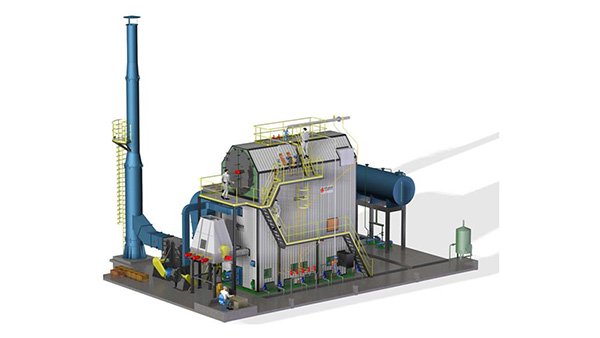

Industrial biomass boilers operate under harsh combustion conditions due to variable fuel quality, high ash content, and fluctuating moisture levels. Without proper and regular maintenance, issues such as slagging, fouling, corrosion, unstable combustion, and unplanned shutdowns can quickly reduce efficiency and reliability. Poor maintenance not only increases operating costs but can also shorten boiler lifespan and create safety risks.

Regular maintenance of industrial biomass boilers includes daily operational checks, routine cleaning of ash and heat exchange surfaces, inspection of fuel feeding and combustion systems, periodic maintenance of refractory and pressure parts, and scheduled servicing of control and emission systems. A structured maintenance program is essential to ensure stable combustion, high efficiency, regulatory compliance, and long-term safe operation.

Implementing consistent maintenance practices allows operators to maximize uptime, control costs, and extend the service life of biomass boiler systems.

What Daily Operational Checks Are Required to Keep Industrial Biomass Boilers Running Safely?

Industrial biomass boilers play a critical role in converting renewable solid fuels—such as wood chips, pellets, agricultural residues, and energy crops—into reliable thermal energy. However, compared with gas- or oil-fired boilers, biomass systems involve more complex fuel handling, variable fuel quality, ash generation, and higher fire and explosion risks. Many serious incidents in biomass boiler plants are not caused by design defects, but by lapses in routine daily operational checks that allow small abnormalities to escalate into fires, explosions, corrosion damage, or unplanned shutdowns. Daily operational checks are therefore the most important frontline defense for safe, stable, and compliant biomass boiler operation.

Daily operational checks keep industrial biomass boilers running safely by ensuring stable fuel feeding, controlled combustion, effective ash removal, proper draft and pressure balance, reliable safety interlocks, and early detection of fire, corrosion, slagging, or mechanical failures before they become hazardous.

To understand why daily checks are so essential, it is necessary to examine the unique risk profile of biomass boilers and how disciplined daily routines directly reduce those risks.

Biomass boilers require fewer daily safety checks than gas-fired boilers because biomass is a renewable fuel.False

Biomass boilers require more intensive daily checks due to fuel variability, ash handling, fire risk, and mechanical complexity.

Most biomass boiler safety incidents are preceded by warning signs detectable during routine inspections.True

Abnormal temperatures, fuel feed issues, ash buildup, and draft instability are usually visible before serious incidents occur.

Understanding the Safety Challenges of Industrial Biomass Boilers

Biomass boilers differ fundamentally from fossil-fuel boilers in several safety-relevant aspects. Solid fuels must be stored, conveyed, dried, and fed mechanically into the furnace. Combustion characteristics vary widely with moisture content, particle size, and composition. Ash, slag, and unburned material accumulate continuously. These factors create multiple potential hazard pathways if not controlled daily.

Key safety risks include:

- Furnace backfire and fuel silo fires

- Dust explosions in fuel handling systems

- Slagging and fouling leading to overheating

- Corrosion from acidic flue gas components

- Mechanical failure of feeders, grates, and conveyors

Daily operational checks are designed specifically to interrupt these risk pathways.

Fuel Receiving and Storage Checks

Safe biomass boiler operation begins long before fuel reaches the furnace.

Daily checks of fuel storage areas should include:

- Visual inspection for hot spots or smoke

- Verification of temperature monitoring in silos and bunkers

- Confirmation that fire suppression systems are armed

- Removal of spilled or accumulated biomass dust

Biomass fuels can self-heat and smolder, especially when moist. Early detection of abnormal temperatures in storage areas is critical to preventing fires.

Fuel Quality and Condition Assessment

Operators should assess incoming and stored fuel daily for:

- Excessive moisture

- Foreign objects (metal, stones, plastics)

- Unusual odor indicating microbial activity or heating

Poor fuel quality directly affects combustion stability and safety. Wet or contaminated fuel increases the risk of incomplete combustion, slagging, and unstable furnace conditions.

Fuel Feeding and Conveying System Inspection

Fuel feeding systems are among the highest-risk areas in biomass plants.

Daily checks must include:

- Inspection of conveyors, screws, and belts

- Verification of proper operation of rotary valves and airlocks

- Confirmation that backfire prevention devices are functional

Any abnormal noise, vibration, or blockage should be addressed immediately, as feed interruptions can destabilize combustion and increase backfire risk.

Table: Fuel Handling Checks and Safety Impact

| Check Item | Potential Hazard Prevented | Safety Benefit |

|---|---|---|

| Conveyor condition | Mechanical failure | Fire risk reduction |

| Airlock integrity | Backfire | Explosion prevention |

| Fuel buildup | Dust ignition | Safer operation |

Consistent fuel flow is a cornerstone of safe biomass combustion.

Furnace and Combustion Chamber Observations

The furnace is the heart of the biomass boiler and requires daily visual and data-based checks.

Operators should monitor:

- Flame shape and stability

- Bed condition on grates or fluidized beds

- Presence of unburned fuel

Irregular flames, dark smoke, or uneven fuel beds are early indicators of combustion imbalance that can lead to overheating or emissions violations.

Combustion Air and Draft System Checks

Proper air supply and draft control are essential for safe combustion.

Daily checks include:

- Verification of primary and secondary air fan operation

- Inspection of dampers and actuators

- Monitoring furnace pressure and draft stability

Poor draft can cause flue gas leakage into the boiler room or unstable combustion conditions, both of which are serious safety hazards.

Temperature and Pressure Monitoring Review

Operators should review daily trends—not just alarms—for:

- Furnace temperature

- Flue gas temperature

- Steam or hot water pressure

Unexpected temperature rises often indicate slag buildup or restricted heat transfer, while pressure anomalies may signal blockages or control failures.

Table: Key Parameters to Review Daily

| Parameter | Normal Behavior | Warning Sign |

|---|---|---|

| Furnace temperature | Stable profile | Sudden spikes |

| Flue gas temperature | Gradual change | Rapid increase |

| Furnace pressure | Slight negative | Positive pressure |

Trend awareness is more valuable than single-point readings.

Ash Removal and Handling System Checks

Ash management is a continuous safety requirement in biomass boilers.

Daily ash-related checks include:

- Verification of ash conveyor operation

- Inspection for ash buildup in hoppers

- Confirmation of cooling before ash discharge

Hot ash accumulation is a major fire hazard, particularly in enclosed ash handling systems.

Slagging and Fouling Inspection

Biomass fuels often contain alkali metals that promote slag formation.

Operators should:

- Inspect accessible heat transfer surfaces

- Monitor pressure drop across the boiler

- Watch for signs of reduced heat absorption

Unchecked slagging can cause tube overheating and structural damage.

Flue Gas Cleaning and Emission Control Checks

Electrostatic precipitators, bag filters, or cyclones require daily attention.

Checks include:

- Differential pressure monitoring

- Hopper discharge verification

- Inspection for leaks or blockages

Failure of flue gas cleaning systems can create fire hazards and regulatory non-compliance.

Fire Detection and Suppression System Verification

Daily verification of fire protection systems is essential.

This includes:

- Checking fire detectors in fuel and ash systems

- Confirming water, inert gas, or foam systems are pressurized

- Ensuring manual firefighting equipment is accessible

Passive reliance on fire systems without daily confirmation is a common cause of incident escalation.

Safety Interlocks and Emergency Systems

Operators should verify daily that:

- Emergency stops are functional

- Boiler trip logic is active

- Interlocks are not bypassed

Temporary bypasses must never become permanent through neglect.

Electrical and Control System Observations

While not dismantled daily, electrical and control systems require observation.

Operators should note:

- Control panel alarms or warnings

- Unusual actuator behavior

- Communication faults between subsystems

Control system anomalies often precede mechanical failures.

Housekeeping and Cleanliness

Good housekeeping is a safety-critical daily task.

This includes:

- Removing biomass dust from floors and structures

- Keeping walkways clear

- Preventing accumulation near hot surfaces

Dust accumulation significantly increases fire and explosion risk.

Documentation and Logbook Review

Daily operation logs should be:

- Completed accurately

- Reviewed for recurring issues

- Used to identify abnormal patterns

Documentation turns daily checks into a cumulative safety record.

Operator Communication and Shift Handover

Safe operation depends on information continuity.

Daily handovers should include:

- Current boiler condition

- Known issues or watch points

- Recent parameter deviations

Poor communication is a frequent root cause of biomass boiler incidents.

Human Awareness as a Safety System

Daily checks are not merely procedural—they depend on operator awareness.

Trained operators:

- Recognize abnormal smells or sounds

- Trust experience alongside instruments

- Act early rather than waiting for alarms

Human vigilance complements automation.

Economic and Reliability Benefits of Daily Safety Checks

Beyond safety, daily checks:

- Reduce unplanned outages

- Extend component life

- Improve fuel efficiency

Safe operation and economic performance are tightly linked.

Regulatory and Insurance Considerations

Daily operational checks support:

- Compliance with fire and safety regulations

- Insurance requirements

- Audit readiness

Documented daily routines demonstrate responsible operation.

Best Practices for Effective Daily Checking Routines

Effective routines are:

- Clearly documented

- Time-efficient

- Integrated with control system data

Checklists should evolve with operating experience and incident learning.

Long-Term Risk Reduction Through Daily Discipline

Most biomass boiler accidents result from gradual neglect, not sudden failure.

Daily checks:

- Catch small issues early

- Prevent unsafe accumulation of risk

- Maintain safe operating margins

Discipline at daily scale delivers safety at system scale.

Daily operational checks are essential to keeping industrial biomass boilers running safely because they directly address the unique risks associated with solid fuel handling, variable combustion behavior, ash management, and fire potential. By systematically inspecting fuel storage, feeding systems, combustion conditions, ash handling, draft control, safety interlocks, and housekeeping, operators can detect early warning signs and intervene before hazards escalate. Over time, disciplined daily checks transform safety from a reactive response into a proactive operating culture, ensuring that biomass boilers deliver renewable energy reliably, efficiently, and safely throughout their service life.

How Should Ash Removal, Slag Cleaning, and Heat Exchanger Cleaning Be Performed Regularly?

In industrial boilers—especially biomass, coal-fired, and waste-to-energy systems—ash accumulation, slag formation, and fouling of heat exchange surfaces are not occasional inconveniences but continuous by-products of combustion. When these by-products are not removed in a disciplined and regular manner, they progressively degrade boiler performance, restrict heat transfer, increase fuel consumption, raise fire and explosion risks, and accelerate irreversible damage to pressure parts. Many boiler efficiency losses and tube failures blamed on “fuel quality” or “aging equipment” are, in reality, the result of inadequate ash handling and cleaning practices. Regular, methodical ash removal, slag cleaning, and heat exchanger cleaning are therefore essential operational activities that directly protect safety, efficiency, and long-term asset value.

Ash removal, slag cleaning, and heat exchanger cleaning should be performed through a structured, risk-based routine that combines continuous or daily removal of loose ash, scheduled mechanical or thermal slag removal, and condition-driven cleaning of heat transfer surfaces using appropriate on-line and off-line methods to maintain safe operation, stable combustion, and high thermal efficiency.

Understanding how to perform these tasks correctly requires looking at why deposits form, how they affect boiler behavior, and how cleaning methods must be matched to fuel type, boiler design, and operating regime.

Ash and slag buildup mainly affects housekeeping and has little impact on boiler efficiency.False

Ash and slag deposits directly reduce heat transfer, increase flue gas temperatures, raise fuel consumption, and create safety risks.

Regular heat exchanger cleaning can significantly extend boiler tube life.True

By preventing overheating, corrosion under deposits, and thermal stress, regular cleaning protects pressure parts and extends service life.

Why Regular Ash, Slag, and Fouling Control Is Critical

Combustion of solid and impure fuels inevitably produces inorganic residues. These residues behave differently depending on temperature, composition, and location in the boiler.

If not controlled, they cause:

- Insulation of heat transfer surfaces

- Localized overheating of tubes

- Blockage of gas paths and draft instability

- Increased corrosion risk under deposits

- Higher fire and explosion probability in ash systems

Regular removal is not just maintenance—it is an operational necessity.

Ash Removal: Continuous Control of Loose Combustion Residues

Ash consists of fine, solid particles carried by flue gas (fly ash) and heavier material that settles at the furnace bottom or grates (bottom ash).

Ash removal must be treated as a continuous or daily process, not an occasional task.

Bottom Ash Removal Practices

Bottom ash accumulates in:

- Furnace hoppers

- Grate discharge zones

- Fluidized bed drain points

Best practices include:

- Continuous or frequent discharge to prevent buildup

- Verification that ash is cooled before transport

- Regular inspection of screws, conveyors, and seals

Hot ash accumulation is one of the most common ignition sources in biomass and waste-fired boilers.

Table: Bottom Ash Removal and Risk Control

| Aspect | Proper Practice | Risk if Neglected |

|---|---|---|

| Discharge frequency | Continuous/daily | Furnace overheating |

| Ash temperature | Controlled cooling | Conveyor fires |

| Mechanical integrity | Inspected daily | Blockage and backfire |

Bottom ash systems must never be allowed to operate intermittently without clear temperature control.

Fly Ash Handling and Removal

Fly ash is captured by:

- Cyclones

- Bag filters

- Electrostatic precipitators

Daily checks and regular discharge are essential to prevent hopper overfilling and dust release.

Operators should:

- Verify differential pressure across filters

- Ensure hopper discharge devices are operating

- Prevent ash bridging and compaction

Poor fly ash handling can quickly lead to filter fires or emission exceedances.

Slag Formation and Its Unique Challenges

Slag differs from loose ash because it is partially or fully molten material that adheres to furnace walls, grates, or heat transfer surfaces.

Slagging is influenced by:

- Fuel ash melting point

- Furnace temperature

- Alkali and chlorine content

Unlike ash, slag cannot be ignored until shutdown; it must be actively managed.

Routine Slag Observation and Assessment

Operators should routinely assess:

- Slag thickness and hardness

- Locations of active buildup

- Impact on flame shape and gas flow

Visual inspection ports and furnace cameras are critical tools for early detection.

Slag Cleaning Methods and Scheduling

Slag cleaning methods must be selected based on deposit characteristics.

Common methods include:

- Manual mechanical removal during planned outages

- Pneumatic or acoustic cleaning

- Thermal shock techniques (controlled load changes)

Slag cleaning should follow a planned schedule based on observed growth rate, not arbitrary intervals.

Table: Slag Cleaning Methods and Application

| Slag Condition | Cleaning Method | Application Timing |

|---|---|---|

| Soft, fresh slag | On-line soot/slag blowers | Continuous |

| Medium hardness | Acoustic or pneumatic | On-line or short stop |

| Hard, fused slag | Mechanical removal | Planned outage |

Attempting to remove hard slag on-line often causes refractory or tube damage.

Heat Exchanger Fouling: The Silent Efficiency Killer

Heat exchanger fouling occurs when ash, dust, or condensable compounds deposit on tubes and surfaces in convection passes, economizers, and air preheaters.

Even thin fouling layers can dramatically reduce heat transfer.

Consequences include:

- Rising flue gas temperature

- Increased fuel consumption

- Tube metal overheating

Regular cleaning is therefore a performance-critical activity.

On-Line Heat Exchanger Cleaning

On-line cleaning allows the boiler to remain in operation while deposits are removed.

Typical methods include:

- Soot blowers (steam, air, or water)

- Acoustic cleaners

- Pulse detonation systems

On-line cleaning should be optimized to remove deposits without eroding tube material.

Table: On-Line Cleaning Effectiveness

| Method | Best For | Key Advantage |

|---|---|---|

| Steam soot blowers | Loose ash | Continuous control |

| Acoustic cleaning | Fine dust | No erosion |

| Pulse systems | Sticky deposits | High effectiveness |

On-line cleaning frequency should be adjusted based on fouling rate, not fixed assumptions.

Off-Line Heat Exchanger Cleaning

Off-line cleaning is required for hardened or accumulated deposits that on-line systems cannot remove.

Methods include:

- Manual brushing or scraping

- High-pressure water jetting

- Chemical cleaning (when appropriate)

Off-line cleaning is typically performed during planned shutdowns and should be carefully supervised to avoid tube damage.

Condition-Based Cleaning vs. Calendar-Based Cleaning

Modern best practice favors condition-based cleaning.

Key indicators include:

- Rising stack temperature

- Increasing pressure drop

- Declining boiler efficiency

Cleaning triggered by real performance indicators prevents both under-cleaning and unnecessary over-cleaning.

Safety Considerations During Cleaning Activities

Ash and slag cleaning involve significant hazards.

Safety measures include:

- Lockout/tagout of relevant systems

- Use of appropriate PPE

- Dust suppression during ash handling

- Monitoring for hot spots and combustible gases

Cleaning activities must be treated as safety-critical tasks, not routine chores.

Integration with Maintenance and Operations

Effective cleaning requires coordination between:

- Operators observing trends

- Maintenance teams executing cleaning

- Engineering staff analyzing performance

This integration ensures cleaning actions are timely and effective.

Impact on Combustion Stability and Control

Ash and slag buildup alters:

- Furnace geometry

- Air distribution

- Flame shape

Regular removal stabilizes combustion, reduces CO formation, and improves controllability.

Long-Term Protection of Pressure Parts

Deposits create localized overheating and corrosion under ash layers.

Regular cleaning:

- Reduces tube metal temperature

- Prevents stress concentration

- Slows creep and fatigue mechanisms

Tube life extension is one of the most valuable outcomes of disciplined cleaning.

Economic Impact of Regular Cleaning

The economic benefits are substantial:

- Lower fuel consumption

- Fewer forced outages

- Reduced tube replacement costs

Cleaning costs are typically a fraction of the losses caused by fouling and slagging.

Documentation and Continuous Improvement

Cleaning activities should be:

- Logged and documented

- Correlated with performance data

- Used to refine cleaning intervals

Data-driven adjustment improves long-term effectiveness.

Training and Procedural Discipline

Personnel involved in ash and slag management must be trained to:

- Recognize abnormal deposits

- Use correct tools and methods

- Avoid damaging equipment

Standardized procedures ensure consistency and safety.

Role in Regulatory and Insurance Compliance

Proper ash handling and cleaning:

- Reduce fire and explosion risk

- Support environmental compliance

- Meet insurer requirements

Neglect in this area is a common audit finding.

Best-Practice Cleaning Strategy Summary

An effective strategy includes:

- Continuous ash removal

- Early-stage slag control

- Condition-based heat exchanger cleaning

- Strong safety discipline

This holistic approach prevents escalation of deposit-related risks.

Long-Term Operational Reliability Through Cleanliness

Clean boilers operate predictably. Dirty boilers operate dangerously.

Regular ash removal, slag cleaning, and heat exchanger cleaning:

- Preserve design heat transfer

- Maintain stable draft and combustion

- Protect equipment integrity

Over years of operation, cleanliness translates directly into reliability.

Ash removal, slag cleaning, and heat exchanger cleaning must be performed regularly through a structured, condition-driven approach that combines continuous ash handling, scheduled slag management, and both on-line and off-line heat exchanger cleaning methods. These activities are essential not only for maintaining efficiency, but for preventing overheating, fires, corrosion, and unplanned shutdowns. When cleaning practices are integrated into daily operation, supported by monitoring data, and executed with proper safety discipline, they transform deposit control from reactive maintenance into a core pillar of safe, efficient, and long-term boiler performance.

What Maintenance Is Required for Fuel Handling, Feeding, and Storage Systems?

In industrial boiler plants—particularly those using biomass, coal, refuse-derived fuel, or other solid fuels—the fuel handling, feeding, and storage systems are not auxiliary equipment but mission-critical safety and reliability systems. A boiler can be mechanically sound and well-controlled, yet still suffer frequent trips, fires, explosions, or severe efficiency losses if fuel handling systems are poorly maintained. In practice, many of the most serious boiler incidents originate upstream of the furnace: blocked conveyors, leaking airlocks, overheated silos, degraded feeders, or neglected dust control. Because these systems operate continuously, often in harsh environments with abrasive, wet, or combustible materials, they demand structured, frequent, and technically informed maintenance to ensure safe and uninterrupted boiler operation.

Fuel handling, feeding, and storage systems require regular preventive and condition-based maintenance covering mechanical integrity, fire and explosion protection, cleanliness, alignment, lubrication, sealing, and control functionality to ensure consistent fuel flow, prevent ignition hazards, and protect boiler reliability and safety.

To understand what maintenance is truly required, it is essential to examine these systems as an integrated fuel delivery chain—where failure at any point can compromise the entire boiler plant.

Fuel handling systems mainly affect boiler availability and have limited impact on safety.False

Fuel handling systems are a primary source of fire, explosion, and backfire risk and are critical to overall plant safety.

Regular maintenance of feeders and storage systems significantly reduces boiler trips and combustion instability.True

Stable, well-maintained fuel handling ensures consistent fuel flow, which is essential for safe and stable combustion.

Why Fuel Handling and Storage Systems Demand Intensive Maintenance

Unlike gaseous fuels, solid fuels must be physically moved, stored, metered, and isolated from the furnace. This introduces multiple failure mechanisms:

- Mechanical wear from abrasive materials

- Blockage due to moisture or particle size variation

- Dust accumulation and ignition risk

- Air leakage leading to backfire or explosions

- Corrosion in damp or acidic environments

Maintenance is therefore not optional—it is a continuous risk management activity.

Fuel Receiving and Transfer Equipment Maintenance

Fuel handling begins at the receiving point, such as truck tippers, rail unloaders, or ship unloaders.

Maintenance requirements include:

- Inspection of structural integrity and load-bearing components

- Checking wear liners, chutes, and impact zones

- Ensuring sensors and interlocks function correctly

Neglected receiving systems often generate excessive fines and dust, increasing downstream fire and explosion risk.

Conveyor Systems: The Backbone of Fuel Transport

Conveyors—belt, chain, screw, or pneumatic—are among the most maintenance-intensive components.

Key maintenance activities include:

- Daily visual inspection for misalignment, wear, and spillage

- Regular tensioning and tracking of belts or chains

- Inspection of idlers, bearings, and rollers

- Lubrication according to manufacturer specifications

Even small conveyor defects can escalate into fires due to frictional heating or dust ignition.

Table: Conveyor Maintenance Focus Areas

| Component | Maintenance Action | Risk if Neglected |

|---|---|---|

| Bearings | Lubrication & temperature check | Overheating, fire |

| Belts/chains | Alignment & tension | Breakage, spillage |

| Chutes | Wear inspection | Blockage |

| Guards | Integrity check | Personnel hazard |

Conveyors should always be treated as safety-critical systems.

Fuel Storage Systems: Silos, Bunkers, and Yards

Fuel storage areas represent one of the highest fire-risk zones in solid-fuel boiler plants.

Maintenance of storage systems includes:

- Inspection of walls, roofs, and discharge points

- Verification of temperature and gas monitoring sensors

- Testing of fire suppression and inerting systems

- Removal of accumulated dust and spilled fuel

Self-heating and smoldering inside silos often develop slowly and can go unnoticed without proper maintenance.

Prevention of Fuel Degradation and Bridging

Fuel quality degrades in storage due to:

- Moisture ingress

- Biological activity

- Compaction and bridging

Maintenance actions include:

- Ensuring weatherproofing and drainage

- Inspecting reclaim devices and agitators

- Preventing dead zones where fuel stagnates

Poor storage maintenance leads directly to feeder blockages and unstable boiler operation.

Feeders and Metering Devices: Precision and Reliability

Fuel feeders—such as screw feeders, rotary valves, and belt weigh feeders—control the boiler’s energy input.

Required maintenance includes:

- Wear inspection of screws, flights, and housings

- Calibration of weighing and speed control systems

- Inspection of seals to prevent air leakage

- Monitoring vibration and noise

Feeder degradation causes fuel flow fluctuations, which destabilize combustion and increase trip frequency.

Table: Feeder Maintenance and Boiler Impact

| Feeder Issue | Boiler Effect | Operational Risk |

|---|---|---|

| Worn screws | Variable fuel flow | Combustion instability |

| Seal leakage | Air ingress | Backfire risk |

| Sensor drift | Incorrect firing rate | Efficiency loss |

Feeder accuracy is directly linked to boiler safety and efficiency.

Airlocks and Backfire Protection Devices

Airlocks and rotary valves isolate the furnace from upstream fuel systems.

Maintenance requirements include:

- Inspection of rotor clearance and wear

- Verification of drive integrity

- Testing of backfire detection and isolation devices

Worn airlocks are a common root cause of flame propagation into conveyors and silos.

Dust Control and Explosion Protection Systems

Dust is an unavoidable by-product of solid fuel handling.

Maintenance of dust-related safety systems includes:

- Cleaning of dust extraction ducts and filters

- Inspection of explosion vents and suppression systems

- Verification of grounding and bonding

Dust accumulation combined with poor maintenance is a leading cause of catastrophic incidents.

Electrical Motors, Drives, and Instrumentation

Fuel handling systems rely heavily on motors and controls.

Maintenance activities include:

- Motor temperature and vibration monitoring

- Inspection of cables and junction boxes

- Verification of speed controllers and interlocks

Electrical faults in dusty environments pose both reliability and ignition hazards.

Lubrication and Wear Management

Fuel handling equipment operates continuously under load.

Maintenance must include:

- Strict lubrication schedules

- Use of appropriate lubricants for dusty or wet conditions

- Regular wear measurement and replacement planning

Poor lubrication accelerates wear and increases energy consumption.

Cleaning and Housekeeping as Maintenance Tasks

Housekeeping is a core maintenance activity, not an aesthetic concern.

Regular cleaning should:

- Remove fuel dust from floors and structures

- Prevent accumulation near hot surfaces

- Keep access routes clear for inspection

Clean systems are inherently safer and easier to maintain.

Fire Detection and Suppression System Maintenance

Fuel handling areas must be protected by dedicated fire systems.

Maintenance includes:

- Testing flame, smoke, and temperature detectors

- Verifying water, foam, or inert gas supply

- Ensuring nozzles and lines are unobstructed

A fire system that is not maintained is effectively non-existent.

Control Logic and Interlock Verification

Automation protects fuel systems from unsafe conditions.

Maintenance must verify:

- Interlock logic is active and not bypassed

- Emergency stops function correctly

- Fault responses are appropriate

Temporary bypasses are a major hidden risk if not controlled through maintenance discipline.

Predictive Maintenance and Condition Monitoring

Modern best practice supplements routine maintenance with predictive tools.

These include:

- Vibration monitoring on drives

- Thermal imaging of bearings and silos

- Trend analysis of motor loads

Predictive maintenance detects degradation before failure or ignition occurs.

Documentation and Maintenance Records

Maintenance must be documented to be effective.

Records should include:

- Inspection findings

- Corrective actions

- Recurring issues

Documentation enables trend analysis and continuous improvement.

Training and Competence of Maintenance Personnel

Fuel handling maintenance requires specific competence.

Personnel must understand:

- Fire and explosion mechanisms

- Mechanical wear behavior

- Interaction between fuel systems and boiler operation

Untrained maintenance introduces as much risk as no maintenance.

Coordination with Operations

Maintenance and operations must be tightly coordinated.

This ensures:

- Maintenance is performed under safe conditions

- Operators understand equipment limitations

- Early operational warnings trigger maintenance action

Silos between departments increase risk.

Regulatory, Insurance, and Audit Expectations

Fuel handling maintenance is heavily scrutinized by:

- Safety regulators

- Environmental authorities

- Insurers

Demonstrable maintenance programs are often mandatory.

Economic Impact of Proper Maintenance

Although maintenance requires resources, neglect is far more expensive.

Benefits include:

- Fewer boiler trips

- Reduced fire incidents

- Longer equipment life

- Stable fuel supply and efficiency

Most lifecycle cost savings originate upstream of the furnace.

Best-Practice Maintenance Strategy Summary

An effective strategy includes:

- Daily visual inspections

- Scheduled preventive maintenance

- Condition-based monitoring

- Strong housekeeping discipline

- Continuous training

This integrated approach addresses both reliability and safety.

Long-Term Reliability Through Upstream Discipline

Fuel handling systems set the tone for boiler operation.

Well-maintained systems:

- Deliver consistent fuel quality

- Enable stable combustion

- Minimize safety incidents

Poorly maintained systems undermine even the best boiler design.

Fuel handling, feeding, and storage systems require comprehensive, regular maintenance focused on mechanical integrity, fire and explosion prevention, cleanliness, sealing, lubrication, and control functionality. Because these systems operate continuously and handle combustible materials, even minor neglect can escalate into serious safety incidents or chronic boiler instability. Through disciplined preventive maintenance, condition-based monitoring, and strong operational coordination, fuel handling systems can reliably deliver consistent fuel flow while minimizing risk. In industrial boiler plants—especially those using solid fuels—robust fuel system maintenance is not a secondary task, but a foundational requirement for safe, efficient, and long-term boiler performance.

How Often Should Combustion Systems, Grates, and Refractory Linings Be Inspected and Serviced?

In solid-fuel and gas-fired industrial boilers alike, the combustion system, grate assembly, and refractory linings form the core physical interface between fuel energy and thermal output. These components operate continuously under extreme thermal, mechanical, and chemical stress. When inspection and servicing intervals are poorly defined or inconsistently followed, degradation often progresses unnoticed until it manifests as unstable combustion, reduced efficiency, clinker formation, tube overheating, or sudden structural failure of refractory and grates. In practice, many forced outages and safety incidents are not caused by unexpected fuel behavior, but by deferred inspection and reactive maintenance of these critical components. Establishing clear, technically justified inspection and service frequencies is therefore essential for safe, efficient, and long-term boiler operation.

Combustion systems, grates, and refractory linings should be inspected at multiple intervals—daily by operators, weekly to monthly by maintenance teams, and thoroughly serviced during planned outages—using a risk-based approach that accounts for fuel type, operating temperature, load cycling, and observed wear patterns.

To understand how often inspection and servicing should occur, it is necessary to examine how these components degrade, what early warning signs look like, and how inspection frequency directly affects safety, efficiency, and asset life.

Combustion systems and refractory linings only require inspection during major annual shutdowns.False

Early-stage wear, cracking, or misalignment often develops during operation and must be detected through routine inspections.

Frequent visual inspections significantly reduce the risk of grate failure and refractory collapse.True

Most severe failures are preceded by visible deformation, cracking, or abnormal temperature patterns detectable during regular inspections.

Why Inspection Frequency Matters for Combustion and Furnace Components

Combustion systems, grates, and refractory linings are exposed to:

- High and uneven temperatures

- Thermal cycling during load changes

- Abrasive ash and slag contact

- Chemical attack from alkalis, sulfur, and chlorine

Damage accumulates progressively. If inspections are too infrequent, deterioration reaches a point where corrective action is no longer simple or safe.

Daily Operator Inspections: The First Line of Defense

Daily inspection does not involve dismantling equipment but relies on trained observation.

Operators should visually and instrumentally check:

- Flame shape, stability, and color

- Combustion noise or pulsation

- Furnace pressure and temperature trends

- Visible grate movement and fuel bed behavior

Abnormal flame impingement or uneven fuel distribution often signals early grate or air distribution problems.

Daily Observations of Grates and Fuel Bed Behavior

Grates are mechanical systems operating inside high-temperature zones.

Operators should look for:

- Uneven fuel bed thickness

- Dead zones or excessive fuel accumulation

- Abnormal grate movement or vibration

Changes in fuel bed behavior often precede mechanical grate damage.

Refractory Indicators Visible During Operation

Even without direct access, refractory condition can be inferred daily through:

- Hot spots on furnace casing

- Rising shell or wall temperatures

- Changes in furnace draft behavior

Thermal imaging, when available, significantly enhances daily inspection effectiveness.

Weekly Inspections: Focused Mechanical and Functional Checks

Weekly inspections typically involve short access windows or external checks.

Maintenance personnel should:

- Inspect burners or fuel injection nozzles

- Check actuator movement and damper response

- Listen for abnormal grate drive noises

- Inspect accessible refractory edges and expansion joints

Weekly inspections bridge the gap between daily observation and deeper maintenance.

Table: Typical Weekly Inspection Focus Areas

| Component | Inspection Focus | Early Warning Sign |

|---|---|---|

| Burners | Flame symmetry, nozzle wear | Flame distortion |

| Grates | Drive condition, alignment | Irregular motion |

| Refractory | Cracks, joint movement | Local overheating |

Weekly inspections are particularly important for boilers operating continuously at high load.

Monthly Inspections: Condition Assessment and Minor Servicing

Monthly inspections allow for more detailed assessment, often during short planned load reductions.

Activities include:

- Measurement of grate wear or deformation

- Inspection of secondary air distribution ports

- Checking refractory surface integrity in accessible zones

- Verification of combustion instrumentation accuracy

Monthly checks are ideal for identifying trends rather than isolated defects.

Combustion System Servicing Intervals

Combustion systems include burners, air registers, dampers, igniters, flame scanners, and control actuators.

Servicing frequency depends on fuel type:

- Gas-fired systems: inspection monthly, servicing semi-annually

- Biomass and solid fuel systems: inspection weekly to monthly, servicing quarterly to semi-annually

Burner tips, nozzles, and air registers should be cleaned and adjusted before deposits or misalignment affect flame stability.

Grate System Inspection and Servicing Frequency

Grates experience both thermal stress and mechanical wear.

Recommended intervals include:

- Daily visual observation during operation

- Weekly mechanical checks of drives and linkages

- Monthly wear measurement and alignment verification

- Full inspection and refurbishment during annual outages

The more abrasive and ash-rich the fuel, the shorter the recommended service interval.

Table: Grate Inspection and Service Frequency by Fuel Type

| Fuel Type | Inspection Frequency | Major Service Interval |

|---|---|---|

| Wood chips | Weekly | 12–18 months |

| Agricultural residues | Weekly | 6–12 months |

| Coal | Monthly | 18–24 months |

| RDF/Waste | Weekly | 6–12 months |

Fuel variability is a primary driver of grate maintenance intensity.

Refractory Lining Inspection: A Multi-Layered Approach

Refractory linings protect pressure parts and maintain stable furnace geometry.

Inspection frequency should be:

- Daily indirect monitoring via temperatures

- Weekly visual checks of accessible surfaces

- Monthly detailed inspection during short outages

- Full internal inspection during major shutdowns

Refractory rarely fails suddenly; progressive cracking and spalling are almost always detectable if inspections are frequent.

Common Refractory Degradation Mechanisms

Understanding degradation helps define inspection needs.

Key mechanisms include:

- Thermal shock cracking

- Chemical attack from alkalis and chlorine

- Mechanical erosion from ash and fuel

- Structural movement and expansion mismatch

Each mechanism produces distinct visual and thermal signatures.

Service Intervals for Refractory Repair and Replacement

Minor refractory repairs may be needed:

- Quarterly in high-stress zones

- Semi-annually in moderate zones

Full relining intervals typically range from:

- 2–5 years for biomass and waste-fired boilers

- 5–10 years for gas-fired boilers

Operating discipline strongly influences these intervals.

Role of Operating Load and Cycling

Inspection frequency should increase when boilers:

- Operate at partial load for long periods

- Experience frequent start-stop cycles

- Undergo rapid load changes

Thermal cycling accelerates refractory cracking and grate distortion.

Instrumentation-Assisted Inspection

Modern plants increasingly rely on data to guide inspection.

Useful tools include:

- Thermal imaging of furnace walls

- Trend analysis of flue gas temperature

- Monitoring of pressure drop and air distribution

Data-driven inspection reduces unnecessary shutdowns while improving detection accuracy.

Planned Outage Inspections: The Most Critical Opportunity

Major outages provide the only chance for full internal inspection.

During outages:

- All grate sections should be visually and dimensionally inspected

- Refractory thickness, adhesion, and anchoring should be assessed

- Burners and air registers should be dismantled and serviced

Skipping or shortening outage inspections dramatically increases risk during subsequent operation.

Safety Considerations During Inspection and Servicing

Inspection activities themselves carry risk.

Key safety measures include:

- Proper cooling and ventilation

- Lockout/tagout of drives and fuel systems

- Confined space entry procedures

- Use of appropriate PPE

Rushed inspections often miss defects and create hazards.

Documentation and Inspection Records

Inspection frequency is only effective if findings are recorded.

Records should:

- Track defect progression

- Link operating conditions to wear rates

- Support maintenance planning

Good records transform inspections into predictive tools.

Training and Competence of Inspectors

Inspection quality depends on human skill.

Inspectors must understand:

- Normal vs. abnormal combustion behavior

- Acceptable refractory cracking patterns

- Early signs of grate misalignment

Training directly affects inspection effectiveness.

Economic Impact of Proper Inspection Frequency

Although frequent inspections require labor, the cost is small compared to:

- Forced outages

- Emergency refractory repairs

- Grate collapse or furnace damage

Inspection discipline consistently delivers high return on investment.

Regulatory and Insurance Expectations

Many codes and insurers require documented inspection regimes for:

- Combustion safety systems

- Furnace linings

- Mechanical fuel-support equipment

Failure to meet these expectations increases liability exposure.

Risk-Based Adjustment of Inspection Intervals

Best practice is not fixed intervals, but adaptive frequency.

Inspection intervals should be shortened when:

- Fuel quality worsens

- Load cycling increases

- Early-stage defects are detected

Risk-based inspection aligns effort with actual degradation.

Integration with Preventive and Predictive Maintenance

Inspection findings should feed directly into:

- Maintenance scheduling

- Spare parts planning

- Operational adjustments

Disconnected inspection and maintenance programs lose much of their value.

Long-Term Asset Protection Through Inspection Discipline

Over the life of a boiler, inspection frequency determines:

- Refractory life

- Grate replacement intervals

- Combustion stability

Consistent inspection is one of the strongest predictors of long-term reliability.

Best-Practice Inspection Frequency Summary

An effective regime includes:

- Daily operator observations

- Weekly mechanical and functional checks

- Monthly condition assessments

- Comprehensive outage inspections

This layered approach balances safety, cost, and availability.

Combustion systems, grates, and refractory linings should be inspected and serviced at multiple, clearly defined intervals that range from daily operator observations to comprehensive inspections during planned outages. Daily and weekly checks detect early warning signs, monthly inspections support condition-based maintenance, and outage servicing addresses structural and material degradation that cannot be corrected on-line. Inspection frequency must be adjusted based on fuel type, operating regime, and observed wear patterns. When inspections are systematic, well-documented, and performed by trained personnel, they prevent sudden failures, stabilize combustion, extend component life, and ensure that industrial boilers operate safely, efficiently, and reliably over the long term.

What Periodic Maintenance Is Necessary for Pressure Parts, Water Treatment, and Safety Devices?

In industrial boilers—whether gas-fired, biomass, coal, or waste-to-energy—the integrity of pressure parts, the quality of boiler water, and the reliability of safety devices together determine whether the system operates safely or drifts toward catastrophic failure. Unlike auxiliary equipment, pressure parts and safety devices operate under strict regulatory limits and unforgiving physical laws. Corrosion, scale, fatigue cracking, sensor drift, or valve sticking rarely occur suddenly; instead, they develop gradually when periodic maintenance is inadequate or improperly executed. Many boiler explosions, tube ruptures, and emergency shutdowns are ultimately traced back to neglected inspections, poor water chemistry control, or improperly maintained safety devices. Periodic maintenance is therefore not optional or administrative—it is fundamental to life safety, regulatory compliance, and long-term boiler reliability.

Periodic maintenance for pressure parts, water treatment systems, and safety devices requires a structured program of routine inspections, non-destructive testing, chemical control verification, functional testing, and documented servicing at defined intervals to prevent corrosion, scaling, overheating, and loss of overpressure protection.

To understand what maintenance is truly necessary, it is important to examine each of these elements individually while recognizing that they function as a tightly coupled safety system.

Pressure parts usually fail without warning, making frequent inspection of limited value.False

Most pressure part failures are preceded by detectable signs such as corrosion, thinning, overheating, or abnormal water chemistry.

Proper water treatment significantly reduces the maintenance burden on boiler pressure parts.True

Correct water chemistry prevents scale, corrosion, and deposit-related overheating, extending pressure part life.

Why Periodic Maintenance of Core Boiler Systems Is Critical

Pressure parts, water treatment, and safety devices are subject to:

- High pressure and temperature

- Continuous thermal and mechanical stress

- Chemical attack from water and combustion by-products

Because failure consequences include personnel injury, plant damage, and legal liability, maintenance of these systems is governed by codes, standards, and insurance requirements.

Pressure Parts: The Structural Backbone of the Boiler

Pressure parts include:

- Boiler drums

- Headers

- Waterwalls

- Superheater and reheater tubes

- Economizers

These components contain pressurized water and steam and must maintain integrity throughout the boiler’s service life.

Daily and Weekly Monitoring of Pressure Parts

While full inspection is periodic, daily and weekly monitoring provides early warning.

Operators should routinely observe:

- Steam pressure and temperature stability

- Unusual noise or vibration

- Evidence of leakage or wet insulation

Abnormal operating behavior often indicates developing pressure part issues.

Monthly External Inspection of Pressure Parts

Monthly inspections typically focus on accessible areas.

Activities include:

- Visual inspection of external tube surfaces

- Checking insulation condition for signs of leakage

- Monitoring metal temperature indicators

Wet insulation is a critical early indicator of internal leakage.

Annual Internal Inspection and Non-Destructive Testing

Annual or outage-based inspections are the most critical for pressure parts.

These inspections may include:

- Internal visual examination of drums and headers

- Ultrasonic thickness measurement

- Magnetic particle or dye penetrant testing

- Inspection of welds and attachment points

Non-destructive testing (NDT) identifies thinning, cracking, and creep damage before failure occurs.

Table: Pressure Part Maintenance Activities and Intervals

| Activity | Typical Interval | Purpose |

|---|---|---|

| External visual inspection | Monthly | Leak detection |

| UT thickness measurement | 1–3 years | Corrosion monitoring |

| Internal drum inspection | Annually | Deposit and crack detection |

| Weld inspection | Outage-based | Structural integrity |

Intervals should be shortened for aggressive fuels or poor water chemistry history.

Water Treatment Systems: The First Line of Defense

Water treatment directly protects pressure parts.

Systems typically include:

- Make-up water treatment

- Chemical dosing systems

- Blowdown systems

- Monitoring and control instrumentation

Failure in water treatment rapidly translates into pressure part damage.

Daily Water Chemistry Monitoring

Daily testing is essential, even though maintenance is periodic.

Parameters include:

- pH

- Conductivity

- Dissolved oxygen

- Hardness and alkalinity

Deviation from target ranges must trigger immediate corrective action.

Weekly and Monthly Water Treatment Equipment Maintenance

Water treatment equipment requires regular servicing.

This includes:

- Inspection and cleaning of dosing pumps

- Calibration of sensors and analyzers

- Checking chemical storage and injection points

- Verification of blowdown valve operation

Instrument drift is a common cause of hidden water chemistry problems.

Periodic Cleaning and Overhaul of Treatment Systems

At defined intervals, typically annually:

- Filters and softeners are regenerated or replaced

- Reverse osmosis membranes are inspected

- Chemical tanks and lines are cleaned

Neglected water treatment hardware undermines even the best chemical program.

Table: Water Treatment Maintenance and Risk Control

| System Element | Maintenance Action | Risk if Neglected |

|---|---|---|

| Sensors | Calibration | Undetected chemistry drift |

| Dosing pumps | Inspection | Under/over dosing |

| Blowdown valves | Functional test | TDS buildup |

| Filters | Cleaning/replacement | Contaminant ingress |

Water treatment maintenance is preventive maintenance for pressure parts.

Safety Devices: The Last Line of Protection

Safety devices protect against conditions that exceed design limits.

Key safety devices include:

- Safety relief valves

- Pressure switches and transmitters

- Low-water cutoffs

- Flame detection systems

- Interlocks and trip logic

These devices must function correctly every time they are needed.

Periodic Testing of Safety Valves

Safety valves require strict maintenance discipline.

Typical requirements include:

- Visual inspection quarterly

- Functional testing annually

- Certified bench testing at defined intervals

Valves must open at the correct pressure and reseat properly.

Table: Safety Valve Maintenance Intervals

| Activity | Interval | Purpose |

|---|---|---|

| Visual inspection | Quarterly | Detect leakage |

| Lift testing | Annually | Verify set pressure |

| Certification | Code-defined | Regulatory compliance |

A safety valve that has not been tested cannot be assumed reliable.

Low-Water Protection and Level Measurement Devices

Low-water conditions are among the most dangerous boiler hazards.

Maintenance includes:

- Weekly functional checks of level controls

- Cleaning of probes and float chambers

- Calibration of transmitters

Fouled or stuck level devices are a leading cause of boiler damage.

Pressure and Temperature Instrumentation Maintenance

Pressure parts depend on accurate instrumentation.

Periodic maintenance includes:

- Calibration of pressure and temperature sensors

- Verification of alarm setpoints

- Testing of trip functions

Incorrect readings can mask dangerous operating conditions.

Interlocks, Trips, and Control Logic Verification

Automation protects boilers only if logic is intact.

Maintenance must ensure:

- Interlocks are not bypassed

- Trip logic responds correctly

- Emergency shutdown functions operate as designed

Temporary bypasses must be controlled and documented.

Integrated Maintenance Scheduling

Pressure parts, water treatment, and safety devices must be maintained as a system.

Integrated scheduling ensures:

- Inspections occur under safe conditions

- Water chemistry history informs pressure part inspection focus

- Safety device testing aligns with outage planning

Fragmented maintenance increases risk.

Documentation and Regulatory Compliance

Maintenance of these systems is heavily regulated.

Records should include:

- Inspection reports

- Test results

- Calibration certificates

- Corrective actions

Documentation is both a legal requirement and a technical tool.

Training and Competence Requirements

Maintenance of pressure parts and safety devices requires certified competence.

Personnel must understand:

- Boiler codes and standards

- Failure mechanisms

- Safe testing procedures

Improper testing can be as dangerous as no testing.

Economic Impact of Proper Periodic Maintenance

Although periodic maintenance requires planned downtime and resources, it prevents:

- Catastrophic failures

- Extended outages

- Regulatory penalties

- Insurance disputes

Lifecycle cost is minimized through disciplined maintenance.

Risk-Based Adjustment of Maintenance Intervals

Best practice adapts maintenance frequency based on:

- Operating pressure and temperature

- Water chemistry stability

- Historical degradation rates

High-risk systems demand shorter intervals.

Long-Term Asset Protection Through Maintenance Discipline

Over decades of operation, pressure part life is determined by:

- Water chemistry control

- Inspection quality

- Safety device reliability

Periodic maintenance preserves design margins.

Cultural Importance of Safety-Critical Maintenance

Organizations with strong maintenance culture:

- Treat safety devices as operational equipment

- Invest in training and documentation

- Learn from inspection findings

This culture directly correlates with lower incident rates.

Best-Practice Periodic Maintenance Framework

An effective framework includes:

- Routine monitoring

- Scheduled inspection and testing

- Condition-based adjustments

- Strong documentation

This approach balances safety, compliance, and availability.

Periodic maintenance for pressure parts, water treatment systems, and safety devices is essential to safe and reliable boiler operation. Pressure parts require regular inspection and non-destructive testing to detect corrosion, thinning, and cracking before failure occurs. Water treatment systems must be maintained and calibrated to prevent scale and corrosion that directly damage pressure boundaries. Safety devices—including safety valves, level controls, and interlocks—must be tested and certified at defined intervals to ensure they function when needed. When these maintenance activities are structured, documented, and adjusted based on operating conditions, they form a robust defense against catastrophic failures, extend equipment life, and ensure long-term compliance and operational integrity of industrial boiler systems.

How Do Control Systems, Emission Equipment, and Monitoring Instruments Require Routine Maintenance?

In modern industrial boiler plants, control systems, emission control equipment, and monitoring instruments form the “nervous system” of safe, efficient, and compliant operation. Even when pressure parts, fuel systems, and combustion hardware are well maintained, failures or drift in automation, emission equipment, or sensors can silently undermine performance, trigger false alarms or missed trips, cause regulatory violations, and ultimately lead to unsafe operating conditions. Unlike mechanical components that often fail visibly, control and monitoring systems tend to degrade subtly through signal drift, fouling, software errors, or loss of redundancy. For this reason, routine maintenance of control systems, emission equipment, and monitoring instruments is not optional support work; it is a core operational discipline that directly affects safety margins, efficiency, availability, and legal compliance.

Control systems, emission equipment, and monitoring instruments require routine maintenance through regular inspection, calibration, functional testing, cleaning, software verification, and redundancy checks to ensure accurate measurement, reliable automation, effective emission control, and timely protective responses under all operating conditions.

To understand what routine maintenance is required, it is necessary to examine how these systems age, how failures typically develop, and how structured maintenance prevents hidden degradation from escalating into operational or regulatory crises.

Control and monitoring systems usually fail abruptly, so preventive maintenance offers limited benefit.False

Most failures develop gradually through sensor drift, fouling, software errors, or communication degradation, which preventive maintenance can detect early.

Regular calibration of emission monitoring instruments is essential for regulatory compliance.True

Accurate, calibrated emission measurements are legally required and prevent false compliance or undetected violations.

Why Routine Maintenance of Automation and Monitoring Systems Is Critical

Control systems and monitoring instruments operate continuously in harsh environments characterized by:

- Heat, vibration, and dust

- Corrosive flue gases

- Electrical noise and humidity

- Software and firmware complexity

Unlike mechanical failures, automation failures often remain hidden until they cause unsafe decisions, delayed trips, or incorrect operator actions.

Control Systems: The Backbone of Safe Boiler Operation

Control systems typically include:

- Distributed Control Systems (DCS)

- Programmable Logic Controllers (PLC)

- Burner Management Systems (BMS)

- Safety Instrumented Systems (SIS)

Routine maintenance ensures these systems respond correctly to changing operating conditions.

Routine Inspection of Control Hardware

Control system hardware requires regular physical inspection.

Maintenance activities include:

- Checking control cabinets for dust, heat, and moisture

- Inspecting power supplies and cooling fans

- Verifying tightness of terminals and connectors

- Inspecting grounding and shielding

Overheating or loose connections are common causes of intermittent control faults.

Functional Testing of Control Logic and Interlocks

Automation is only effective if logic executes as designed.

Routine testing should verify:

- Start-up and shutdown sequences

- Interlock activation under simulated fault conditions

- Alarm prioritization and annunciation

- Trip responses and reset logic

Testing identifies logic errors, bypassed protections, or unintended changes.

Table: Control System Maintenance Focus Areas

| Area | Maintenance Action | Risk if Neglected |

|---|---|---|

| Power supplies | Inspection & testing | Sudden control loss |

| Interlocks | Functional testing | Unsafe operation |

| Cooling systems | Cleaning | Overheating failures |

| Grounding | Verification | Signal noise |

Routine logic testing is a cornerstone of functional safety.

Software, Firmware, and Configuration Management

Modern control systems rely heavily on software.

Routine maintenance includes:

- Backing up control programs and configurations

- Verifying firmware compatibility

- Managing version control and change logs

- Testing updates in controlled conditions

Uncontrolled software changes are a frequent root cause of automation-related incidents.

Emission Control Equipment: Mechanical and Control Integration

Emission control systems typically include:

- Bag filters or electrostatic precipitators

- SCR or SNCR systems

- Wet or dry scrubbers

- Fans, dampers, and reagent dosing systems

These systems combine mechanical equipment with sophisticated controls, requiring integrated maintenance.

Routine Mechanical Maintenance of Emission Equipment

Mechanical maintenance focuses on maintaining physical effectiveness.

Typical tasks include:

- Inspecting filter bags, electrodes, or internals

- Checking ash discharge and hopper evacuation

- Verifying damper movement and sealing

- Inspecting fans for vibration and wear

Mechanical degradation directly reduces emission removal efficiency.

Control and Dosing System Maintenance for Emission Equipment

Emission performance depends on accurate control.

Routine tasks include:

- Calibration of reagent flow meters

- Verification of injection nozzle condition

- Testing of control loops and feedback signals

- Inspection of chemical storage and delivery systems

Poor control tuning often causes excessive reagent consumption or emission spikes.

Table: Emission Equipment Maintenance and Impact

| System | Maintenance Activity | Consequence of Neglect |

|---|---|---|

| Baghouse | Bag inspection | Dust breakthrough |

| SCR | Catalyst monitoring | NOx exceedance |

| Dosing system | Flow calibration | Inefficient control |

| Fans | Vibration checks | Forced outages |

Emission equipment reliability depends on both mechanical and control health.

Continuous Emission Monitoring Systems (CEMS)

CEMS are legally mandated in many jurisdictions.

They typically measure:

- NOx, SO₂, CO, O₂

- Particulate matter

- Flow and temperature

Routine maintenance is essential to ensure data validity.

Calibration and Validation of Monitoring Instruments

Monitoring instruments require frequent calibration.

Maintenance activities include:

- Zero and span calibration using certified gases

- Linearity checks

- Cross-sensitivity verification

- Drift analysis and correction

Calibration frequency is often defined by regulation and permit conditions.

Sampling System Cleaning and Inspection

Many monitoring errors originate in sampling systems.

Routine maintenance includes:

- Cleaning probes and filters

- Inspecting heated sample lines

- Checking condensate removal systems

- Verifying sample flow rates

Plugged or contaminated sampling lines cause false readings.

Table: Monitoring Instrument Maintenance Tasks

| Component | Maintenance Task | Risk if Neglected |

|---|---|---|

| Analyzers | Calibration | Invalid data |

| Probes | Cleaning | Measurement bias |

| Sample lines | Leak check | Data loss |

| Data systems | Verification | Reporting errors |

Accurate monitoring depends as much on sampling as on analyzers.

Alarm Management and Operator Interface Maintenance

Human-machine interfaces (HMI) are critical.

Routine maintenance includes:

- Verifying alarm limits and priorities

- Removing nuisance alarms

- Testing alarm annunciation

- Ensuring display accuracy

Alarm overload reduces operator effectiveness during abnormal conditions.

Data Integrity, Logging, and Reporting Systems

Control and monitoring systems generate regulatory and operational records.

Routine maintenance must ensure:

- Data is recorded continuously

- Time synchronization is correct

- Backup systems function properly

- Reports reflect actual conditions

Data gaps or errors can lead to compliance disputes.

Cybersecurity and Access Control Maintenance

Digitalization introduces cyber risk.

Routine maintenance includes:

- Reviewing access privileges

- Updating security patches

- Monitoring unauthorized access attempts

- Backing up critical systems

Cyber incidents can compromise both safety and compliance.

Environmental Conditions and Housekeeping

Automation equipment is sensitive to environment.

Maintenance includes:

- Maintaining clean control rooms

- Ensuring proper HVAC operation

- Preventing dust ingress into cabinets

Environmental neglect shortens equipment life dramatically.

Testing Redundancy and Fail-Safe Functions

Many critical systems rely on redundancy.

Routine maintenance must verify:

- Redundant sensors agree within tolerance

- Failover logic functions correctly

- Backup power supplies operate

Redundancy that is never tested cannot be trusted.

Documentation and Change Management

Effective maintenance relies on documentation.

Records should include:

- Calibration certificates

- Test results

- Software changes

- Fault histories

Documentation transforms routine maintenance into institutional knowledge.

Training and Competence of Instrument and Control Technicians

Maintenance quality depends on skill.

Technicians must understand:

- Process behavior

- Instrument principles

- Control logic intent

Improper maintenance can introduce more risk than neglect.

Regulatory and Audit Expectations

Control, emission, and monitoring systems are heavily audited.

Routine maintenance supports:

- Environmental permits

- Safety compliance

- Insurance requirements

Poor maintenance records often result in penalties or restrictions.

Economic Impact of Routine Automation Maintenance

Although often underestimated, benefits include:

- Fewer nuisance trips

- Optimized combustion and efficiency

- Reduced reagent consumption

- Lower risk of fines

Automation maintenance pays for itself through stability.

Risk-Based Maintenance Scheduling

Best practice adapts maintenance frequency based on:

- Criticality of the system

- Failure history

- Operating environment

High-impact systems require more frequent attention.

Integration with Overall Maintenance Strategy

Automation maintenance should be integrated with:

- Mechanical maintenance

- Operations feedback

- Performance analysis

Siloed maintenance reduces effectiveness.

Long-Term Reliability Through Digital Discipline

As plants become more digital, reliability increasingly depends on invisible systems.

Routine maintenance ensures:

- Decisions are based on accurate data

- Automation responds correctly

- Emissions remain under control

Digital neglect undermines even robust mechanical designs.

Best-Practice Routine Maintenance Framework

An effective framework includes:

- Regular inspection and cleaning

- Scheduled calibration and testing

- Software and configuration control

- Strong documentation and training

This approach aligns safety, efficiency, and compliance.

Control systems, emission equipment, and monitoring instruments require routine maintenance because they are continuously exposed to harsh operating conditions and because their degradation is often subtle but highly consequential. Control systems must be inspected, tested, and verified to ensure logic, interlocks, and alarms function correctly. Emission equipment requires both mechanical and control maintenance to sustain removal efficiency and regulatory compliance. Monitoring instruments must be regularly calibrated, cleaned, and validated to provide accurate data for control, reporting, and safety decisions. When routine maintenance of these systems is structured, documented, and performed by competent personnel, it prevents hidden failures, stabilizes operation, ensures environmental compliance, and preserves the overall safety and reliability of industrial boiler plants over the long term.

🔍 Conclusion

Regular maintenance is critical to the safe, efficient, and economical operation of industrial biomass boilers. By combining daily inspections, routine cleaning, scheduled overhauls, and proper fuel management, operators can significantly reduce failures, maintain efficiency, and comply with environmental regulations. A well-maintained biomass boiler delivers stable performance and strong long-term returns.

🔹 Contact us today to ensure your industrial biomass boiler operates safely, efficiently, and reliably year after year. 🌿🔥🏭✅

FAQ

Q1: Why is regular maintenance critical for industrial biomass boilers?

A1: Regular maintenance is critical for industrial biomass boilers because biomass fuels typically contain higher moisture, ash, and corrosive elements than fossil fuels. Without consistent upkeep, these characteristics can lead to slagging, fouling, corrosion, and unstable combustion, all of which reduce efficiency and increase failure risk. Routine maintenance ensures stable heat transfer, consistent fuel feeding, and safe operation while minimizing unplanned downtime. Additionally, well-maintained biomass boilers are more likely to meet emissions regulations and achieve their designed lifespan of 20–30 years. Over time, proactive maintenance is far more cost-effective than reactive repairs or premature boiler replacement.

Q2: What daily and weekly inspection tasks are required?

A2: Daily and weekly inspections focus on operational stability and early fault detection. Operators should check fuel feeding systems, grates, screw conveyors, and air fans for blockages or abnormal vibration. Combustion conditions—such as flame stability, furnace temperature, and flue gas appearance—should be monitored closely. Ash removal systems, including ash screws and hoppers, must be inspected and emptied regularly to prevent buildup. Weekly tasks typically include checking lubrication points, tightening loose mechanical connections, and verifying sensor readings from pressure, temperature, and oxygen probes. These routine checks help identify small issues before they escalate into costly shutdowns.

Q3: How often should cleaning and ash management be performed?

A3: Cleaning and ash management are among the most important maintenance tasks for biomass boilers. Heat exchange surfaces, such as boiler tubes and economizers, should be cleaned weekly or monthly, depending on fuel quality and ash content. Excessive ash or soot deposits reduce heat transfer efficiency and increase fuel consumption. Ash handling systems—including cyclones, bag filters, and ash conveyors—must be inspected and cleaned regularly to avoid clogging. In high-ash applications, more frequent cleaning may be required. Proper ash management not only improves efficiency but also reduces fire risk and extends component life.

Q4: What periodic maintenance is required for pressure parts and auxiliary systems?

A4: Periodic maintenance, typically performed quarterly or annually, focuses on pressure parts and auxiliary systems. This includes inspection of boiler tubes, drums, headers, and refractory linings for signs of corrosion, erosion, or cracking. Safety valves, pressure relief devices, and interlocks must be tested and calibrated to ensure safe operation. Fuel handling equipment, fans, dampers, and emission control devices such as baghouses or ESPs should also be serviced. Water treatment systems must be reviewed to prevent scaling and corrosion. These tasks are often carried out during scheduled shutdowns to minimize production impact.

Q5: How does preventive maintenance improve long-term performance and cost control?

A5: Preventive maintenance significantly improves long-term performance by reducing unexpected failures and stabilizing operating costs. By tracking trends in efficiency, emissions, and component wear, operators can plan maintenance activities before problems become critical. This approach lowers spare parts consumption, reduces emergency repair costs, and extends boiler lifespan. Preventive maintenance also supports regulatory compliance and improves overall plant reliability. In the long run, industrial biomass boilers with structured maintenance programs deliver lower lifecycle costs, higher availability, and better return on investment compared to poorly maintained systems.

References

- U.S. Department of Energy – Biomass Boiler Maintenance Practices – https://www.energy.gov/ – DOE

- International Energy Agency (IEA) – Biomass Heat and Power Systems – https://www.iea.org/ – IEA

- ASME – Boiler and Pressure Vessel Code (BPVC) – https://www.asme.org/ – ASME

- International Renewable Energy Agency (IRENA) – Biomass Operations and Maintenance – https://www.irena.org/ – IRENA

- Spirax Sarco – Boiler Maintenance and Reliability – https://www.spiraxsarco.com/ – Spirax Sarco

- Engineering Toolbox – Biomass Boiler Operation and Cleaning – https://www.engineeringtoolbox.com/ – Engineering Toolbox

- ScienceDirect – Maintenance Strategies for Biomass Boilers – https://www.sciencedirect.com/ – ScienceDirect

- ISO 50001 – Energy Management Systems – https://www.iso.org/ – ISO

- World Bioenergy Association – Biomass Boiler Best Practices – https://www.worldbioenergy.org/ – World Bioenergy Association

- World Bank – Industrial Biomass Energy Projects – https://www.worldbank.org/ – World Bank