20t/h High-Efficiency Coal-Fired Steam Boiler Shipped to Cambodia

20t/h High-Efficiency Coal-Fired Steam Boiler Shipped to Cambodia

1️⃣ Shipment Overview: Timely Delivery of Industrial Steam Boiler

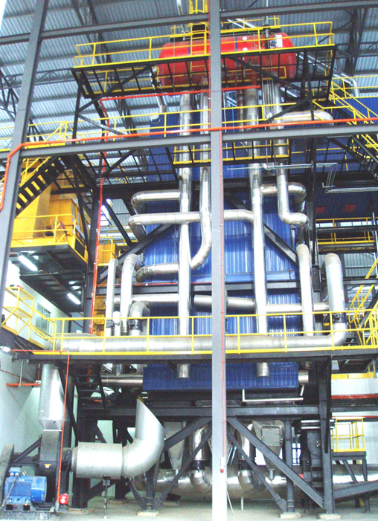

Taishan Group, a leading industrial boiler manufacturer and exporter, is pleased to announce the successful shipment of a 20t/h coal-fired steam boiler along with its auxiliary equipment to a valued client in Cambodia. The shipment marks another milestone in our international delivery record and showcases our ability to meet the demands of overseas projects efficiently.

The boiler was carefully prepared for transport, with every component inspected and secured according to international shipping standards. This ensures not only timely delivery but also the safety and integrity of the equipment during the overseas journey. By providing reliable steam boiler solutions for industrial applications, we continue to expand our footprint in Southeast Asia and other global markets.

2️⃣ Boiler Specifications & Advanced Features

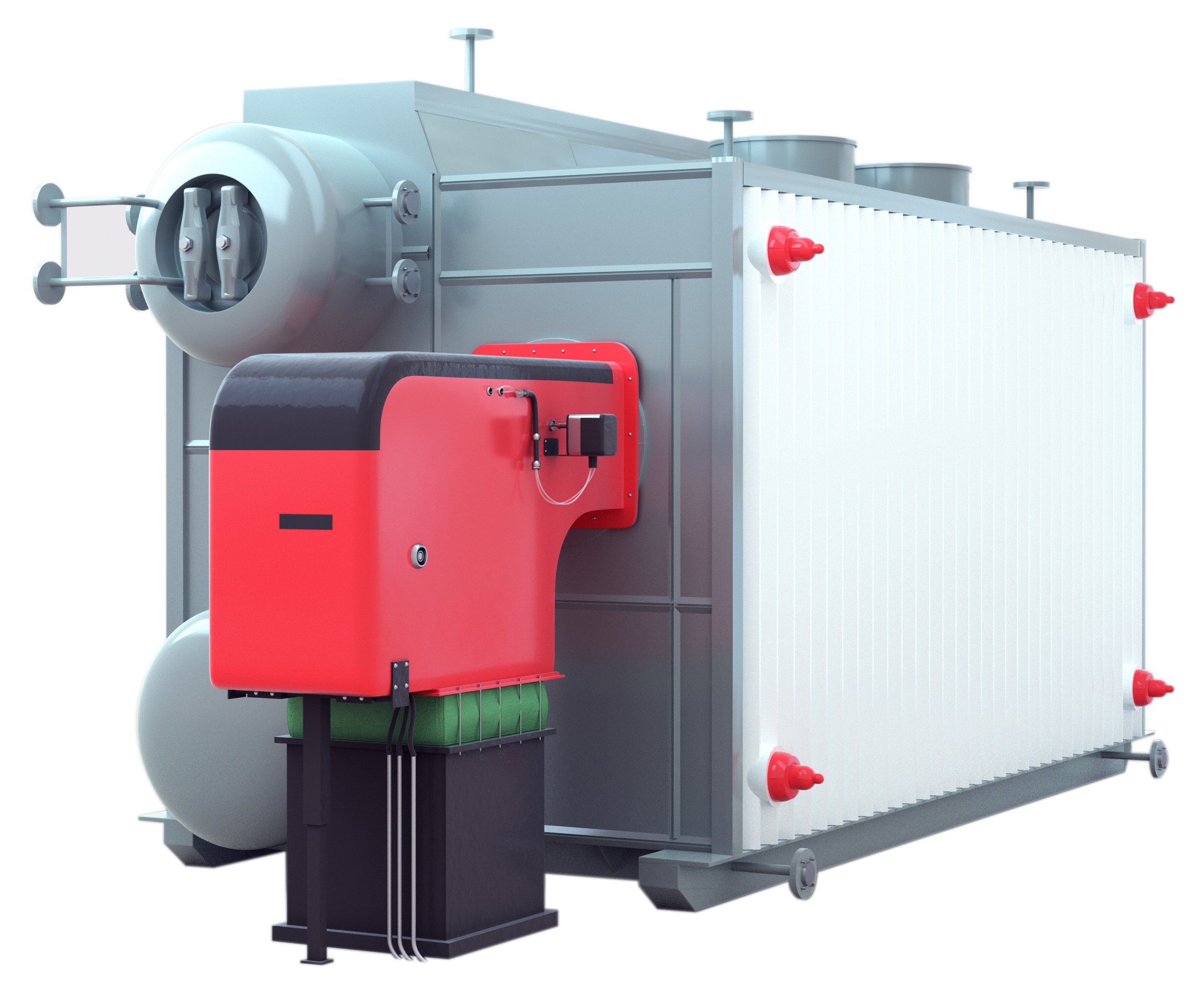

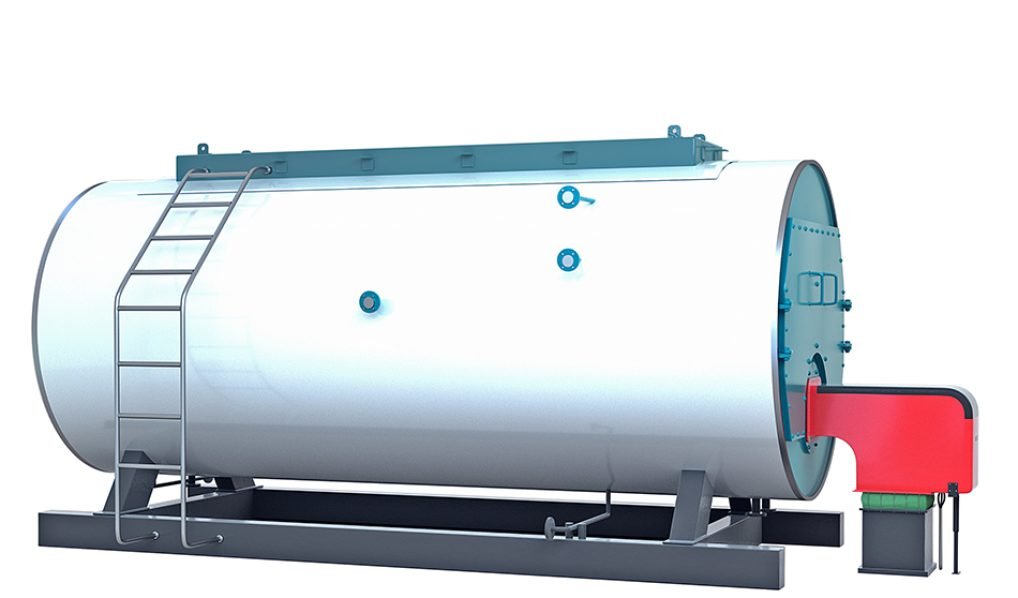

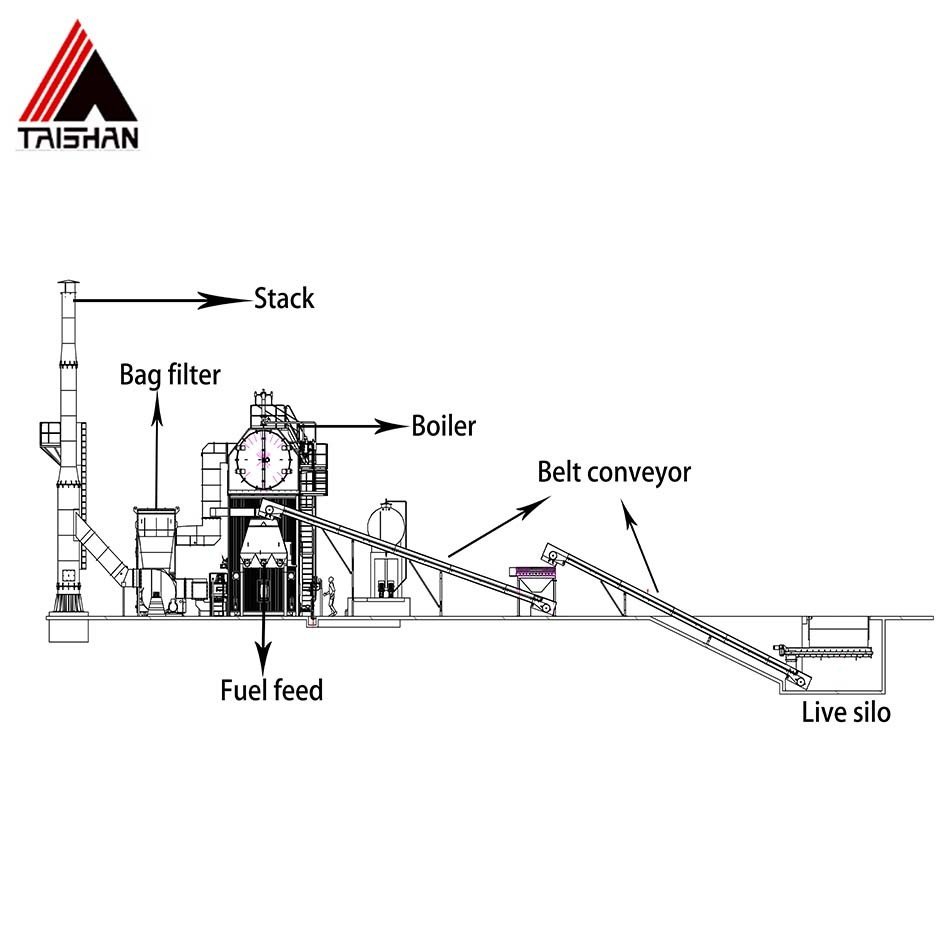

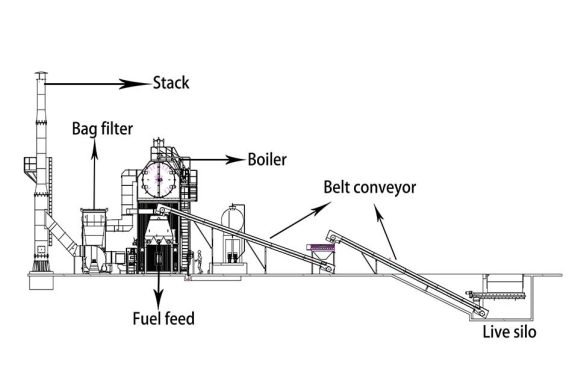

The exported boiler is a double-drum coal-fired steam boiler featuring a chain grate stoker, designed for stable combustion and high thermal efficiency. Key technical specifications include:

Steam Flow: 20t/h

Design Pressure: 2.5 MPa

Boiler Structure: Double-drum

Fuel Type: Anthracite coal

Application: Suitable for industrial processes including manufacturing, chemical, and energy production

The chain grate stoker ensures uniform coal combustion and efficient fuel utilization, reducing operating costs while maintaining consistent steam output. The boiler’s robust design, high efficiency, and compliance with modern industrial standards make it a reliable solution for clients seeking long-term performance and energy savings.

3️⃣ Packaging, Transportation & Logistics Management

To guarantee the safe delivery of heavy industrial equipment, the boiler and its auxiliary units were packed using reinforced protective materials, secured on transport vehicles, and carefully inspected by our logistics and engineering teams.

International shipment of industrial boilers requires meticulous planning, including:

Load distribution and weight balance

Reinforced packaging to withstand transport stress

Compliance with export regulations and customs documentation

By leveraging years of experience in industrial boiler export and overseas logistics, [Company Name] ensures that every project reaches the client on schedule and in perfect working condition. Our proactive planning minimizes risk, avoids shipment delays, and ensures a seamless boiler delivery process.

4️⃣ Customer Value, Application, & After-Sales Support

This successful shipment highlights our dedication to providing clients with high-performance, energy-efficient steam boiler solutions. By choosing [Company Name], customers benefit from:

Industry-leading coal-fired steam boiler technology

Stable operation under demanding industrial conditions

Timely and professional international delivery

Comprehensive after-sales support including installation guidance, commissioning, and operational advice

The 20t/h steam boiler shipped to Cambodia will support the client’s production efficiency, optimize energy consumption, and enhance overall operational reliability. Our commitment to quality, service, and innovation ensures that our clients achieve long-term value from every boiler investment.

📞 Contact Us

💡 Looking for a high-capacity coal-fired steam boiler for your project? We specialize in custom design, energy-efficient solutions, and global delivery services for industrial boilers.

🔹 Contact us today to discuss your boiler requirements and turnkey project solutions. 🏭⚡✅

FAQ

What are the features of the 20t/h coal-fired steam boiler shipped to Cambodia?

This industrial steam boiler is designed with:

High thermal efficiency (80–85%) through optimized combustion.

Advanced grate system for stable coal firing.

Economizer and air preheater for heat recovery.

Low NOx combustion design to meet emissions standards.

Robust structure suitable for long-term industrial use.

What industries in Cambodia will benefit from this boiler?

Industries such as:

Textiles and garments – For dyeing and finishing.

Food and beverage processing – For sterilization and cooking.

Rice mills and agriculture – For paddy drying and process heating.

Pharmaceuticals and chemicals – For process steam and heating.

This 20t/h boiler ensures reliable and cost-effective steam supply across multiple sectors.

Why choose a high-efficiency coal-fired boiler?

Fuel cost savings – More steam per ton of coal.

Lower emissions – Advanced combustion reduces pollutants.

Durability – Designed for continuous 24/7 operation.

Flexibility – Handles variable coal qualities.

How was the shipment of the 20t/h steam boiler managed?

The shipment process included:

Modular design for easy transport and installation.

Heavy-duty packaging to protect boiler components.

Sea freight logistics coordinated from the manufacturing site to Cambodia.

On-site technical support for installation and commissioning.

What benefits will the Cambodian client achieve with this project?

Stable steam supply for industrial operations.

Reduced fuel and operational costs through high efficiency.

Improved environmental compliance with lower emissions.

Technical support and after-sales service ensuring long-term reliability.

References

U.S. Department of Energy – Industrial Boiler Efficiency – https://www.energy.gov

IEA – Coal-Fired Power and Steam Systems – https://www.iea.org

Babcock & Wilcox – Coal-Fired Boiler Systems – https://www.babcock.com

Cleaver-Brooks – High-Efficiency Boiler Technologies – https://www.cleaverbrooks.com

Forbes Marshall – Industrial Steam Solutions – https://www.forbesmarshall.com

Thermax – Industrial Coal Boilers – https://www.thermaxglobal.com

Spirax Sarco – Steam Boiler Applications – https://www.spiraxsarco.com

ResearchGate – Coal-Fired Boiler Efficiency Studies – https://www.researchgate.net

ScienceDirect – Advances in Coal Combustion Technology – https://www.sciencedirect.com

Engineering Toolbox – Steam Boiler Data and Fuel Efficiency – https://www.engineeringtoolbox.com

Wade Zhang

20t/h High-Efficiency Coal-Fired Steam Boiler Shipped to Cambodia Read More »

-scaled.jpg)