For industries that rely on continuous and reliable steam supply, selecting the right oil fired boiler is a critical decision. Choosing the wrong size, design, or configuration can lead to higher fuel bills, increased emissions, frequent breakdowns, and costly retrofits. Many companies struggle to balance performance, fuel efficiency, and lifecycle costs when evaluating boiler options.

To choose the right industrial oil fired boiler, businesses should evaluate steam capacity requirements, operating pressure, oil fuel type and quality, combustion efficiency, emission compliance, and automation features. Additional considerations include auxiliary systems (burner, economizer, feedwater treatment), installation space, and after-sales service support. Matching boiler design with process needs ensures safe, efficient, and long-term operation.

By following a structured selection approach, companies can avoid costly mistakes and secure a boiler system that delivers both energy efficiency and reliability.

What Factors Determine the Correct Steam Capacity and Pressure for an Oil-Fired Boiler?

When selecting an oil-fired boiler, one of the most common mistakes plant managers make is oversizing or undersizing capacity and pressure. If the boiler is too small, production bottlenecks, unstable steam supply, and forced outages occur. If the boiler is too large, efficiency drops, operating costs rise, and investment is wasted. The pain point is that misjudging steam demand leads to either underperformance or inflated costs. The solution is to carefully evaluate the steam capacity and working pressure requirements based on process demand, peak loads, and safety margins.

The correct steam capacity and pressure for an oil-fired boiler are determined by process steam demand (continuous and peak loads), equipment specifications, distribution losses, steam quality requirements, and safety margins, with working pressure selected slightly above the highest process pressure requirement.

This ensures the boiler consistently delivers stable, high-quality steam without excessive cost or operational inefficiency.

Steam capacity should always be selected at the maximum possible value for future growth.False

Oversizing leads to low efficiency, cycling losses, and higher OPEX. Capacity should be based on realistic demand plus a calculated safety margin.

Boiler working pressure must be higher than the maximum process requirement to allow stable distribution.True

A 10–20% pressure margin above the highest process requirement ensures stable delivery across the steam network.

1. Key Factors for Correct Steam Capacity

| Factor | Impact on Boiler Sizing |

|---|---|

| Base Steam Demand | Defines minimum continuous load requirement |

| Peak Steam Load | Determines maximum boiler firing capacity |

| Load Variation | Affects whether single or multiple boilers are needed |

| Future Expansion | Guides safety margin (10–15%, not oversizing) |

| Distribution Losses | Adds 3–5% to demand estimate |

| Standby Redundancy | N+1 boiler concept for critical plants |

Example: A plant requiring 20 tph continuous and 25 tph peak demand should size a boiler for ~27–28 tph (including margin + losses), not 35–40 tph.

2. Key Factors for Correct Steam Pressure

| Consideration | Typical Practice |

|---|---|

| Process Requirement | E.g., 8 bar for sterilization, 15–20 bar for power generation |

| Pressure Drop in Distribution | 0.5–2 bar allowance |

| Boiler Pressure Margin | 10–20% above highest process need |

| Equipment Compatibility | Must not exceed design limits of steam-using equipment |

| Safety and Efficiency | Too high = energy waste, too low = unstable supply |

Example: If a process needs 10 bar steam at equipment, and piping drops 1 bar, boiler should be designed for 12–13 bar.

3. Oil-Specific Considerations

Combustion system flexibility: Oil burners can modulate easily, but excess capacity leads to inefficient low-load firing.

Steam quality requirements: Food and pharma often require dry saturated steam, affecting pressure selection.

Fuel cost factor: Oil is more expensive than coal or biomass, so precise sizing is critical to avoid waste.

4. Decision-Making Flow

Calculate base and peak steam loads from process flow sheets.

Add distribution losses and minimum redundancy (if required).

Select working pressure based on highest-pressure process + pipeline drop + margin.

Check burner/boiler turndown ratio to ensure stable low-load operation.

Validate against future expansion plans.

5. Example Case – Oil-Fired Boiler Sizing

Pharma plant steam demand:

Continuous: 8 tph @ 8 bar

Peak: 10 tph

Distribution losses: 0.5 tph equivalent

Boiler pressure selection: 10 bar at process → +2 bar margin → 12 bar design

Correct boiler size: 12 tph @ 12 bar

If the plant wrongly chose a 15 tph, 16 bar boiler, efficiency would drop, OPEX would increase, and unnecessary CAPEX would be wasted.

Conclusion

The correct steam capacity and pressure of an oil-fired boiler are determined by process steam demand, peak load, system losses, and safety margin, not by “bigger is better.” For oil-fired units, precise sizing is even more important due to higher fuel cost per MMBtu compared to coal or gas. Getting this right reduces both CAPEX and OPEX while ensuring reliable steam supply.

How Does the Type and Quality of Fuel Oil Affect Boiler Design and Performance?

When designing or operating an oil-fired boiler, a critical but often underestimated factor is the type and quality of fuel oil used. The pain point is clear: using the wrong grade of oil without adapting boiler design leads to poor atomization, incomplete combustion, corrosion, slagging, higher emissions, and costly maintenance shutdowns. For operators, this means rising fuel bills and lower reliability. The solution lies in understanding how each fuel oil type (diesel, light oil, heavy oil, crude residues) influences boiler design, performance, and lifecycle costs.

The type and quality of fuel oil affect boiler design and performance by dictating the burner and atomization system, furnace size, fuel handling requirements, emission control needs, and maintenance schedules. Cleaner light oils allow higher efficiency and simpler design, while heavy and low-quality oils require preheating, soot blowing, larger combustion chambers, and corrosion-resistant materials.

Choosing the right match between fuel properties and boiler design ensures stable operation, compliance with emissions, and cost-effectiveness.

All grades of fuel oil can be used interchangeably in the same boiler without modification.False

Each oil type has distinct viscosity, sulfur, and impurity levels that require specific burner designs and boiler configurations.

Heavy fuel oil requires heating before atomization to ensure proper combustion.True

HFO must be preheated to around 100–150°C to reduce viscosity and allow efficient burner atomization.

1. Types of Fuel Oils and Boiler Implications

| Fuel Oil Type | Viscosity & Quality | Boiler Design Implication |

|---|---|---|

| Diesel / Light Fuel Oil (LFO) | Low viscosity, clean, low sulfur | Simple burners, high efficiency, minimal fouling |

| Marine Fuel Oil (MFO) | Moderate viscosity, some impurities | Preheating required, moderate fouling and corrosion control |

| Heavy Fuel Oil (HFO) | High viscosity, high sulfur and ash | Needs heating, large furnaces, soot blowers, stronger emission controls |

| Residual / Crude Oils | Very impure, variable quality | Complex fuel treatment, robust materials, frequent cleaning |

2. Critical Fuel Oil Properties That Influence Performance

| Property | Impact on Boiler |

|---|---|

| Viscosity | Determines need for preheating and atomization method |

| Sulfur Content | Leads to SO₂/acid corrosion; requires emission scrubbers |

| Ash & Metals (Vanadium, Sodium) | Fouling, slagging, high-temp corrosion |

| Calorific Value | Affects fuel consumption and heat balance |

| Contaminants/Water | Instability in flame, corrosion, loss of efficiency |

3. Boiler Design Adjustments by Fuel Type

Burners and Atomization

Light oils: pressure jet burners.

Heavy oils: steam or air atomizing burners with large nozzles.

Fuel Handling Systems

Diesel: direct pumping.

HFO: storage heating (~40°C) + preheating (~100–150°C).

Combustion Chamber Design

Heavier fuels: larger chamber to ensure complete combustion.

Heat Transfer Surfaces

Soot blowers required for HFO.

Fouling-resistant surfaces designed into boiler.

Emission Control

Light oil: minimal treatment.

HFO: scrubbers, ESPs, desulfurization systems.

4. Performance Impacts of Fuel Oil Choice

| Fuel Oil | Efficiency | Maintenance | Emission Profile |

|---|---|---|---|

| Diesel | 90–95% | Low | Very low |

| MFO | 85–90% | Medium | Moderate |

| HFO | 80–88% | High (soot, corrosion) | High (SO₂, particulates) |

| Residual oils | 75–85% | Very high | Very high |

5. Example Case Study

A cement plant opted to switch from light diesel to cheaper heavy fuel oil. While fuel savings were expected, problems soon arose: inadequate preheating led to poor atomization, soot accumulation reduced heat transfer efficiency, and acid corrosion increased maintenance downtime. The result was efficiency losses and unexpected O&M costs, proving that lower fuel price does not guarantee lower lifecycle cost.

Conclusion

The fuel oil’s type and quality directly affect boiler design and performance. Light oils simplify design and improve efficiency but are more expensive. Heavy oils are cheaper but require more complex systems, higher CAPEX, and stricter maintenance to avoid fouling and emissions penalties. The key is to balance fuel cost vs. design complexity vs. long-term OPEX for each specific plant.

What Combustion and Heat Recovery Technologies Improve Oil-Fired Boiler Efficiency?

AI Prompt: Oil-fired boiler with advanced combustion burners + economizer heat recovery system + industrial cutaway illustration + high-efficiency design + modern clean energy plant environment + technical schematic style lighting

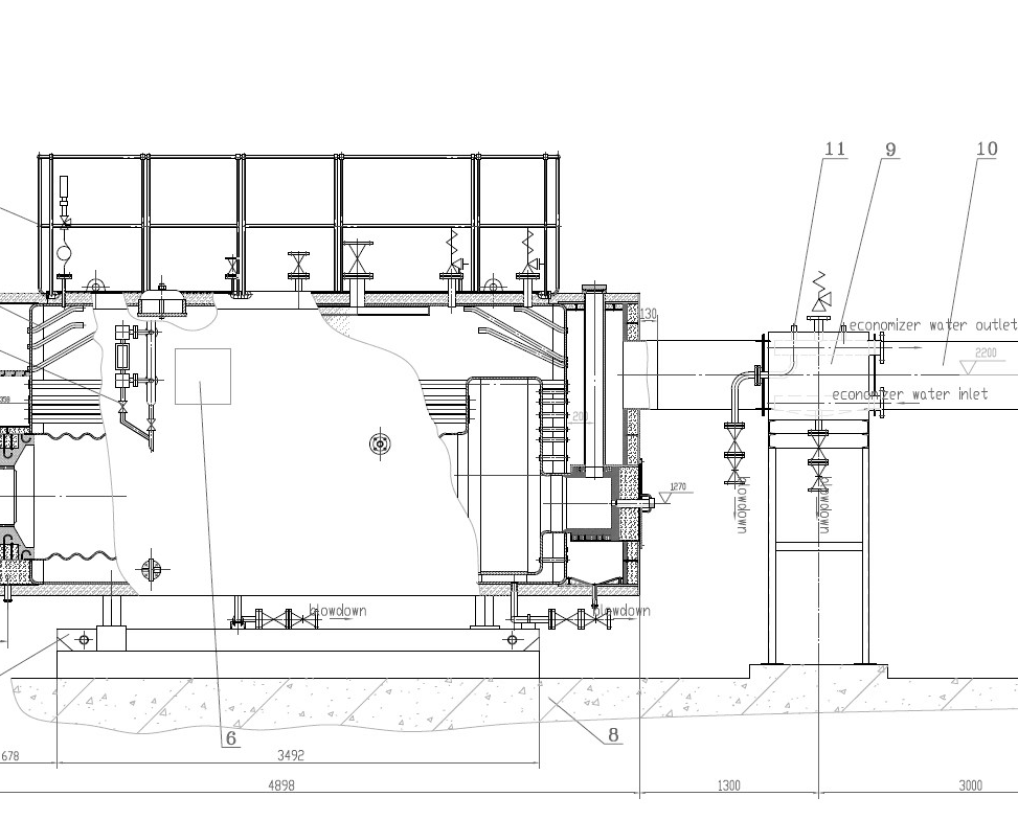

The greatest challenge for industries relying on oil-fired boilers is the ever-increasing cost of fuel and the pressure to meet emission standards. A poorly optimized boiler burns more oil than necessary, wastes valuable heat energy through flue gases, and produces higher levels of pollutants—leading to rising operating expenses and compliance risks. The solution is the integration of advanced combustion technologies and heat recovery systems that maximize energy use, improve thermal efficiency, and cut both costs and emissions.

Combustion and heat recovery technologies such as low-NOx burners, advanced atomization systems, flue gas economizers, air preheaters, condensers, and modern control automation significantly improve oil-fired boiler efficiency by ensuring complete combustion, reducing unburned fuel losses, and recovering waste heat for reuse.

This means that by selecting the right combination of combustion optimization and heat recovery equipment, industries can achieve fuel savings of 10–25%, extend boiler life, and meet stricter environmental standards without compromising steam reliability.

Most of the energy loss in oil-fired boilers comes from unburned fuel in ash and incomplete combustion.False

The largest energy loss in oil-fired boilers typically occurs through hot flue gas leaving the stack, not unburned fuel.

Installing an economizer can increase boiler efficiency by 5–10% by recovering heat from flue gases.True

Economizers use hot exhaust gases to preheat feedwater, reducing fuel required for steam generation.

1. Advanced Combustion Technologies

| Technology | Efficiency Impact | Notes |

|---|---|---|

| Low-NOx Burners | Optimize air-fuel mixing for complete combustion | Reduces excess air and fuel wastage |

| Steam/air-assisted Atomization | Improves droplet fineness of heavy oil | Essential for efficient combustion of HFO |

| Oxygen Trim Controls | Adjusts air supply in real-time | Prevents excess air or oxygen starvation |

| Flame Monitoring & Sensors | Ensures flame stability | Avoids incomplete combustion and fuel loss |

2. Heat Recovery Technologies

| System | Efficiency Gain | Function |

|---|---|---|

| Economizer | +5–10% | Recovers flue gas heat to preheat feedwater |

| Air Preheater | +2–5% | Uses exhaust gases to preheat combustion air |

| Condensing Heat Exchanger | +8–12% | Captures latent heat by condensing water vapor in flue gases |

| Blowdown Heat Recovery | +1–2% | Reclaims heat from boiler blowdown water |

3. Integrated Efficiency Approach

Combustion optimization reduces fuel waste by achieving near-complete burning of oil droplets.

Heat recovery systems capture energy that would otherwise escape through the stack.

Automated control systems link the two, adjusting burner settings and recovery equipment operation based on steam demand.

4. Example Efficiency Comparison

| Boiler Setup | Efficiency % | Fuel Consumption Impact |

|---|---|---|

| Conventional Oil Boiler (no recovery) | 80–85% | Baseline consumption |

| With Economizer + Oxygen Trim | 88–92% | Fuel savings ~6–10% |

| With Condensing Recovery + Advanced Controls | 92–95% | Fuel savings ~12–18% |

5. Case Example

A food processing plant upgraded its 10-ton oil-fired boiler by installing steam atomizing burners, an economizer, and oxygen trim controls. Efficiency rose from 84% to 92%, reducing annual fuel consumption by 12%. The investment paid back in less than 2 years while lowering CO₂ emissions.

Conclusion

The efficiency of oil-fired boilers depends not only on fuel type but also on how effectively the boiler burns the oil and recovers waste heat. By implementing low-NOx burners, economizers, air preheaters, condensers, and advanced controls, operators can achieve substantial fuel savings, extend equipment life, and reduce emissions.

How to Ensure Compliance with Emission Standards for Oil-Fired Boilers?

For operators of oil-fired boilers, one of the greatest pain points is meeting increasingly strict emission standards. Non-compliance leads to regulatory penalties, forced shutdowns, costly retrofits, and reputational risks. Oil fuels, especially heavy fuel oils, produce SO₂, NOx, CO₂, particulates, and trace metals, all of which are regulated under environmental laws worldwide. The solution is to integrate the right combination of fuel quality management, advanced combustion optimization, and flue gas cleaning technologies to keep emissions within permitted limits while maintaining boiler performance.

Compliance with emission standards for oil-fired boilers is achieved by selecting the correct grade of fuel oil, using advanced low-NOx burners and combustion controls, installing flue gas treatment systems such as desulfurization scrubbers, selective catalytic reduction (SCR), and electrostatic precipitators (ESPs), and maintaining continuous emission monitoring (CEMS) for verification.

This means compliance is not a one-time upgrade but an ongoing system of design, operation, and monitoring that ensures boilers operate cleanly and reliably under varying load and fuel conditions.

Switching to light fuel oil automatically eliminates the need for emission controls in oil-fired boilers.False

While light oil contains less sulfur and impurities, it still produces NOx, CO₂, and requires combustion optimization and monitoring for compliance.

Selective catalytic reduction (SCR) can reduce NOx emissions by more than 90% in oil-fired boilers.True

SCR systems use ammonia injection and catalysts to convert NOx into nitrogen and water vapor, making them one of the most effective NOx control technologies.

1. Key Emissions from Oil-Fired Boilers

| Pollutant | Source | Environmental Impact |

|---|---|---|

| SO₂ | Sulfur content in fuel oil | Acid rain, corrosion |

| NOx | High combustion temperatures | Smog, ozone formation |

| CO₂ | Combustion of hydrocarbons | Greenhouse gas emissions |

| Particulates & Soot | Incomplete combustion, ash in fuel | Health hazard, fouling |

| Metals (V, Ni, Na) | Impurities in heavy oils | Toxic emissions, equipment corrosion |

2. Strategies for Emission Compliance

| Approach | Methods | Impact on Compliance |

|---|---|---|

| Fuel Management | Use low-sulfur or ultra-low-sulfur fuel oils | Reduces SO₂ emissions significantly |

| Combustion Optimization | Low-NOx burners, staged combustion, oxygen trim | Cuts NOx and unburned hydrocarbons |

| Flue Gas Treatment | – Flue Gas Desulfurization (FGD) |

Selective Catalytic Reduction (SCR)

Electrostatic Precipitators (ESP)

Baghouse Filters | Removes SO₂, NOx, particulates, heavy metals |

| Heat Recovery Systems | Economizers and condensers | Improves efficiency, reduces CO₂ per unit steam |

| Monitoring & Maintenance | Continuous Emission Monitoring Systems (CEMS) + regular cleaning | Ensures consistent compliance |

3. Typical Emission Control Technologies

| Technology | Target Pollutant | Reduction Efficiency |

|---|---|---|

| Wet Scrubbers (FGD) | SO₂ | 90–98% |

| Dry Sorbent Injection | SO₂ | 50–70% |

| SCR (Selective Catalytic Reduction) | NOx | 90–95% |

| SNCR (Non-Catalytic Reduction) | NOx | 40–70% |

| Electrostatic Precipitator (ESP) | Dust/Particulates | 95–99% |

| Bag Filters | Dust/Particulates | 99% |

4. Case Study

A power plant operating heavy fuel oil boilers faced tightening SO₂ and NOx limits. By installing wet FGD units, low-NOx burners, and SCR systems, emissions of SO₂ dropped by 95% and NOx by 92%. Although the retrofit added 12% to project CAPEX, fuel efficiency improvements and regulatory compliance avoided millions in penalties and downtime.

5. Role of Monitoring

Compliance is not just about installing technology—it requires proof of performance. Modern regulations demand Continuous Emission Monitoring Systems (CEMS) to measure SO₂, NOx, CO₂, and particulates in real-time, ensuring transparency and automatic reporting to regulators.

Conclusion

Ensuring compliance for oil-fired boilers requires a holistic approach: choosing cleaner fuels, optimizing combustion, installing advanced flue gas treatment systems, and maintaining continuous monitoring. While this may increase initial investment, it ensures long-term operational stability, lower risk of fines, and improved sustainability.

Why Are Auxiliary Systems Like Burners, Economizers, and Feedwater Systems Essential?

When evaluating a steam boiler, many users focus on the boiler body itself, but often overlook the auxiliary systems that make it function efficiently, safely, and economically. Without proper auxiliary equipment, boilers face risks such as low combustion efficiency, wasted heat energy, poor water quality, scale formation, unsafe pressure fluctuations, and premature failure. These issues result in higher operating costs, unplanned downtime, and environmental non-compliance. The solution is recognizing that a boiler is not a standalone unit but an integrated system, where auxiliaries like burners, economizers, and feedwater systems are just as critical as the pressure vessel.

Auxiliary systems such as burners, economizers, and feedwater systems are essential because they ensure complete combustion, improve thermal efficiency by recovering waste heat, and provide treated water to protect boiler tubes—ultimately guaranteeing safe, reliable, and cost-effective operation.

In other words, these systems are not optional add-ons but core components of any industrial or power boiler setup. Their absence or poor performance directly translates into higher fuel consumption, unsafe operation, and shorter equipment lifespan.

A boiler can achieve high efficiency without an economizer as long as the burner is optimized.False

Even with optimized combustion, significant energy is lost in flue gases. Economizers recover this waste heat, typically improving efficiency by 5–10%.

Untreated feedwater can cause scale buildup and tube failure in boilers.True

Impurities in water precipitate under high temperature and pressure, leading to scale, reduced heat transfer, and eventual tube rupture.

1. Burners – The Heart of Combustion

Burners are responsible for mixing fuel (oil, gas, coal, or biomass) with combustion air in the correct ratio to achieve complete, stable, and efficient combustion.

Low-NOx and staged burners reduce emissions.

Atomizing systems (steam/air-assisted) are critical for heavy oils.

Oxygen trim controls ensure the burner operates at peak efficiency.

Without a properly designed burner, even the most advanced boiler cannot deliver efficiency or emissions compliance.

2. Economizers – Recovering Waste Heat

Economizers capture heat from flue gases and use it to preheat boiler feedwater. This reduces the energy required to convert water into steam.

| With Economizer | Without Economizer |

|---|---|

| Efficiency: 88–92% | Efficiency: 80–85% |

| Fuel savings: 6–10% | Higher operating costs |

| Lower CO₂ emissions | Increased environmental footprint |

This makes economizers one of the most cost-effective auxiliary systems with a 2–3 year payback period in most industrial applications.

3. Feedwater Systems – Protecting Boiler Integrity

Feedwater systems supply treated water at the right pressure, temperature, and chemical balance. They typically include:

Deaerators to remove oxygen and CO₂ (preventing corrosion).

Softening/Demineralization to prevent scale formation.

Pumps and controls to maintain consistent water supply.

Failure to treat feedwater leads to:

Scale buildup → reduced efficiency.

Tube overheating → ruptures.

Corrosion → premature failure.

4. Integrated Role of Auxiliaries

Auxiliary systems work together to improve safety, efficiency, and sustainability.

| Auxiliary System | Primary Function | Impact on Boiler |

|---|---|---|

| Burners | Ensure complete combustion | Efficiency & emissions |

| Economizers | Recover waste heat | Lower fuel use |

| Feedwater Systems | Provide treated, deaerated water | Protects boiler tubes |

| Draft Fans | Maintain proper air flow | Stable combustion |

| Blowdown Systems | Control water chemistry | Prevents scale/corrosion |

5. Case Example

A textile plant upgraded its boiler by installing a modern low-NOx burner, an economizer, and a deaerator system. Boiler efficiency rose from 82% to 91%, fuel costs dropped by 12% annually, and downtime due to tube leaks was reduced to zero.

Conclusion

Auxiliary systems like burners, economizers, and feedwater treatment are indispensable for any oil, gas, coal, or biomass-fired boiler. They not only save energy and reduce emissions but also ensure long-term operational safety and reliability.

How Do Automation, Monitoring, and After-Sales Services Influence Boiler Selection?

When choosing an industrial or power boiler, many buyers primarily compare capacity, pressure, and fuel type, but often underestimate the importance of automation, monitoring, and after-sales services. The absence of advanced automation leads to inefficient combustion, frequent manual adjustments, and safety risks. Without proper monitoring, operators risk undetected failures, higher fuel use, and unexpected shutdowns. Similarly, lack of strong after-sales service can cause long downtime, poor spare parts availability, and high lifecycle costs. The solution is to consider not only the boiler hardware but also the control intelligence and service ecosystem that ensure long-term reliable operation.

Automation, monitoring, and after-sales services strongly influence boiler selection because they enhance operational safety, maximize efficiency through real-time optimization, minimize unplanned downtime with predictive maintenance, and provide long-term technical support and spare parts availability. A boiler is not just a one-time purchase but an investment that requires lifecycle reliability, which is only achievable with integrated controls and strong service support.

This means that the most cost-effective boiler is not necessarily the cheapest upfront—it is the one that combines high automation, advanced monitoring systems, and comprehensive after-sales support, delivering lower total cost of ownership (TCO) and higher plant reliability.

Manual operation of industrial boilers is sufficient for efficiency and safety in modern plants.False

Manual control cannot ensure stable combustion, emissions compliance, or predictive maintenance. Automation and monitoring are essential in modern industrial environments.

After-sales service contracts with spare parts supply reduce total lifecycle costs of boilers.True

Regular maintenance and fast spare parts availability prevent costly shutdowns and extend boiler life.

1. Role of Automation in Boiler Selection

Automation ensures stable, efficient, and safe boiler operation through:

Oxygen trim controls → optimized combustion air ratio.

Automatic load adjustment → efficiency under variable steam demand.

Safety interlocks → prevention of dry firing, flame failure, and overpressure.

Integrated PLC/SCADA systems → central plant control and easy operator interface.

| Automation Level | Features | Impact on Performance |

|---|---|---|

| Basic | Manual control + simple alarms | High risk of inefficiency & human error |

| Semi-Automated | Digital controls + basic safety interlocks | Moderate efficiency, safer operation |

| Fully Automated | PLC/SCADA + oxygen trim + load control | High efficiency, low emissions, safe 24/7 operation |

2. Importance of Monitoring

Modern monitoring goes beyond temperature and pressure readings—it includes:

Continuous Emissions Monitoring Systems (CEMS) to comply with environmental laws.

Predictive maintenance tools (vibration, thermal, and acoustic monitoring).

Energy management dashboards showing fuel use vs. steam output.

Remote monitoring for centralized plant supervision.

Without real-time monitoring, operators may only detect issues after failure occurs, leading to expensive downtime.

3. After-Sales Services – The Hidden Value

Strong after-sales support is one of the biggest differentiators in boiler selection. This includes:

Spare parts availability (burners, tubes, pumps, controls).

Scheduled maintenance contracts with original engineers.

Emergency repair response times (critical in continuous process industries).

Training programs for plant operators.

Case Example: A refinery with 3 × 50 t/h oil-fired boilers signed a long-term service contract with guaranteed 24h spare parts supply. Result: 98.5% boiler uptime compared to <92% industry average, saving millions in avoided downtime.

4. Integrated Impact on Lifecycle Costs

| Factor | Without Automation/Service | With Automation/Service |

|---|---|---|

| Efficiency | 78–82% | 88–92% |

| Safety | High accident risk | Fail-safe, automated |

| Downtime | 5–10 days/year | <2 days/year |

| Lifecycle Costs | 20–30% higher | Reduced by up to 25% |

Conclusion

Automation, monitoring, and after-sales services are not optional—they are critical decision factors when selecting a boiler. They determine not only short-term performance but also long-term safety, compliance, and operating costs. Choosing a boiler without these elements often results in hidden costs and operational risks far exceeding initial savings.

🔍 Conclusion

Choosing the right industrial oil fired boiler requires evaluating both technical specifications and operational requirements. A well-matched system can deliver reliable steam, optimized fuel use, and regulatory compliance, ensuring a strong return on investment.

📞 Contact Us

💡 Looking for the right oil fired boiler for your plant? We provide customized boiler design, fuel analysis, and turnkey solutions to meet your operational needs.

🔹 Reach out today to find the ideal oil fired boiler solution for your industry. 🛢️🔥🏭✅

FAQ

How do I choose the right industrial oil-fired boiler?

Choosing the right oil-fired boiler requires evaluating:

Steam or hot water demand – Ensure the boiler matches process requirements in capacity (t/h) and pressure (bar/MPa).

Fuel type and quality – Light oil, heavy oil, or dual-fuel options.

Efficiency level – Select boilers with 85–92% efficiency, ideally with economizers or condensing technology.

Industry-specific needs – Food, textiles, chemicals, and power sectors have different steam requirements.

Compliance – Must meet ASME, ISO, CE, or local safety/environmental codes.

What capacity oil-fired boiler do I need?

The right capacity depends on:

Steam load calculation – Daily average and peak demand.

Operating hours – Continuous vs batch processing.

Future expansions – Plan for at least 10–20% margin.

Process type – Small industries may need 1–20 t/h, while heavy industries may require 50–200+ t/h.

What are the types of oil-fired industrial boilers?

Common options include:

Fire-tube boilers – Compact, suitable for small-to-medium industries.

Water-tube boilers – High-capacity, efficient, ideal for large-scale power and process plants.

Condensing boilers – Use flue gas heat recovery, efficiency up to 95%.

Packaged boilers – Pre-assembled units with burner, controls, and auxiliaries for faster installation.

How does oil quality affect boiler performance?

Oil quality impacts efficiency, maintenance, and lifespan:

Light oil (diesel, kerosene) – Cleaner combustion, less fouling, higher cost.

Heavy oil – More economical, but requires preheating and better atomization.

Impurities (sulfur, ash, water) – Cause corrosion, slagging, and higher maintenance.

Routine fuel testing and filtration can prevent performance losses.

What are the cost considerations for oil-fired boilers?

Cost evaluation should consider:

Initial investment – Varies with type, size, and features.

Fuel cost – Major operating expense, efficiency reduces fuel use.

Maintenance cost – Oil boilers need regular cleaning of tubes and burners.

Emission control – Extra cost for desulfurization or NOx reduction if required.

Lifecycle cost – A high-efficiency boiler may cost more initially but saves money over 20+ years.

References

DOE – Guide to Industrial Boilers – https://www.energy.gov

ASME – Boiler and Pressure Vessel Code – https://www.asme.org

Forbes Marshall – Industrial Boiler Selection – https://www.forbesmarshall.com

Babcock & Wilcox – Oil-Fired Boilers – https://www.babcock.com

Spirax Sarco – Boiler Selection Guide – https://www.spiraxsarco.com

Cleaver-Brooks – Boiler Efficiency by Fuel – https://www.cleaverbrooks.com

IEA – Industrial Boiler Energy Trends – https://www.iea.org

Engineering Toolbox – Boiler Sizing Calculations – https://www.engineeringtoolbox.com

ResearchGate – Oil Boiler Performance Analysis – https://www.researchgate.net

National Board – Boiler Safety Resources – https://www.nationalboard.org