Many businesses are considering biomass boilers as an alternative to fossil-fuel systems to cut energy costs and reduce carbon emissions. However, one of the most common concerns is that biomass boilers usually have a higher upfront cost compared to gas or oil boilers, making decision-making challenging. Without clear cost analysis, companies risk underestimating both investment and long-term benefits.

A biomass boiler typically costs between $50,000 and $500,000 depending on capacity, pressure, fuel type (wood chips, pellets, agricultural residues), combustion technology (fixed grate, fluidized bed, gasification), efficiency features, and level of automation. When including auxiliary systems such as fuel storage, handling, feed systems, and emission control, the total installed cost can exceed $1 million for large-scale industrial operations. While initial costs are high, lower fuel expenses and renewable energy incentives often provide attractive payback periods.

Understanding these cost factors allows businesses to make better financial and operational decisions when investing in biomass boiler systems.

What Factors Have the Greatest Impact on Biomass Boiler Cost?

When companies consider biomass boilers, they are often motivated by sustainability goals, renewable fuel incentives, and long-term energy savings. However, one of the most common pain points is the high upfront investment cost, which can vary significantly depending on several factors. Without a clear understanding of these cost drivers, investors risk underestimating total installed costs, leading to budget overruns and reduced return on investment. The solution is to carefully evaluate the key technical, fuel-related, and site-specific factors that directly determine biomass boiler pricing.

The greatest factors impacting biomass boiler cost include boiler capacity, fuel type and moisture content, combustion technology, emission control requirements, auxiliary equipment, and site-specific installation conditions. Larger capacities and advanced technologies (like fluidized bed combustion) raise capital costs but improve efficiency, while fuel quality and emission compliance strongly influence both upfront investment and long-term operating expenses.

In short, the real cost of a biomass boiler is not just the boiler itself, but the entire system tailored to the chosen fuel and environmental compliance requirements.

Biomass boilers are generally cheaper to install than gas-fired boilers.False

Biomass boilers typically require higher CAPEX due to fuel handling, storage, and emission control systems.

Fuel moisture content has a major impact on biomass boiler efficiency and cost.True

High-moisture biomass reduces combustion efficiency and increases equipment cost due to the need for drying or specialized boiler design.

1. Boiler Capacity and Output Requirement

Small-scale biomass boilers (0.5–5 MWth) → lower CAPEX, simpler design.

Utility-scale boilers (>50 MWth) → high efficiency but expensive fluidized bed or moving grate systems.

Scaling effect: cost per kW decreases with size, but total investment rises steeply.

| Capacity Range | Typical Boiler Type | Cost per kWth Installed |

|---|---|---|

| 0.5–5 MWth | Fire-tube / Small water-tube | $600–$1,000 |

| 5–20 MWth | Moving grate / Hybrid | $450–$800 |

| >50 MWth | CFB (Circulating Fluidized Bed) | $300–$600 |

2. Fuel Type, Quality, and Moisture Content

Fuel variability is one of the biggest drivers of cost:

Wood pellets → uniform, high calorific value, lower storage/feeding costs.

Wood chips / agricultural residues → cheaper fuel but higher moisture and inconsistent size.

High-moisture biomass (e.g., bagasse, wet chips) → requires drying systems, robust grates, and larger combustion chambers.

| Fuel Type | Moisture Content (%) | Effect on Boiler Design | Cost Impact |

|---|---|---|---|

| Wood Pellets | 6–10% | Compact, stable combustion | Lower CAPEX/OPEX |

| Wood Chips | 20–50% | Larger furnace, drying system | Higher CAPEX |

| Straw/Agro Residues | 10–40% | Special grates, corrosion-resistant alloys | High CAPEX |

| Bagasse (Sugarcane) | 45–55% | Integrated drying/CFB needed | High CAPEX/OPEX |

3. Combustion Technology

Fixed Grate / Step Grate: Low-cost, suitable for chips/pellets, up to ~20 MW.

Fluidized Bed (BFB/CFB): Handles mixed fuels and high moisture but at much higher investment cost.

Gasification + Boiler: Niche technology, higher efficiency, but capital-intensive.

4. Emission Control and Environmental Compliance

Biomass combustion generates particulates, NOx, SO₂, and volatile organic compounds (VOCs).

Stricter emission regulations = higher cost due to ESPs (electrostatic precipitators), baghouse filters, or SNCR/SCR systems.

Compliance costs can add 15–30% to CAPEX.

| Pollutant | Control Equipment | CAPEX Impact |

|---|---|---|

| Dust/PM | Cyclone, ESP, bag filter | +10–20% |

| NOx | Low-NOx burners, SNCR, SCR | +5–15% |

| SO₂ | Limestone injection, scrubbers | +10–15% |

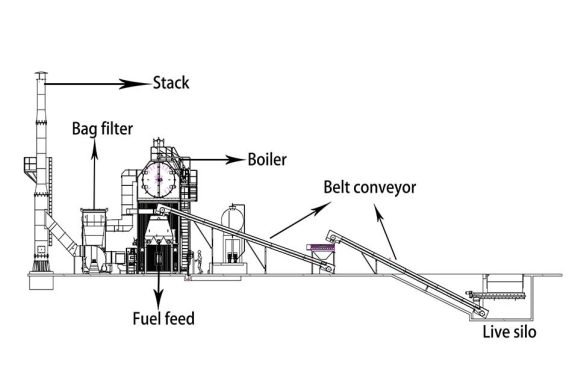

5. Auxiliary Systems and Balance of Plant

Biomass boilers require significantly more auxiliary equipment compared to gas-fired systems:

Fuel handling and storage: conveyors, silos, drying systems.

Ash handling systems: conveyors, hoppers, ash silos.

Water treatment and economizers: critical for efficiency.

These can add 20–40% of total installed cost.

6. Site-Specific Factors

Available space: large storage and handling areas required.

Local fuel supply chain: long-term biomass availability and transport costs.

Altitude & climate: may influence combustion air and drying needs.

Grid/steam network connection: infrastructure modifications raise costs.

Case Study – District Heating Plant in Northern Europe

A district heating company installed a 15 MW biomass boiler using wood chips (35% moisture).

Base boiler cost: $8 million.

Fuel storage/handling: $3 million.

ESP and bag filters: $2 million.

Total installed cost: $13 million.

Payback: ~7 years, due to low-cost local biomass supply compared to natural gas.

Engineering Insights

Fuel quality and consistency are the most underestimated cost drivers. Cheap fuel may cause expensive operational challenges.

CAPEX vs. OPEX trade-off: More advanced combustion and emission controls raise CAPEX but reduce maintenance and penalties.

Auxiliary systems often equal the boiler price—buyers must budget for the entire installation, not just the boiler unit.

Location-specific subsidies and carbon credits can greatly improve ROI for biomass projects.

Conclusion

The cost of a biomass boiler depends on much more than the boiler unit itself. Capacity, fuel type and moisture, combustion technology, emission controls, auxiliary systems, and site-specific conditions are the dominant factors shaping total investment. A well-optimized system balances CAPEX and OPEX, ensuring efficiency, compliance, and long-term economic viability.

How Does Boiler Size and Steam Output Capacity Affect Pricing?

When businesses or utilities evaluate boiler investments, one of the most confusing aspects is the relationship between boiler size, steam output capacity, and overall cost. A common pain point is that buyers assume cost increases linearly with size, but in reality, pricing follows complex scaling laws. Underestimating this can lead to budget shortfalls, underestimated lifecycle costs, or overinvestment in oversized units. The solution is to understand exactly how capacity scaling affects both capital cost and long-term operating economics.

Boiler size and steam output capacity have a direct impact on pricing: smaller fire-tube and package boilers cost less but have higher cost per unit of steam, while larger water-tube or utility-scale boilers require higher upfront investment but offer economies of scale. As capacity increases, total installed cost rises steeply, but the cost per ton of steam or per kWth output decreases, making large units more cost-effective for high-demand applications.

In short, larger capacity = higher CAPEX but lower unit cost of steam, while small boilers remain cheaper upfront but more expensive per unit of output.

The cost of a boiler increases linearly with its steam output.False

Boiler costs follow an economy of scale: larger boilers cost disproportionately more in absolute terms but less per unit of steam.

Smaller boilers are always more economical to operate.False

Small boilers may be cheaper initially but often have higher fuel consumption per ton of steam and lower efficiency, raising OPEX.

1. Economies of Scale in Boiler Pricing

Fire-tube boilers (up to ~30 TPH): Compact, lower CAPEX, but efficiency limited.

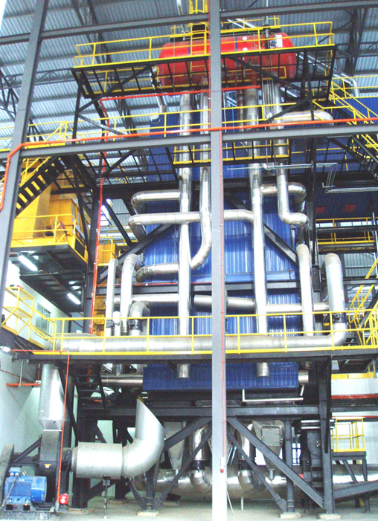

Water-tube boilers (20 TPH–200+ TPH): Higher pressure/temperature, larger CAPEX, lower cost per ton steam.

Utility-scale boilers (>500 TPH): Enormous CAPEX but cheapest per unit steam.

| Boiler Type | Capacity Range (TPH) | Approx. Cost Range ($/kWth) | Application |

|---|---|---|---|

| Fire-tube Package | 1–30 TPH | $500–$900 | Food, textiles, small industry |

| Water-tube (D-Type) | 20–200 TPH | $300–$600 | Chemical plants, power cogeneration |

| Utility CFB/PC | 200–1000+ TPH | $150–$400 | Power generation, district heating |

2. Steam Output vs Cost of Steam

| Boiler Size | Typical Investment ($ million) | Efficiency (%) | Cost per ton of steam ($) |

|---|---|---|---|

| Small Industrial (10 TPH) | 1.5–2.5 | 80–84 | 25–32 |

| Medium Industrial (50 TPH) | 7–12 | 85–88 | 15–20 |

| Large Utility (300 TPH) | 60–90 | 88–92 | 8–12 |

Observation: Larger boilers demand higher capital cost but deliver cheaper steam over time.

3. Pressure and Temperature Impact

Low-pressure boilers (<20 bar): Cheaper to build, limited industrial use.

Medium-pressure (20–60 bar): Balance between cost and efficiency.

High-pressure (>100 bar, superheated): Expensive materials and designs, but needed for turbines and cogeneration.

4. Auxiliary Costs Scaling

Fuel handling systems → grow disproportionately with size (coal, biomass).

Water treatment plants → more complex for high-capacity, high-pressure boilers.

Emission control → scales with total output, often adding 15–25% of CAPEX in large units.

Case Study – Cement Industry Boiler Upgrade

A cement manufacturer replaced a 25 TPH fire-tube boiler with a 60 TPH water-tube boiler:

CAPEX increased from $3.5 million to $7 million.

Efficiency rose from 82% to 87%.

Steam cost dropped by ~30% due to lower fuel consumption per ton steam.

Payback achieved in 4.5 years.

Engineering Insights

Right-sizing is critical—oversized boilers waste capital, undersized boilers limit production.

Economy of scale favors large plants with steady high steam demand.

For intermittent loads, multiple small boilers may be cheaper to operate than one oversized boiler.

Pressure and temperature requirements often drive cost more than just TPH capacity.

Conclusion

Boiler size and steam output capacity directly shape capital cost, efficiency, and cost per ton of steam. While large units demand higher upfront investment, they typically offer better lifetime economics for industries with high continuous demand. Smaller units remain practical where demand is low, intermittent, or space is limited.

What Are the Cost Differences Between Pellet, Wood Chip, and Agricultural Waste Boilers?

One of the biggest challenges for industries and heating networks investing in biomass boilers is choosing the right fuel type. Each option—pellets, wood chips, or agricultural residues—comes with different capital investment, operating costs, and infrastructure needs. The pain point arises when decision-makers underestimate how much fuel quality, moisture content, and handling systems affect both CAPEX and OPEX. This often leads to higher than expected costs or poor ROI. The solution lies in comparing these biomass fuels not only by market price but also by their true system cost over the boiler’s lifetime.

Pellet boilers are the most expensive in terms of fuel cost but require lower capital investment in handling systems, wood chip boilers balance moderate CAPEX with lower OPEX in regions with cheap supply, while agricultural waste boilers have the lowest raw fuel cost but the highest CAPEX due to complex combustion and ash-handling requirements.

In short, the real cost difference is not just in fuel price, but in the total installed system—fuel storage, drying, emission control, and maintenance.

Pellet boilers always have the lowest cost of operation.False

While pellet boilers have high efficiency, their fuel cost is often 2–3x higher than wood chips or agri-residues, making OPEX higher.

Agricultural waste is the cheapest boiler fuel option.True

Agricultural residues like straw, husk, and bagasse often have near-zero market value, but handling, corrosion, and emission controls raise system CAPEX.

1. Comparative CAPEX and OPEX

| Fuel Type | Typical CAPEX ($/kWth) | Fuel Cost ($/MWh) | Boiler Efficiency (%) | OPEX Trend |

|---|---|---|---|---|

| Wood Pellets | 500–800 | 45–70 | 85–90 | High (fuel cost dominated) |

| Wood Chips | 600–1,000 | 20–40 | 80–88 | Medium |

| Agricultural Waste | 800–1,400 | 5–25 | 70–85 | Low fuel cost, high maintenance |

Key takeaway: Pellets = high fuel cost but easy to operate, chips = balance of cost/efficiency, agro-residues = cheap fuel but high technical challenges.

2. Fuel Handling and Storage Costs

Pellets: Flow easily like grain, require minimal handling equipment.

Chips: Require conveyors, silos, sometimes drying systems.

Agro waste: Needs specialized grates, high-volume storage, corrosion-resistant alloys.

| Fuel Type | Storage/Handling Complexity | Additional Cost Impact |

|---|---|---|

| Pellets | Low (gravity-fed silos) | +5–10% CAPEX |

| Wood Chips | Medium (belt conveyors, drying) | +10–20% CAPEX |

| Agro Waste | High (custom feeding, separation, ash handling) | +20–35% CAPEX |

3. Emission Control Requirements

Pellets: Very clean, minimal particulate matter (PM).

Wood chips: Moderate PM, needs cyclones or bag filters.

Agro residues: High ash, alkali metals → corrosion, slagging, NOx and SO₂ → requires ESP + advanced flue gas treatment.

Cost impact: Agro-waste boilers may require 15–30% higher emission control investment compared to pellet or chip boilers.

4. Fuel Supply Chain and Regional Availability

Pellets: Often imported in bulk, high price volatility.

Wood Chips: Cheapest in forestry-rich regions (Northern Europe, Canada, US).

Agro residues: Abundant in agricultural economies (India, Southeast Asia, Brazil), but seasonal and inconsistent quality.

5. Case Example – District Heating Plant

Option 1: Pellet Boiler (10 MW) → CAPEX: $8 million, Fuel cost: $3.5 million/year.

Option 2: Wood Chip Boiler (10 MW) → CAPEX: $10 million, Fuel cost: $1.8 million/year.

Option 3: Agro Waste Boiler (10 MW) → CAPEX: $13 million, Fuel cost: $0.7 million/year.

Result: Agro waste cheapest in long-term fuel cost, but higher CAPEX and operational challenges delayed payback. Chips offered the best balance of CAPEX + OPEX for this project.

Engineering Insights

Pellets = Low risk, high OPEX → Ideal for urban heating, stable supply chains.

Wood chips = Balanced economics → Best option for mid/large-scale plants near forests.

Agro residues = High risk, high reward → Excellent for regions with abundant residues, but requires strong technical expertise.

Conclusion

The cost difference between pellet, wood chip, and agricultural waste boilers lies in a trade-off between fuel price and system complexity. While pellets are the most user-friendly but expensive, wood chips are cost-effective in the right regions, and agricultural residues offer the lowest fuel costs but require higher CAPEX, complex combustion, and stricter maintenance.

How Do Combustion Technologies (Grate, Fluidized Bed, Gasification) Influence Cost?

When planning a biomass boiler project, one of the most underestimated decisions is the choice of combustion technology. Many buyers focus only on the boiler capacity or fuel price, but the type of combustion system—grate, fluidized bed, or gasification—can drastically change both capital cost (CAPEX) and operating cost (OPEX). Choosing the wrong technology can result in inefficient combustion, excessive emissions, fuel incompatibility, or unsustainable maintenance costs. The solution is to compare how each combustion technology handles different fuels, efficiency levels, and environmental compliance, and how that translates into real project costs.

Grate combustion is the simplest and cheapest but best suited for clean, uniform fuels; fluidized bed systems (BFB/CFB) cost more but handle diverse fuels efficiently with better emission control; gasification is the most expensive and technically demanding but offers the highest efficiency and potential for advanced applications like syngas and CHP.

In short, the choice of combustion technology directly influences both CAPEX and OPEX, with higher sophistication bringing higher upfront cost but potentially lower long-term fuel and emission costs.

Grate combustion boilers are always the cheapest to operate.False

While grate systems have the lowest CAPEX, they can have higher fuel costs and maintenance if used with low-grade or variable fuels.

Gasification systems offer the highest efficiency but also the highest initial investment.True

Gasification requires advanced reactors, gas cleanup, and control systems, making it costly but highly efficient.

1. Comparative Cost and Performance

| Technology | CAPEX ($/kWth) | Efficiency (%) | Fuel Flexibility | OPEX Trend | Typical Application |

|---|---|---|---|---|---|

| Grate Combustion | 400–800 | 70–85 | Low–Medium | Medium–High | Small/medium boilers, pellets, clean chips |

| Bubbling Fluidized Bed | 700–1,200 | 80–88 | High | Medium | Medium–large, mixed fuels |

| Circulating Fluidized Bed | 900–1,400 | 85–92 | Very High | Medium–Low | Utility scale, coal/biomass co-firing |

| Gasification | 1,200–2,000+ | 85–95 | Medium–High | Low (if integrated CHP) | Advanced plants, syngas, bio-refineries |

2. Fuel Handling and Preparation Costs

Grate systems: Require clean, uniform fuel size (pellets, clean chips). Moisture tolerance <40%. Low fuel prep cost if using pellets.

Fluidized beds: Can handle a wide range of fuels (chips, agro-residues, low-grade biomass, coal blends). Require particle sizing but tolerate higher moisture.

Gasification: Needs pre-processed fuel (drying, size reduction). Higher preparation cost, but produces syngas for flexible end uses.

| Fuel Type | Best Fit Technology | Handling Cost Impact |

|---|---|---|

| Pellets | Grate / Gasification | Low |

| Wood Chips | Grate (clean chips), BFB/CFB (mixed) | Medium |

| Agro Waste | BFB/CFB (straw, husk, bagasse) | Medium–High |

| MSW/Refuse | CFB / Gasification | High |

3. Emission Compliance Cost

Grates: Higher NOx and PM → needs cyclones, bag filters.

Fluidized beds: Lower NOx (due to staged combustion), in-bed desulfurization possible → lower FGD cost.

Gasification: Low direct combustion emissions, but syngas cleanup is costly and complex.

Example cost impact:

Grate boiler with pellet fuel: emission system adds ~10–15% CAPEX.

CFB boiler with agro residues: emission system adds ~15–20% CAPEX.

Gasification + syngas cleanup: adds ~25–40% CAPEX.

4. Case Example – Pulp and Paper Mill

A pulp mill compared three technologies for a 50 MWth biomass boiler:

Grate system: CAPEX $25M, fuel restricted to clean chips, OPEX $6M/year.

BFB system: CAPEX $35M, fuel flexibility enabled use of bark + residues, OPEX $4.5M/year.

CFB system: CAPEX $42M, able to co-fire coal for backup, OPEX $4.3M/year.

Result: Although grate CAPEX was lower, fluidized bed offered $1.5M annual fuel savings, reaching payback in 6–7 years.

5. Engineering Insights

Small plants (<10 MWth) → Grate boilers are most economical.

Medium plants (10–100 MWth) → Fluidized bed strikes best balance between CAPEX and OPEX.

Large-scale/utility plants → CFB or hybrid systems preferred due to co-firing and fuel flexibility.

Advanced CHP or syngas projects → Gasification is future-oriented but requires long-term fuel security and strong technical support.

Conclusion

The choice of combustion technology is one of the most critical cost drivers in a biomass boiler project. While grate systems are affordable and simple, fluidized beds offer the best long-term economics through fuel flexibility, and gasification represents the cutting edge for high-efficiency, integrated energy systems. Balancing CAPEX, OPEX, and fuel security is key to selecting the right technology.

What Is the Total Installed Cost Including Fuel Handling and Emission Systems?

When companies budget for a biomass boiler project, they often make the mistake of looking only at the boiler island cost. The pain point comes later—when they discover that fuel handling, storage, drying, and emission control systems can double the total investment. Without accounting for these auxiliary systems, projects face cost overruns, delays, or underperforming equipment. The solution is to evaluate the Total Installed Cost (TIC), which includes all auxiliary systems, site-specific construction, and compliance requirements.

The total installed cost of a biomass boiler system is typically 1.8–3 times the base boiler price, once fuel handling, storage, emission controls, civil works, piping, electricals, and commissioning are included.

This means that a $5 million boiler package can easily result in a $10–15 million installed plant, depending on fuel type, emission standards, and site conditions.

The boiler unit itself represents the majority of project cost.False

In reality, the boiler island is often only 30–50% of TIC, with the rest coming from fuel handling, emission systems, and balance-of-plant.

Emission control systems can account for 15–30% of total installed cost.True

Especially for agricultural residues with high ash, alkali, and PM, advanced filters, scrubbers, and ESPs significantly raise investment.

1. Cost Breakdown of Biomass Boiler Plant

| System Component | Share of Total Installed Cost (%) | Cost Impact Factors |

|---|---|---|

| Boiler Island (core boiler + pressure parts) | 30–50% | Capacity, pressure, combustion type |

| Fuel Handling & Storage | 15–25% | Fuel type, moisture, particle size, silos, conveyors |

| Emission Control Systems | 10–30% | Local regulations, fuel ash, NOx, SO₂ requirements |

| Balance of Plant (BOP) | 10–20% | Pumps, piping, water treatment, electricals |

| Civil & Structural Works | 10–15% | Foundations, building, chimneys |

| Engineering & Commissioning | 5–10% | Design, automation, testing |

Key Insight: A plant using pellets will spend less on fuel handling and emissions, while a plant using agro residues (rice husk, straw, bagasse) may spend 40–50% of TIC on handling + emissions alone.

2. Fuel Handling Cost Variations

| Fuel Type | Typical Fuel Handling System | Cost Addition to TIC |

|---|---|---|

| Pellets | Simple silos + screw feeders | +5–10% |

| Wood Chips | Belt conveyors, screening, drying | +10–20% |

| Agro Waste | Specialized feeding, drying, ash systems | +20–35% |

Example: A 20 MW chip-fired plant may require $3–4M in conveyors and silos, while an agro-residue plant may spend $6–7M for robust feeding/drying/ash equipment.

3. Emission Control Cost Variations

Pellet boilers: Usually need cyclones + bag filters.

Wood chips: Require bag filters or ESPs depending on ash.

Agro residues: Require ESP + desulfurization + NOx control (SNCR/SCR).

| Regulation Level | Typical Systems | Cost Impact on TIC |

|---|---|---|

| Basic compliance (PM only) | Cyclones / Multicyclones | +5–10% |

| Medium compliance (PM + NOx) | Bag filters + SNCR | +15–20% |

| Strict compliance (PM + NOx + SO₂) | ESP + SCR + FGD | +20–30% |

4. Example – Installed Cost Calculation

For a 50 MW biomass boiler (CFB type) firing agro residues:

Boiler island: $20 million

Fuel handling & storage: $10 million

Emission systems: $12 million

Balance of plant: $7 million

Civil works: $6 million

Engineering & commissioning: $5 million

Total Installed Cost (TIC) = $60 million

If the same system fired pellets, TIC would likely be $40–45 million, due to simpler handling and cleaner combustion.

5. Engineering Insights

Boiler-only budget = misleading → Always factor in auxiliaries.

Fuel type drives TIC → Cheap fuel (agro residues) often requires higher CAPEX.

Emission rules change the game → EU/US strict standards can add 30%+ to TIC compared to less regulated regions.

Turnkey EPC supply reduces risk → Integrates handling, emissions, and boiler into one cost package.

Conclusion

The total installed cost of a biomass boiler project is typically 2–3x the boiler island cost, with fuel handling and emission control as the biggest add-ons. Pellet plants are simpler and cheaper to install, while agro-residue plants need heavy investment in fuel prep and emission systems. Accurate TIC estimation requires fuel analysis, regulatory mapping, and site-specific engineering.

How Do Biomass Boiler Operating Costs Compare with Coal, Oil, and Gas Systems?

When industrial users evaluate a new steam boiler system, they often underestimate the long-term operating cost differences between fuel types. The pain point is that while capital expenditure (CAPEX) for a biomass boiler may be higher than coal or gas, the operating cost structure (fuel, maintenance, emissions, labor) can either deliver long-term savings or create hidden expenses. Misjudging OPEX leads to uncompetitive production costs, budget overruns, and sometimes stranded assets. The solution is a clear comparison of biomass vs. coal, oil, and gas boiler operating costs, considering fuel price volatility, efficiency, emission compliance, and maintenance requirements.

Biomass boilers usually have higher OPEX for maintenance and labor but can achieve lower fuel costs (depending on local biomass supply) compared to oil and gas; coal remains competitive in fuel cost but suffers from rising emission compliance costs.

This means biomass can be the lowest-cost option in regions with abundant residues or pellets, while in areas with cheap natural gas, gas boilers usually win on OPEX.

Biomass fuel is always cheaper than fossil fuels.False

Biomass is only cheaper where local supply chains exist; imported pellets can cost more than coal or gas.

Natural gas boilers typically have the lowest maintenance and labor costs.True

Gas-fired boilers are automated, clean, and require less ash handling or soot cleaning compared to coal and biomass.

1. Comparative OPEX Breakdown

| Cost Factor | Biomass | Coal | Oil | Natural Gas |

|---|---|---|---|---|

| Fuel Price ($/MMBtu) | 3–8 (local), 10–14 (imported pellets) | 2–5 | 10–20 | 6–12 |

| Boiler Efficiency (%) | 75–90 | 80–88 | 82–90 | 90–95 |

| Fuel Handling Labor | High (manual/complex systems) | High | Medium | Low |

| Maintenance Costs | High (ash, fouling, corrosion) | High (slagging, SO₂ issues) | Medium | Low |

| Emission Compliance | Medium–High (particulates, NOx) | Very High (SO₂, NOx, CO₂) | Medium–High | Low–Medium |

| OPEX Trend | Stable if local supply | Rising (emission cost) | Volatile (oil price) | Volatile but usually lower O&M |

Key Insight: Biomass OPEX strongly depends on local feedstock price and availability. Where residues are free or low-cost, biomass beats coal and oil. But if biomass must be imported, it may be more expensive than natural gas.

2. Annual OPEX Comparison (for 50 MWth Boiler, 8,000 h/year)

| Fuel Type | Annual Fuel Cost | Annual O&M Cost | Total OPEX ($/year) |

|---|---|---|---|

| Biomass (local residues, $4/MMBtu) | $12M | $3M | $15M |

| Coal ($3/MMBtu) | $9M | $5M (ash + emission) | $14M |

| Oil ($15/MMBtu) | $36M | $2M | $38M |

| Natural Gas ($8/MMBtu) | $19M | $1.5M | $20.5M |

Example Insight: Coal looks cheapest on fuel cost alone, but once emission and ash disposal costs are added, OPEX can be close to biomass. Oil is always the most expensive. Gas is clean but price-sensitive to regional supply.

3. Impact of Emission Costs

Coal boilers: Need expensive SO₂ scrubbers, NOx controls, and CO₂ taxes in regulated markets. This can add $3–8M/year in OPEX for large plants.

Biomass boilers: Avoid CO₂ taxes (carbon neutral), but particulate controls (ESP/bag filters) are expensive.

Gas boilers: Lowest emissions, minimal add-on cost.

Oil boilers: Moderate sulfur content → requires scrubbers in strict regions.

4. Regional Fuel Price Variability

Europe: Natural gas expensive (post-2022) → biomass competitive, especially pellets/residues.

Asia (India/China): Coal cheap → coal still widely used, but emission compliance raising OPEX.

North America: Gas cheap → gas-fired boilers dominate OPEX competitiveness.

Latin America: Bagasse and agro residues abundant → biomass often cheapest option.

5. Engineering Insights

Biomass = lowest OPEX only where feedstock is secure and local.

Coal = risky due to rising carbon and emission costs.

Oil = only for backup or where other fuels unavailable.

Natural gas = lowest OPEX in most developed regions, provided gas prices are stable.

Conclusion

The operating cost ranking depends heavily on local conditions:

Cheapest overall: Biomass (if residues are local and abundant) or Natural Gas (if pipeline supply is low-cost).

Mid-range: Coal (but OPEX rising due to emission penalties).

Most expensive: Oil (fuel price too high for base-load).

The smartest strategy is to evaluate local fuel markets and emission policies before committing to a fuel type.

🔍 Conclusion

The cost of a biomass boiler depends on capacity, fuel type, and system configuration, but when properly designed, it can deliver significant long-term savings, energy security, and sustainability benefits. A complete evaluation of both investment and operating costs is key to achieving the best return.

📞 Contact Us

💡 Planning to invest in a biomass boiler? We provide detailed cost analysis, fuel sourcing studies, and turnkey biomass boiler solutions tailored to your project.

🔹 Contact us today for a customized biomass boiler proposal and ROI assessment. 🌱🔥🏭✅

FAQ

How much does a biomass boiler cost?

The cost of a biomass boiler depends on its size, technology, and application:

Small commercial biomass boilers (100 kW – 500 kW): $60,000 – $250,000

Medium industrial biomass boilers (1 – 5 MW): $250,000 – $2 million

Large-scale power plant biomass boilers (5 – 50 MW+): $2 million – $20 million+

Prices vary widely based on fuel type (wood chips, pellets, agricultural residues), pressure rating, emission control systems, and automation level.

What factors affect the cost of a biomass boiler?

Key factors include:

Boiler capacity (kW/MW) – Larger units have higher upfront costs but lower per-unit energy costs.

Fuel type & availability – Pellet systems cost more but offer higher efficiency and cleaner combustion than wood chip systems.

Efficiency & emissions compliance – High-efficiency, low-NOx models require advanced technology and increase costs.

Auxiliary systems – Includes feedwater system, economizer, ash handling, and emission controls.

Civil works & installation – Site preparation, foundations, piping, and electricals can equal 30–50% of boiler equipment cost.

What is the installation cost for a biomass boiler?

Installation can add significantly to total investment:

Small commercial units: 30–50% of equipment cost

Industrial biomass plants: 40–60% of equipment cost

Large power stations: Costs can double the equipment price due to civil works, conveyors, silos, and emission controls.

Example: A $1 million boiler package may result in a $1.5 – $2 million total installed cost.

How much does it cost to run a biomass boiler?

Running costs depend on fuel price, efficiency, and maintenance:

Fuel cost: Biomass fuels (wood chips, pellets) are often cheaper than oil or gas but require storage and handling.

Efficiency: Typically 75–90%, depending on technology and fuel quality.

Maintenance: Higher than gas boilers due to ash removal, fuel handling, and cleaning.

Labor cost: More manual work compared to gas/oil boilers unless automated.

Is a biomass boiler cost-effective compared to gas or coal?

Yes, in the right conditions:

Advantages: Renewable fuel, carbon-neutral potential, lower long-term fuel cost, energy independence.

Challenges: Higher capital investment, space requirement for fuel storage, more complex operation.

Biomass boilers are most cost-effective in regions with abundant, low-cost biomass and strict carbon regulations.

References

DOE – Biomass Boiler Cost and Efficiency Studies – https://www.energy.gov

Carbon Trust – Biomass Heating Guide – https://www.carbontrust.com

IEA Bioenergy – Biomass Boiler Market Trends – https://www.ieabioenergy.com

Spirax Sarco – Biomass Boiler Applications – https://www.spiraxsarco.com

Forbes Marshall – Industrial Biomass Boiler Costs – https://www.forbesmarshall.com

Babcock & Wilcox – Biomass Boiler Technology – https://www.babcock.com

Engineering Toolbox – Boiler Cost Estimation – https://www.engineeringtoolbox.com

ScienceDirect – Techno-Economic Biomass Boiler Studies – https://www.sciencedirect.com

ResearchGate – Biomass Boiler Performance & Costs – https://www.researchgate.net

BioEnergy Consult – Cost of Biomass Heating Systems – https://www.bioenergyconsult.com