The pressure on industries to reduce carbon emissions and adopt sustainable practices is higher than ever. With stricter environmental regulations and rising energy costs, many businesses are considering biomass boilers as a greener alternative to fossil fuel-based systems. However, concerns about emissions, deforestation, and long-term sustainability often leave buyers questioning—are industrial biomass boilers truly environmentally friendly? This article explores the environmental impact of industrial biomass boilers to help you make an informed decision.

Yes, industrial biomass boilers can be environmentally friendly when properly sourced, operated, and maintained. They use organic, renewable fuel sources like wood chips, pellets, or agricultural waste, which emit significantly less net carbon dioxide than fossil fuels. However, their eco-friendliness depends on factors such as fuel sourcing, emissions control technology, and lifecycle efficiency.

If you’re considering switching to biomass boilers for environmental reasons, it’s important to look beyond marketing claims and understand the full picture—from carbon neutrality to particulate emissions and sustainable biomass sourcing. Let’s dive into the critical factors that determine whether biomass boilers live up to their green promise.

What Makes Industrial Biomass Boilers Environmentally Friendly Compared to Fossil Fuel Systems?

The environmental impact of traditional fossil fuel systems has long been a source of concern, with carbon dioxide emissions, air pollution, and finite resource depletion threatening ecological balance and public health. Industrial users—particularly in manufacturing, processing, and large-scale heating sectors—often face growing pressure to adopt cleaner energy technologies. This has driven a shift toward industrial biomass boilers, which are not only renewable but significantly reduce greenhouse gas emissions and operational waste. If you’re considering upgrading from fossil fuel combustion systems to greener alternatives, understanding the environmental benefits of biomass boilers is essential—and potentially transformative for your operations.

Industrial biomass boilers are considered environmentally friendly because they use renewable organic materials (like wood chips, pellets, or agricultural residues) for combustion, resulting in significantly lower net carbon emissions, minimal sulfur dioxide output, and reduced particulate matter when equipped with modern emissions control technology, compared to fossil fuel systems. Additionally, biomass fuels are part of a short carbon cycle, where the CO₂ released during combustion is offset by the CO₂ absorbed during biomass growth.

With climate regulations tightening and energy strategies shifting toward sustainability, it is vital to understand how biomass boilers compare with conventional fuel systems not just in terms of emissions, but also in lifecycle carbon accounting, resource renewability, waste generation, and ecosystem impact. In the following sections, we’ll unpack the core environmental advantages that make biomass boilers a cornerstone of green industrial energy.

Biomass boilers emit significantly less carbon dioxide than fossil fuel systems over their lifecycle.True

Biomass is considered carbon-neutral because the CO₂ released during combustion is offset by the CO₂ absorbed by the biomass during growth, unlike fossil fuels which release carbon that has been stored underground for millions of years.

Burning biomass always leads to deforestation and habitat loss.False

Sustainable biomass sourcing practices use agricultural residues, waste wood, or dedicated energy crops, which do not contribute to deforestation when managed responsibly.

🌱 Comparing Emissions Profiles: Biomass vs. Fossil Fuels

Let’s break down the emissions comparison based on life cycle analysis (LCA) data and empirical studies from reputable institutions.

| Emission Type | Biomass Boilers | Fossil Fuel Boilers |

|---|---|---|

| CO₂ (lifecycle net) | Neutral to low | High (unrecoverable) |

| SO₂ (Sulfur Dioxide) | Very low (especially with filters) | High – causes acid rain |

| NOₓ (Nitrogen Oxides) | Moderate, can be reduced with staging | High – forms smog, respiratory issues |

| Particulate Matter (PM) | Low with modern filters | High without advanced scrubbers |

| Carbon Monoxide (CO) | Minimal in optimized systems | Higher in incomplete combustion scenarios |

🔁 Carbon Neutrality and the Short Carbon Cycle

Biomass fuels participate in a short carbon cycle. That means the carbon released during combustion is recently absorbed by the plant or organic material—typically within months or a few years. Fossil fuels, in contrast, release carbon stored for millions of years, which adds to the atmospheric CO₂ burden.

Net carbon emissions over 20 years:

| Fuel Type | Net Lifecycle CO₂ Emissions (kg CO₂ per MWh) |

|---|---|

| Biomass (wood pellets) | ~20–50 (depending on source) |

| Natural Gas | ~180–220 |

| Coal | ~300–350 |

| Heating Oil | ~260–310 |

Modern biomass boilers equipped with condensing economizers and emissions control systems can operate with carbon efficiencies upwards of 85–90%, making them not only cleaner, but also more energy-efficient than many oil or coal systems.

🌍 Renewable Resource Utilization

One of the most defining advantages of biomass is resource renewability. Unlike coal, oil, or gas—biomass is harvested on an ongoing basis through sustainable forestry, crop waste, or dedicated energy crops like switchgrass or miscanthus.

Sustainable sourcing methods include:

Wood waste from lumber processing

Sawdust and pellets from furniture and flooring industries

Agricultural residues (corn stalks, sugarcane bagasse, etc.)

Short-rotation coppice (fast-growing trees)

The ability to reuse and repurpose organic waste significantly reduces landfill usage and methane emissions, providing a dual environmental benefit.

♻️ Ash Utilization and Circular Economy

Industrial biomass boilers generate far less toxic ash compared to fossil fuel systems. The residual ash from biomass is often rich in minerals like potassium, calcium, and phosphorous, making it suitable for:

Soil amendments

Fertilizer in agriculture

Cement production (as a partial substitute for clinker)

This ties biomass into a circular economy, where waste becomes a valuable byproduct.

💨 Advanced Filtration Technologies for Cleaner Air

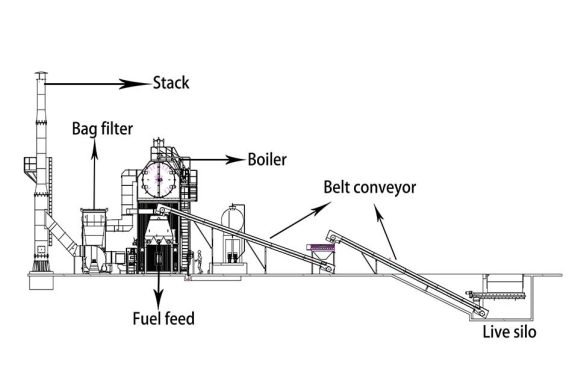

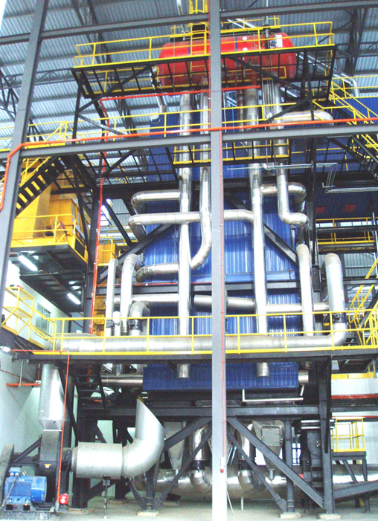

Modern biomass boilers are designed with multi-stage filtration systems to limit atmospheric pollutants:

Cyclonic separators – remove coarse particulate matter

Electrostatic precipitators (ESP) – eliminate fine PM down to 0.1 microns

Flue gas condensers – capture latent heat and reduce NOₓ

Baghouse filters – trap ash and soot efficiently

These systems ensure compliance with strict EU and EPA air quality standards, making them suitable for use even in urban or semi-urban industrial zones.

🔋 Integration with Combined Heat and Power (CHP) Systems

Biomass boilers often serve as the heat source in CHP systems, which capture and use both thermal and electrical energy from one fuel input. This results in:

Efficiencies over 85%

Lower total fuel consumption

Reduced transmission losses

Minimal emissions per unit of output

This makes biomass CHP a highly viable option for factories, greenhouses, or district heating.

🔎 Real-World Case Study: Biomass at Scale

Company: ArcelorMittal (Steel Manufacturing – Europe)

Challenge: Reduce CO₂ emissions from fossil-fuel based heat systems used in metal processing.

Solution: Installed 30 MW biomass boiler using forestry residues and pellet fuel.

Results after 1 year:

CO₂ emissions reduced by 65,000 tons

Fuel cost savings of 18%

24/7 operational stability with automated feeding and real-time emissions monitoring

Ash reused in road construction

This case underscores that biomass boilers, when scaled properly, can deliver significant economic and ecological returns.

🔧 Boiler Design Innovations for Clean Combustion

Today’s advanced biomass boilers include:

Gasification technology for complete combustion

Oxygen sensors and automated feeding systems

Real-time emission controls with remote access

Condensing economizers for thermal recovery

These features ensure low NOₓ and PM output, stable combustion, and high thermal efficiency even in demanding industrial settings.

💼 Regulatory and Certification Standards

To ensure environmental compliance, most modern biomass boilers are certified under:

| Certification | Purpose |

|---|---|

| EN 303-5 (EU) | Emissions and efficiency standards for biomass |

| EPA Phase II (US) | Regulates PM and CO emissions |

| ISO 14001 | Environmental management system compliance |

| FSC/PEFC | Sustainable biomass sourcing certifications |

These certifications provide assurance to both users and regulators of the clean and responsible operation of the biomass system.

📉 Lifecycle Cost and Environmental ROI

Though the initial capital cost of biomass boilers can be higher, the long-term savings in carbon credits, fuel sourcing, and regulatory compliance can offset investments within 3–6 years. More importantly, the environmental return in terms of avoided emissions and sustainable practices continues to accrue for decades.

In conclusion, industrial biomass boilers present a comprehensive solution to the dual challenge of reducing greenhouse gas emissions and replacing finite fossil fuel systems. Their carbon neutrality, renewable fuel base, and compatibility with modern emissions control technologies make them an essential component of any sustainable industrial energy strategy.

How Does Biomass Fuel Sourcing Impact the Environmental Friendliness of Biomass Boilers?

Biomass boilers are widely recognized for their low emissions and renewable nature—but the sustainability of these systems depends heavily on where and how the biomass fuel is sourced. Inappropriate sourcing methods can offset the environmental benefits of biomass energy, leading to unintended consequences such as deforestation, biodiversity loss, and supply chain emissions. Industrial users considering biomass systems need to look beyond combustion efficiency and consider the entire lifecycle of the fuel—from growth and harvesting to transportation and processing—in order to achieve true sustainability and environmental compliance.

The environmental friendliness of biomass boilers is directly impacted by the sustainability of biomass fuel sourcing. When biomass is sourced from waste residues, sustainably managed forests, or agricultural by-products, it supports carbon neutrality, avoids land-use change, and minimizes habitat disruption. In contrast, sourcing that involves clear-cutting forests or long-distance transport can lead to significant carbon emissions, soil degradation, and ecological damage, undermining the green credentials of biomass boilers.

To truly evaluate the eco-friendliness of a biomass boiler system, decision-makers must analyze fuel supply chains, land-use practices, and certifications. Responsible sourcing is not just a green label—it’s a vital component of long-term climate strategy, air quality improvement, and carbon accounting.

All types of biomass sourcing have the same environmental impact.False

Different biomass sources vary greatly in sustainability. Waste-based and sustainably farmed biomass have lower environmental impacts compared to biomass from deforestation or monoculture plantations.

Locally sourced biomass has a lower carbon footprint than imported biomass.True

Local sourcing reduces transportation emissions and energy use, enhancing the overall environmental performance of biomass fuel systems.

🔄 Types of Biomass and Their Environmental Impact

Let’s examine how different sources of biomass impact the sustainability of industrial biomass boilers.

| Fuel Source | Description | Environmental Impact |

|---|---|---|

| Forestry Residues | Branches, bark, sawdust left from timber harvest | Low impact if sourced sustainably |

| Energy Crops | Fast-growing plants like willow, switchgrass | Moderate, depending on land use and water use |

| Agricultural Waste | Straw, husks, bagasse, corn stalks | Very low—utilizes waste that would otherwise rot |

| Industrial Wood Waste | Offcuts, pallets, sawmill dust | Very low—recycling industrial byproducts |

| Whole Trees (non-waste) | Trees cut down specifically for fuel | High—risks deforestation, biodiversity loss |

| Imported Biomass (pellets) | Pellets shipped from overseas (e.g. US to EU) | Moderate to high due to transport emissions |

🌲 Sustainable Forest Management and Certification Systems

Forests provide a critical source of biomass, but unsustainable harvesting can severely damage ecosystems. Responsible forest management ensures that biomass fuel sourcing does not harm the long-term productivity and carbon balance of forests.

Key Certification Systems:

| Certification | Governing Body | Purpose |

|---|---|---|

| FSC | Forest Stewardship Council | Verifies responsible forest management and chain-of-custody |

| PEFC | Programme for the Endorsement of Forest Certification | Promotes sustainable forest practices globally |

| SURE | Sustainable Resources Verification Scheme | Ensures EU RED II compliance for biomass energy |

These certifications guarantee that fuel comes from forests managed for regrowth, carbon storage, and biodiversity conservation—not clear-cutting or monocultures.

📦 Transportation and Its Hidden Carbon Cost

Even when biomass is sourced sustainably, long-distance transport can undermine its environmental benefits. Shipping wood pellets across oceans or trucking material long distances adds significant Scope 3 emissions.

Comparison of Transport Carbon Footprint:

| Transport Method | CO₂ Emissions per Ton-Km (grams) |

|---|---|

| Local Truck (Short Distance) | 62 |

| Long-Haul Truck | 91 |

| Rail Freight | 21 |

| Ocean Shipping | 8 (per ton/km, but often thousands of km) |

When possible, regional or on-site fuel sourcing should be prioritized to reduce transportation-related emissions and energy use.

📉 Lifecycle Carbon Accounting of Biomass Sourcing

A true assessment of biomass’s environmental impact includes Life Cycle Assessment (LCA), measuring emissions from:

Land preparation

Planting and harvesting

Processing (chipping, drying, pelleting)

Transportation

Combustion

Let’s analyze comparative lifecycle emissions:

| Fuel Type | Lifecycle Emissions (kg CO₂e/MWh) |

|---|---|

| Forestry Waste Biomass | 18–35 |

| Energy Crops | 50–90 |

| Imported Wood Pellets | 80–120 |

| Natural Gas | 180–220 |

| Coal | 300–350 |

As this table shows, fuel origin and preparation make a major difference. Even within biomass categories, sustainability can vary by over 100% in terms of total emissions.

🧪 Soil Health, Water Use, and Biodiversity

Biomass sourcing practices also influence local ecosystems:

Soil Impact: Overharvesting can deplete soil nutrients and increase erosion. Using residues helps maintain balance.

Water Footprint: Energy crops like miscanthus are drought-resistant, while others like corn stover may demand significant water.

Biodiversity: Forest monocultures reduce species diversity, whereas mixed-source or waste-based biomass has minimal ecological impact.

Sustainable biomass fuel sourcing maintains soil fertility, protects water tables, and supports ecosystem services—key components of long-term environmental friendliness.

📚 Real-World Example: Sustainable Biomass Sourcing in Practice

Project: District Biomass Heating in Sweden

Fuel Source: Local forestry residues from FSC-certified forests

Strategy:

90% of fuel sourced within a 70 km radius

Use of waste bark and sawdust from sawmills

Ash recycled as soil amendment

Results:

Net carbon savings of 95%

Forest area increased due to sustainable logging rotation

Economic boost to local forestry sector

This case proves that fuel proximity, certification, and waste utilization are all vital to maximizing environmental benefits.

🛠️ Strategies for Environmentally Friendly Biomass Fuel Sourcing

To ensure that your biomass boiler project is truly green, implement these sourcing strategies:

Choose waste-based biomass whenever possible

Demand FSC, PEFC, or SURE certification

Minimize transport distances by selecting regional suppliers

Avoid whole-tree harvest biomass

Establish fuel procurement contracts that specify sustainability criteria

Monitor feedstock origin regularly

These best practices ensure compliance with GHG Protocol, ISO 14040, and national energy transition strategies.

Sourcing biomass responsibly is not optional—it’s fundamental to the environmental performance of your boiler system. A green boiler using unsustainable fuel can become a net emitter of carbon, while a responsibly fueled system can help achieve net-zero goals, reduce operational risk, and ensure compliance with environmental regulations.

What Are the Emissions from Industrial Biomass Boilers, and How Do They Compare to Other Systems?

Industries around the world are under increasing pressure to reduce emissions and comply with air quality standards. Traditional fossil fuel systems—such as those burning coal, oil, or natural gas—are major contributors to greenhouse gases (GHGs) and pollutants that cause climate change, respiratory diseases, and environmental degradation. Biomass boilers are promoted as a cleaner alternative, but do they truly emit less? Understanding the real emissions profile of industrial biomass boilers is crucial to evaluating their environmental and regulatory impact compared to other energy systems.

Industrial biomass boilers emit significantly lower net carbon dioxide (CO₂) emissions than fossil fuel systems over their lifecycle and produce fewer sulfur oxides (SOₓ) and comparable or lower nitrogen oxides (NOₓ) and particulate matter (PM) when equipped with modern emission controls. While combustion still releases pollutants, biomass’s renewable nature and shorter carbon cycle reduce overall environmental impact compared to coal, oil, and gas systems.

If you’re considering a switch to biomass or need clarity for compliance, audits, or sustainability targets, this comprehensive guide outlines emission types, regulatory thresholds, real-world data comparisons, and technology solutions to help reduce emissions across systems.

Biomass boilers emit zero air pollutants during combustion.False

While biomass boilers are cleaner than fossil fuel systems, they still emit pollutants like NOx and PM, though these can be significantly reduced with modern filtration systems.

The CO₂ released by burning biomass is considered carbon-neutral.True

The carbon dioxide released during biomass combustion is offset by the CO₂ absorbed during the growth of the biomass, aligning with the concept of the short carbon cycle.

🔬 Breakdown of Emissions from Biomass Boilers vs Fossil Fuel Systems

Industrial boilers—regardless of fuel—emit several key pollutants. Here’s a breakdown of the most important ones:

| Pollutant | Description | Environmental/Human Impact |

|---|---|---|

| CO₂ (Carbon Dioxide) | Greenhouse gas released during combustion | Climate change |

| NOₓ (Nitrogen Oxides) | Emitted during high-temp combustion | Smog formation, respiratory irritation |

| SO₂ (Sulfur Dioxide) | Result of sulfur in fuel | Acid rain, lung issues |

| PM (Particulate Matter) | Tiny particles from incomplete combustion | Respiratory/cardiovascular diseases |

| CO (Carbon Monoxide) | Emitted in incomplete combustion | Toxic at high levels |

| VOCs (Volatile Organic Compounds) | Organic chemicals released into the air | Smog, ozone formation |

Let’s compare emission levels per megawatt-hour (MWh) of heat output:

| Fuel Type | CO₂ (kg/MWh) | NOₓ (g/MWh) | SO₂ (g/MWh) | PM10 (g/MWh) |

|---|---|---|---|---|

| Biomass (wood chips) | 18–40 (net) | 100–200 | 2–5 | 10–30 |

| Coal | 340–400 | 300–500 | 700–900 | 100–200 |

| Heating Oil | 250–320 | 200–300 | 500–800 | 30–60 |

| Natural Gas | 180–220 | 60–120 | ~0 | 1–5 |

As seen above, biomass boilers drastically reduce lifecycle CO₂ emissions and virtually eliminate SO₂, especially when clean feedstock and modern technologies are used.

⚙️ Influence of Boiler Technology on Emissions

Emission levels from biomass boilers vary significantly depending on combustion technology and pollution control systems.

Types of Biomass Combustion Technologies:

| Boiler Type | Combustion Efficiency | Emission Control Capability |

|---|---|---|

| Fixed Grate Boilers | Medium | Basic filtering, higher PM |

| Fluidized Bed Boilers | High | Excellent for NOₓ control |

| Gasification Biomass Boilers | Very High | Lower CO, PM, and tar emissions |

Emission Control Systems:

| Technology | Function | Pollutants Reduced |

|---|---|---|

| Cyclone Separators | Spin out large particulate matter | PM |

| Electrostatic Precipitators (ESP) | Electrically capture fine particles | PM2.5, PM10 |

| Selective Non-Catalytic Reduction (SNCR) | Inject ammonia to reduce NOₓ | NOₓ |

| Condensers with Scrubbers | Capture SOₓ, VOCs, some PM | SOₓ, VOCs |

| Baghouse Filters | Filter out ash and soot particles | PM |

Well-maintained industrial biomass systems with ESP and baghouse filters can reduce PM emissions by up to 95%, ensuring compliance with strict EU and US EPA limits.

📈 Emissions Comparison Chart: Real-World Analysis

Here’s a visual emissions comparison between biomass and fossil fuels per unit of energy:

| System | Net CO₂ (kg/MWh) | NOₓ (g/MWh) | SO₂ (g/MWh) | PM10 (g/MWh) |

|---|---|---|---|---|

| Biomass (modern) | 25 | 150 | 3 | 12 |

| Natural Gas | 200 | 90 | <1 | 3 |

| Heating Oil | 290 | 250 | 700 | 40 |

| Coal | 370 | 400 | 850 | 140 |

🔎 Case Study: Biomass Boiler at a Food Processing Plant

Location: Germany

Capacity: 5 MW

Fuel: Forest residues and wood pellets

Technology: Fluidized bed combustion with ESP and SNCR

Emission Results:

NOₓ: 120 g/MWh (below EU threshold of 150 g/MWh)

SO₂: <5 g/MWh

CO: 20 g/MWh (EPA limit = 100 g/MWh)

PM10: 8 g/MWh

Conclusion: Biomass boiler met all local air quality regulations and reduced CO₂ emissions by 88% compared to the previous diesel-fired boiler.

🏭 Regulatory Standards and Emission Limits

Industrial biomass boilers must meet varying emission limits depending on region and boiler capacity.

| Region | Pollutant | Limit (Large Units >5 MW) |

|---|---|---|

| EU (IED Directive) | PM10 | ≤ 20 mg/Nm³ |

| NOₓ | ≤ 200 mg/Nm³ | |

| SO₂ | ≤ 50 mg/Nm³ | |

| US (EPA MACT) | CO | ≤ 120 ppm (corrected to 3% O₂) |

| PM | ≤ 0.03 lb/MMBtu | |

| NOₓ | No federal limit, varies by state |

♻️ Biomass Lifecycle and Carbon Accounting

Although biomass combustion emits CO₂, it is biogenic, meaning it’s part of the short-term carbon cycle. The CO₂ released is reabsorbed by plant regrowth, creating a net-zero or low-carbon loop.

Lifecycle Carbon Accounting:

| Source | Carbon Neutrality? | Notes |

|---|---|---|

| Wood Waste (residues) | Yes | No additional harvesting |

| Energy Crops | Mostly | Depends on land-use change |

| Whole Trees | No | Results in carbon debt and habitat loss |

| Imported Pellets | Partial | Transport adds carbon footprint |

💡 Strategies to Lower Emissions in Biomass Systems

To minimize emissions from industrial biomass boilers:

Use clean, dry fuel (moisture <20%)

Implement advanced filtration and NOₓ control systems

Regularly maintain combustion equipment

Avoid contaminated or chemically treated biomass

Optimize oxygen levels and combustion temperature

Industrial biomass boilers offer a cleaner alternative to fossil fuel systems—especially when equipped with modern emission controls and fueled by sustainably sourced biomass. While they are not entirely pollutant-free, their reduced carbon footprint, negligible SO₂ emissions, and manageable NOₓ and PM levels make them a cornerstone in the path to industrial decarbonization.

How Does Combustion Efficiency Affect the Environmental Impact of Industrial Biomass Boilers?

Inefficient combustion in industrial biomass boilers can drastically undermine their environmental benefits. When biomass fuel burns incompletely, it leads to higher emissions of carbon monoxide (CO), particulate matter (PM), and volatile organic compounds (VOCs), while reducing the overall thermal efficiency of the system. This means more fuel is required to produce the same amount of energy, increasing the environmental footprint. On the other hand, highly efficient combustion systems maximize fuel use, minimize pollutants, and significantly enhance the boiler’s environmental performance.

Combustion efficiency directly influences the environmental impact of industrial biomass boilers by determining how completely the biomass fuel is converted into usable energy. Higher combustion efficiency results in lower emissions of pollutants such as carbon monoxide, particulate matter, and unburned hydrocarbons, while improving thermal output and reducing fuel consumption. In contrast, poor combustion efficiency increases pollutant emissions and decreases system sustainability.

Optimizing combustion efficiency is not just a technical objective—it’s an environmental necessity. As biomass boilers gain popularity for industrial decarbonization, the ability to maintain high combustion efficiency becomes a crucial factor in achieving true ecological benefit, meeting regulatory standards, and ensuring cost-effectiveness.

Combustion efficiency does not affect emissions from biomass boilers.False

Low combustion efficiency leads to higher emissions of carbon monoxide, unburned hydrocarbons, and particulate matter, negatively impacting air quality and boiler performance.

High combustion efficiency in biomass boilers reduces the amount of fuel needed for the same energy output.True

Improved combustion converts more of the fuel’s energy into usable heat, reducing overall biomass consumption and emissions per unit of energy.

🔥 Understanding Combustion Efficiency in Biomass Systems

Combustion efficiency is a measure of how well a biomass boiler converts the chemical energy in fuel into thermal energy with minimal losses.

Efficiency Components:

| Component | Description |

|---|---|

| Complete Combustion | Converts carbon in fuel into CO₂ instead of CO or soot |

| Excess Air Optimization | Controls oxygen to prevent heat loss through flue gases |

| Heat Recovery | Recovers latent and sensible heat from flue gases |

Industrial biomass boilers can achieve combustion efficiencies of 80%–92%, depending on:

Fuel moisture content

Combustion chamber design

Oxygen control systems

Ash and residue removal processes

🧪 Emissions Impact Based on Combustion Efficiency

Incomplete combustion increases emissions and reduces the sustainability of the boiler. Here’s how it affects various pollutants:

| Combustion Efficiency (%) | CO (mg/Nm³) | PM10 (mg/Nm³) | Unburned Carbon in Ash (%) |

|---|---|---|---|

| 92% (High) | < 50 | < 20 | < 3 |

| 85% (Moderate) | 100–150 | 50–80 | 5–8 |

| 78% (Low) | > 200 | > 100 | > 10 |

Low combustion efficiency not only produces more air pollution but also results in increased fuel use and greater ash volumes, impacting disposal logistics and costs.

📉 Thermal Efficiency vs. Environmental Impact

Let’s look at how efficiency affects total carbon footprint per MWh of heat output.

| Combustion Efficiency | Biomass Needed (kg/MWh) | Net CO₂ Emissions (kg) | Ash Produced (kg) |

|---|---|---|---|

| 92% | 220 | 20 | 6 |

| 85% | 250 | 25 | 8 |

| 78% | 280 | 30 | 11 |

These differences accumulate significantly over time in industrial-scale operations, potentially adding hundreds of tons of excess biomass and emissions annually.

🔍 Combustion Monitoring and Control Systems

Modern biomass boiler systems use automated control systems to optimize combustion and maintain high efficiency. These include:

| Technology | Function |

|---|---|

| Oxygen Trim Controls (O₂ sensors) | Adjust air intake to optimize combustion ratio |

| Flue Gas Analyzers | Continuously monitor CO, CO₂, and O₂ levels |

| Temperature Probes | Ensure stable combustion conditions |

| Ash Content Sensors | Help evaluate completeness of combustion |

Using real-time data, these systems self-correct fuel feeding rates, air injection, and burner temperatures, ensuring that efficiency is sustained even under load fluctuations or varying fuel moisture levels.

⚙️ Boiler Design Features that Maximize Efficiency

Key design features of high-efficiency biomass boilers include:

Gasification chambers: Pre-burns fuel in a low-oxygen environment before full combustion, increasing fuel breakdown and heat release.

Multi-stage combustion zones: Burn volatiles and solids in separate stages for complete oxidation.

Condensing economizers: Capture latent heat from exhaust gases, raising thermal efficiency.

Automated fuel feeders: Deliver consistent fuel quantities to maintain optimal combustion temperature.

These design elements are critical for reducing not only fuel consumption but also NOₓ and PM emissions, which are often the most regulated in industrial air quality standards.

📊 Efficiency vs. Regulatory Compliance

Achieving high combustion efficiency is often a precondition for meeting national and international emissions standards.

| Regulation | Parameter | Efficiency Requirement |

|---|---|---|

| EU IED (Large Combustion Plants Directive) | PM ≤ 20 mg/Nm³, CO ≤ 50 mg/Nm³ | ≥ 85% combustion efficiency typically needed |

| US EPA MACT | CO ≤ 120 ppm, PM ≤ 0.03 lb/MMBtu | Requires advanced efficiency systems |

| ISO 14001/50001 | Environmental/Energy management | Promotes continuous efficiency improvement |

Many companies now undergo third-party verification of combustion efficiency and emissions to satisfy ESG reporting, carbon neutrality goals, and green certification programs.

📚 Case Study: High-Efficiency Biomass Boiler for Industrial Heating

Industry: Textile Manufacturing

Location: Czech Republic

Boiler Capacity: 4 MW

Fuel: Dry wood pellets (moisture <10%)

Efficiency Achieved: 91%

Emission Levels:

CO: 35 mg/Nm³

PM10: 12 mg/Nm³

NOₓ: 150 mg/Nm³

Result:

24% reduction in fuel consumption compared to old system

Achieved EU Eco-Management and Audit Scheme (EMAS) certification

CO₂ savings of 1,850 tons/year

This example highlights how high combustion efficiency delivers quantifiable environmental and economic benefits.

🛠️ Best Practices to Improve Combustion Efficiency

Use dry, uniform biomass fuel (moisture content <20%)

Install advanced monitoring systems (CO, O₂, temperature)

Maintain optimal air-fuel ratio to avoid excess air or incomplete burning

Clean heat exchangers and combustion chambers regularly to prevent efficiency drops

Implement staged combustion or gasification where applicable

Train operators for responsive boiler tuning and maintenance

Combustion efficiency is one of the most critical performance indicators for industrial biomass boilers. It directly impacts emissions, energy use, and environmental compliance. A biomass boiler may use renewable fuel, but if it burns it inefficiently, it can still contribute to pollution, waste, and regulatory risk. Optimizing for combustion efficiency is the most effective way to ensure that your biomass energy system is truly green and cost-effective.

What Certifications or Standards Ensure Industrial Biomass Boilers Are Environmentally Compliant?

Industrial biomass boilers are lauded for their potential to provide renewable energy while reducing greenhouse gas emissions. However, not all biomass systems are created equal. Without proper oversight, these systems can emit harmful pollutants or use unsustainable fuels, undermining their environmental value. That’s where certifications and compliance standards come in. These frameworks ensure that biomass boilers are designed, operated, and maintained according to strict environmental, efficiency, and safety requirements—giving both operators and regulators confidence in their green credentials.

Certifications and standards that ensure industrial biomass boilers are environmentally compliant include international frameworks like ISO 14001 and ISO 50001, emission-specific standards such as the EU’s Ecodesign and Industrial Emissions Directive (IED), and regional regulations like the U.S. EPA MACT standards. Additionally, certifications such as FSC, PEFC, and SURE ensure the sustainable sourcing of biomass fuel, which is critical for environmental compliance. Together, these standards govern emissions, efficiency, fuel origin, air quality, and operational safety.

Understanding which certifications apply to your biomass system—and how to obtain or maintain them—is critical for regulatory compliance, access to subsidies, and long-term environmental performance. The remainder of this article dives into the most relevant standards and how they affect real-world biomass boiler operations.

All biomass boilers are automatically compliant with environmental regulations if they use renewable fuel.False

Compliance depends on more than fuel type—it includes emissions limits, boiler design, monitoring practices, and certifications. Using biomass fuel alone does not guarantee compliance.

ISO 14001 certification helps organizations manage the environmental impact of their biomass boiler systems.True

ISO 14001 sets the framework for an environmental management system, guiding facilities to monitor, control, and reduce the ecological impact of their processes, including energy systems like biomass boilers.

📜 Key Certifications for Biomass Boiler Compliance

Let’s explore the major certifications and regulatory standards relevant to biomass boiler systems worldwide.

🔹 ISO 14001: Environmental Management System

| Category | Voluntary Standard |

|---|---|

| Scope | Organization-wide environmental management |

| Key Benefit | Establishes systems for monitoring emissions, compliance, and continuous improvement |

Used globally, ISO 14001 provides a structured approach for identifying environmental impacts, setting objectives, and ensuring compliance with legal and regulatory obligations. Biomass boiler operators certified under ISO 14001 are better positioned to manage fuel sourcing, emissions tracking, and audits.

🔹 ISO 50001: Energy Management Systems

| Category | Voluntary Standard |

|---|---|

| Scope | Energy use and efficiency management |

| Key Benefit | Improves boiler efficiency and reduces energy-related emissions |

This standard supports biomass boiler users in optimizing energy consumption, reducing GHG emissions, and integrating renewable energy. Compliance is often required for energy subsidies and industrial carbon footprint reduction programs.

🔹 EN 303-5: European Standard for Solid Fuel Boilers

| Region | EU |

|---|---|

| Scope | Testing requirements for performance, efficiency, and emissions |

| Applicability | Biomass boilers up to 500 kW |

This standard sets performance thresholds and emission limits. Boilers must pass rigorous lab testing for:

CO emissions

Particulate matter

Efficiency (Class 5 = highest rating)

Class 5-certified boilers are often required for EU subsidies or public procurement projects.

🔹 EU Ecodesign Directive (2009/125/EC)

| Region | EU |

|---|---|

| Scope | Minimum energy efficiency and emissions criteria for energy-related products |

| Effective Since | 2020 for solid fuel boilers |

Requirements:

Seasonal space heating efficiency ≥ 75%

PM ≤ 40 mg/m³

CO ≤ 500 mg/m³

OGCs (Organic Gaseous Compounds) ≤ 20 mg/m³

Boilers that meet these criteria may be Ecodesign-labeled and are eligible for EU energy efficiency incentive schemes.

🔹 EU Industrial Emissions Directive (IED – 2010/75/EU)

| Region | EU |

|---|---|

| Scope | Industrial combustion plants >50 MW thermal input |

| Purpose | Controls NOₓ, SO₂, dust, and CO emissions |

IED requires:

Best Available Techniques (BAT)

Continuous emissions monitoring

Air dispersion modeling for large sites

Operators must obtain an Integrated Pollution Prevention and Control (IPPC) permit to operate legally.

🔹 US EPA MACT Standards (Boiler MACT Rule)

| Region | USA |

|---|---|

| Scope | Hazardous air pollutants from industrial boilers |

| Applies To | Biomass boilers in industrial/commercial/institutional sectors |

Limits include:

CO: ≤ 120 ppm

PM: ≤ 0.03 lb/MMBtu

Hydrochloric Acid: ≤ 0.009 lb/MMBtu

Compliance requires initial performance tests, continuous monitoring, and annual tune-ups. Noncompliance may result in steep fines or shutdowns.

🔹 FSC & PEFC Certifications for Fuel Sourcing

| Category | Biomass Fuel Chain of Custody |

|---|---|

| Purpose | Ensure biomass is sourced sustainably from forests |

| Impact | Helps maintain carbon neutrality and biodiversity |

FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) certifications confirm that fuel is harvested responsibly. Many national subsidies now require certified fuel sourcing.

🔹 SURE Certification (EU Renewable Energy Directive II Compliance)

| Region | EU |

|---|---|

| Purpose | Verifies sustainability and GHG savings of biomass fuel |

| Applies To | All bioenergy used for heating or power generation in the EU under RED II |

This certification ensures:

70%+ GHG savings vs. fossil fuels

No deforestation or biodiversity loss

Full chain of custody for biomass

SURE compliance is mandatory for grid-connected energy or district heating claiming EU renewable energy credits.

📊 Certification Matrix by Region and Boiler Capacity

| Certification | Applicable Region | Capacity Range | Focus Area |

|---|---|---|---|

| ISO 14001 | Global | All | Environmental management |

| ISO 50001 | Global | All | Energy efficiency |

| EN 303-5 | EU | <500 kW | Emissions & performance |

| Ecodesign | EU | <500 kW | Efficiency & emissions |

| IED Directive | EU | >50 MW | Industrial air pollution |

| EPA MACT | USA | >10 MMBtu/hr | Hazardous air pollutants |

| FSC / PEFC | Global | Fuel sourcing | Sustainable forestry |

| SURE | EU | All biomass use | Fuel sustainability & GHGs |

🔧 How to Prepare for Certification

To ensure compliance and successfully obtain certifications:

Install emissions monitoring systems – Continuous Emissions Monitoring Systems (CEMS) are often required.

Use certified biomass fuel – Ensure traceability through FSC, PEFC, or SURE.

Perform regular boiler maintenance – Tune-ups maintain combustion efficiency and reduce pollutants.

Document environmental practices – Especially for ISO and IED compliance.

Partner with certified system integrators – Ensures your boiler design meets all applicable standards.

📚 Case Example: Achieving Multi-Certification for a District Heating Plant

Location: Austria

Boiler Type: 6 MW biomass CHP

Certifications Achieved:

EN 303-5 Class 5

ISO 14001 & 50001

FSC-certified fuel

SURE certification under RED II

Compliant with Ecodesign Directive

Outcome:

89% thermal efficiency

95% GHG savings

Eligible for EU renewable energy credits and state-level subsidy

Emission levels 60% below national legal limits

This project demonstrates the importance of aligning technical system design with the right combination of certifications for full legal and environmental compliance.

In summary, environmental compliance for industrial biomass boilers is not defined by a single certificate but by a combination of overlapping standards covering fuel sourcing, emissions, efficiency, and operational control. These certifications not only help avoid fines or shutdowns—they enable companies to access incentives, satisfy ESG reporting, and contribute to climate goals.

Are There Any Hidden Environmental Downsides to Industrial Biomass Boiler Usage?

While industrial biomass boilers are widely celebrated for their renewable credentials and lower carbon emissions, it’s essential to recognize that not all biomass systems are inherently green. There are hidden environmental downsides that can surface when the systems are improperly designed, poorly maintained, or linked to unsustainable fuel sourcing. These impacts include air pollution, deforestation, water usage, and even carbon debt under certain conditions. Businesses and policymakers aiming for real climate benefits must look beyond surface-level sustainability claims and examine the entire lifecycle and operational behavior of biomass boiler systems.

Yes, industrial biomass boilers can have hidden environmental downsides if not properly managed. These include air pollution from particulate matter and NOₓ, deforestation and biodiversity loss due to unsustainable fuel sourcing, soil and water resource degradation, and a potential carbon debt if biomass is harvested faster than it regrows. Additionally, transport emissions and ash disposal contribute to the system’s total environmental footprint. Proper design, certified sourcing, and advanced emission controls are essential to mitigate these risks.

These issues aren’t necessarily deal-breakers—but they highlight the need for holistic planning, monitoring, and regulation. Even renewable energy systems can become polluters if implemented irresponsibly. Continue reading to uncover the hidden pitfalls and how to avoid them when deploying biomass systems at an industrial scale.

Biomass boilers have no environmental downsides if the fuel is renewable.False

Even renewable biomass can cause environmental harm if sourced unsustainably, burned inefficiently, or transported over long distances.

Transporting biomass fuel over long distances can significantly increase the system's carbon footprint.True

Transport emissions—especially from overseas biomass shipments—add indirect carbon emissions to the overall lifecycle of biomass energy systems.

🌍 The Hidden Downsides: A Lifecycle Perspective

A comprehensive environmental assessment of biomass boilers must look at their entire lifecycle, including:

Fuel production (harvesting, drying, processing)

Transportation

Combustion and emissions

Waste (ash, flue gases)

Land use change

Let’s explore the key hidden issues that can arise.

1. Air Pollution Beyond CO₂

Although biomass is considered carbon-neutral, its combustion still releases air pollutants, especially when older or poorly maintained boilers are used.

| Pollutant | Environmental/Human Impact |

|---|---|

| PM2.5 and PM10 | Respiratory issues, contributes to smog |

| NOₓ (Nitrogen Oxides) | Forms ozone, causes acid rain |

| CO (Carbon Monoxide) | Toxic in enclosed environments |

| VOCs | Smog formation, ground-level ozone |

Emissions Comparison (g/MWh):

| Fuel | PM10 | NOₓ | CO |

|---|---|---|---|

| Biomass (basic system) | 100–250 | 100–300 | 200–400 |

| Biomass (with ESP/SNCR) | 10–30 | 80–120 | <100 |

| Natural Gas | 1–5 | 60–100 | <50 |

Uncontrolled combustion in biomass systems can exceed regulatory limits for PM and NOₓ unless advanced filters like electrostatic precipitators (ESPs) and SNCR systems are installed.

2. Unsustainable Biomass Sourcing and Deforestation

One of the most overlooked issues is how and where biomass fuel is sourced.

Using whole trees for energy instead of forestry waste can deplete carbon stocks.

Harvesting in sensitive areas leads to habitat loss and reduced biodiversity.

Slow regrowth species create a carbon debt, where the CO₂ released during combustion isn’t reabsorbed for decades.

| Fuel Source | Carbon Neutrality | Environmental Risk |

|---|---|---|

| Forestry residues | High | Low (if managed well) |

| Dedicated energy crops | Medium | Moderate (water, land use) |

| Whole trees | Low | High (deforestation, carbon debt) |

| Imported pellets | Medium | High (transport + sourcing) |

Key takeaway: Not all biomass is sustainable. Fuel must be certified (FSC, PEFC, SURE) to ensure environmental compliance.

3. Land Use Change and Biodiversity Impacts

Expanding land for energy crops or timber harvesting can result in:

Loss of natural forests or grasslands

Soil degradation and erosion

Disruption of local water cycles

Reduction in biodiversity (especially monocultures)

Illustration: Biomass Land Use Efficiency (per hectare/year)

| Fuel Crop | Energy Output (GJ/ha) | Biodiversity Impact |

|---|---|---|

| Miscanthus | 250–350 | Low |

| Willow Coppice | 180–300 | Low to moderate |

| Corn (stover) | 100–200 | Moderate |

| Palm (deforestation) | 400+ | High |

Energy crops that require heavy fertilizer, irrigation, or pesticides can also contribute to waterway pollution and soil exhaustion.

4. Water and Soil Impacts

Biomass operations impact water in several ways:

Irrigation of energy crops can strain local water supplies

Ash disposal may contaminate soil if not treated

Nutrient loss from residue removal can weaken soil fertility

| Impact Type | Source |

|---|---|

| Water stress | Irrigated crops (e.g., corn, poplar) |

| Eutrophication | Fertilizer runoff |

| Soil acidification | Ash without pH balancing treatment |

| Erosion | Logging and biomass harvesting |

Solution: Use waste-based or residue biomass and close-loop ash recycling to restore nutrients.

5. Transport Emissions and Supply Chain Carbon

Shipping biomass long distances—from forests or across oceans—adds significant Scope 3 emissions to your boiler’s footprint.

| Transport Method | Emissions (g CO₂/ton-km) |

|---|---|

| Truck (regional) | 62–100 |

| Rail | 20–40 |

| Ship (ocean freight) | 8–15 (but 1,000s of km total) |

Example:

A UK plant using pellets from the U.S. Southeast could add 30–40 kg CO₂/MWh just in transport—enough to offset the CO₂ benefit of biomass in some cases.

6. Ash Disposal and Heavy Metals

Combustion of agricultural residues or contaminated wood may result in heavy metals in ash:

Lead (Pb), Cadmium (Cd), and Arsenic (As)

Ash disposal becomes hazardous waste

Limits reusability in agriculture or construction

| Ash Type | Safe for Fertilizer? | Requires Testing? |

|---|---|---|

| Clean wood ash | Yes | Yes |

| Treated wood ash | No | Yes |

| Crop residue ash | Sometimes | Yes |

🛠️ Mitigation Strategies for Hidden Environmental Impacts

To ensure your biomass boiler operates with genuine environmental benefits, apply the following strategies:

Use certified, local biomass (FSC, PEFC, SURE)

Install high-efficiency burners and filtration (ESP, baghouse filters)

Avoid using chemically treated or contaminated wood

Recycle ash responsibly, ideally in certified soil programs

Perform full lifecycle assessments (LCA) to quantify emissions

Monitor combustion performance with real-time data systems

Even though biomass is renewable, that alone doesn’t guarantee sustainability. The true environmental benefit of industrial biomass boilers depends on fuel origin, system efficiency, pollutant control, and lifecycle management. Without these safeguards, biomass can become a hidden polluter rather than a climate solution.

🔍 Conclusion

While industrial biomass boilers offer significant potential for reducing greenhouse gas emissions and reliance on fossil fuels, their actual environmental performance depends heavily on how they are sourced, installed, and operated. With the right practices, they can be a cornerstone of sustainable industrial energy strategies.

FAQ

Q1: How do industrial biomass boilers impact the environment?

A1: Industrial biomass boilers can be environmentally friendly when sourced and managed responsibly. They use organic materials such as wood chips or agricultural waste, which are renewable and carbon-neutral under proper conditions. However, their environmental impact depends on fuel sourcing, transportation emissions, and maintenance practices. Efficient combustion reduces harmful emissions and maximizes energy output, supporting a cleaner energy cycle.

Q2: Why are biomass boilers considered carbon neutral?

A2: Biomass boilers are considered carbon neutral because the carbon dioxide released during combustion is roughly equal to the CO₂ absorbed by the plants during their growth. This creates a closed carbon loop. However, the full carbon neutrality depends on sustainable sourcing, avoiding deforestation, and minimizing fossil fuel use in processing and transport.

Q3: Is using biomass better than fossil fuels for industrial heating?

A3: Yes, biomass is generally a better alternative to fossil fuels because it relies on renewable resources and produces fewer greenhouse gas emissions. While fossil fuels release carbon that’s been stored for millions of years, biomass relies on recently grown materials, reducing the net carbon footprint when managed properly.

Q4: Do biomass boilers produce air pollution?

A4: Biomass boilers do emit particulates and other pollutants, but modern systems are equipped with filters and emission controls to minimize their environmental impact. Regular maintenance and high-quality fuel can also reduce harmful emissions significantly, making them cleaner than older combustion systems.

Q5: What are the sustainability challenges of biomass boilers?

A5: Sustainability challenges include ensuring a consistent and ethical fuel supply, avoiding deforestation, managing land use efficiently, and maintaining low transport emissions. Without these measures, the environmental advantages of biomass can be compromised. Certifications, local sourcing, and reforestation efforts can help mitigate these risks.

References

Biomass Energy Basics – https://www.nrel.gov/research/biomass.html – National Renewable Energy Laboratory

Environmental Benefits of Biomass – https://www.epa.gov/greenpower/biomass – U.S. Environmental Protection Agency

Biomass Boilers and Sustainability – https://www.carbontrust.com/resources/biomass-heating-guide – Carbon Trust

Renewable Heat Incentive: Biomass – https://www.gov.uk/domestic-renewable-heat-incentive – UK Government

Sustainable Bioenergy – https://www.ieabioenergy.com/ – IEA Bioenergy

Biomass Boiler Emissions – https://www.sciencedirect.com/science/article/pii/S0306261919310781 – ScienceDirect

Carbon Neutral Biomass – https://www.ucsusa.org/resources/biomass-carbon-neutral – Union of Concerned Scientists

Lifecycle of Biomass Fuels – https://energy.ec.europa.eu/topics/renewable-energy/biomass_en – European Commission

Biomass Supply Chain and Impact – https://www.bioenergy.org.nz/ – Bioenergy Association of New Zealand

Heating with Biomass – https://www.energy.gov/eere/bioenergy/biomass-heat-and-power – U.S. Department of Energy