CFB Biomass Boiler Supplier ANDRITZ Audit

CFB Biomass Boiler Supplier ANDRITZ Audit

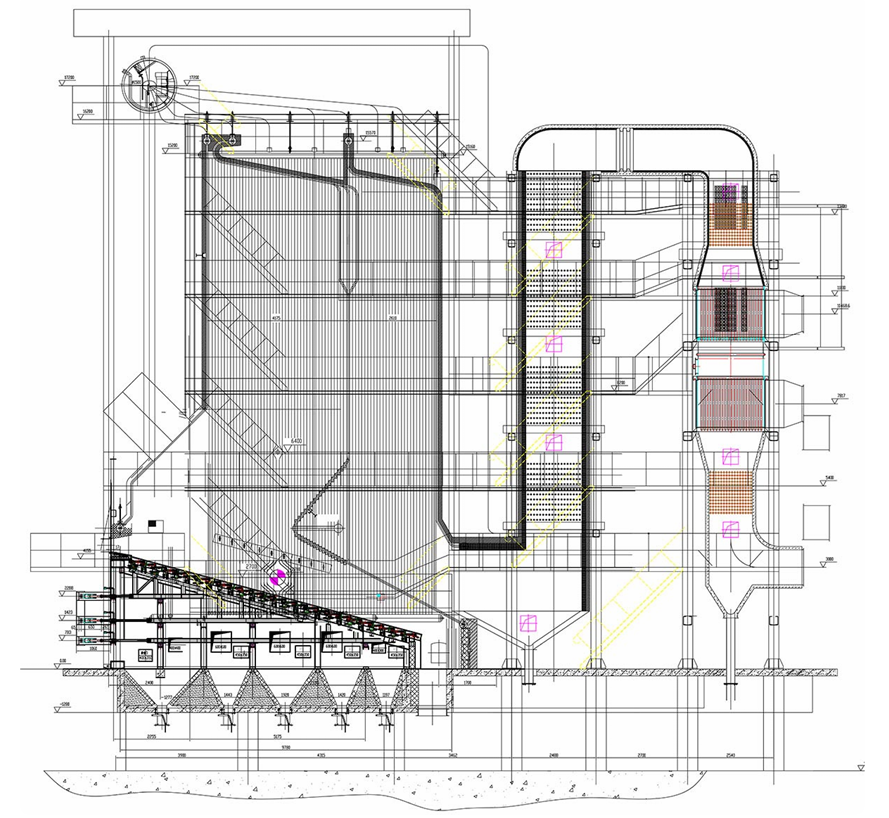

CFB Biomass Boiler is a kind of biomass boiler adopting CFB technology. On June 18 2020, two Supplier Auditing Engineers from ANDRITZ Austria visited Taishan Group for audit as a new supplier. This audit mainly focuses on the review of quality control system based on ISO (ISO9001, ISO14001, OHSAS18001) and ASME S. Company certificates, HSE management performance, key factory facilities & maintenance plan and record, ITP and process record (process shop traveler), welding procedure and NDT, etc.

Taishan Group was invited to participate in two new power plant projects in GAMAGORI and Omaezaki of Japan. Shidao Heavy Industry (Taishan Group pressure vessel factory) has been qualified supplier of pressure vessel for its paper& pulp section.

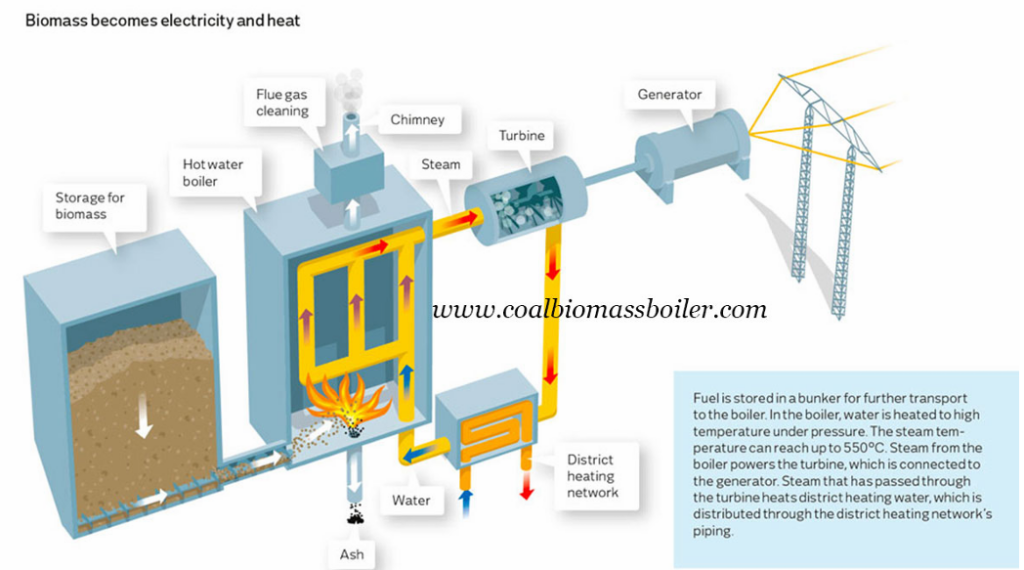

The required biomass boiler is subcritical boiler (superheated steam pressure 167 bars, steam temperature 540 degrees). The CFB Biomass Boiler capacity is 180t/h, and can generate 50MW electricity per hour. The fuel is wood chip. These two projects are important to ANDRITZ because of Japanese severe quality requirement as well as welding requirement of METI.

CFB Biomass Boiler supplier ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. It is one of the technology and global market leaders in hydropower business, pulp and paper industry, metal working and steel industries, and solid/liquid separation.

It has nearly 170 years of experience, approximately 28,400 employees, and over 280 locations in 40 countries worldwide.

ANDRITZ is also active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasi cation plants). It offers equipment for production of nonwovens, dissolving pulp, and panelboard, recycling plants, animal feed and biomass pelleting, automation.

In the first half of 2020, ANDRITZ had been awarded three new biomass power plant projects in Japan. It is also a great opportunity for Taishan Group to develop big capacity CFB Biomass Boiler.

Norma Wang

Taishan Group website editor, specializing in international marketing. Focus on the global market of industrial boilers.

75吨生物质发电厂.jpg)