Building a power plant boiler system is a large-scale capital project where the boiler itself is only one part of the total investment. Without considering the cost of auxiliary equipment, installation, and civil works, decision-makers risk underestimating budgets, delaying project timelines, and compromising plant performance.

The total installed cost of a power plant boiler—including auxiliary equipment (burner, economizer, air preheater, feedwater system, control panels, emission control units) and civil works—typically ranges from $1,500 to $4,000 per kW of output capacity. For medium-sized utility boilers (100–300 MW), this can translate into $150 million to $900 million depending on fuel type, technology (subcritical, supercritical, ultra-supercritical), site location, and environmental compliance requirements. Civil works such as foundations, structural steel, and plant buildings often account for 20–35% of total installed cost.

By evaluating the complete installed scope, project owners can plan funding more accurately and avoid costly surprises during execution.

What Components Are Included in the “Total Installed Cost” of a Power Plant Boiler?

When budgeting for a power plant boiler, many buyers focus solely on the equipment price, only to find the actual project cost is far higher once installation, site preparation, auxiliary systems, and commissioning are included. Misjudging this “total installed cost” can lead to budget overruns, financing delays, and compromised project scope. Understanding all cost components from the start allows for accurate investment planning and realistic payback projections.

The total installed cost of a power plant boiler includes the base boiler equipment, combustion and fuel systems, pressure parts, auxiliary systems (such as feedwater, air, and flue gas handling), safety and control systems, structural supports, site preparation, transportation, installation labor, commissioning, testing, training, and required certifications—plus contingency and project management fees.

Accurately identifying these elements early ensures your financial planning reflects the real project scope, avoiding unpleasant surprises mid-construction.

The cost of a power plant boiler is limited to the equipment purchase price.False

In reality, total installed cost includes installation labor, civil works, auxiliary systems, commissioning, and other services that often exceed the boiler’s base price.

🔹 Main Cost Categories in a Power Plant Boiler Project

| Category | Typical Inclusions |

|---|---|

| Boiler Equipment | Pressure vessel, heat exchangers, burners, economizers, superheaters, reheaters |

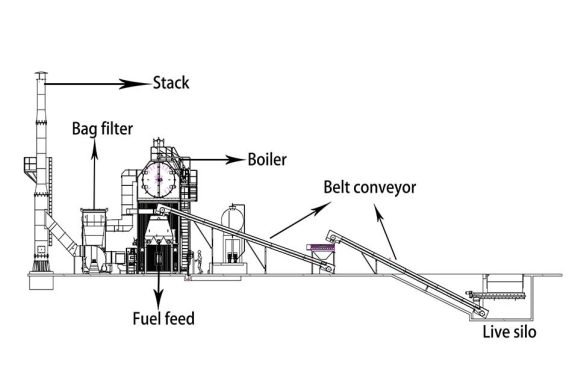

| Combustion & Fuel Systems | Fuel feed conveyors/pumps, pulverizers, storage silos, fuel handling controls |

| Auxiliary Systems | Feedwater pumps, deaerators, air preheaters, blowdown systems, flue gas ducts, emission controls |

| Safety & Controls | Burner management system, flame scanners, pressure/temperature controls, interlocks, DCS integration |

| Structural & Civil Works | Steel supports, access platforms, foundations, concrete work, seismic reinforcement |

| Installation & Labor | On-site assembly, welding, alignment, piping, electrical connections |

| Commissioning & Testing | Performance tuning, safety checks, emissions measurement, trial operation |

| Training & Documentation | Operator training, O&M manuals, spare parts lists, certification paperwork |

| Logistics & Handling | Transport from manufacturer, unloading, lifting/rigging, insurance |

| Project Management | Scheduling, supervision, contingency allowances, engineering consultancy |

📊 Typical Cost Share Distribution for a Utility-Scale Boiler Project

| Component | Approx. % of Total Installed Cost |

|---|---|

| Boiler Pressure Parts | 30–35% |

| Auxiliaries & Controls | 20–25% |

| Civil & Structural Works | 15–20% |

| Installation Labor | 10–15% |

| Commissioning & Training | 5–10% |

| Logistics & Miscellaneous | 5–10% |

✅ Practical Advice for Buyers

Request itemized quotations from suppliers separating equipment cost and installation-related services

Factor in site-specific variables such as soil conditions, seismic codes, and climate requirements

Include a contingency budget (5–10%) for unexpected scope changes

Consider the total lifecycle cost, not just initial CAPEX—operating efficiency impacts long-term ROI

Work with an EPC contractor for integrated cost control from design to commissioning

How Do Boiler Type and Fuel Choice Affect Cost per kW?

When planning a power generation or industrial steam project, buyers often compare supplier quotes by boiler price alone, but this can be misleading. The real investment efficiency comes from calculating cost per kW of installed capacity—where boiler type and fuel choice play a decisive role. Ignoring these variables can result in paying more upfront for a unit that delivers less output or higher operating costs over its lifecycle.

Different boiler types (fire-tube, water-tube, circulating fluidized bed, etc.) have different capital costs per kW based on their pressure/temperature ratings, construction complexity, and scalability. Fuel choice—whether coal, biomass, gas, or oil—affects both the initial system cost (due to fuel handling, storage, and emission controls) and long-term operating cost, directly influencing cost per kW over the boiler’s life.

Understanding this relationship allows buyers to select the best balance between CAPEX and OPEX, ensuring both affordable installation and efficient long-term performance.

Fuel choice only affects operational cost, not capital cost per kW.False

Fuel choice impacts capital cost through required handling systems, emission controls, and burner design, as well as operational cost through fuel price and efficiency.

🔹 Typical Cost per kW Ranges by Boiler Type & Fuel

| Boiler Type | Typical Fuels | Installed Cost per kW (USD) | Key Notes |

|---|---|---|---|

| Fire-Tube Boiler | Gas, Oil | $500–$900 | Lower pressure, small-medium capacity, compact footprint |

| Water-Tube Boiler | Coal, Biomass, Gas, Oil | $800–$1,500 | High pressure, large capacity, flexible for utility-scale use |

| Circulating Fluidized Bed | Coal, Biomass | $1,200–$2,200 | Handles low-grade fuels, complex fuel feed & ash removal systems |

| Package Boiler | Gas, Light Oil | $400–$800 | Pre-assembled, short installation time, lower output |

| Waste Heat Recovery Boiler | Process gas, exhaust | $300–$700 | Uses waste heat, low additional fuel cost, high ROI in certain industries |

📊 Fuel Impact on Cost per kW

| Fuel Type | CAPEX Impact | OPEX Impact | Overall Effect on Cost per kW |

|---|---|---|---|

| Natural Gas | Lower emission system cost | Fuel cost varies regionally | Often lowest lifecycle cost in areas with cheap gas |

| Coal | Higher emission control cost | Lower fuel price but higher maintenance | Competitive CAPEX but rising environmental compliance cost |

| Biomass | Higher fuel handling/storage cost | Moderate fuel cost, renewable incentives | Attractive where subsidies or feedstock is abundant |

| Oil | Moderate system cost | High fuel cost, volatile prices | Higher cost per kW long-term unless oil is discounted |

✅ Buyer Tips

Always compare total installed cost per kW, not just boiler base price

Consider fuel supply stability—cheap fuel today may become expensive in 5–10 years

Factor in emission compliance costs for the full lifecycle

Evaluate load profile—some boiler/fuel combinations suit base load better than variable demand

Where possible, run a sensitivity analysis on fuel prices to see long-term effects on LCOE (Levelized Cost of Energy)

What Share of Cost Comes from Auxiliary Equipment in an Industrial Boiler System?

When budgeting for an industrial boiler, many buyers focus on the pressure vessel price, but that’s often only part of the total cost. The full system requires auxiliary equipment—burners, feedwater systems, fans, economizers, control panels, safety devices—which together can make up a substantial portion of the investment. Underestimating this share can lead to budget overruns or incomplete specifications that delay commissioning.

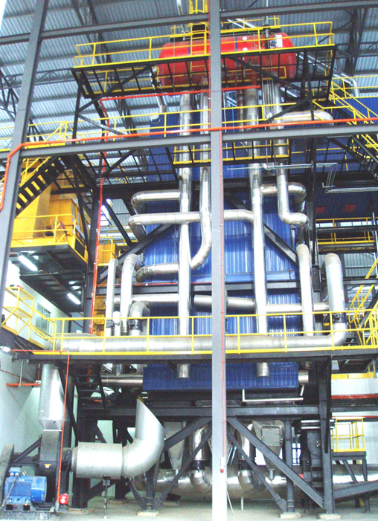

Auxiliary equipment typically accounts for 25%–40% of the total installed cost of an industrial boiler system, depending on boiler type, fuel choice, and plant design. High-pressure or fuel-flexible boilers may have a larger auxiliary share due to more complex combustion, feedwater, and emission systems.

Understanding this percentage helps buyers allocate funds correctly and avoid surprises during project execution.

Auxiliary equipment makes up less than 10% of a boiler project's total installed cost.False

In most industrial boiler projects, auxiliary equipment accounts for 25%–40% of total installed cost, as it includes burners, pumps, fans, control systems, and emission controls.

🔹 Typical Cost Breakdown for Industrial Boiler Systems

| System Component | Cost Share (%) | Notes |

|---|---|---|

| Boiler Pressure Vessel | 45–60% | Includes shell, tubes, refractory, insulation |

| Burner System | 8–15% | Size & cost vary by fuel type and emissions requirements |

| Feedwater & Pump System | 5–10% | Includes pumps, deaerator, storage tanks |

| Fans & Air Handling | 4–8% | Forced draft, induced draft, overfire air fans |

| Economizer / Heat Recovery | 5–12% | Improves efficiency, more common in high-capacity systems |

| Control & Monitoring Systems | 3–7% | PLC, instrumentation, safety interlocks |

| Emission Control Equipment | 0–10% | SCR, baghouse, scrubbers depending on fuel type and regulations |

📊 Example: 50-Ton/Hr Gas-Fired Water-Tube Boiler

| Cost Item | Estimated Cost (USD) | Share of Total |

|---|---|---|

| Boiler Vessel | $1,800,000 | 55% |

| Burner System | $400,000 | 12% |

| Feedwater & Pumps | $250,000 | 8% |

| Fans & Air Systems | $180,000 | 6% |

| Economizer | $300,000 | 9% |

| Controls & Safety | $170,000 | 5% |

| Total | $3,300,000 | 100% |

✅ Buyer Takeaways

Always request a cost breakdown from suppliers to understand auxiliary share

Efficiency-boosting auxiliaries (e.g., economizers) add upfront cost but can reduce lifecycle fuel costs significantly

For solid-fuel boilers, auxiliary share tends to be higher due to more complex fuel handling and emission control systems

Ensure auxiliary equipment matches boiler capacity and fuel to avoid bottlenecks or underperformance

How Significant Are Civil Works in the Total Budget Allocation for an Industrial Boiler Project?

When planning an industrial boiler project, many buyers think mostly about the equipment cost, but civil works—like foundations, structural supports, pipe racks, and building modifications—can take a surprisingly large share of the budget. Ignoring this part in early planning can result in serious cost overruns, especially if the site requires extensive preparation or compliance with strict structural and safety codes.

Civil works typically account for 10%–25% of the total installed cost of an industrial boiler project, with the percentage varying depending on boiler size, site conditions, and whether a new building or retrofitting is required.

Factoring civil works into early cost planning ensures you have a realistic budget and can avoid mid-project delays due to design changes or foundation reinforcements.

Civil works generally cost less than 5% of a boiler project's budget.False

For industrial boiler projects, civil works typically consume 10%–25% of the total budget, especially when heavy foundations, new buildings, or structural modifications are needed.

🔹 Typical Civil Works Cost Components

| Civil Works Item | Cost Share (%) | Description |

|---|---|---|

| Foundation & Piling | 4–10% | Reinforced concrete base to support boiler weight and vibrations |

| Structural Steel Supports | 2–6% | Frames for boiler, ducts, and platforms |

| Buildings & Enclosures | 3–8% | Boiler house, control room, operator facilities |

| Piping Racks & Trenches | 1–3% | For steam, feedwater, fuel, and blowdown lines |

| Drainage & Floor Finishes | 0.5–2% | Slope floors, drain systems to handle spills and condensate |

📊 Example Budget Impact: 75-Ton/Hr Solid-Fuel Boiler

| Cost Item | Estimated Cost (USD) | Share of Total |

|---|---|---|

| Boiler & Auxiliaries | $4,200,000 | 78% |

| Civil Works | $1,050,000 | 19% |

| Project Contingency | $150,000 | 3% |

| Total | $5,400,000 | 100% |

✅ Buyer Tips for Managing Civil Works Costs

Engage a structural engineer early to ensure foundations match equipment weight and seismic/wind loads

Use modular boiler designs where possible to reduce foundation and building scope

Factor in local labor rates and material availability—these can swing costs significantly

Plan integrated schedules so civil works finish just before equipment delivery to avoid storage or delay costs

What Regional and Regulatory Factors Influence the Installed Cost of an Industrial Boiler?

When budgeting for an industrial boiler project, regional and regulatory factors can significantly affect your total installed cost—sometimes more than the equipment price itself. Many buyers overlook these external cost drivers, only to face unplanned expenses from local labor rates, permitting delays, or stricter environmental requirements. Factoring them in from the start is essential to avoid budget overruns and schedule slippage.

Key cost influencers include local labor and material prices, environmental emission limits, safety compliance standards, import duties, and project permitting timelines.

Knowing these regional and regulatory variables early allows you to make informed decisions, choose the right supplier approach, and reduce cost surprises during execution.

Industrial boiler installation costs are the same across different regions if the equipment is identical.False

Even with identical equipment, total installed cost varies due to differences in local labor rates, materials pricing, permitting requirements, and compliance costs.

🔹 Common Regional & Regulatory Cost Drivers

| Factor | Impact on Cost | Details |

|---|---|---|

| Labor Rates | 10–30% difference | Highly skilled boiler welders and pipefitters cost more in developed markets. |

| Material Availability | +5–15% | Remote or import-dependent regions pay more for steel, insulation, and refractory materials. |

| Import Duties & Taxes | 0–25% | Customs tariffs on boilers, pressure vessels, or auxiliaries. |

| Environmental Regulations | +10–20% | Stricter NOx, SO₂, and particulate limits require additional emission control systems. |

| Safety Standards | +5–15% | Higher compliance costs for ASME, PED, or local equivalent certification. |

| Permit & Inspection Delays | Time impact | Longer lead times can increase site mobilization and overhead costs. |

📊 Example Installed Cost Variation by Region (Same 50-Ton/Hr Gas-Fired Boiler)

| Region | Installed Cost (USD) | Key Cost Drivers |

|---|---|---|

| Western Europe | $6.2M | High labor rates, strict EU emissions compliance |

| Southeast Asia | $4.5M | Lower labor, moderate environmental requirements |

| Middle East | $5.1M | High import duties, lower labor cost |

| North America | $5.8M | Strong ASME compliance, medium labor cost |

✅ Buyer Tips for Cost Planning Across Regions

Request a breakdown of labor, materials, and compliance costs in supplier proposals

Confirm local code equivalence to avoid surprise re-engineering fees

Factor in import lead times and customs clearance when setting project schedules

Engage local consultants for permitting and environmental reporting to speed up approval

How Can EPC Contracts Help Manage Total Project Expenses?

Industrial boiler projects often involve multiple suppliers, subcontractors, and regulatory steps—making it easy for expenses to spiral out of control if responsibilities aren’t clearly defined. Without a single accountable party, hidden costs from delays, scope overlaps, or change orders can quickly erode budgets. For buyers, this means higher financial risk and less cost predictability.

An EPC (Engineering, Procurement, and Construction) contract helps manage total project expenses by assigning full responsibility for design, equipment supply, construction, and commissioning to one contractor under a fixed or guaranteed price, reducing coordination complexity and budget uncertainty.

By consolidating scope and accountability, EPC contracts streamline procurement, minimize dispute risks, and allow for better cost forecasting. This structure benefits buyers who need certainty on total installed cost and delivery timelines.

EPC contracts always eliminate all cost overruns in industrial boiler projects.False

While EPC contracts reduce the likelihood of cost overruns through fixed pricing and scope control, unexpected site conditions or buyer-requested changes can still increase costs.

🔹 How EPC Contracts Control Costs

| EPC Feature | Cost Control Benefit | Example in Boiler Projects |

|---|---|---|

| Single-Point Responsibility | Prevents scope gaps and overlaps | EPC manages both boiler and auxiliary equipment supply |

| Fixed-Price Agreements | Caps total project spend | No cost increase unless scope changes |

| Integrated Scheduling | Reduces idle time and penalties | Simultaneous design, procurement, and site works |

| Value Engineering | Optimizes CAPEX without sacrificing performance | Adjusting boiler layout to reduce steel structure cost |

| Risk Transfer | Contractor assumes more risk for overruns | EPC bears labor productivity risk |

📊 Cost Risk Comparison: EPC vs. Multi-Contract Approach

| Risk Category | EPC Model | Multi-Contract Model |

|---|---|---|

| Budget Overruns | Low | Medium–High |

| Schedule Delays | Low | Medium–High |

| Change Order Volume | Low | High |

| Coordination Costs | Low | High |

✅ Buyer Takeaways

Use EPC for complex, high-stakes boiler projects to consolidate control and improve budget predictability

Clearly define scope, specifications, and performance guarantees before signing

Include incentives for early completion and penalties for delays

Request open-book cost reporting for transparency in long-term EPC partnerships

🔍 Conclusion

The total installed cost of a power plant boiler depends on technology, fuel, auxiliary systems, and site conditions. A realistic budget must account for both equipment and civil works to ensure project success.

📞 Contact Us

💡 Looking for an accurate total installed cost estimate for your power plant boiler project? We offer detailed feasibility studies, cost modeling, and EPC execution for utility-scale boiler installations.

🔹 Partner with us for cost-optimized, on-time, and compliant power plant boiler solutions. ⚡🏭📊✅

FAQ

What is the total installed cost of a power plant boiler?

The total installed cost of a power plant boiler typically ranges from $500,000 to over $10 million, depending on:

Boiler capacity (MW or tons of steam per hour)

Boiler type (subcritical, supercritical, ultra-supercritical)

Fuel type (coal, gas, biomass, oil)

Efficiency and emission control systems

Geographic location and labor rates

Smaller industrial-sized units may be at the lower end, while large utility-scale systems can exceed tens of millions.

What auxiliary equipment is included in the cost?

Auxiliary systems in a total installed cost estimate often include:

Burner systems and fuel handling equipment

Economizers and air preheaters

Feedwater pumps and treatment plants

Fans (forced draft, induced draft, primary air)

Ash handling systems

Control and instrumentation systems

These components are critical for boiler efficiency, emissions control, and safe operation.

How much do civil works add to the total cost?

Civil works typically account for 10–25% of the total installed cost and may cover:

Foundations and structural supports

Boiler house or shelter construction

Chimney or stack installation

Access roads and drainage

Heavy equipment handling and crane access

Site-specific conditions—such as soil quality, seismic design, and space constraints—can significantly affect this cost.

What factors influence the total installed cost?

Key cost drivers include:

Boiler design and material quality

Level of automation

Emission compliance requirements

Import duties and logistics (for international projects)

Project timeline and labor market conditions

Custom engineering, tighter emission limits, and faster schedules often increase project budgets.

How can cost be optimized without sacrificing quality?

Strategies for cost control include:

Standardizing boiler designs where possible

Sourcing auxiliary equipment from competitive suppliers

Using modular construction to reduce site labor time

Early engineering planning to minimize change orders

Selecting the optimal balance between efficiency and capital cost

Balancing efficiency, lifetime operating cost, and upfront investment is key for long-term project success.

References

IEA – Power Plant Investment Costs – https://www.iea.org

DOE – Utility Boiler Systems Cost Guide – https://www.energy.gov

ASME – Boiler Auxiliary Systems Overview – https://www.asme.org

Cleaver-Brooks – Boiler Room Equipment Costs – https://www.cleaverbrooks.com

Hurst Boiler – Boiler & Auxiliary Packages – https://www.hurstboiler.com

Spirax Sarco – Feedwater & Heat Recovery Systems – https://www.spiraxsarco.com

Engineering Toolbox – Boiler Efficiency & Equipment Data – https://www.engineeringtoolbox.com

Powerhouse – Boiler Installation Cost Factors – https://www.powerhouse.com

BioEnergy Consult – Biomass Power Boiler Costs – https://www.bioenergyconsult.com

DNV – EPC Cost Estimation for Power Boilers – https://www.dnv.com