With growing pressure to reduce carbon emissions and energy costs, many industries are turning to biomass boilers as a renewable alternative to coal, oil, or gas. However, selecting the wrong biomass boiler can lead to fuel handling issues, low efficiency, frequent maintenance, and high lifecycle costs. Businesses need a clear framework to evaluate the right type and size for their application.

To choose the right industrial biomass boiler, companies should assess steam capacity and pressure requirements, fuel type and availability (wood chips, pellets, agricultural residues), combustion technology, emission compliance, and efficiency-enhancing features such as economizers or flue gas recirculation. Installation space, automation level, and long-term maintenance support also play a crucial role. By matching boiler design with operational needs and fuel logistics, industries can secure reliable, cost-effective, and sustainable steam generation.

This structured approach ensures the biomass boiler becomes a strategic energy solution instead of an operational burden.

What Factors Determine the Correct Capacity and Pressure for a Biomass Boiler?

Many industrial users struggle when sizing a biomass boiler. If the boiler is undersized, it will fail to meet process demand, forcing reliance on costly backup systems. If it is oversized, efficiency will drop at part load, leading to fuel waste, higher emissions, and unnecessary investment costs. The key to successful biomass boiler projects is accurately determining the correct steam capacity (tons/hour) and working pressure (bar/MPa) that match process and fuel conditions.

The correct capacity and pressure of a biomass boiler are determined by the plant’s steam demand profile, process pressure requirements, fuel availability and calorific value, boiler type, and emission compliance needs. Engineers calculate maximum and average steam load, required steam quality (saturated or superheated), and distribution losses to size the boiler so it operates efficiently at 70–90% load, while ensuring adequate pressure for downstream equipment.

This balance ensures reliable steam supply, stable efficiency, and minimized lifecycle cost.

Biomass boilers should always be designed for the maximum possible steam demand.False

Oversizing a biomass boiler leads to poor efficiency, higher emissions, and excessive capital costs. Boilers should be sized to handle typical loads with margin for peak demand.

Boiler pressure must be matched to the highest process requirement plus distribution losses.True

Steam pressure must account for process equipment needs and piping system drops to ensure reliable supply.

1. Steam Demand Profile

Maximum Load: Peak steam consumption (e.g., during startup or process spikes).

Average Load: Typical steady-state consumption.

Load Variation: Wide fluctuations require flexible boiler control systems.

Design Rule: Boilers should operate 70–90% of rated capacity during normal conditions, with margin for peak loads.

2. Process Pressure Requirements

Food, textile, and chemical industries often need saturated steam at 6–12 bar.

Power generation or combined heat and power (CHP) plants may require 30–90 bar superheated steam.

Steam pressure must include distribution losses (~3–10%) between boiler and process end-use.

3. Fuel Characteristics

| Fuel Type | Typical Moisture Content | Efficiency Impact | Boiler Design Impact |

|---|---|---|---|

| Wood Pellets | 8–12% | High efficiency | Smaller furnace, stable combustion |

| Wood Chips | 20–40% | Lower efficiency | Larger furnace, robust fuel handling |

| Agri-residues | 15–35% | Variable quality | Ash handling and fouling control needed |

Low-calorific fuels require higher feeding rates to achieve the same steam output.

Boiler size must account for fuel variability.

4. Boiler Type & Technology

Grate-fired boilers: Suitable for medium pressure (up to ~25 bar).

Circulating Fluidized Bed (CFB): Handles diverse fuels, high efficiency, and pressures >60 bar.

Gasification-based systems: Lower capacity, but efficient for small-scale CHP.

5. Efficiency and Emissions Balance

Higher pressure and superheated steam improve thermodynamic efficiency but increase cost and maintenance.

Emission compliance (NOx, SOx, particulates) may dictate advanced combustion or flue gas cleaning technology, impacting boiler sizing.

Example: Sizing a Biomass Boiler for a Paper Mill

Steam requirement: 25 t/h at 12 bar (average 18 t/h, peak 25 t/h).

Fuel: Wood chips (20 MJ/kg, 30% moisture).

Boiler type: Water-tube, grate-fired.

Final selection: 30 t/h boiler at 14 bar, ensuring reliability with 20% margin and covering distribution losses.

Key Takeaways

Correct capacity = average demand + peak margin.

Correct pressure = highest process requirement + distribution loss.

Fuel type and quality directly influence boiler furnace size and feeding systems.

Boiler efficiency is optimized when operating close to design load.

Conclusion

Determining biomass boiler capacity and pressure is not a “one-size-fits-all” task—it requires careful analysis of steam demand, process requirements, and fuel quality. A properly sized biomass boiler balances efficiency, reliability, and cost while ensuring environmental compliance.

How Does the Choice of Biomass Fuel Affect Boiler Design and Performance?

A major challenge when considering a biomass boiler is the wide variability of fuels. Unlike standardized coal, gas, or oil, biomass fuels vary dramatically in moisture content, calorific value, ash composition, and bulk density. This variability directly influences boiler design, combustion stability, maintenance needs, and efficiency. Choosing the wrong boiler for the chosen fuel—or the wrong fuel for the installed boiler—leads to fouling, unburned fuel, higher emissions, and costly downtime.

The choice of biomass fuel affects boiler design and performance by determining the furnace size, combustion technology, feeding system, ash handling requirements, and achievable efficiency. Wood pellets allow for compact, high-efficiency systems; wood chips require larger furnaces and robust fuel handling; agricultural residues demand advanced ash removal and fouling prevention. Engineers must match boiler design to fuel properties to achieve reliable, efficient, and environmentally compliant operation.

Selecting the right fuel-boiler combination ensures efficiency, stable performance, and long-term operating cost savings.

Any biomass fuel can be burned efficiently in any boiler type.False

Boiler design must match the chosen fuel’s moisture, ash, and calorific value. Using unsuitable fuels causes slagging, corrosion, and poor efficiency.

Wood pellets are the most efficient biomass fuel due to low moisture and high uniformity.True

Their standardized properties allow stable combustion, compact boiler design, and lower maintenance.

1. Key Fuel Properties and Their Impact

| Property | Typical Range | Impact on Boiler Design | Performance Impact |

|---|---|---|---|

| Moisture Content | 8–50% | High moisture requires larger furnaces and stronger fuel feeding systems | Increases fuel use, reduces efficiency |

| Calorific Value | 8–20 MJ/kg | Determines required fuel input rate for target steam capacity | Higher CV improves efficiency, lowers fuel volume |

| Ash Content | 0.5–15% | Requires suitable ash removal, refractory protection | High ash causes slagging, fouling, corrosion |

| Particle Size/Density | Fine pellets vs. bulky chips | Affects feeding system design (screws, conveyors, feeders) | Poor sizing leads to feeding blockages, uneven combustion |

2. Common Biomass Fuels and Boiler Implications

Wood Pellets

Low moisture (~8–12%), high density.

Compatible with compact boilers.

Best for stable combustion and highest efficiency (85–90%).

Wood Chips

Moisture content varies (20–40%).

Requires larger furnaces and drying systems.

Efficiency depends on consistent fuel supply quality.

Agricultural Residues (straw, husks, shells)

Often high ash (5–15%) with alkali compounds.

Needs fluidized bed or specially designed grate systems.

Fouling and slagging must be controlled with advanced ash handling.

Energy Crops (miscanthus, switchgrass)

Bulkier and lower density.

Higher logistics and storage costs.

Requires oversized fuel conveyors.

3. Boiler Technology Selection Based on Fuel

| Boiler Type | Suitable Fuels | Strengths | Limitations |

|---|---|---|---|

| Fixed/Moving Grate | Chips, pellets | Simple, robust | Less efficient for fine fuels |

| Bubbling Fluidized Bed (BFB) | Chips, residues | Handles varied fuels, moderate scale | Higher CAPEX |

| Circulating Fluidized Bed (CFB) | Mixed residues, high-ash fuels | High efficiency, flexible | Complex design, higher OPEX |

| Gasification | Pellets, dry residues | High-quality syngas, small-scale CHP | Limited to specific fuels |

4. Case Study Example

A textile plant in India switched from imported coal to rice husk.

Challenge: High silica ash caused slagging in grate-fired boiler.

Solution: Replaced with fluidized bed boiler designed for high-ash fuels.

Result: 78% boiler efficiency maintained with stable operation, fuel cost reduced by 40% annually.

Conclusion

Biomass fuel choice is not interchangeable—the right match between fuel and boiler design determines long-term performance, efficiency, and maintenance costs. Understanding moisture, ash, and calorific value is critical in selecting both the fuel and the boiler technology.

Which Combustion Technologies Are Most Suitable for Different Biomass Fuels?

When selecting a biomass boiler, one of the biggest challenges is matching the right combustion technology to the fuel type. Using the wrong technology results in poor combustion efficiency, unburned carbon, slagging, fouling, and high maintenance costs. Since biomass fuels vary widely in moisture, calorific value, particle size, and ash content, no single boiler technology fits all fuels. The choice of combustion system directly influences efficiency, emissions, and operating costs.

The most suitable combustion technology depends on the biomass fuel properties: fixed or moving grate systems are ideal for uniform, low-ash fuels like wood pellets; bubbling fluidized bed (BFB) boilers handle moist fuels like wood chips; circulating fluidized bed (CFB) systems are best for diverse, high-ash fuels such as agricultural residues; and gasification technologies are suitable for dry, consistent fuels when syngas production is required.

All biomass fuels can be burned efficiently in simple grate-fired boilers.False

High-ash and variable fuels like rice husks or straw cause slagging in grates. Fluidized bed or CFB technologies are required for efficient combustion.

Fluidized bed combustion offers the highest flexibility across biomass fuel types.True

BFB and CFB systems handle varied fuels, tolerate moisture, and reduce emissions, making them suitable for mixed biomass.

1. Overview of Biomass Combustion Technologies

| Technology | Suitable Fuels | Key Advantages | Limitations | Efficiency Range |

|---|---|---|---|---|

| Fixed/Moving Grate | Pellets, dry chips | Simple, low-cost, robust | Poor for high-ash fuels, limited flexibility | 70–85% |

| Bubbling Fluidized Bed (BFB) | Wet chips, residues | Good moisture tolerance, fuel flexibility | Medium-scale only, higher CAPEX | 80–88% |

| Circulating Fluidized Bed (CFB) | High-ash fuels, residues | Very fuel-flexible, high efficiency | Complex, high investment | 85–90% |

| Gasification | Pellets, dry residues | Produces syngas for CHP, high efficiency | Sensitive to fuel variability, smaller scale | 80–90% |

2. Fixed/Moving Grate Combustion

Best for: Wood pellets, dry wood chips.

Design: Simple grate with mechanical or hydraulic fuel feeding.

Advantages: Low investment, easy operation.

Limitations: Poor tolerance to fuels with >10% ash or high moisture.

Application: Small to medium heating plants, food and textile industries.

3. Bubbling Fluidized Bed (BFB)

Best for: Moist fuels (up to 50% moisture), wood chips, some residues.

Design: Sand bed fluidized with air ensures even heat distribution.

Advantages: Excellent combustion efficiency, fuel flexibility, lower NOx.

Limitations: Requires higher CAPEX and skilled operation.

Application: Medium-sized industrial plants, district heating.

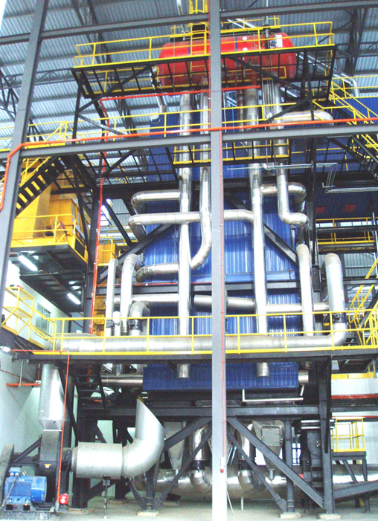

4. Circulating Fluidized Bed (CFB)

Best for: High-ash agricultural residues, mixed fuels, waste biomass.

Design: Fuel particles circulate in high-velocity air, allowing complete combustion.

Advantages: Handles wide fuel variety, reduces SOx/NOx, higher capacity (>100 MWth).

Limitations: Higher cost and complexity, needs larger scale to be economical.

Application: Utility-scale plants, large paper mills, sugar industries.

5. Biomass Gasification

Best for: Uniform, dry fuels like pellets or clean chips.

Design: Converts biomass into syngas (CO, H₂, CH₄) for engines, turbines, or boilers.

Advantages: High efficiency in CHP, lower emissions.

Limitations: Sensitive to fuel variability, tar formation issues.

Application: Small-scale CHP plants, distributed power.

6. Case Study Comparison

| Fuel Type | Best Technology | Real-World Example | Performance Result |

|---|---|---|---|

| Wood Pellets | Grate-fired | District heating in Germany | 88% efficiency, low maintenance |

| Wet Wood Chips | BFB | Finnish paper mill | 82% efficiency, stable operation |

| Rice Husk | CFB | Indian sugar mill | 85% efficiency, reduced slagging |

| Straw Pellets | Gasification | Danish CHP plant | 87% efficiency, clean syngas for power |

Conclusion

The right combustion technology must be matched to the fuel type to maximize efficiency, minimize downtime, and meet environmental standards. While grate-fired systems are economical for standardized fuels, fluidized bed technologies offer the best flexibility for mixed or challenging biomass, and gasification is increasingly attractive for CHP applications.

How Can Emission Control Systems Ensure Compliance with Environmental Standards?

One of the most critical challenges for biomass, coal, or oil-fired boilers is air pollution control. Combustion of solid and liquid fuels generates particulates, SOx, NOx, CO, and VOCs, which are tightly regulated by local and international standards. Failing to comply can result in hefty fines, plant shutdowns, or loss of permits. Beyond regulatory risks, poor emission control damages brand reputation and community relations. The solution is a well-integrated emission control system tailored to the fuel, boiler design, and emission limits.

Emission control systems ensure compliance with environmental standards by targeting specific pollutants with advanced technologies such as electrostatic precipitators (ESP) or baghouse filters for dust, scrubbers for SO₂, selective non-catalytic or catalytic reduction (SNCR/SCR) for NOx, and condensers or oxidation systems for VOCs. By combining the right control methods with continuous monitoring, plants can reliably stay within regulatory limits while improving efficiency and public trust.

All biomass boilers automatically comply with emission standards because they use renewable fuel.False

While biomass is renewable, its combustion still produces particulates, NOx, and sometimes SO₂. Emission control equipment is necessary for compliance.

Electrostatic precipitators are effective in reducing fine particulate matter emissions from biomass combustion.True

ESPs can capture over 99% of fine dust and ash particles, ensuring boilers meet PM emission limits.

1. Key Emissions from Biomass and Oil-Fired Boilers

| Pollutant | Main Source | Environmental Impact | Control Technology |

|---|---|---|---|

| Particulates (PM10, PM2.5) | Ash, incomplete combustion | Respiratory health hazards | ESPs, baghouse filters, cyclones |

| SO₂ (Sulfur Dioxide) | Sulfur in fuel (oil, residues) | Acid rain, corrosion | Wet scrubbers, dry sorbent injection |

| NOx (Nitrogen Oxides) | High combustion temperatures | Smog, ozone formation | Low-NOx burners, SNCR, SCR |

| CO (Carbon Monoxide) | Incomplete combustion | Toxic, safety hazard | Optimized burners, excess air control |

| VOC/Tars | Gasification, poor combustion | Smog precursors | Thermal oxidation, catalytic converters |

2. Emission Control Technologies in Detail

a) Particulate Matter Control

Electrostatic Precipitators (ESP): Use electric fields to remove up to 99.9% of fine particulates.

Baghouse Filters: Fabric filters capturing even ultrafine particles (<1 μm).

Cyclone Separators: Pre-cleaning of coarse dust before ESP or baghouse.

b) Sulfur Control

Wet Flue Gas Desulfurization (FGD): Uses limestone slurry to absorb SO₂.

Dry Sorbent Injection (DSI): Injects lime or sodium bicarbonate for SO₂ neutralization.

c) Nitrogen Oxide Control

Low-NOx Burners (LNB): Reduce flame temperature to minimize NOx formation.

Selective Non-Catalytic Reduction (SNCR): Injects urea or ammonia into furnace to cut NOx by 30–60%.

Selective Catalytic Reduction (SCR): Catalysts achieve 80–95% NOx removal, common in large plants.

d) CO and VOC Control

Advanced Combustion Controls: Maintain correct air-fuel ratio for complete combustion.

Oxidizers/Catalysts: Eliminate VOCs from gasification or incomplete combustion.

3. Integration with Monitoring Systems

Modern plants combine Continuous Emission Monitoring Systems (CEMS) with control technologies:

Real-time measurement of SO₂, NOx, CO, O₂, and PM.

Automatic adjustment of combustion and reagent dosing.

Digital reporting for environmental authorities.

4. Case Study Example

A biomass CHP plant in Denmark burning straw faced high particulate emissions.

Problem: Standard multicyclones only captured 70% of dust.

Solution: Installation of ESP + baghouse hybrid system.

Result: Particulate emissions dropped by 98%, well below EU Industrial Emissions Directive (IED) limits.

5. Comparative Efficiency of Control Systems

| Technology | Pollutant Targeted | Typical Removal Efficiency |

|---|---|---|

| ESP | PM | 95–99.9% |

| Baghouse Filter | PM | 99–99.9% |

| Wet FGD | SO₂ | 90–98% |

| SNCR | NOx | 30–60% |

| SCR | NOx | 80–95% |

| Thermal Oxidizer | VOCs | 95–99% |

Conclusion

Emission control systems are not optional extras but essential components of modern biomass and oil-fired boiler plants. By combining fuel-specific combustion design, advanced emission reduction technologies, and real-time monitoring, industries can ensure compliance with environmental laws, reduce liability, and support sustainable operations.

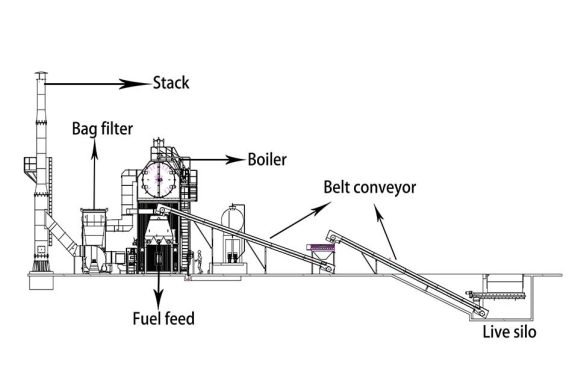

Why Are Automation, Feeding Systems, and Ash Handling Important in Biomass Boilers?

One of the biggest operational challenges in biomass boiler plants is fuel variability and high ash content. Unlike standardized natural gas or oil, biomass fuels differ in size, density, moisture, and ash characteristics. Without reliable automation, fuel feeding, and ash removal systems, boilers suffer from blockages, uneven combustion, higher emissions, and costly downtime. The solution lies in integrating smart automation, robust fuel handling, and efficient ash disposal systems to ensure stable operation, safety, and cost-effectiveness.

Automation, feeding systems, and ash handling are essential in biomass boilers because they ensure consistent fuel supply, maintain optimal combustion, minimize manual labor, and prevent operational interruptions. Automated controls optimize air-fuel ratios and emissions, feeding systems handle diverse fuels reliably, and ash management prevents fouling, corrosion, and environmental non-compliance. Together, they maximize efficiency, reliability, and long-term savings.

Efficient handling of fuel and byproducts, coupled with automation, allows biomass boilers to operate closer to the performance levels of gas or oil-fired systems—while keeping maintenance and operating costs under control.

Biomass boilers can be operated manually without significant performance losses.False

Manual operation leads to uneven combustion, higher emissions, and frequent downtime. Automation ensures efficiency and compliance.

Ash handling is crucial in biomass boilers due to the high ash content of agricultural residues and some wood fuels.True

Efficient ash handling systems reduce slagging, fouling, and disposal issues, ensuring stable long-term operation.

1. Role of Automation in Biomass Boilers

Combustion Optimization: Automated systems continuously adjust air-fuel ratios to maintain high efficiency and low emissions.

Load Management: Intelligent controls respond to demand fluctuations, avoiding oversupply or heat loss.

Emission Control Integration: Automation links boiler operation with ESP, baghouse filters, and SNCR/SCR systems for compliance.

Safety Assurance: Monitors temperature, pressure, and CO/NOx levels, preventing accidents.

Remote Operation: Digital interfaces and IoT connectivity allow remote monitoring and predictive maintenance.

2. Feeding Systems – Matching Boiler Design to Fuel Type

| Fuel Type | Common Feeding Method | Boiler Type Suitability | Challenges |

|---|---|---|---|

| Wood Pellets | Screw feeders, pneumatic conveyors | Grate, fluidized bed | Easy, but requires dry storage |

| Wood Chips | Hydraulic pushers, conveyor belts | Grate, BFB | Moisture variation, risk of blockages |

| Agricultural Residues (straw, husks, shells) | Hydraulic rams, augers, spreaders | Fluidized bed, CFB | High ash, low density, uneven flow |

| Energy Crops | Conveyor belts, chain feeders | Grate, BFB | Bulk density requires oversized systems |

Design Importance:

A misfit feeding system causes uneven combustion, unburned fuel, and boiler trips.

Large-scale boilers often integrate pre-drying systems for wet fuels before feeding.

3. Ash Handling Systems – Keeping Boilers Clean and Efficient

Bottom Ash Removal: Scraper conveyors or hydraulic systems for continuous removal.

Fly Ash Capture: ESPs, baghouses, and cyclones to prevent particulate emissions.

Slag Management: Fluidized bed boilers need systems to prevent alkali-rich slag buildup.

Recycling Potential: Some ash can be reused in cement or fertilizers if free from contaminants.

| Fuel Type | Ash Content (%) | Ash Handling Requirement |

|---|---|---|

| Pellets | 0.5–1.5 | Minimal ash, simple removal |

| Wood Chips | 1–3 | Moderate ash, standard conveyors |

| Straw/Agro-residues | 5–15 | High ash, requires advanced extraction & fouling control |

4. Case Study Example

A paper mill in Eastern Europe installed a 20 MW biomass boiler using mixed wood chips and bark.

Problem: Manual feeding caused frequent shutdowns and slagging.

Solution: Upgraded to a hydraulic feeding system + automatic ash extraction + advanced PLC automation.

Result: Plant efficiency increased from 72% to 84%, downtime reduced by 60%, and annual savings reached $750,000 in labor and fuel costs.

Conclusion

Automation, feeding, and ash handling are not auxiliary extras but core components of biomass boiler design. They directly influence efficiency, uptime, maintenance, and compliance. Choosing the right systems ensures stable combustion, longer equipment life, and lower operating costs.

How Do Lifecycle Costs, Maintenance, and After-Sales Support Impact Boiler Selection?

When purchasing a new industrial boiler, many buyers focus only on the initial purchase price. However, the true financial impact comes from the total lifecycle cost—including fuel consumption, maintenance, downtime, spare parts, and service contracts. A cheap boiler that consumes more fuel, requires frequent repairs, or lacks reliable support can cost two to three times more over its operational life compared to a higher-quality system with strong after-sales support. Therefore, evaluating lifecycle costs, maintenance requirements, and service availability is critical to making the right selection.

Lifecycle costs, maintenance, and after-sales support impact boiler selection by determining long-term operating expenses, system reliability, and uptime. A boiler with higher efficiency, robust design, and reliable service support delivers lower total cost of ownership, even if the upfront price is higher. Buyers should assess efficiency, durability, spare parts availability, and service response times before finalizing a purchase.

Thinking beyond the purchase price ensures that businesses select a boiler that delivers reliable performance, minimizes downtime, and keeps operating costs under control throughout its lifetime.

The lowest purchase price always means the lowest overall cost for a boiler project.False

Lifecycle costs, including fuel, maintenance, and downtime, often outweigh the initial purchase price. A higher-priced boiler can deliver lower total cost of ownership.

After-sales service and spare parts availability directly affect boiler uptime and reliability.True

A boiler without reliable service support risks costly downtime, production losses, and higher repair expenses.

1. Lifecycle Costs in Boiler Investment

Lifecycle costs typically represent 70–80% of the total project cost over 20–25 years. They include:

Fuel Costs: The largest contributor, accounting for 60–75% of lifecycle costs.

Maintenance & Repairs: Annual maintenance, replacement of refractory linings, burners, tubes, etc.

Downtime Costs: Production losses during breakdowns or inefficient operation.

Compliance Costs: Upgrades for emissions or safety standards over time.

| Cost Category | Typical Share of Total Lifecycle Cost | Notes |

|---|---|---|

| Fuel | 60–75% | Strongly affected by efficiency and fuel type |

| Maintenance | 10–15% | Preventive maintenance reduces breakdowns |

| Downtime | 5–10% | Avoidable with reliable systems and service |

| Compliance & Upgrades | 5–10% | Emission standards and automation retrofits |

2. Importance of Maintenance Strategy

Preventive Maintenance: Scheduled inspections, cleaning, and replacements to avoid failures.

Predictive Maintenance: Using sensors and IoT to forecast wear and optimize service timing.

Corrective Maintenance: Emergency repairs after breakdowns—most expensive and disruptive.

Case Study: A food processing plant compared two 10-ton/hr boilers:

Boiler A (cheaper, no long-term service support) → Required frequent tube replacements, downtime 20 days/year.

Boiler B (higher upfront cost, with OEM service contract) → Downtime only 5 days/year, 8% fuel savings.

Over 10 years, Boiler B saved $1.2 million despite costing 20% more upfront.

3. Role of After-Sales Support

Spare Parts Availability: OEMs or certified partners ensure faster replacement.

Service Response Times: 24/7 remote monitoring and local service networks reduce downtime.

Training & Manuals: Skilled operators extend equipment life and maintain efficiency.

Warranty & Extended Contracts: Predictable OPEX and lower repair costs.

4. How to Evaluate Lifecycle Costs Before Purchase

Request Total Cost of Ownership (TCO) analysis from suppliers.

Compare efficiency guarantees, not just nameplate capacity.

Assess fuel-flexibility if fuel markets are volatile.

Verify local service centers and spare part logistics.

Review customer references for long-term reliability and service.

Conclusion

Boiler selection should be based on total lifecycle value, not only the sticker price. A well-supported, efficient, and durable boiler can cut millions in long-term costs, while poor maintenance and lack of service support can turn a “cheap” investment into the most expensive mistake.

🔍 Conclusion

Choosing the right industrial biomass boiler requires a balanced evaluation of fuel, technology, and operational factors. When properly selected, a biomass boiler can provide sustainable steam generation, lower fuel costs, and regulatory compliance for long-term industrial success.

📞 Contact Us

💡 Planning to switch to biomass energy? We offer biomass boiler design, fuel testing, turnkey solutions, and lifecycle support tailored to your plant’s needs.

🔹 Contact us today to select the right biomass boiler and achieve sustainable energy efficiency. 🌱🔥🏭✅

FAQ

How do I choose the right industrial biomass boiler?

Selecting the right biomass boiler depends on:

Fuel type & availability – Wood chips, pellets, rice husk, bagasse, or other agricultural residues.

Steam demand & capacity – Match boiler output (t/h) to process requirements without oversizing.

Efficiency – Look for designs with economizers, air preheaters, and advanced combustion controls.

Emission compliance – Ensure the boiler meets local environmental regulations (low NOx, SOx, PM).

Space & installation – CFB (Circulating Fluidized Bed) boilers offer flexibility but need more space; grate-fired boilers are compact.

What capacity biomass boiler should I choose?

Capacity selection depends on industry needs:

Small industries (food, textile, dairy): 1–20 t/h.

Medium industries (paper, chemicals, breweries): 20–75 t/h.

Large-scale plants & utilities: 75–300+ t/h.

Conduct a steam load analysis to determine peak and average demands for accurate sizing.

Which biomass fuels are best for industrial boilers?

Wood pellets & chips – Consistent quality, high efficiency.

Agricultural residues (rice husk, corn stalks, bagasse) – Cost-effective but may require fuel preparation.

Energy crops & forestry waste – Sustainable but logistics-heavy.

Fuel choice should consider calorific value, moisture content, and local supply stability.

What efficiency levels can I expect from a biomass boiler?

Typical efficiency ranges:

Grate-fired boilers: 75–85%

CFB (Circulating Fluidized Bed) boilers: 80–90%

Advanced biomass systems with heat recovery: up to 92%

Efficiency improves with fuel drying, optimized combustion, and flue gas heat recovery systems.

Why choose biomass boilers over coal or oil boilers?

Biomass boilers offer:

Lower carbon footprint – Biomass is renewable and often considered carbon-neutral.

Fuel flexibility – Can burn a wide range of organic materials.

Lower operational costs – Especially where biomass residues are locally available.

Regulatory compliance – Meets sustainability and green energy mandates.

References

IEA – Biomass for Heat and Power – https://www.iea.org

U.S. Department of Energy – Biomass Boiler Guide – https://www.energy.gov

European Biomass Association – Boiler Applications – https://www.biomass-europe.org

Spirax Sarco – Biomass Boiler Selection Criteria – https://www.spiraxsarco.com

Forbes Marshall – Biomass Boiler Technology – https://www.forbesmarshall.com

Babcock & Wilcox – Biomass-Fired Boiler Solutions – https://www.babcock.com

ScienceDirect – Biomass Boiler Efficiency Studies – https://www.sciencedirect.com

ResearchGate – Performance of Biomass Boilers – https://www.researchgate.net

BioEnergy Consult – Biomass vs Fossil Fuels – https://www.bioenergyconsult.com

Engineering Toolbox – Biomass Fuel Properties – https://www.engineeringtoolbox.com