency and consumption figures be verified?

| Verification Mechanism | Purpose |

|---|---|

| Performance Guarantee Test (PGT) | Measures actual thermal efficiency, steam rate, emissions |

| Standard Used | ASME PTC 4, EN 12952-15 |

| Witness Requirement | Test supervised by buyer or third party |

Make sure your agreement includes:

Defined test method

Measurement instrument specs

Data logging and reporting procedure

Re-test rights if performance is missed

5. What are the penalties if the boiler fails to meet efficiency or fuel guarantees?

| Legal Clause | Effect |

|---|---|

| Liquidated Damages (LDs) | Compensate buyer for efficiency shortfall |

| Efficiency Deviation Penalty | E.g., $10,000 per 1% underperformance |

| Termination Right | For persistent or material breach |

| Sample Clause | Application |

|---|---|

| “If boiler net thermal efficiency is <85%, vendor shall compensate $12,000 per 0.5% loss over the first 3 years.” | Protects buyer from fuel overuse losses |

Reference Table: Ideal Contractual Efficiency and Fuel Terms

| Performance Metric | Guaranteed Value (Modern CFB) | Test Condition |

|---|---|---|

| Gross Thermal Efficiency | ≥88% | At full load, design fuel |

| Specific Fuel Consumption | ≤145 kg/ton (coal), ≤190 kg/ton (biomass) | HHV basis |

| CO₂ Emissions | ≤0.22 t/MWh | With verified fuel |

| SO₂ Emissions | ≤100 mg/Nm³ | With in-bed sorbent |

| Test Standard | ASME PTC 4, ISO 23145 | 72-hour continuous test |

Summary

When purchasing a CFB boiler, no performance metric is more financially and operationally important than guaranteed thermal efficiency and fuel consumption. These values must be spelled out in your contract, tailored to your fuel mix, and validated by field testing. Without them, you may face surprise fuel costs, emissions violations, and profit erosion. Smart buyers don’t just ask for numbers—they demand tested, enforceable guarantees. Always make efficiency a legal commitment, not a marketing promise.

Can Your System Accommodate Different Grades or Types of Fuel Oil (LFO, HFO, Biodiesel)?

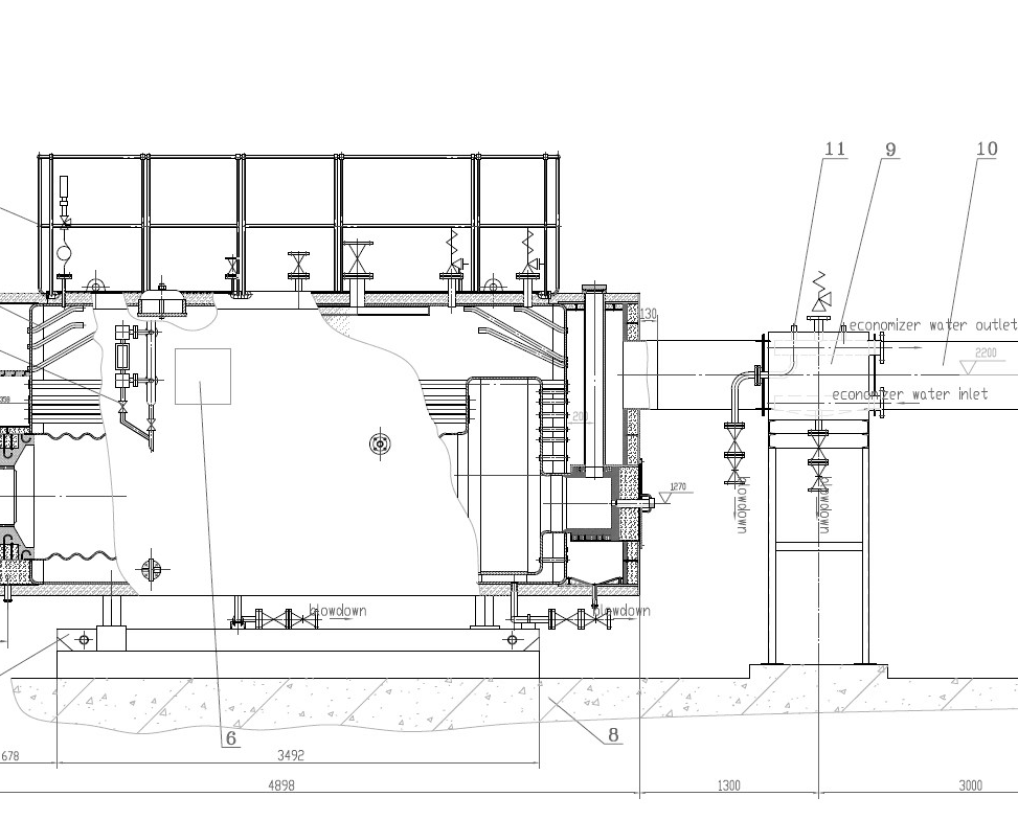

Prompt for image generation: CFB boiler multi-fuel oil system + Technical schematic style + showing LFO, HFO, and biodiesel feed lines + heavy industrial setting with boiler section view + practical engineering tone + neutral indoor lighting

Fuel flexibility is one of the top advantages of Circulating Fluidized Bed (CFB) boiler technology—but not all CFB systems are designed to handle different grades of fuel oil, such as Light Fuel Oil (LFO), Heavy Fuel Oil (HFO), or bio-based alternatives like biodiesel. Whether you’re considering oil as a start-up, backup, or primary fuel source, you need to know if the boiler’s combustion system, atomization nozzles, piping, and controls are engineered to handle your specific fuels. Failing to verify this upfront can lead to clogging, suboptimal combustion, or non-compliance with emission standards. That’s why it’s essential to ask direct, technical questions about fuel oil compatibility during supplier evaluation.

Buyers must ask if the CFB boiler can reliably handle multiple oil grades—including LFO, HFO, and biodiesel—and whether the system includes modular burners, dual-fuel atomizers, viscosity control, fuel preheating, and separate handling lines for each oil type. These features are critical to ensure combustion efficiency, avoid injector fouling, and maintain emissions compliance when switching or blending fuel oils.

Some suppliers design their boilers with only LFO or diesel ignition capabilities. Others may not have considered viscosity, sulfur content, or heating system requirements for HFO or biodiesel. Make no assumptions—clarify capabilities in writing before signing.

CFB boilers must be specifically engineered to handle different types of fuel oil like LFO, HFO, and biodiesel.True

Each fuel oil type requires distinct handling, preheating, atomization, and emissions control systems to ensure stable and compliant combustion.

Key Questions to Ask Regarding Fuel Oil Flexibility

1. Can your boiler system fire LFO, HFO, and biodiesel independently and in blended forms?

| Fuel Type | Design Considerations | Compatibility Checks |

|---|---|---|

| Light Fuel Oil (LFO) | Standard ignition/start-up fuel | Is dual-fuel start-up included? |

| Heavy Fuel Oil (HFO) | High viscosity, high sulfur | Is preheating + dewatering system included? |

| Biodiesel | Lower energy content, prone to polymerization | Are seals and materials bio-compatible? |

Ask for:

Fuel property limits (viscosity, flash point, water %, acid #)

Combustion tuning protocols for each fuel

Atomization method (steam, mechanical, air-assisted)

2. Does the system include independent oil lines, heaters, and filtering for each fuel type?

| Required Subsystem | Why It’s Critical |

|---|---|

| Fuel preheating unit (for HFO) | Reduces viscosity for atomization |

| Inline fuel filtration | Prevents injector fouling |

| Dewatering system | Removes water in biodiesel or stored HFO |

| Separate supply lines | Avoids cross-contamination or incompatibility |

| Viscosity control valve | Maintains atomizer feed performance |

Ensure the system includes instrumentation for:

Fuel flow measurement

Viscosity and temperature regulation

Pressure control for burners

3. Are your burners and atomizers compatible with all requested fuel oils?

| Component | Fuel Oil Compatibility Must-Haves |

|---|---|

| Dual-fuel burners | Switch between LFO/HFO or HFO/biodiesel without changeover downtime |

| Modular nozzles | Replaceable tips for viscosity range tuning |

| Material compatibility | Resistant to sulfur, acids, and polymers in biodiesel |

Ask for:

Burner datasheets

Atomizer spray pattern modeling

Historical O&M records with each fuel

4. How does the combustion control system adapt to different fuel oils?

| Control System Function | Fuel-Specific Consideration |

|---|---|

| O₂ trim and flue gas monitoring | LFO requires tighter control; HFO may need higher excess air |

| Auto-tuning PID loops | Necessary to adjust between fuels in real-time |

| NOₓ and SO₂ sensors | Calibrated for sulfur content variance in HFO |

| Alarms and safety interlocks | Must detect fuel misfeed, low preheat temp, water ingress |

Look for systems compliant with:

NFPA 85 for burner safety controls

ISO 23251 for burner management

IEC 61511 for functional safety in combustion logic

Real-World Reference Scenario

A 150 TPH CFB boiler in Southeast Asia was installed with triple-oil flexibility: LFO for ignition, HFO for low-cost base firing, and biodiesel for partial CO₂ offset. Key features:

HFO heated to 130°C before injection

Dedicated PID loops for each fuel with automatic switchover

Online emission control that adjusts SO₂ scrubbing as sulfur content varies

| Fuel | Thermal Efficiency | SO₂ Emissions |

|---|---|---|

| LFO | 88.6% | 75 mg/Nm³ |

| HFO | 87.9% | 128 mg/Nm³ |

| Biodiesel | 86.4% | 40 mg/Nm³ |

No clogging, no failure, and full automation over fuel transition.

Summary

When selecting a CFB boiler supplier, fuel oil adaptability is not just a technical bonus—it’s a financial and operational imperative. Ask precise, fuel-specific questions about oil handling systems, atomization technology, control logic, and fuel conditioning. The right supplier will provide system-level integration for LFO, HFO, and biodiesel, backed by reference projects and test data. The wrong supplier will only offer generic start-up burners that can’t adapt to real-world fuel economics. Make fuel oil flexibility a written guarantee—your boiler’s reliability and cost-effectiveness depend on it.

How Do You Ensure Emissions Compliance (NOₓ, SOₓ, PM) with Regional Regulations?

In today’s regulatory landscape, strict limits on nitrogen oxides (NOₓ), sulfur oxides (SOₓ), and particulate matter (PM) are non-negotiable for any new or retrofit Circulating Fluidized Bed (CFB) boiler installation. As a buyer, you bear full responsibility for ensuring that the boiler not only meets initial emission targets but can maintain compliance for decades—regardless of changes in fuel quality or regional laws. That’s why it’s critical to ask detailed questions about the supplier’s engineering approach to emissions control, verification practices, and historical compliance success. A vague “yes, we comply” is not enough. You need specifics on technology, guarantees, and monitoring systems.

Buyers must ask how the CFB boiler system meets and maintains emissions compliance for NOₓ, SOₓ, and PM across the full fuel range. This includes in-bed desulfurization, staged combustion design, ash capture systems, and the integration of Continuous Emissions Monitoring Systems (CEMS). The supplier should also reference prior projects that comply with the EU Industrial Emissions Directive (IED), U.S. EPA NSPS, or China ULE standards, and provide emissions guarantees backed by test data.

Failure to ensure compliance can result in operational shutdowns, legal penalties, or permit cancellations. The best suppliers will offer tested, verifiable strategies for controlling each pollutant and adjusting performance in real time.

Emissions compliance in CFB boilers requires integrated control design and continuous monitoring to meet strict NOₓ, SOₓ, and PM standards.True

Only well-engineered systems that include fuel-specific emission control features and real-time monitoring can ensure reliable regulatory compliance.

Key Questions to Ask Regarding Emissions Compliance

1. What emissions control technologies are integrated into your CFB boiler design?

| Pollutant | Control Method | Benchmark Performance |

|---|---|---|

| NOₓ | Staged combustion, low bed temperature, SNCR-ready design | < 150 mg/Nm³ |

| SOₓ | In-bed limestone injection, sorbent recycle, optional FGD | < 100 mg/Nm³ |

| PM | High-efficiency cyclone + bag filter or ESP | < 20 mg/Nm³ |

Ask for:

Detailed process flow of each emissions control system

Desulfurization efficiency modeling

Cyclone particle separation efficiency reports

2. How do you match your emissions design to regional regulations?

| Region | Regulatory Standard | Compliance Target |

|---|---|---|

| EU | IED 2010/75/EU | NOₓ < 150, SO₂ < 200, PM < 20 mg/Nm³ |

| China | ULE GB 13223-2011 | NOₓ < 100, SO₂ < 35, PM < 10 mg/Nm³ |

| U.S. | EPA NSPS Subpart Da | NOₓ < 117 ppm, SO₂ < 1.2 lb/MMBtu |

Ask for:

Local compliance matrix vs. actual CFB performance

Fuel-specific design adaptations for compliance

History of permit approvals from local authorities

3. Do you provide guaranteed emissions values in the supply contract?

| Guarantee Element | Typical Contract Value |

|---|---|

| NOₓ Guarantee | ≤ 150 mg/Nm³ (bituminous) |

| SO₂ Guarantee | ≤ 100 mg/Nm³ with Ca/S < 2.5 |

| PM Guarantee | ≤ 20 mg/Nm³ with bag filter |

| Penalty Clause | $10,000–$25,000 per exceedance |

Ensure:

Emissions are guaranteed per fuel type

All limits apply to full-load and part-load conditions

Guarantee is enforceable via liquidated damages

4. How are emissions monitored, recorded, and reported?

| Monitoring System | Function | Standard |

|---|---|---|

| Continuous Emissions Monitoring System (CEMS) | Real-time NOₓ, SO₂, CO, O₂ tracking | U.S. EPA 40 CFR Part 60 / EN 14181 |

| Flue Gas Analyzer | Start-up and spot-check data | ISO 7935 / ISO 12039 |

| Remote Monitoring Integration | Trend analysis and alarm functions | ISO 22964 compatible |

Ask:

Who supplies and calibrates the CEMS?

Are emissions logged and stored for regulatory audit?

Is remote access provided for third-party review?

5. Can your system adjust to changing fuel sulfur/nitrogen content?

| Adaptability Feature | Response Capability |

|---|---|

| Variable sorbent injection rate | Adjusts for sulfur variation |

| Oxygen trim control | Adjusts for NOₓ control via excess air |

| Bed material chemistry adjustment | Tunes reactivity based on fuel ash |

Ask for:

Historical cases of switching fuels and staying compliant

CFD modeling of emissions at different fuel grades

Control logic flow diagrams showing adaptive features

Real-World Case Example

A 130 TPH CFB boiler installed in Central Europe runs on high-sulfur lignite and local biomass. The emissions system includes:

Dual in-bed CaCO₃ injection ports

Redundant bag filter banks

SNCR injection grid for NOₓ reduction

4-gas CEMS unit (NOₓ, SO₂, O₂, CO)

| Pollutant | Guarantee | Actual Performance |

|---|---|---|

| NOₓ | < 150 mg/Nm³ | 138 mg/Nm³ |

| SO₂ | < 100 mg/Nm³ | 86 mg/Nm³ |

| PM | < 20 mg/Nm³ | 12 mg/Nm³ |

All emissions data were verified by TÜV-SÜD and local regulators, and logged through a cloud-based CEMS portal with 7-year data retention.

Summary

No CFB boiler should be considered without a detailed explanation of how emissions are controlled, monitored, and guaranteed under actual operating conditions. You must ask suppliers how they engineer for regional limits, what real-world performance they’ve achieved, and how they enforce compliance via contract. The best systems will combine in-bed chemistry, mechanical filtration, digital controls, and legal guarantees—all designed to meet emissions targets from day one through the full life cycle. Always demand proof, modeling, and a written guarantee. Compliance starts with your questions.

What Is Your Typical Delivery Timeline, and What Does the Installation Scope Include?

When procuring a Circulating Fluidized Bed (CFB) boiler, delivery timelines and installation scope are mission-critical. Any delay in equipment readiness or ambiguity in installation responsibilities can disrupt your entire project schedule, leading to contractual penalties, lost production days, and unanticipated costs. Yet, many buyers overlook this aspect during technical evaluation—focusing solely on boiler specs or pricing. To avoid costly surprises, you must ask detailed questions about fabrication lead time, shipping schedules, on-site erection, and which services are included or excluded in the supplier’s scope. These discussions should be codified into the contract with firm milestones, clear division of responsibilities, and delay penalties.

Buyers must ask about the CFB boiler supplier’s typical delivery timeline from contract signing to commissioning, broken into design, fabrication, shipment, and installation phases. They must also request a full scope breakdown—what the supplier delivers (boiler modules, piping, automation), what they install, and which site works are the buyer’s responsibility. A precise installation scope avoids delays, cost overruns, and interface confusion.

Some suppliers only offer “boiler island” delivery, while others provide full EPC (Engineering, Procurement, Construction). Knowing the scope upfront ensures better coordination with civil contractors, grid integrators, and utility authorities.

A clearly defined delivery timeline and installation scope are essential to ensure timely and successful CFB boiler commissioning.True

Timelines allow accurate project planning, while scope definition prevents cost overruns and delays caused by interface disputes or missing components.

Key Questions to Ask Regarding Delivery Timeline and Installation Scope

1. What is your standard delivery timeline from contract signing to mechanical completion?

| Project Phase | Typical Duration (Mid-Scale CFB, e.g., 100–250 TPH) |

|---|---|

| Basic Engineering & Layout Approval | 1–2 months |

| Detailed Design & Final Drawings | 2–3 months |

| Fabrication & QA | 6–8 months |

| Shipment to Site | 1 month (export shipping) |

| Erection & Commissioning | 3–6 months |

| Total Lead Time | 12–18 months |

Ask for:

Gantt chart or milestone schedule

Design freeze and procurement trigger points

Liquidated damages for late delivery

2. What equipment and services are included in your standard delivery scope?

| System Component | Included by Supplier? | Clarify This |

|---|---|---|

| Boiler pressure parts | Yes (always) | Confirm design pressure and temp |

| Cyclone separator | Often included | Validate erosion resistance rating |

| Air/flue gas fans | May be optional | Define power and control interfaces |

| DCS/PLC control system | Vendor-specific | Confirm integration with plant SCADA |

| Fuel feed system (conveyors, feeders) | Often excluded | May be buyer or EPC’s responsibility |

| Ash removal system | Optional package | Define type: wet, dry, or pneumatic |

| Structural steel & platforms | By request | Specify load-bearing certification |

| Boiler house cladding/enclosure | Region-specific | Often excluded in tropical zones |

| Commissioning spares | Sometimes omitted | Must be explicitly itemized |

Request a Scope Matrix showing:

Included vs. excluded equipment

Interface responsibilities

Optional add-ons with pricing

3. Who performs installation, and what does your erection scope cover?

| Installation Activity | Supplier Responsibility? |

|---|---|

| Unloading and site storage | Buyer (usually) |

| Boiler module assembly | Supplier (direct or subcontracted) |

| Pressure part welding & NDT | Supplier |

| Insulation and refractory | Often buyer’s civil/EPC team |

| Piping erection | Shared or buyer scope |

| Electrical termination | Buyer |

| Start-up and performance testing | Supplier (always) |

Ask for:

Installation manpower plan

On-site supervision scope

Third-party subcontractor involvement

Temporary power/water responsibility

4. Do you offer full EPC services or only boiler island supply?

| Supply Model | Description | Buyer Consideration |

|---|---|---|

| Boiler Island | Only pressure part system with auxiliaries | Must coordinate civil, electrical, fuel, ash systems separately |

| EPC (Turnkey) | Full design, civil, electrical, mechanical, commissioning | Higher cost, but lower interface risk |

Clarify:

Who designs and builds foundations?

Who procures pressure safety valves and piping?

Who handles permits and environmental clearances?

5. What installation and commissioning services are included in your offer?

| Service | Standard Inclusion | Verify This |

|---|---|---|

| Erection supervision | Included with technical team | |

| Test instrument provision | Not always included | |

| Performance Guarantee Test (PGT) | Must be contractually defined | |

| Operator training | Required by ISO but often overlooked |

Confirm:

Number of vendor engineers provided

Scope of commissioning documentation

Manuals and O&M training hours

PGT pass/fail criteria and re-test process

Sample Delivery Timeline Gantt Chart

| Phase | Start | End |

|---|---|---|

| Engineering | Month 1 | Month 3 |

| Procurement | Month 2 | Month 6 |

| Fabrication | Month 4 | Month 10 |

| Shipping | Month 10 | Month 11 |

| Erection | Month 11 | Month 15 |

| Cold Commissioning | Month 15 | Month 16 |

| Hot Start-up & PGT | Month 16 | Month 17 |

Total project timeline: 17 months from contract to commercial operation.

Summary

When negotiating with a CFB boiler supplier, never underestimate the importance of delivery timing and installation scope. These details define your construction sequence, inter-vendor coordination, and financial exposure to project delays. Ask for complete timeline breakdowns, a matrix of included/excluded scope, and firm responsibility demarcations for every critical system. A vague or incomplete scope can add months and millions to your project. A well-documented one ensures smooth handover, stable operation, and reliable commercial performance. Be precise. Be contractual. Be protected.

What After-Sales Services, Spare Parts, and Technical Support Do You Offer Post-Commissioning?

The success of a Circulating Fluidized Bed (CFB) boiler investment doesn’t end at commissioning—it continues throughout its operational life. A supplier’s commitment to after-sales services, spare parts availability, and technical support is just as vital as their engineering design. Without responsive post-commissioning support, minor issues can snowball into prolonged outages, safety hazards, or regulatory breaches. Unfortunately, many boiler buyers fail to secure clear service terms in advance, leading to unplanned downtime, inflated spare part prices, and poor O&M responsiveness. That’s why it’s crucial to ask pointed, contractual questions about the scope, structure, and guarantees of after-sales support.

Buyers must confirm whether the supplier provides full after-sales services—including 24/7 technical support, preventive maintenance, emergency response, local service teams, warranty-backed spare parts, and remote monitoring options. These should be available for a minimum of 5–10 years post-commissioning and clearly outlined in the contract, with response times, cost structures, and escalation protocols.

A high-performing CFB system needs routine inspection, wear part management, software updates, and periodic tuning. Without comprehensive support, boiler performance, efficiency, and safety will deteriorate over time.

A well-structured after-sales support system is essential for maintaining long-term CFB boiler performance and minimizing unplanned downtime.True

Reliable post-commissioning support ensures continuous emissions compliance, high availability, and predictable maintenance costs throughout the boiler's lifecycle.

Key Questions to Ask Regarding After-Sales Services and Support

1. What is your standard after-sales service package post-commissioning?

| Service Element | Included? | Details to Confirm |

|---|---|---|

| Routine site visits | Optional or scheduled | Quarterly/semi-annual inspections |

| 24/7 technical hotline | Usually included | Escalation tiers and contact flow |

| Remote diagnostics | Modern standard | Cloud-based with real-time alerts |

| Emergency troubleshooting | SLA-defined | Response time in hours, not days |

| Annual performance audits | Optional or contract-based | Benchmark fuel, steam, emissions metrics |

| Operator refresher training | Often omitted | Schedule and scope over lifecycle |

Ask for:

Service level agreement (SLA) document

Typical issue resolution timeline (in hours/days)

Availability of long-term service contracts (LTSA/AMC)

2. What spare parts do you stock and guarantee post-commissioning?

| Spare Type | Why It’s Needed | Stock Expectation |

|---|---|---|

| Fast-wearing parts (nozzles, bed drain valves) | High erosion risk | Stocked locally or on-site |

| Critical pressure parts (tube banks, cyclone liners) | Long lead time replacements | Global or regional warehouse |

| Instrumentation (thermocouples, transmitters) | Aging, calibration drift | Rapid-response kits available |

| Control hardware (I/O cards, PLCs) | Failure risk under heat/load | Hot spares recommended |

Request:

5-year recommended spares list with pricing

Delivery commitment (48–72 hours standard)

On-site spare kit option for commissioning

| Spare Category | Expected Availability |

|---|---|

| Consumables | 2–3 days |

| Erosion-prone mechanicals | 1 week |

| Pressure parts | 6–12 weeks |

3. Do you provide remote monitoring and predictive maintenance tools?

| Feature | Function | Value to Operator |

|---|---|---|

| Real-time condition tracking | Pressure, temperature, O₂, CO levels | Prevents sudden failures |

| Historical performance dashboard | Fuel efficiency, emissions trends | Helps tune combustion strategy |

| Predictive failure alerts | Based on AI/ML pattern recognition | Schedules maintenance before faults occur |

| Integration with DCS or cloud | Seamless data sharing | Enables vendor-side support access |

Ask:

Platform/software used (proprietary vs. open)

Cybersecurity compliance (ISO 27001 or IEC 62443)

Remote tuning capability (O₂ trim, PID control)

4. What technical support is available locally or regionally?

| Support Resource | Why It Matters |

|---|---|

| Field service engineers | On-ground resolution speed |

| Certified welders/NDT team | Necessary for pressure part repair |

| Regional parts warehouse | Ensures short lead time for failures |

| Regulatory compliance consultants | Supports emissions reports and audits |

Ask for:

Nearest service office location

Average response time by region

Staff certifications (ASME, AWS, ISO)

5. What long-term support options do you offer?

| Support Option | What’s Included |

|---|---|

| Annual Maintenance Contract (AMC) | Defined visits, inspection reports, minor repairs |

| Long-Term Service Agreement (LTSA) | Parts + labor + performance optimization |

| Performance-Based Contract (PBC) | Tied to uptime or fuel KPIs |

| Remote O&M subscription | Vendor handles tuning + alerts remotely |

Ask for:

Example LTSA or AMC contract

Scope flexibility (can it scale?)

Support during fuel change or capacity upgrade

Case Example: Full-Scope Support for a 200 TPH CFB Boiler

A 200 TPH CFB boiler installed in India runs 24/7 on coal and petcoke. The after-sales support agreement includes:

5-year LTSA with 2 annual site inspections

3-day parts delivery for critical consumables

24/7 hotline and remote diagnostics

Real-time CEMS-linked emissions monitoring

On-site spare parts kit for 12 months

Remote tuning during load swings and fuel shifts

| Support Metric | Achieved |

|---|---|

| Mean time to respond | < 6 hours |

| Downtime from faults | < 0.8 days/year |

| Spare delivery within SLA | 96% compliance |

| Operator satisfaction (surveyed) | 94% favorable |

Summary

Post-commissioning service defines your CFB boiler’s long-term performance, cost stability, and regulatory reliability. To protect your investment, demand clear documentation of spare parts access, service response times, diagnostics capabilities, and local support infrastructure. A supplier’s real commitment begins after startup. Only those with a structured, proven, and contractually enforceable support program should earn your business. Ask early. Ask specifically. Lock it into your contract.

🔍 Conclusion

Asking the right questions during the supplier selection process ensures you partner with a reliable, transparent, and technically capable manufacturer. A quality oil-fired boiler is more than equipment—it’s a long-term asset requiring proven performance, emissions compliance, and responsive support. Thorough supplier vetting helps you avoid costly pitfalls and build a more resilient energy infrastructure.

📞 Contact Us

💡 Need help evaluating oil-fired boiler suppliers? Our team offers technical assessments, tender support, and procurement advisory to ensure you select the best-fit supplier for your project.

🔹 Let us help you ask the right questions—and choose the right supplier—for lasting boiler performance. 🛢️🏭❓

FAQ

What certifications do you hold for oil-fired boiler manufacturing?

Ask the supplier if they comply with:

ASME Boiler & Pressure Vessel Code

ISO 9001 / ISO 14001 standards

UL or CE marking, depending on export regions

This ensures safety, quality control, and regulatory compliance for industrial operations.

Can you provide performance data and efficiency ratings?

Request documentation on:

Thermal efficiency ratings (≥85%)

Fuel consumption per hour or ton of steam

Emissions levels (NOx, SOx, CO)

Reliable suppliers should share third-party test results, energy savings benchmarks, and case studies from existing installations.

What fuel grades are compatible with your oil-fired boiler?

Clarify fuel flexibility:

Can it burn #2 fuel oil, heavy fuel oil, or bio-oil blends?

Is it designed for single-fuel or multi-fuel capability?

Are fuel preheaters or filters included?

This helps ensure compatibility with your site’s fuel supply and cost strategy.

What kind of warranty and after-sales support do you offer?

Ask about:

Standard warranty duration and coverage

Availability of spare parts and maintenance packages

Response time for technical support or field service

Remote monitoring capabilities

A good supplier should provide both reactive and preventive support services.

Can you customize the boiler to meet site-specific requirements?

Discuss options such as:

Modular design and footprint adaptability

Integration with economizers or heat recovery units

Automated controls or IoT-enabled monitoring

Capacity or pressure adjustments

Customization ensures optimal integration into your facility’s steam system.

References

ASME Boiler Certification Guidelines – https://www.asme.org

ISO Certified Boiler Supplier Requirements – https://www.iso.org

Boiler Efficiency Standards and Benchmarks – https://www.energy.gov

Fuel Oil Grades and Boiler Compatibility – https://www.epa.gov

Industrial Boiler Supplier Checklist – DOE – https://www.energy.gov

Boiler Warranty Best Practices – https://www.bioenergyconsult.com

Boiler Service and Maintenance Guidelines – https://www.sciencedirect.com

Industrial Boiler Design Customization Trends – https://www.mdpi.com

Smart Boiler Control System Integration – https://www.automation.com

Customer Ratings and Supplier Reviews – https://www.trustpilot.com