Selecting the right industrial oil-fired boiler is a critical step in ensuring reliable heat and steam generation for manufacturing, chemical, food, textile, and power industries. A poorly matched boiler can result in inefficient combustion, increased fuel consumption, and frequent maintenance, affecting both productivity and operational costs. Therefore, understanding and evaluating key technical and operational parameters is essential before making a purchase.

The essential parameters for selecting an industrial oil-fired boiler include steam capacity and pressure, fuel type and quality, thermal efficiency, combustion system design, emission control requirements, and automation level. Additional considerations such as heat exchanger configuration, material durability, installation space, and maintenance accessibility also play vital roles. By carefully aligning these parameters with process requirements, industries can achieve stable combustion, high efficiency, and compliance with environmental regulations while minimizing lifecycle costs.

A well-selected oil-fired boiler delivers consistent performance, long service life, and reduced energy expenses, making it a dependable choice for continuous industrial operations.

How Do Steam Capacity and Pressure Requirements Determine Oil-Fired Boiler Selection?

In industrial and power generation applications, choosing the right oil-fired boiler is far more complex than simply matching the fuel type or size. The steam capacity (measured in tons per hour or kg/h) and the steam pressure requirement (measured in bar or MPa) are two decisive parameters that define the boiler’s thermal design, construction material, safety systems, and overall efficiency. Selecting a unit that does not precisely meet these parameters can lead to operational inefficiency, excessive fuel consumption, and premature equipment wear.

Steam capacity and pressure requirements determine oil-fired boiler selection by defining the necessary heat transfer area, furnace design, material strength, and control system configuration. The boiler must produce the required amount of steam (capacity) at the designated pressure and temperature levels safely, efficiently, and continuously. Mismatch between capacity and pressure specification leads to unstable operation, lower efficiency, and increased operational costs.

In essence, the capacity determines the boiler’s size and fuel demand, while the pressure determines its structural integrity, safety rating, and thermodynamic efficiency—making both parameters inseparable in the selection process.

Steam capacity only affects the boiler’s output rate and has no link to efficiency.False

Capacity influences the furnace size, heat transfer rate, and combustion efficiency, directly affecting thermal performance.

High-pressure boilers achieve greater energy conversion efficiency than low-pressure systems.True

Higher pressure allows higher steam temperature and enthalpy, leading to improved turbine and process efficiency.

The Significance of Steam Capacity in Oil-Fired Boiler Selection

Steam capacity refers to the maximum continuous steam output that the boiler can generate under rated conditions. It determines the size, burner output, fuel feed rate, and heat transfer surface area required for the system.

| Parameter | Typical Range | Effect on Boiler Design | Operational Consideration |

|---|---|---|---|

| Steam Capacity | 0.5 – 200 TPH | Determines furnace volume and tube area | Impacts fuel consumption rate |

| Fuel Input Rate | 35 – 15,000 kg/h (depending on capacity) | Affects burner sizing | Requires proper atomization system |

| Heat Transfer Area | 10 – 5,000 m² | Directly proportional to capacity | Governs thermal efficiency |

| Steam Drum Volume | 0.3 – 60 m³ | Impacts steam quality and stability | Larger drums reduce pressure fluctuation |

Small-capacity boilers can handle the same fuel input rate as large industrial units.False

Fuel input and furnace volume must be proportionally scaled to ensure complete combustion and avoid flame impingement.

Key Design Implications:

Higher capacity = larger furnace and more heating surface to ensure complete combustion and efficient heat transfer.

Proportional burner output adjustment is necessary to maintain fuel-air balance across the load range.

Adequate steam drum volume ensures dryness fraction and reduces priming or carryover.

Condensate recovery and deaerator sizing must match capacity for stable feedwater supply.

| Steam Capacity Tier | Common Boiler Type | Application Area | Fuel-to-Steam Conversion Efficiency (%) |

|---|---|---|---|

| <5 TPH | Vertical shell/tube | Small industries, laundries | 83–88 |

| 5–30 TPH | Horizontal fire-tube / packaged | Food, textile, chemical | 88–92 |

| 30–150 TPH | Water-tube (bi-drum) | Power, refinery | 90–94 |

| >150 TPH | Once-through or Benson-type | Large power plants | 93–96 |

Fire-tube boilers are suitable for very high steam capacities (>150 TPH).False

Fire-tube designs are limited to moderate capacities due to heat transfer and pressure constraints.

Steam Pressure: The Thermodynamic Backbone

Steam pressure dictates not only the energy content (enthalpy) of the steam but also the materials, wall thickness, and safety systems required to withstand operational stress.

| Pressure Range | Classification | Design Characteristics | Typical Application |

|---|---|---|---|

| <1.0 MPa (10 bar) | Low-pressure boiler | Simple shell design | Heating, process steam |

| 1.0–3.9 MPa | Medium-pressure boiler | Bi-drum or water-tube | Textile, paper, small power |

| 4.0–9.0 MPa | High-pressure boiler | Alloy steel, superheater | Power generation, refinery |

| >9.0 MPa | Supercritical | Once-through design | Large-scale power stations |

Boiler pressure has no influence on the choice of materials.False

Higher pressure requires stronger materials like Cr-Mo alloys and thicker drum walls to resist creep and thermal fatigue.

Key Implications of Steam Pressure on Design:

Material Selection:

Low pressure: Carbon steel

Medium pressure: Low-alloy steel (e.g., 1.25Cr–0.5Mo)

High pressure: 2.25Cr–1Mo or 9Cr–1Mo

Thermal Efficiency:

Increases with pressure due to higher enthalpy and reduced moisture content.

Safety Requirements:

Requires certified pressure vessels and automatic safety valves.

Superheating Necessity:

For pressures >4 MPa, superheating improves turbine and process efficiency.

| Pressure (bar) | Saturation Temp (°C) | Steam Enthalpy (kJ/kg) | Relative Efficiency (%) |

|---|---|---|---|

| 10 | 180 | 2776 | 85 |

| 30 | 234 | 2803 | 88 |

| 60 | 275 | 2808 | 91 |

| 100 | 311 | 2810 | 94 |

| 160 | 347 | 2812 | 96 |

Raising boiler pressure always increases energy efficiency indefinitely.False

Efficiency gains plateau beyond a certain point due to higher heat losses and equipment complexity.

Interrelation Between Capacity and Pressure

| Capacity–Pressure Combination | Boiler Type | Efficiency (%) | Recommended Application |

|---|---|---|---|

| Low Capacity + Low Pressure | Fire-tube shell | 80–88 | Laundry, small process |

| Medium Capacity + Medium Pressure | Bi-drum water-tube | 88–92 | Industrial plants |

| High Capacity + High Pressure | Single drum or once-through | 93–96 | Power generation |

| High Capacity + Ultra-High Pressure | Supercritical once-through | 96–98 | Utility power plants |

Capacity and pressure can be designed independently without affecting performance.False

They are interdependent; capacity affects furnace volume, while pressure affects material and circulation design.

A high-pressure, large-capacity boiler demands forced circulation, advanced metallurgy, and precise automation, while low-pressure, small-capacity units use natural circulation and simpler controls.

Thermal Design Example

| Parameter | Unit | Low Pressure (10 bar) | High Pressure (80 bar) |

|---|---|---|---|

| Steam Output | TPH | 20 | 20 |

| Fuel Type | – | Diesel | Diesel |

| Boiler Type | – | Fire-tube | Water-tube |

| Efficiency (%) | % | 87 | 93 |

| Fuel Rate | kg/h | 1,170 | 1,010 |

| Steam Temperature | °C | 184 | 295 |

| Construction Material | – | Carbon Steel | Alloy Steel |

This example demonstrates that even for the same steam capacity, higher pressure yields greater thermal efficiency and lower fuel consumption—provided materials and design support the stress levels.

Higher steam pressure reduces fuel consumption per ton of steam produced.True

High-pressure steam contains more usable energy, reducing the heat input required per unit of steam.

Key Performance Design Considerations

| Aspect | Influenced by Steam Capacity | Influenced by Pressure | Selection Impact |

|---|---|---|---|

| Furnace Volume | ✓ | – | Determines combustion efficiency |

| Material Grade | – | ✓ | Affects mechanical strength |

| Efficiency | ✓ | ✓ | Influences fuel cost |

| Circulation Method | ✓ | ✓ | Impacts reliability and maintenance |

| Heat Transfer Area | ✓ | – | Drives boiler sizing |

| Safety Valves & Controls | – | ✓ | Ensures compliance and safety |

Boiler pressure determines the type of safety valve and drum thickness required.True

Safety valves and drum thickness are engineered based on the maximum allowable working pressure.

Case Study: 50 TPH Oil-Fired Boiler for Refinery

| Parameter | Medium-Pressure Design | High-Pressure Design |

|---|---|---|

| Steam Capacity | 50 TPH | 50 TPH |

| Pressure | 3.9 MPa | 8.0 MPa |

| Efficiency | 90.1% | 93.8% |

| Fuel Consumption | 2,950 kg/h | 2,740 kg/h |

| NOx Emission | 120 mg/Nm³ | 95 mg/Nm³ |

| Maintenance Cost | Moderate | High |

| Material | Low-alloy steel | Cr-Mo alloy |

| ROI Period | 5.2 years | 4.3 years |

This case reveals that although high-pressure systems cost more initially, their improved efficiency and fuel savings lead to shorter payback times and lower lifetime costs.

Future Trends: Smart Selection and Adaptive Design

| Innovation | Function | Advantage |

|---|---|---|

| AI-Assisted Boiler Sizing | Dynamic matching of load & pressure | Optimizes capacity–pressure ratio |

| Advanced CFD Modelling | Simulates furnace flow and heat transfer | Minimizes overdesign |

| Adaptive Pressure Control | Variable steam output | Reduces part-load inefficiencies |

| High-Temperature Alloys | Withstands >600°C | Enables ultra-supercritical operation |

| Digital Twin Performance Tracking | Predictive modeling | Reduces design risk and improves selection accuracy |

AI tools can optimize the selection of boiler capacity and pressure combination.True

AI-based simulations analyze operating data to recommend optimal pressure–capacity pairings for efficiency and reliability.

Conclusion

Steam capacity and pressure requirements are the core technical determinants of oil-fired boiler selection. Capacity defines the energy output, burner size, and heat transfer design, while pressure determines material choice, safety features, and thermodynamic efficiency. An optimal balance between the two ensures not only high combustion efficiency and stable steam quality but also long-term operational reliability and cost-effectiveness. Engineers must always integrate these parameters with automation, fuel type, and maintenance considerations for sustainable boiler performance.

Why Is Fuel Type, Viscosity, and Quality Important for Combustion Performance in Oil-Fired Boilers?

Efficient and reliable combustion is the beating heart of every oil-fired boiler. Yet, many operational inefficiencies, excess emissions, and maintenance issues stem from improper fuel characteristics—particularly the type, viscosity, and quality of the fuel used. When these properties deviate from the design parameters, the result can be poor atomization, incomplete combustion, carbon deposits, increased fuel consumption, and even burner failures.

Fuel type, viscosity, and quality are critical for combustion performance because they directly determine how effectively fuel can be atomized, mixed with air, and burned in the furnace. Proper viscosity ensures fine droplet formation, correct fuel type ensures compatible energy content and ignition characteristics, and high fuel quality prevents fouling, corrosion, and incomplete combustion. Together, these parameters control flame stability, efficiency, and emission levels in oil-fired boilers.

In short, if the fuel doesn’t flow, atomize, or burn correctly, even the most sophisticated boiler system will underperform, leading to energy loss and equipment degradation.

All oil fuels perform equally in any combustion system.False

Different fuels have distinct viscosities, calorific values, and impurity levels, which require specific burner and preheating configurations.

Correct fuel viscosity improves atomization and flame stability.True

Proper viscosity ensures fine droplet formation, complete mixing with air, and uniform combustion, enhancing efficiency and reducing soot formation.

The Impact of Fuel Type on Combustion Efficiency

Oil-fired boilers can use various fuels—diesel, heavy fuel oil (HFO), light fuel oil (LFO), or bio-based oils—each with unique combustion characteristics. Selecting the correct type ensures compatibility with burner design, atomization pressure, and heating requirements.

| Fuel Type | Density (kg/m³) | Viscosity @ 50°C (cSt) | Calorific Value (MJ/kg) | Typical Application |

|---|---|---|---|---|

| Diesel (LDO) | 830–850 | 2–5 | 43.0 | Small to medium boilers |

| Light Fuel Oil (LFO) | 860–880 | 6–10 | 42.5 | Industrial heating |

| Heavy Fuel Oil (HFO 180 cSt) | 950–990 | 180 | 40.5 | Large power boilers |

| Biodiesel (B100) | 880–920 | 4–7 | 37.5 | Green retrofits |

| Marine Fuel Oil (MFO) | 970–1010 | 380 | 40.0 | Marine and large industrial units |

Heavy fuel oil offers the highest energy content among all oil fuels.False

Although dense, heavy fuel oil has slightly lower calorific value due to higher impurity and residual content compared to distillate oils.

Combustion Behavior by Fuel Type

Diesel/LFO: Easy ignition, clean burning, ideal for automatic start-stop cycles.

HFO: Requires preheating to 100–130°C for proper atomization, high ash and sulfur content.

Bio-oils: Renewable but may introduce higher moisture and oxygen content, reducing flame temperature.

Emulsified Fuels: Improve atomization but demand specialized burner design.

Why Viscosity Is the Critical Parameter for Atomization

Viscosity controls how fuel flows and breaks into droplets during injection. Too high viscosity results in large droplets and incomplete combustion; too low viscosity causes poor spray formation and burner instability.

| Viscosity Range (cSt) | Condition | Combustion Effect | Operational Result |

|---|---|---|---|

| <2 | Over-thin | Poor atomization | Flame instability |

| 8–12 | Optimal (for diesel/LFO) | Fine spray, uniform flame | High efficiency |

| 15–25 | Acceptable (for moderate oils) | Stable combustion | Moderate efficiency |

| >100 | Thick (for heavy oil) | Incomplete combustion | High soot and CO levels |

Viscosity has no significant effect on burner performance.False

Viscosity directly influences droplet formation and air-fuel mixing, affecting flame temperature and efficiency.

Viscosity Control Methods

Fuel Preheating:

HFO must be heated to 100–130°C before injection.

Reduces viscosity to 10–15 cSt (ideal range).

Fuel Blending:

Mixing HFO with lighter distillates to achieve operational viscosity.

Inline Viscosity Control:

Automatic viscosity controllers ensure consistent atomization even with variable fuel quality.

| Parameter | Without Control | With Viscosity Control |

|---|---|---|

| Atomization Quality | Variable | Stable |

| CO Emission (ppm) | 210 | 85 |

| Soot Index | High | Low |

| Fuel Efficiency (%) | 88 | 92 |

Preheating heavy fuel oil to reduce viscosity improves combustion efficiency.True

Preheating optimizes fuel flow and atomization, ensuring complete combustion and reducing soot formation.

Fuel Quality: Purity Defines Reliability

Fuel quality refers to chemical composition, impurity level, and contaminant content (water, ash, sulfur, or metals). Poor-quality fuels damage burners and reduce efficiency.

| Fuel Contaminant | Typical Source | Adverse Effect | Prevention Method |

|---|---|---|---|

| Water | Condensation, storage | Poor ignition, flameouts | Centrifugal separator |

| Ash | Residual crude, dirt | Slagging and fouling | Fuel filtration |

| Sulfur | Heavy oil fractions | SO₂, SO₃ formation | Low-sulfur fuel or scrubber |

| Vanadium/Nickel | Crude residue | High-temperature corrosion | Additives or fuel treatment |

Fuel impurities have minimal effect on boiler operation.False

Contaminants cause corrosion, scaling, and incomplete combustion, leading to lower efficiency and higher maintenance costs.

Example: Effect of Poor Fuel Quality

A refinery running on untreated HFO faced fouling in its atomizers and air preheaters. After installing a fuel purification system:

| Parameter | Before Purification | After Purification |

|---|---|---|

| Soot Emission (mg/Nm³) | 280 | 120 |

| Fuel Efficiency (%) | 88.3 | 91.7 |

| Maintenance Interval | Every 3 weeks | Every 8 weeks |

| Burner Tip Erosion | Severe | Minimal |

Relationship Between Fuel Quality, Viscosity, and Efficiency

| Fuel Condition | Viscosity (cSt) | Quality | Combustion Efficiency (%) | CO Emission (ppm) |

|---|---|---|---|---|

| Diesel (Clean) | 4 | Excellent | 93–95 | 80 |

| HFO (Untreated) | 180 | Poor | 85–88 | 220 |

| HFO (Preheated + Filtered) | 12 | Good | 91–93 | 95 |

| Biofuel (Unblended) | 6 | Moderate | 89–91 | 110 |

| Biofuel (Stabilized Blend) | 5 | High | 92–94 | 85 |

Treating heavy fuel oil before combustion can improve efficiency by up to 5%.True

Preheating, filtering, and chemical conditioning improve atomization, combustion completeness, and heat recovery efficiency.

Influence on Flame Pattern and Combustion Stability

Fuel characteristics directly affect flame geometry, temperature distribution, and emission profiles:

High viscosity → elongated, smoky flame (poor atomization).

Low viscosity → unstable, oscillating flame (poor air mixing).

Poor quality → yellowish flame with soot deposits (incomplete combustion).

Optimal viscosity and clean fuel → bright, steady blue flame (complete combustion).

| Flame Characteristic | Cause | Effect on Performance |

|---|---|---|

| Flickering or Pulsating Flame | Low viscosity or excess air | Instability, heat loss |

| Long Smoky Flame | High viscosity or poor mixing | Soot buildup |

| Steady Blue Flame | Correct atomization | Optimal combustion |

| Yellow Flame with Soot | Contaminated fuel | Fouling and emission rise |

A bright yellow flame indicates perfect combustion in oil-fired boilers.False

A yellow flame often signals incomplete combustion and soot formation; an ideal flame is blue and steady.

Design and Operational Adjustments Based on Fuel Properties

| Fuel Parameter | Design Adjustment | Operational Control | Monitoring Method |

|---|---|---|---|

| Viscosity | Preheater and pump selection | Maintain 10–15 cSt | Viscosity sensor |

| Sulfur Content | Corrosion-resistant materials | Flue gas scrubber | SO₂ analyzer |

| Water Content | Fuel heating & separator | Drain daily | Online moisture detector |

| Calorific Value | Burner capacity & nozzle sizing | Adjust firing rate | Fuel calorimeter |

Online viscosity control systems can automatically maintain ideal combustion conditions.True

Modern control systems adjust fuel temperature in real-time to stabilize viscosity, ensuring consistent atomization and efficiency.

Case Study: Viscosity Optimization in a 25 TPH HFO Boiler

| Parameter | Before Optimization | After Optimization |

|---|---|---|

| Fuel Temperature | 80°C | 120°C |

| Viscosity (cSt) | 85 | 12 |

| CO Emission (ppm) | 200 | 80 |

| Soot Index | High | Low |

| Boiler Efficiency (%) | 87.4 | 92.1 |

| Burner Maintenance Interval | 2 weeks | 6 weeks |

This industrial case proved that proper viscosity control and fuel conditioning directly enhance performance, reduce emissions, and extend equipment life.

Future Trends: Smart Fuel Management

| Innovation | Function | Benefit |

|---|---|---|

| AI-Based Fuel Blending | Adjusts fuel properties dynamically | Ensures optimal viscosity |

| Real-Time Fuel Analysis | Monitors impurities online | Prevents fouling |

| Adaptive Combustion Control | Links viscosity and flame sensors | Maintains steady flame |

| Renewable Biofuel Integration | Hybrid operation | Reduces carbon footprint |

| Nanotechnology Additives | Enhance atomization | Improve heat release and reduce soot |

AI-based fuel control systems can automatically adjust preheating and air ratios for maximum efficiency.True

AI algorithms analyze combustion data and adjust fuel and air parameters to maintain optimal atomization and flame temperature.

Conclusion

In oil-fired boiler systems, fuel type, viscosity, and quality are fundamental parameters that determine combustion efficiency, stability, and reliability. Selecting the correct fuel type ensures compatibility with burner and furnace design, maintaining the right viscosity guarantees fine atomization and clean burning, while high-quality fuel prevents fouling, corrosion, and emission problems. Together, they define the true performance and lifecycle economics of any oil-fired combustion system.

How Does Boiler Efficiency and Heat Exchanger Design Affect Fuel Economy?

In today’s energy-intensive industries, the cost of fuel is one of the most significant operating expenses. Yet, many facilities unknowingly waste up to 20–30% of their fuel energy due to inefficient boiler operation and suboptimal heat exchanger design. The consequences include not only higher fuel bills, but also increased CO₂ emissions, reduced equipment lifespan, and greater maintenance frequency. The solution lies in improving boiler efficiency through advanced heat exchanger engineering, ensuring that every joule of fuel energy is effectively converted into useful steam or hot water output.

Boiler efficiency and heat exchanger design directly determine fuel economy because they control how effectively the combustion heat is transferred to the working fluid (water or steam). Efficient heat exchangers with optimized surface area, material selection, and gas flow geometry maximize heat recovery from flue gases, minimize losses, and reduce fuel consumption per unit of output. In simple terms, better heat transfer equals lower fuel costs and higher operational profitability.

Understanding how thermal performance and heat recovery design interplay is crucial for industries striving for sustainable and cost-effective energy use. Let’s explore this relationship in depth.

Boiler efficiency improvements have negligible impact on fuel economy.False

Even a 1% improvement in boiler efficiency can yield significant annual fuel savings and emission reductions.

Optimized heat exchanger design enhances thermal transfer and reduces fuel waste.True

Modern designs maximize flue gas heat recovery and minimize stack losses, directly improving fuel economy.

The Fundamentals: What Defines Boiler Efficiency?

Boiler efficiency measures how much of the fuel’s energy content is converted into usable heat. It depends on combustion performance, heat transfer effectiveness, and thermal losses through flue gases, walls, and unburned fuel.

| Efficiency Type | Definition | Typical Value (%) | Influence on Fuel Economy |

|---|---|---|---|

| Combustion Efficiency | Heat released vs. theoretical fuel energy | 90–94 | Ensures complete burning |

| Thermal Efficiency | Heat absorbed by steam vs. heat available | 85–92 | Determines heat exchanger performance |

| Overall Boiler Efficiency | Net steam energy vs. fuel energy | 80–90 | Determines total fuel use |

| Condensing Efficiency | Includes latent heat recovery | 90–98 | Enables ultra-efficient systems |

Boiler efficiency above 95% is impossible in conventional non-condensing systems.True

Only condensing boilers utilizing flue gas condensation can achieve efficiencies above 95%.

A 1% rise in boiler efficiency often translates into a 2–3% reduction in fuel consumption, especially in large industrial boilers operating continuously.

The Role of Heat Exchanger Design in Fuel Economy

The heat exchanger is the heart of the boiler, where the transfer of energy from hot combustion gases to water or steam occurs. Its design determines how effectively this heat exchange happens.

Key Design Parameters Influencing Fuel Efficiency

| Parameter | Design Focus | Effect on Efficiency |

|---|---|---|

| Heat Transfer Area | Larger surface improves heat absorption | Reduces fuel requirement |

| Gas Velocity | Balanced flow avoids erosion and improves heat pickup | Enhances convective transfer |

| Tube Geometry | Finned, corrugated, or spiral tubes increase turbulence | Boosts efficiency |

| Material Conductivity | High thermal conductivity materials (Cu, Inconel) | Improves heat transfer |

| Fouling Resistance | Smooth surfaces reduce deposit formation | Maintains consistent efficiency |

Design Comparison Example

| Boiler Type | Heat Exchanger Design | Efficiency (%) | Fuel Use (kg/hr) |

|---|---|---|---|

| Fire-Tube (Conventional) | Plain tubes | 82 | 550 |

| Fire-Tube (Finned Tube) | Extended surface | 88 | 495 |

| Water-Tube (Economizer Integrated) | Multi-pass + economizer | 91 | 470 |

| Condensing Boiler | Heat recovery from condensate | 96 | 445 |

Adding finned or extended surfaces can increase boiler efficiency by 5–7%.True

Extended surface area increases gas-side turbulence and heat transfer rates, enhancing efficiency.

Heat Exchanger Efficiency and Flue Gas Heat Recovery

Flue gases leaving a boiler still contain substantial heat energy. Economizers and air preheaters recover this energy and feed it back into the system.

Heat Recovery Components

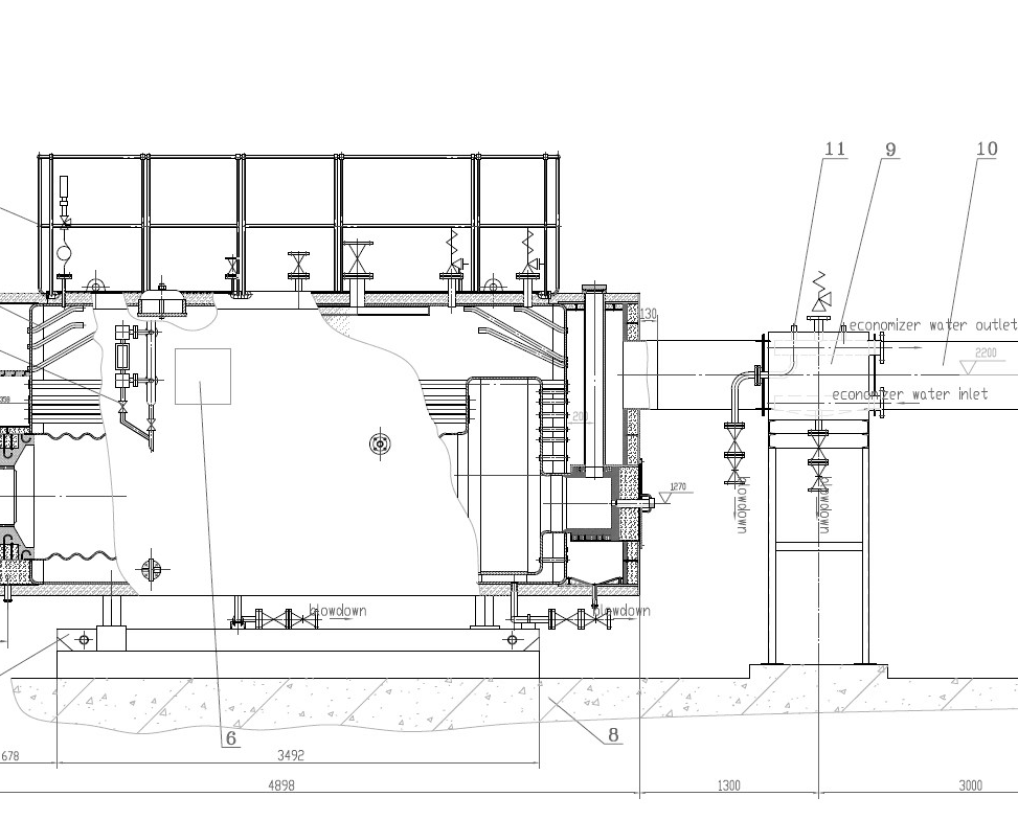

Economizer: Transfers flue gas heat to boiler feedwater, reducing the fuel needed to reach steam temperature.

Air Preheater: Warms combustion air using flue gas, improving flame temperature and combustion stability.

Condensing Heat Exchanger: Captures latent heat by cooling exhaust gases below dew point.

| Component | Temperature Recovery (°C) | Efficiency Gain (%) | Fuel Savings (%) |

|---|---|---|---|

| Economizer | 60–80 | 4–6 | 2–4 |

| Air Preheater | 30–50 | 2–4 | 1–2 |

| Condenser | 50–70 | 6–10 | 4–6 |

Economizers only recover sensible heat, not latent heat.True

Economizers operate above dew point, capturing sensible heat from flue gases, while condensing exchangers recover latent heat.

Case Study: Economizer Integration and Fuel Savings

A textile plant operating a 10 TPH diesel-fired boiler installed an economizer system to recover 75°C from flue gases.

| Parameter | Before Economizer | After Economizer |

|---|---|---|

| Feedwater Temp (°C) | 60 | 135 |

| Flue Gas Temp (°C) | 240 | 165 |

| Boiler Efficiency (%) | 84.5 | 90.1 |

| Fuel Consumption (kg/hr) | 580 | 520 |

| Annual Fuel Savings (tons) | – | 1,200 |

This 6% efficiency improvement translated to a 10% reduction in annual fuel cost, proving the link between heat exchanger design and fuel economy.

Thermal Losses and Their Control

Heat loss mechanisms—radiation, convection, and exhaust—directly determine fuel wastage.

| Loss Type | Cause | Fuel Impact | Mitigation Method |

|---|---|---|---|

| Flue Gas Loss | High exhaust temperature | 10–20% | Economizer or condenser |

| Radiation Loss | Poor insulation | 1–2% | Insulated casing |

| Unburnt Fuel | Poor combustion | 2–5% | Air-fuel ratio control |

| Blowdown Loss | Excessive water discharge | 1–2% | Heat recovery from blowdown |

Flue gas losses are negligible in modern boiler systems.False

Even high-efficiency systems can lose up to 15% energy through flue gases without recovery devices.

Relationship Between Boiler Efficiency and Fuel Economy

| Efficiency Level (%) | Fuel Economy Gain (%) | CO₂ Reduction (%) |

|---|---|---|

| 80 | – | – |

| 85 | 5.9 | 6.2 |

| 90 | 11.8 | 12.5 |

| 95 | 17.6 | 18.8 |

| 98 (Condensing) | 21.2 | 22.5 |

Even incremental gains lead to exponential economic and environmental benefits.

An efficiency increase from 85% to 90% can reduce fuel consumption by approximately 6%.True

Higher efficiency directly reduces the amount of fuel required to achieve the same steam output.

Advanced Heat Exchanger Designs for Maximum Efficiency

1. Spiral and Helical Tube Economizers

Enhance turbulence and promote uniform heat distribution.

2. Dual-Pass Condensing Exchangers

Recover latent and sensible heat simultaneously.

3. Waste Heat Boilers (WHRB)

Utilize flue gases from gas turbines or process furnaces to generate steam without additional fuel.

4. Ceramic Coated Tubes

Provide resistance to corrosion and fouling, maintaining performance longer.

| Design Type | Efficiency Improvement (%) | Maintenance Interval (Months) | Lifespan (Years) |

|---|---|---|---|

| Plain Tube | – | 3 | 10 |

| Finned Tube | +5 | 6 | 12 |

| Spiral Tube | +8 | 8 | 14 |

| Condensing Tube | +10 | 10 | 15 |

Spiral tube economizers increase heat recovery compared to straight tubes.True

Helical geometry creates turbulence that improves convective heat transfer and reduces fouling.

Practical Design Considerations

Material Selection: Use alloys with high thermal conductivity and corrosion resistance.

Flow Pattern Optimization: Ensure counterflow design to maximize temperature differential.

Maintenance Accessibility: Allow easy cleaning of heat exchanger surfaces.

Instrumentation: Use thermocouples and flow sensors to track real-time efficiency.

Condensate Management: For condensing exchangers, prevent acid corrosion by neutralization systems.

Counterflow heat exchangers are less efficient than parallel flow systems.False

Counterflow designs maintain a higher average temperature difference, yielding better thermal performance.

Example: Heat Exchanger Retrofitting Payback Analysis

| Retrofit Type | Cost (USD) | Efficiency Gain (%) | Fuel Savings (USD/Year) | Payback Period (Years) |

|---|---|---|---|---|

| Economizer | 45,000 | 6 | 35,000 | 1.3 |

| Air Preheater | 25,000 | 3 | 18,000 | 1.4 |

| Condensing Heat Exchanger | 65,000 | 10 | 50,000 | 1.2 |

Fuel economy improvements often yield payback in less than 18 months, with continuing savings throughout the equipment lifetime.

Future Innovations in Boiler Heat Transfer Efficiency

| Technology | Function | Impact on Efficiency | Fuel Economy Benefit |

|---|---|---|---|

| Nanofluid Heat Transfer Media | Increases thermal conductivity | +3–5% | Reduced fuel demand |

| AI-Based Efficiency Monitoring | Optimizes combustion and heat balance | +2–4% | Continuous optimization |

| Phase-Change Material Heat Recovery | Stores and reuses waste heat | +6–8% | Enhanced thermal recycling |

| 3D Printed Heat Exchangers | Custom surface geometry | +5–7% | Lightweight, high-efficiency |

AI and IoT technologies have no role in boiler fuel economy improvement.False

Smart monitoring and control technologies optimize combustion and heat exchange for maximum fuel savings.

Conclusion

Boiler efficiency and heat exchanger design are inseparable factors that define fuel economy, operational reliability, and environmental impact. An efficient heat exchanger ensures that maximum heat from combustion is transferred to the process fluid, while modern recovery systems like economizers, air preheaters, and condensers reduce waste and fuel costs. For industries seeking energy security and sustainability, optimizing heat exchange design is not optional—it’s essential.

What Emission Control Technologies Ensure Compliance with Environmental Standards?

Stringent global and regional environmental regulations—such as the EU Industrial Emissions Directive (IED), the U.S. Clean Air Act, and local standards like India’s CPCB norms—demand that modern boilers and power plants drastically limit emissions of NOx, SO₂, CO₂, and particulate matter (PM). Non-compliance results not only in environmental harm but also in severe financial penalties, production restrictions, and reputational loss. The solution lies in the integration of advanced emission control technologies that ensure both regulatory compliance and sustainable operation without compromising efficiency.

Modern emission control technologies—such as Selective Catalytic Reduction (SCR), Flue Gas Desulfurization (FGD), Electrostatic Precipitators (ESP), and Low-NOx Burners—are essential for ensuring compliance with environmental standards. These systems effectively remove nitrogen oxides, sulfur oxides, particulates, and volatile organic compounds from flue gases. Integration of these technologies, often supported by Continuous Emission Monitoring Systems (CEMS), helps plants achieve ultra-low emission limits while maintaining fuel flexibility and thermal efficiency.

As emissions limits become stricter worldwide, power producers must transition from basic control methods to multi-stage hybrid systems combining mechanical, chemical, and catalytic processes.

Boiler emission compliance can be achieved solely by optimizing combustion.False

While efficient combustion reduces some emissions, advanced technologies such as SCR, FGD, and ESP are required to meet modern environmental standards.

Electrostatic precipitators are the most effective technology for particulate matter removal in large boilers.True

ESP systems achieve over 99.9% particulate removal efficiency, even under high flue gas volumes.

1. Nitrogen Oxides (NOx) Reduction Technologies

NOx emissions form primarily due to high flame temperatures and excess oxygen during combustion. Controlling NOx involves both primary (combustion-level) and secondary (post-combustion) methods.

1.1 Primary NOx Control – Combustion Optimization

| Technology | Principle | Reduction Efficiency | Advantages |

|---|---|---|---|

| Low-NOx Burners (LNB) | Control air–fuel ratio and flame temperature | 40–60% | Simple retrofit, low cost |

| Overfire Air (OFA) | Injects air above main combustion zone | 20–40% | Reduces thermal NOx |

| Flue Gas Recirculation (FGR) | Mixes cool flue gas with combustion air | 30–50% | Lowers flame temperature |

1.2 Secondary NOx Control – Post-Combustion Technologies

| Technology | Operating Temperature (°C) | NOx Removal Efficiency | Key Reactant |

|---|---|---|---|

| Selective Non-Catalytic Reduction (SNCR) | 850–1100 | 40–70% | Ammonia or urea |

| Selective Catalytic Reduction (SCR) | 300–400 | 90–98% | Ammonia over V₂O₅/TiO₂ catalyst |

SCR systems are now standard in ultra-supercritical (USC) and CFB boilers due to their high removal efficiency and adaptability across varying loads.

Selective Catalytic Reduction (SCR) systems can remove up to 98% of NOx from flue gas.True

Ammonia reacts with NOx in the presence of a catalyst to form nitrogen and water, achieving nearly complete reduction.

2. Sulfur Oxides (SO₂) and Acid Gas Removal Technologies

SO₂ forms during combustion of sulfur-bearing fuels like coal and heavy oil. Flue Gas Desulfurization (FGD) systems chemically remove SO₂ before stack discharge.

| FGD Type | Process | Typical Efficiency | Reagent | Byproduct |

|---|---|---|---|---|

| Wet Limestone FGD | Absorbs SO₂ in slurry | 95–99% | CaCO₃ | Gypsum (CaSO₄·2H₂O) |

| Dry/Semi-Dry FGD | Spray-dryer with hydrated lime | 85–95% | Ca(OH)₂ | Dry salts |

| Seawater FGD | Uses natural alkalinity of seawater | 90–95% | Seawater | Neutralized effluent |

Flue Gas Desulfurization (FGD) removes sulfur oxides by chemical absorption.True

FGD systems use calcium-based reagents to convert SO₂ into stable gypsum or dry salts for safe disposal or reuse.

Case Example: Wet FGD Implementation

A 500 MW coal-fired plant reduced SO₂ emissions from 1600 mg/Nm³ to 40 mg/Nm³ after installing a limestone FGD system.

| Parameter | Before FGD | After FGD | Reduction |

|---|---|---|---|

| SO₂ Concentration (mg/Nm³) | 1600 | 40 | -97.5% |

| Gypsum Yield (tons/day) | 0 | 520 | +520 |

| Power Penalty (%) | 0 | 1.5 | Minor efficiency loss |

3. Particulate Matter (PM) Control Technologies

Fine particulates (PM₂.₅ and PM₁₀) cause air pollution and equipment fouling. Modern plants employ Electrostatic Precipitators (ESP) and Fabric Filters (Baghouses) to meet <10 mg/Nm³ limits.

| Technology | Removal Mechanism | Efficiency | Typical Particle Size Captured |

|---|---|---|---|

| Electrostatic Precipitator (ESP) | Ionization and electrostatic attraction | 99.9% | >0.1 µm |

| Fabric Filter (Baghouse) | Mechanical filtration through fabric | 99.95% | >0.05 µm |

| Cyclone Separator | Centrifugal separation | 70–90% | >10 µm |

Electrostatic precipitators and baghouses can achieve sub-10 mg/Nm³ particulate levels.True

Both systems provide extremely high removal efficiency for fine particulates, suitable for modern emission norms.

ESP Operational Optimization Table

| Parameter | Ideal Range | Effect on Performance |

|---|---|---|

| Gas Temperature | 120–160°C | Optimal ionization |

| Dust Resistivity | 10⁷–10⁹ Ω·cm | Ensures effective charging |

| Voltage Gradient | 40–60 kV/cm | Maximizes collection |

| Rapping Frequency | 10–30 min | Prevents re-entrainment |

4. Carbon and Volatile Organic Compound (VOC) Controls

| Technology | Pollutant Target | Removal Principle | Efficiency |

|---|---|---|---|

| Carbon Capture and Storage (CCS) | CO₂ | Absorption in amine or carbonate solution | 85–95% |

| Activated Carbon Injection (ACI) | Mercury, VOCs, Dioxins | Adsorption | 80–95% |

| Catalytic Oxidizers | VOCs, CO | Oxidation to CO₂/H₂O | 90–98% |

Activated carbon systems are effective for mercury and dioxin removal.True

Activated carbon’s large surface area adsorbs heavy metals and organic pollutants from flue gases.

5. Integration of Multi-Pollutant Control Systems

Modern plants often combine systems to minimize footprint and cost.

| Hybrid System | Components | Advantages |

|---|---|---|

| SCR + ESP + FGD | NOx, PM, SO₂ | Complete emission solution |

| SNCR + Baghouse + Dry FGD | NOx, PM, SO₂ | Compact design for smaller plants |

| SCR + ACI + Wet FGD | NOx, Hg, SO₂ | Mercury and acid gas removal |

Example: 660 MW Supercritical Unit Compliance Data

| Pollutant | Pre-Control (mg/Nm³) | Post-Control (mg/Nm³) | Reduction Efficiency |

|---|---|---|---|

| NOx | 450 | 60 | 87% |

| SO₂ | 1600 | 35 | 97.8% |

| PM | 120 | 7 | 94% |

| Hg | 0.09 | 0.01 | 89% |

Hybrid emission systems can achieve over 90% reduction for all major pollutants.True

Integrating SCR, FGD, and ESP technologies ensures comprehensive pollutant control within ultra-low emission limits.

6. Continuous Emission Monitoring Systems (CEMS)

CEMS provide real-time compliance verification and help optimize system performance.

| Parameter Monitored | Measurement Method | Data Use |

|---|---|---|

| NOx, SO₂ | UV/IR analyzers | Compliance & optimization |

| CO₂, O₂ | Non-dispersive infrared | Combustion efficiency |

| PM | Opacity meters | ESP control tuning |

| Flow, Temp, Pressure | Differential sensors | Mass balance tracking |

Continuous emission monitoring is optional for regulated boilers.False

CEMS are mandatory under most environmental laws to ensure continuous compliance and data reporting.

Conclusion

Emission control is no longer just about compliance—it’s about operational integrity, corporate responsibility, and sustainable performance. By integrating SCR, FGD, ESP, baghouses, and carbon control systems, modern power plants can achieve near-zero emissions while maintaining high efficiency and reliability. The future of boiler design lies in smart, multi-pollutant hybrid systems combined with digital monitoring and predictive analytics for continuous environmental assurance.

How Do Automation, Burner Tuning, and Control Systems Improve Reliability?

Power plant and industrial boiler operators face the constant challenge of balancing efficiency, safety, and uptime. A minor combustion imbalance, delayed operator response, or control system fault can lead to fuel wastage, thermal stress, emission spikes, or unplanned shutdowns, costing thousands of dollars in downtime. The modern solution is found in automation, burner tuning, and integrated control systems, which work together to maintain stable combustion, real-time process optimization, and predictive reliability.

Automation, burner tuning, and control systems improve reliability by maintaining optimal air-to-fuel ratios, monitoring critical process variables in real time, and ensuring consistent performance through predictive maintenance and fault diagnostics. Advanced digital control platforms automatically adjust combustion parameters, detect anomalies, and stabilize steam output, minimizing human error and equipment wear. This integration enhances system responsiveness, prolongs equipment life, reduces unplanned outages, and improves both efficiency and emissions compliance.

The result is not merely operational convenience—it’s the transformation of boiler systems into intelligent, self-regulating assets that deliver stable energy production with reduced risk and maximum reliability.

Automation only helps to reduce operator workload without improving performance.False

Automation systems enhance both operator efficiency and process reliability by continuously optimizing combustion and safety parameters.

Proper burner tuning can improve boiler efficiency and extend component life.True

Accurate burner adjustment ensures complete combustion, reducing fuel waste, carbon buildup, and thermal stress on components.

The Core Functions of Automation and Burner Control

| Function | Purpose | Effect on Reliability | Example Technology |

|---|---|---|---|

| Combustion Control | Maintain air/fuel balance | Reduces flame instability | Oxygen trim control |

| Drum Level Control | Maintain water-steam balance | Prevents tube damage | 3-element control |

| Burner Management System (BMS) | Safe startup/shutdown | Prevents explosions | PLC-based BMS |

| Feedwater Control | Optimize feed rate | Prevents thermal shock | PID control loops |

| Emission Monitoring | Track NOx/CO levels | Ensures compliance | Continuous Emission Monitoring System (CEMS) |

| Predictive Maintenance | Early fault detection | Avoids unplanned downtime | AI-based monitoring |

PID control loops help maintain process variables within tight limits, ensuring stable operation.True

PID algorithms continuously adjust control elements to minimize deviations in temperature, pressure, or flow.

1. Automation and Control Integration

Automation systems, such as Distributed Control Systems (DCS) or Programmable Logic Controllers (PLC), form the backbone of modern boiler operation. They integrate multiple control loops, from combustion to feedwater, under a unified digital interface.

Key Automation Components Include:

PLC/DCS Platform: Coordinates sensors, actuators, and control valves.

Human Machine Interface (HMI): Provides real-time monitoring dashboards.

Field Instrumentation: Measures pressure, temperature, oxygen, and fuel flow.

Networking (Ethernet/Modbus): Links systems for data acquisition and control.

| System Level | Control Function | Technology Example |

|---|---|---|

| Level 1 | Field Control (Sensors/Actuators) | Smart transmitters, VFDs |

| Level 2 | Supervisory Control | PLC/DCS controllers |

| Level 3 | Data Integration | SCADA, Historian |

| Level 4 | Plant-Wide Optimization | AI-based energy management |

Automation increases reliability by removing manual dependencies, maintaining precise responses to load changes, and automatically compensating for disturbances such as fuel variation or air leakage.

Automation reduces the need for human supervision but cannot improve safety.False

Integrated control systems enhance safety by executing automatic interlocks, shutdowns, and flame monitoring far faster than manual intervention.

2. Burner Tuning: The Foundation of Efficient and Reliable Combustion

Burner tuning is the process of adjusting air/fuel ratios, flame shape, and temperature distribution to achieve optimal combustion performance.

Key Benefits of Proper Burner Tuning:

Stable Flame: Prevents flameouts and minimizes incomplete combustion.

Reduced Soot Formation: Keeps heat transfer surfaces clean.

Optimized Fuel Usage: Reduces excess air and fuel wastage.

Lower NOx and CO Emissions: Maintains environmental compliance.

| Parameter | Before Tuning | After Tuning | Improvement (%) |

|---|---|---|---|

| O₂ in Flue Gas (%) | 6.0 | 3.0 | 50 |

| CO Emission (ppm) | 180 | 40 | 78 |

| Thermal Efficiency (%) | 84.5 | 88.0 | 4.1 |

| Steam Pressure Stability | ±3 bar | ±0.5 bar | 83 |

Excess air always improves combustion efficiency.False

Too much excess air cools the flame and increases stack losses, reducing overall thermal efficiency.

Advanced Burner Control Features:

O₂ Trim Control: Adjusts air dampers automatically based on flue gas oxygen measurement.

Cross-Limited Control: Synchronizes fuel and air flow to avoid rich or lean conditions.

Fuzzy Logic Algorithms: Continuously optimize parameters using pattern recognition.

Oxygen trim systems automatically maintain optimal air-to-fuel ratio across varying loads.True

O₂ trim systems measure residual oxygen in the flue gas and fine-tune combustion air, maintaining peak efficiency.

3. Control System Reliability and Redundancy

Reliability in automation isn’t just about control—it’s about resilience. Modern systems incorporate redundant architectures and fail-safe logic to ensure continuous operation even during component failures.

| Reliability Feature | Function | Benefit |

|---|---|---|

| Dual PLC Processors | Backup control brain | Seamless failover |

| Hot-Standby Mode | Real-time backup activation | No downtime |

| Redundant I/O Modules | Backup sensor inputs | Fault isolation |

| Dual Communication Networks | Parallel data paths | Reliable connectivity |

| UPS-Backed Power | Backup supply | Prevents power interruption |

Redundant PLC architecture increases system uptime and safety.True

Parallel processors and hot-standby systems take over instantly during faults, preventing process disruption.

Additionally, diagnostic algorithms continuously monitor control loops, sensor health, and actuator performance. Faults are flagged early, allowing predictive maintenance before failure occurs.

4. Data Analytics and Predictive Maintenance

Smart control systems now include Industrial Internet of Things (IIoT) connectivity and machine learning analytics to identify performance trends.

Predictive Insights Include:

Burner flame stability trends

Valve response time degradation

Feedwater pump vibration anomalies

Oxygen sensor drift detection

| Monitoring Parameter | Tool Used | Predictive Insight |

|---|---|---|

| Flue Gas Composition | CEMS + AI Analytics | Detects incomplete combustion |

| Vibration Data | Accelerometers + ML | Predicts mechanical failure |

| Steam Flow Variations | Historian + Pattern Models | Detects tube fouling |

| Temperature Fluctuations | Thermal Sensors | Identifies scaling or insulation loss |

Predictive analytics can only analyze historical data but cannot predict failures.False

Modern AI models learn from operational patterns and predict upcoming equipment anomalies before they cause downtime.

These predictive insights transform maintenance from reactive to proactive, reducing unexpected shutdowns and increasing mean time between failures (MTBF).

5. Integrated Safety Management

Safety interlocks and burner management systems (BMS) are the foundation of reliable combustion operation.

A PLC-based BMS automates sequences such as purging, ignition, flame detection, and emergency shutdown.

| BMS Function | Purpose | Effect |

|---|---|---|

| Pre-Ignition Purge | Removes residual fuel vapors | Prevents explosions |

| Flame Monitoring | Detects flame-out instantly | Automatic trip |

| Fuel Valve Interlock | Shuts fuel line during fault | Enhances safety |

| Startup Sequencing | Controls ignition and warm-up | Consistent startup |

| Emergency Shutdown | Manual and automatic triggers | Prevents accidents |

Burner Management Systems eliminate the risk of furnace explosions.True

Automated purge and interlock sequences ensure safe ignition and shutdown, reducing explosion risk to near zero.

6. Performance and Economic Impact of Automation and Tuning

| Parameter | Without Automation | With Automation + Tuning | Improvement (%) |

|---|---|---|---|

| Boiler Availability | 89% | 98% | +9 |

| Maintenance Downtime (hrs/year) | 260 | 100 | –61 |

| Fuel Efficiency | 84% | 90% | +7 |

| Emission Compliance Incidents | 12/year | 1/year | –92 |

| Operating Cost Reduction | — | 5–8% | — |

Automation and tuning can reduce operating costs and emissions simultaneously.True

Optimized combustion and predictive controls lower fuel use and emissions, directly reducing costs and environmental impact.

Conclusion

Automation, burner tuning, and control systems form the triad of reliability in modern boiler and power plant operations. Together, they maintain precise combustion control, ensure stable load response, and preemptively identify failures. By merging real-time data analytics, smart tuning, and safety automation, industries achieve higher uptime, longer equipment life, and cleaner energy production—the cornerstones of operational excellence.

What Role Do Materials, Layout, and Maintenance Features Play in Long-Term Performance?

In power plants and industrial heating systems, long-term performance isn’t determined by combustion control alone—it’s built into the very materials, structural layout, and maintenance accessibility of the boiler itself. Poor material choices can lead to corrosion, fatigue, and costly failures, while suboptimal layouts can increase pressure drop, fouling, and maintenance complexity. Over time, these issues degrade thermal efficiency, reliability, and operational lifespan. The solution lies in engineering design optimization, where materials, layout geometry, and maintenance provisions work in harmony to deliver decades of dependable performance.

Materials, layout, and maintenance features directly influence the long-term performance of a boiler by determining its resistance to thermal stress, corrosion, fouling, and mechanical wear. High-grade materials such as chromium-molybdenum steels and Inconel alloys ensure structural durability under high temperatures and pressures. Optimized tube and component layouts enhance heat transfer, reduce pressure loss, and improve cleaning accessibility. Integrated maintenance features—like inspection ports, soot blowers, and modular designs—enable preventive servicing and reduce downtime. Together, these design factors extend boiler life, maintain efficiency, and lower lifecycle costs.

The engineering of a high-performance boiler is therefore as much about its physical integrity and maintainability as it is about combustion or automation.

Material selection has little impact on the operational life of boilers.False

Material properties such as creep strength, corrosion resistance, and thermal expansion directly determine boiler durability under high stress.

Proper component layout and maintenance design reduce long-term maintenance costs.True

Optimized accessibility and cleaning design minimize downtime and increase operational availability.

1. Material Selection and Metallurgical Integrity

Boiler components operate under extreme conditions—high temperature, pressure, and corrosive flue gases. Material selection dictates how well each component resists degradation.

| Boiler Component | Typical Material | Key Property | Failure Risk if Improperly Selected |

|---|---|---|---|

| Furnace Walls | 15Mo3, SA-213 T11 | High-temperature strength | Thermal fatigue |

| Superheaters | Inconel 625, T22 | Oxidation resistance | Scaling, creep |

| Economizers | Carbon steel (SA-210) | Corrosion resistance | Pitting |

| Air Preheaters | Corten steel | Oxidation and corrosion protection | Rust, fouling |

| Drums/Headers | SA-299, SA-106 | Pressure strength | Cracking |

| Tubes (CFB or Oil-fired) | 347H, T23, T91 | High creep and thermal stability | Tube rupture |

Using low-alloy steels in high-temperature zones can cause premature failure.True

Low-alloy steels lack the creep strength and oxidation resistance required for sustained high-temperature service.

Corrosion-Resistant Alloys

In areas exposed to sulfur oxides or chlorides—especially in biomass and oil-fired boilers—high-chromium and nickel alloys provide longer service life.

Chromium (Cr) forms a protective oxide layer.

Molybdenum (Mo) enhances resistance to pitting corrosion.

Nickel (Ni) improves ductility and thermal fatigue resistance.

| Alloy | Max Service Temp (°C) | Corrosion Resistance | Application Zone |

|---|---|---|---|

| Inconel 625 | 980 | Excellent | Superheater tubes |

| T91 (9Cr-1Mo) | 650 | Very good | Furnace walls |

| 347H SS | 700 | Good | Economizer outlet |

| Corten Steel | 450 | Moderate | Air preheater sections |

Inconel alloys are ideal for superheater applications due to superior oxidation resistance.True

Inconel’s nickel-chromium matrix maintains surface integrity even under high thermal loads and oxidizing conditions.

2. Boiler Layout and Flow Optimization

A boiler’s internal and external layout determines how efficiently heat, mass, and gases flow through its system. Poor layout design causes pressure imbalances, uneven heating, or localized hot spots.

Key Layout Principles for Long-Term Reliability:

Symmetrical Heat Distribution: Avoids thermal stress on tube banks.

Optimized Gas Flow Paths: Ensures complete heat utilization and prevents erosion.

Reduced Dead Zones: Prevents ash accumulation and localized corrosion.

Modular Arrangement: Simplifies transport, assembly, and maintenance.

| Design Parameter | Poor Design Impact | Optimized Design Benefit |

|---|---|---|

| Gas Velocity Too High | Tube erosion | Uniform heat transfer |

| Uneven Tube Spacing | Slag deposition | Balanced flow |

| Tight Layout | Difficult cleaning | Easy access |

| Long Gas Path | High pressure drop | Reduced energy loss |

Optimizing tube layout improves both heat transfer and maintainability.True

Even tube spacing and proper flue gas velocity enhance thermal performance and reduce fouling accumulation.

Case Example:

A 100 TPH (ton per hour) CFB boiler redesign improved layout efficiency:

Gas velocity reduced from 6.5 to 5.0 m/s

Tube erosion dropped by 40%

Maintenance intervals extended from 6 to 12 months

| Parameter | Before Layout Optimization | After Optimization | Improvement |

|---|---|---|---|

| Flue Gas Velocity (m/s) | 6.5 | 5.0 | -23% |

| Erosion Rate (mm/year) | 1.2 | 0.7 | -42% |

| Maintenance Interval (months) | 6 | 12 | +100% |

3. Maintenance Accessibility and Design for Serviceability

A critical, yet often overlooked, aspect of long-term reliability is how easily a system can be inspected, cleaned, and repaired. Maintenance-friendly design directly affects plant uptime.

Essential Maintenance Design Features:

Manholes and Handholes: Allow tube and drum inspections.

Removable Panels and Doors: Enable easy access to burners, fans, and valves.

Soot Blowers and Water Blasters: Prevent fouling on heat transfer surfaces.

On-line Monitoring Ports: Facilitate real-time diagnostics.

Quick-Disconnect Piping: Reduces repair downtime.

| Feature | Purpose | Reliability Impact |

|---|---|---|

| Soot Blower | Removes ash/slag | Maintains heat transfer efficiency |

| Inspection Port | Visual checks | Early defect detection |

| Access Ladder/Platform | Safe maintenance | Reduces accident risk |

| Online Temperature Sensors | Detects hotspots | Prevents tube failure |

| Modular Casing Design | Easy component replacement | Reduces downtime |

Regular soot blowing helps maintain boiler efficiency by keeping heat transfer surfaces clean.True

Ash and soot accumulation reduce heat exchange; soot blowers restore thermal performance by removing deposits.

Design for Predictive Maintenance

Smart design integrates sensors and diagnostics directly into the structure.

Corrosion probes track metal thinning.

Acoustic sensors detect tube leaks.

Thermocouples identify scaling or hot spots early.

Integrating monitoring sensors in design improves predictive maintenance accuracy.True

Sensors provide real-time feedback, enabling proactive repairs before catastrophic failures occur.

4. Thermal Stress Management and Expansion Design

Boilers constantly expand and contract due to temperature cycling. Without proper design for expansion, thermal stress cracks and joint failures occur.

Thermal Design Considerations:

Expansion Bellows and Sliding Joints accommodate differential movement.

Flexible Tube Bends prevent stress concentration.

Refractory Linings shield metal from direct flame exposure.

| Design Feature | Function | Effect on Reliability |

|---|---|---|

| Bellows | Absorb expansion | Prevents cracking |

| Floating Headers | Allow differential movement | Reduces fatigue |

| Tube Bends | Flexibility in high-stress zones | Extends life |

| Refractory Coating | Insulation & protection | Minimizes heat damage |

Thermal expansion joints are unnecessary in small boilers.False

Even small units experience cyclic thermal expansion that can cause stress cracking if unmitigated.

5. Coatings and Surface Treatments for Longevity

Protective coatings reduce oxidation, corrosion, and slag adhesion.

| Coating Type | Application | Effect |

|---|---|---|

| Ceramic Coating | Furnace walls | Reflects radiant heat |

| Aluminum Diffusion | Superheaters | Prevents oxidation |

| Thermal Spray (Inconel) | Economizers | Resists erosion |

| Anti-Fouling Paint | Air preheaters | Reduces particulate deposition |

Protective coatings can double component lifespan in high-temperature zones.True

Surface coatings resist oxidation and erosion, significantly reducing metal loss rates.

6. Comparative Impact of Design and Maintenance Choices

| Aspect | Standard Design | Optimized Design | Performance Improvement |

|---|---|---|---|

| Tube Material | Carbon Steel | Alloy Steel T23 | +35% lifespan |

| Tube Layout | Dense Packing | Optimized Pitch | +12% efficiency |

| Maintenance Access | Limited | Full Access Ports | –50% downtime |

| Soot Cleaning | Manual | Auto Soot Blowers | +4% heat transfer |

| Sensor Integration | None | Smart Monitoring | +20% reliability |

Material, layout, and maintenance optimization together deliver exponential reliability improvements.True

Integrated engineering design reduces mechanical failures, improves efficiency, and lowers lifecycle costs simultaneously.

Conclusion

The longevity and reliability of industrial boilers are not accidental—they are the product of engineering foresight. By combining advanced metallurgical selection, optimized layout geometry, and maintenance-oriented design, operators achieve sustained thermal efficiency, minimal downtime, and predictable performance over decades. Investing in these design principles transforms a boiler from a consumable asset into a strategic, long-life energy system.

🔍 Conclusion

Choosing an industrial oil-fired boiler involves balancing capacity, fuel properties, efficiency goals, and emission compliance. By selecting a system designed to match your specific process needs, you can achieve optimal energy utilization, operational safety, and environmental responsibility.

📞 Contact Us

💡 Need help selecting the ideal oil-fired boiler for your facility? We provide customized engineering solutions, fuel system design, and high-efficiency boiler configurations to fit your operational requirements.

🔹 Contact us today to get expert support in selecting and designing your next industrial oil-fired boiler system. ⚙️🔥🏭✅

FAQ

Q1: What are the essential parameters to consider when selecting an industrial oil-fired boiler?

A1: Selecting an industrial oil-fired boiler requires careful evaluation of several parameters to ensure energy efficiency, safety, and reliability. The key parameters include:

Boiler capacity and pressure – must match the plant’s steam or heat demand.

Fuel type and quality – such as diesel, heavy oil, or low-sulfur fuel oil.

Combustion efficiency – influenced by burner design and air-fuel ratio control.

Thermal efficiency – determined by heat transfer surfaces and insulation.

Emission compliance – ensuring adherence to NOx and SOx limits.

By balancing these factors, businesses can select a boiler that minimizes fuel costs while maximizing operational efficiency and environmental performance.

Q2: How does fuel type affect oil-fired boiler performance?

A2: The fuel type used in an oil-fired boiler has a direct effect on efficiency, maintenance, and emissions. Light oils like diesel offer cleaner combustion and higher efficiency but cost more, while heavy fuel oils (HFO) are cheaper but require preheating systems to reduce viscosity for proper atomization. Additionally, low-sulfur fuels help lower SO₂ emissions and reduce corrosion in boiler tubes. Matching the fuel type to the boiler’s burner and combustion system ensures optimal heat output and long-term reliability.

Q3: Why is combustion technology critical in oil-fired boiler selection?

A3: Combustion technology determines how efficiently fuel energy is converted into usable heat. Modern oil-fired boilers use high-efficiency burners—such as pressure atomizing, rotary cup, or steam-assisted burners—to achieve complete combustion and minimize soot formation. Advanced models include low-NOx and flame stabilization systems to meet environmental standards. Properly controlled air-fuel ratios ensure steady flame quality and prevent unburned hydrocarbons, improving both performance and emissions.

Q4: How do efficiency and heat recovery systems influence selection?

A4: Efficiency is a crucial selection parameter, as it directly affects operational costs. High-efficiency oil-fired boilers often integrate economizers, air preheaters, and condensing heat exchangers to recover heat from exhaust gases. These systems can improve overall efficiency by 5–10%. Selecting boilers with fully modulating burners, high-grade insulation, and automated control systems helps maintain consistent performance even under variable loads, reducing fuel consumption and carbon emissions over time.

Q5: What role do emission regulations and maintenance play in boiler selection?

A5: Environmental compliance is a mandatory consideration when selecting an oil-fired boiler. Regulations limit pollutants like NOx, SO₂, and CO₂, making it important to choose boilers equipped with low-NOx burners, flue gas recirculation (FGR), and desulfurization systems. Equally important, maintenance accessibility and after-sales support influence lifecycle costs. Boilers designed for easy inspection, cleaning, and part replacement help sustain peak efficiency and minimize downtime, ensuring long-term operational and environmental performance.

References

U.S. Department of Energy – Industrial Boiler Efficiency and Selection – https://www.energy.gov/ – DOE

ASME Boiler and Pressure Vessel Code (BPVC) – https://www.asme.org/ – ASME

International Energy Agency (IEA) – Efficient Industrial Heating Systems – https://www.iea.org/ – IEA

Carbon Trust – Improving Efficiency in Oil-Fired Boilers – https://www.carbontrust.com/ – Carbon Trust

Mitsubishi Power – Oil-Fired Boiler Solutions – https://power.mhi.com/ – Mitsubishi Power

GE Steam Power – Advanced Oil-Fired Boiler Technology – https://www.ge.com/steam-power/ – GE Steam Power

Spirax Sarco – Boiler Efficiency and Selection Guide – https://www.spiraxsarco.com/ – Spirax Sarco

Engineering Toolbox – Thermal Efficiency Calculations – https://www.engineeringtoolbox.com/ – Engineering Toolbox

ScienceDirect – Analysis of Oil-Fired Boiler Performance – https://www.sciencedirect.com/ – ScienceDirect

MarketsandMarkets – Global Industrial Boiler Market Outlook 2025 – https://www.marketsandmarkets.com/ – Markets and Markets