When selecting a boiler system, buyers often struggle to understand the real difference between commercial and industrial boilers—and choosing the wrong type can result in performance limitations, code violations, or wasted capital investment. While both types produce steam or hot water, they are designed for distinct applications, duty cycles, and engineering standards that must be carefully matched to the intended use.

The primary difference is that commercial boilers are designed for moderate-capacity heating applications such as office buildings, hospitals, or schools, typically ranging from 300,000 to 10 million BTU/hr. Industrial boilers, on the other hand, are engineered for continuous, high-output steam or heat production in manufacturing, chemical, power, and process industries, with much higher pressure ratings, capacities exceeding 10 million BTU/hr, and heavy-duty construction.

Understanding these distinctions ensures that the boiler you choose aligns with your operational requirements, safety standards, and long-term reliability goals. Below is a deeper look into how these two categories compare in practice.

What Defines a Commercial Boiler, and Where Is It Typically Used?

In commercial buildings such as hotels, hospitals, office towers, and schools, the demand for heating and hot water is both intensive and continuous. These environments cannot tolerate cold interiors, poor sanitation, or inconsistent service. When a residential boiler is undersized or inefficient, it leads to guest complaints, energy waste, and regulatory fines. That’s where commercial boilers come in. These units are specifically engineered to handle the scale, reliability, and control requirements of large non-industrial facilities. Understanding their capabilities and limitations is essential for choosing the right boiler system for your commercial needs.

A commercial boiler is a pressurized system designed to supply hot water or steam for heating and domestic purposes in non-residential buildings. Typically rated between 300,000 and 10 million BTU/hr, commercial boilers are used in spaces like hotels, hospitals, schools, malls, and office buildings, providing space heating, hot water, or process heat with high reliability and efficiency.

They bridge the gap between small-scale residential units and heavy-duty industrial boilers.

Commercial boilers are typically used in non-industrial settings such as offices, schools, and hospitals.True

Commercial boilers are engineered to meet the heating and hot water needs of larger non-residential facilities without the high-pressure requirements of industrial boilers.

A residential boiler can be used for any commercial application as long as it is installed properly.False

Residential boilers are not rated for the size, runtime, redundancy, or safety codes required in commercial environments.

Key Features That Define a Commercial Boiler

| Attribute | Commercial Boiler Specification |

|---|---|

| Output Rating | 300,000–10,000,000 BTU/hr (or 88–3,000 kW) |

| Fuel Type | Natural gas, oil, propane, electricity, dual-fuel |

| Efficiency Standards | Condensing (90–98% AFUE) or non-condensing (>80% AFUE) |

| Pressure Range | Typically up to 150 psi (10.3 bar) for hot water, 15 psi for steam |

| Construction | Fire-tube, water-tube, sectional cast iron, or condensing steel |

| Controls | Digital touchscreens, remote monitoring, BACnet, fault detection |

| Redundancy | Often modular or with N+1 configuration for reliability |

Commercial boilers are engineered for long runtime, daily cycling, and low maintenance while complying with regional codes and ASHRAE standards.

Typical Applications of Commercial Boilers

| Industry/Facility Type | Usage Scenario | Boiler Function |

|---|---|---|

| Hospitals | Sterilization, laundry, heating | Steam and hot water |

| Hotels & Resorts | Room heating, showers, laundry | Condensing hot water boilers |

| Office Buildings | Winter heating, reheat coils | Space heating |

| Universities & Schools | Central plant heating, cafeterias | Hot water, sometimes low-pressure steam |

| Retail Malls | HVAC zones, restrooms, food courts | High-efficiency hot water boilers |

| Correctional Facilities | Kitchen, laundry, shower heating | Long-duty hot water supply |

| Nursing Homes | Centralized DHW, space heating | Constant-temperature water boilers |

Commercial systems are often required to have multiple boilers, typically in modular banks, to support redundancy and load balancing.

Commercial Boiler vs. Industrial Boiler: Comparison

| Aspect | Commercial Boiler | Industrial Boiler |

|---|---|---|

| BTU/hr Range | 300,000 – 10 million | 10 million – 300 million+ |

| Pressure Rating | <150 psi (typically) | 150 – 2,000 psi |

| Application | HVAC, hot water, basic steam | Process steam, power generation |

| Control System | Remote BMS, auto-start | PLC + SCADA, advanced instrumentation |

| Fuel Type | Natural gas, electricity, oil | Mostly natural gas, coal, biomass, heavy oil |

| Operation Time | 6–20 hours/day | Often 24/7 continuous |

Common Boiler Types Used in Commercial Buildings

| Boiler Type | Best For | Advantages |

|---|---|---|

| Condensing Boilers | High-efficiency hot water supply | 90–98% efficiency, low emissions |

| Fire-tube Boilers | Moderate-pressure steam or hot water | Compact, easier maintenance |

| Modular Boilers | Facilities with variable load demands | Scalability, redundancy, N+1 design |

| Electric Boilers | Silent operations (hospitals, schools) | No flue gas, fast response, low emissions |

Regulations and Standards for Commercial Boilers

| Standard | Applies To | Purpose |

|---|---|---|

| ASME Section IV | Heating boilers under 15 psi steam/160 psi water | Design, construction, pressure certification |

| ANSI Z21.13 | Gas-fired low-pressure steam/hot water units | Combustion safety and thermal efficiency |

| NFPA 85 | Combustion safeguards | Flame failure, ignition lockouts |

| ASHRAE 90.1 | Energy efficiency for commercial HVAC | Boiler efficiency minimums |

| UL/CSA Certifications | Electrical and burner safety | North American compliance |

Local jurisdictions may also require periodic inspection, emissions reports, or operator training certification.

Conclusion

A commercial boiler is a purpose-built heating system designed to meet the large, continuous, and controlled thermal demands of commercial spaces. Whether it’s providing 24/7 hot water for a hospital or HVAC heating for a high-rise office, commercial boilers are defined by their higher output capacity, integration-ready control systems, and code-compliant designs. Choosing the right type depends on load variability, space constraints, emissions targets, and long-term efficiency goals.

What Defines an Industrial Boiler, and What Are Its Main Applications?

In modern manufacturing and energy production, steam is the lifeblood of countless operations—from sterilizing food to spinning turbines in a power station. Relying on insufficient or underperforming steam systems can result in production delays, product defects, high fuel waste, or safety hazards. That’s why large-scale operations across heavy industries invest in industrial boilers—engineered systems capable of producing massive amounts of high-pressure steam to meet demanding process loads. Understanding what defines an industrial boiler and how it differs from commercial or residential units is essential for planning your plant’s energy infrastructure.

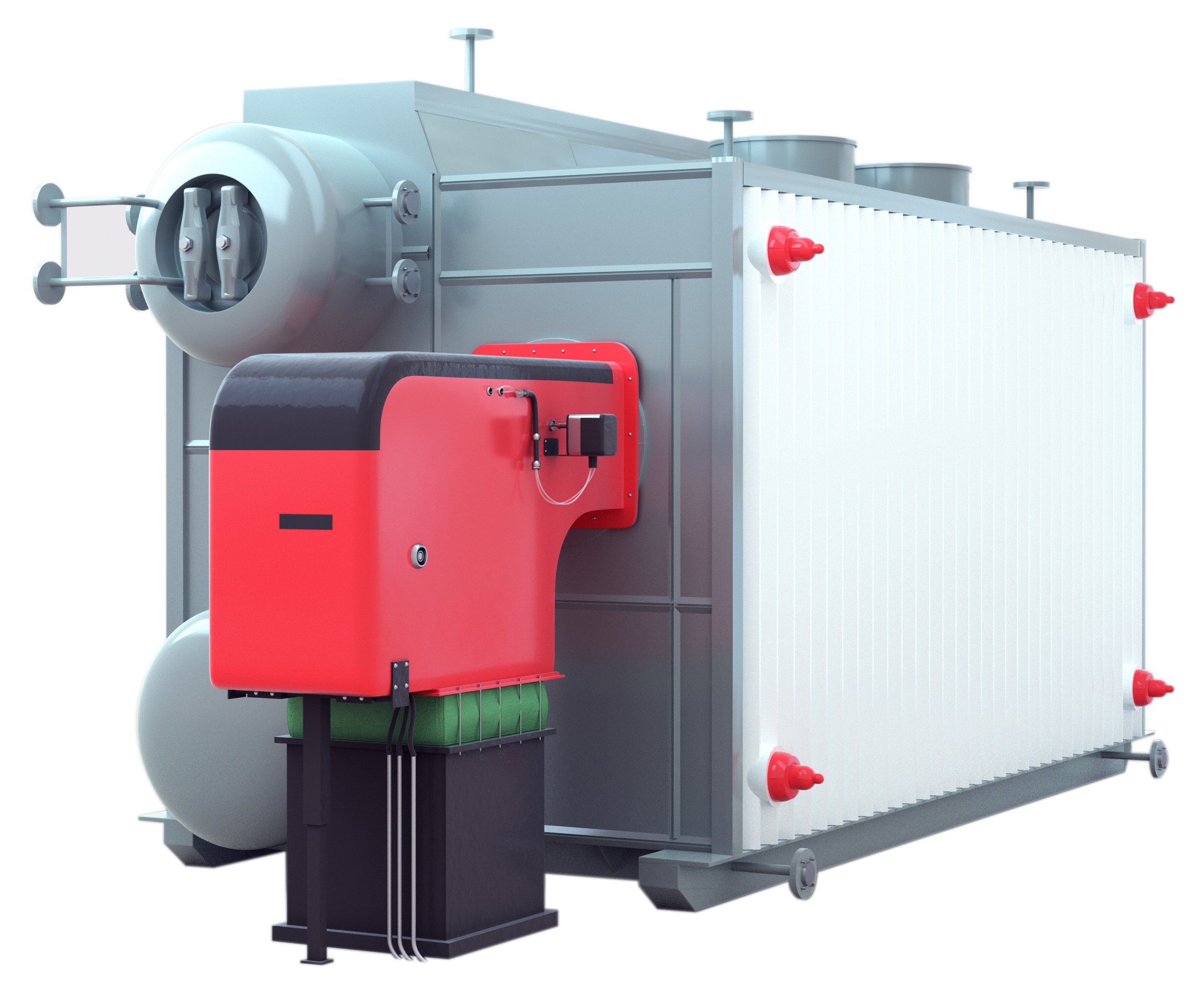

An industrial boiler is a high-capacity pressure vessel designed to generate steam or hot water for manufacturing processes, large-scale heating, or power generation. Typically ranging from 10 to 300+ TPH in capacity and operating at pressures of 10–160 bar, industrial boilers are used in industries such as chemicals, textiles, food processing, petrochemicals, paper, and power plants.

These boilers are engineered for durability, efficiency, and compliance with strict safety and environmental codes.

Industrial boilers are primarily used to provide process steam for manufacturing and power generation.True

Unlike commercial boilers that serve heating needs, industrial boilers support heavy-duty applications such as distillation, drying, sterilization, and turbine drive.

Industrial boilers operate at low pressure and temperature similar to residential systems.False

Industrial boilers typically operate at much higher pressures (10–160 bar) and temperatures (150–540°C) than residential or commercial systems.

Key Characteristics That Define an Industrial Boiler

| Attribute | Industrial Boiler Specification |

|---|---|

| Steam Output | 10 TPH – 300+ TPH |

| Pressure Range | 10 bar – 160 bar (145–2,300 psi) |

| Temperature Range | 180°C – 540°C |

| Fuel Types | Coal, natural gas, oil, biomass, electricity, waste heat |

| Boiler Types | Water-tube (most common), fire-tube (small/legacy), HRSG |

| Control System | PLC/SCADA-based automation with alarms, feedback loops |

| Construction Codes | ASME Section I, EN 12952, IBR, ISO, GB standards |

Industrial boilers are heavily customized based on process demands, emission targets, fuel availability, and layout constraints.

Primary Applications of Industrial Boilers by Industry

| Industry | Main Boiler Role | Steam Usage |

|---|---|---|

| Power Generation | Drives steam turbines for electricity | High-pressure saturated/superheated steam |

| Food & Beverage | Pasteurization, sterilization, cooking | Low to medium pressure steam |

| Chemical & Pharma | Reactions, drying, crystallization | Clean steam or process steam |

| Textiles | Dyeing, printing, drying | Medium-pressure saturated steam |

| Pulp & Paper | Digestion, paper drying, turbine cogeneration | Steam for process + power |

| Oil & Gas | Desalting, cracking, steam injection | High-temperature/high-pressure steam |

| Steel & Metallurgy | Heat treatment, rolling, pickling | High pressure for batch operations |

| Waste-to-Energy | Steam from incineration of waste | Boiler + turbine (cogeneration) |

Many industrial boilers are also designed to co-generate heat and power (CHP) to maximize energy efficiency.

Boiler Types Commonly Used in Industrial Applications

| Boiler Type | Best For | Benefits |

|---|---|---|

| Water-tube Boiler | High-pressure, high-load applications | Fast steam generation, high capacity |

| Fire-tube Boiler | Small/medium industries, lower pressure | Simpler, easier to maintain |

| Electric Boiler | Cleanroom, lab-scale industries | No emissions, compact |

| HRSG (Heat Recovery) | Combined cycle plants, turbines | Uses waste heat, improves energy efficiency |

| Fluidized Bed Boiler | Coal, biomass combustion | Fuel flexibility, low NOx |

Pressure & Temperature Comparison

| Boiler Type | Pressure (bar) | Temperature (°C) |

|---|---|---|

| Commercial Boiler | 6 – 10 bar | 110 – 180°C |

| Industrial Steam Boiler | 20 – 160 bar | 180 – 540°C |

| Power Boiler (Utility) | 160 – 350+ bar | 540 – 620°C |

Many industrial boilers operate in the subcritical range (below 221 bar) but may approach supercritical conditions in cogeneration systems.

Essential Systems Included in an Industrial Boiler Package

| Subsystem | Function |

|---|---|

| Burner System | Fuel-air mixing and ignition |

| Drum & Water Circulation | Separates water/steam, feeds economizers |

| Superheater | Raises steam temperature above saturation |

| Economizer | Recovers flue gas heat to preheat feedwater |

| Deaerator & FW Tank | Removes O₂ and CO₂, preheats feedwater |

| Control Panel | PLC-based automation and diagnostics |

| Safety Valves | Overpressure protection |

| Blowdown System | TDS and sludge removal |

| Emissions Control | SCRs, ESPs, baghouses for NOx, PM, SOx |

Typical Size and Footprint

| Steam Capacity | Boiler Type | Physical Size | Boiler House Needs |

|---|---|---|---|

| 10 TPH | Horizontal water-tube | ~10 m × 3 m × 4 m | Moderate infrastructure |

| 50 TPH | Vertical water-tube | ~15 m × 5 m × 7 m | Foundation, crane, stack system |

| 150 TPH+ | Modular units/HRSG | Multiple modules | Complex piping, emission zones |

Efficiency & Emissions Considerations

| Fuel Type | Efficiency (%) | CO₂ Intensity | Compliance Equipment |

|---|---|---|---|

| Natural Gas | 85–95% | Low | Low-NOx burners, SCR |

| Coal | 75–85% | High | ESP, baghouse, scrubber |

| Biomass | 70–90% | Medium | Multicyclone, CO filters |

| Electricity | 98–100% (point) | Depends on source | No flue needed |

Many modern industrial boilers are designed to meet local emissions codes (e.g., EPA, CPCB, EU) and integrate CEMS (continuous emissions monitoring systems).

Conclusion

An industrial boiler is a high-performance thermal system designed for demanding operations that require high-pressure steam or hot water. These boilers are vital in industries like power generation, food production, chemicals, textiles, and metallurgy—where consistent, scalable, and controllable heat is mission-critical. From 10 TPH water-tube systems to 300 TPH HRSGs, industrial boilers come in a variety of forms, and choosing the right one depends on pressure, process requirements, fuel strategy, and emissions constraints.

How Do Commercial and Industrial Boilers Differ in Pressure, Temperature, and Capacity?

Choosing between a commercial and an industrial boiler isn’t just a matter of size—it’s about matching performance specs to your operation’s intensity. While commercial boilers handle domestic hot water and heating in buildings like hotels and offices, industrial boilers support intense, continuous steam or heat needs in production environments. Selecting the wrong type can lead to dangerous pressure failures, underperformance, or regulatory non-compliance. To prevent costly mistakes and ensure safety and efficiency, it’s crucial to understand how these systems differ in pressure, temperature, and capacity.

Commercial boilers generally operate below 10 bar (145 psi), with output temperatures below 180°C and capacities under 3,000 kW (10 million BTU/hr). Industrial boilers, on the other hand, operate at 10–160 bar, exceed 500°C in temperature, and deliver steam flow up to 300 TPH or more, supporting complex manufacturing and power generation processes.

These differences impact sizing, safety systems, design codes, and energy efficiency.

Commercial boilers operate at significantly lower pressure and temperature than industrial boilers.True

Commercial boilers are designed for building heating or hot water, while industrial boilers must generate high-pressure, high-temperature steam for processing or power.

Commercial and industrial boilers are interchangeable if properly installed.False

Industrial boilers follow stricter codes and are built for higher stress, capacity, and complexity; they are not interchangeable with commercial systems.

🔧 Technical Comparison of Pressure, Temperature & Capacity

| Specification | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Pressure Range | 1–10 bar (15–145 psi) | 10–160 bar (145–2,300 psi) |

| Temperature Range | 60–180°C (140–356°F) | 180–540°C (356–1,004°F) |

| Steam Output | <3 TPH (tons per hour) or <10 million BTU/hr | 10–300+ TPH or 30–1,000+ million BTU/hr |

| Water Output (Hot Water) | Up to 3 MW (10,000,000 BTU/hr) | 3 MW – 200+ MW (10–700+ million BTU/hr) |

| Run Time | Intermittent to 16 hrs/day | Often 24/7 continuous |

| Fuel Types | Natural gas, propane, electricity | Gas, oil, coal, biomass, electricity, waste heat |

| Boiler Types | Fire-tube, condensing, cast iron | Water-tube, HRSG, FBC, high-pressure fire-tube |

| Applications | Heating buildings, domestic hot water | Process steam, cogeneration, sterilization, turbines |

📊 Boiler Pressure vs. Application Requirements

| Application | Required Pressure (bar) | Suitable Boiler Type |

|---|---|---|

| Office Building HVAC | 2–5 bar | Commercial fire-tube or condensing |

| Hotel Hot Water | 3–6 bar | Commercial condensing boiler |

| Food Pasteurization | 8–12 bar | Light industrial fire-tube |

| Textile Steam Processes | 10–16 bar | Industrial water-tube |

| Chemical Processing | 20–40 bar | Industrial high-pressure boiler |

| Power Generation (Turbine) | 60–160 bar | Industrial superheated steam boiler |

High-pressure systems require reinforced drums, certified pressure vessels, and safety interlocks—absent in most commercial units.

🔥 Temperature Range Comparison

| Steam/Water Use | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Domestic hot water | 60–80°C | Often not applicable |

| Radiant space heating | 70–90°C | Rarely used |

| Low-pressure steam | 100–150°C | 180–200°C |

| Process steam (standard) | N/A | 180–400°C |

| Superheated steam | N/A | 400–540°C |

Commercial boilers cannot safely generate steam above 150°C, limiting their role to comfort or light-duty heating.

📐 Real-World Size and Output Examples

| Boiler Application | Boiler Type | Pressure | Capacity | Output |

|---|---|---|---|---|

| Small hotel (60 rooms) | Gas condensing | 4 bar | 500 kW | DHW + HVAC |

| Office tower (20 floors) | Fire-tube modular | 6 bar | 2 MW | Space heating |

| Textile mill (large) | Water-tube | 12 bar | 10 TPH | Steam for dyeing |

| Power plant (medium) | Supercritical water-tube | 165 bar | 250 TPH | Turbine steam |

| Oil refinery | Water-tube + HRSG | 120 bar | 180 TPH | Process + co-gen |

Commercial systems are typically pre-assembled with plug-and-play controls, while industrial systems are custom-engineered.

🧰 Key System Differences

| System Feature | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Control System | BMS compatible, auto-start | PLC/SCADA, interlock redundancy |

| Emissions Control | Low-NOx burner optional | SCR, ESP, CEMS required |

| Feedwater Treatment | Basic softening | Deaerators, TDS blowdown |

| Safety Compliance | ASME Section IV | ASME Section I, IBR, EN 12952 |

| Maintenance | Light duty, occasional | Scheduled, intensive |

Industrial boilers must meet stricter codes, including ASME I, PED, and IBR, often requiring third-party certification and inspections.

Conclusion

The pressure, temperature, and capacity of a boiler determine its suitability for either commercial or industrial applications. Commercial boilers are ideal for comfort heating and hot water in buildings, while industrial boilers are designed to deliver high-pressure steam for demanding processes. Misapplication can lead to equipment failure, inefficiency, and safety risks. Always align your boiler selection with your operational intensity, runtime needs, and regulatory requirements.

What Are the Differences in Materials, Construction, and Service Life Between Commercial and Industrial Boilers?

When evaluating boiler options, most users focus on size, output, and fuel—but often overlook the materials and construction quality, which directly influence durability, corrosion resistance, and safety under pressure. The long-term performance and cost-effectiveness of a boiler depend heavily on how it’s built and what it’s made of. While commercial boilers are optimized for compactness and simplicity, industrial boilers are engineered for longevity under extreme pressures and temperatures—using thicker steel, higher-grade alloys, and advanced welding techniques. These differences translate into distinct lifespans, maintenance schedules, and total cost of ownership.

Commercial boilers use lighter-gauge carbon steel or cast iron and are constructed for intermittent or medium-duty service with a lifespan of 10–15 years. Industrial boilers are built from thick-walled carbon steel or high-alloy materials, designed for high-pressure, high-temperature applications with a service life of 25–35+ years when properly maintained.

Material selection and welding standards vary significantly to meet ASME, EN, or IBR codes, especially for pressure parts in industrial boilers.

Industrial boilers use heavier, higher-grade materials than commercial boilers to withstand higher pressures and temperatures.True

Industrial boilers are made of thicker steel plates, high-alloy tubes, and certified welds to meet safety and durability requirements under extreme operating conditions.

The construction quality of commercial and industrial boilers is nearly the same.False

Commercial boilers are not built to the same codes, stress tolerances, or duty cycles as industrial boilers and therefore have very different construction requirements.

🧱 Material Comparison: Pressure Parts and Shell

| Component | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Shell Material | Carbon steel (3–10 mm thick) | SA-516 Gr.70 carbon steel (12–40+ mm thick) |

| Tube Material | Mild steel or basic ERW tubes | SA-192, SA-210, or 13CrMo44 seamless tubes |

| Drum Material | Thin-walled rolled steel or omitted | Thick-walled forged or welded steel drums |

| Refractory/Insulation | Lightweight ceramic fiber or foam | Dense firebrick, ceramic wool, mineral board |

| Weld Type | MIG or submerged arc, few stress-relieved | Full-penetration, X-ray tested, stress-relieved |

| Flanges & Fittings | ANSI 150# threaded or slip-on | ANSI 300–900#, butt-welded with RT test |

Industrial boilers use certified pressure vessel-grade steels and undergo code-regulated fabrication procedures, including preheat, post-weld heat treatment (PWHT), and NDT.

🏗️ Construction Features That Differentiate Commercial vs. Industrial Boilers

| Design Element | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Boiler Type | Fire-tube, sectional cast iron, condensing | Water-tube, HRSG, FBC, coil-type |

| Tube Arrangement | Horizontal shell with small fire tubes | Multiple passes with wide steam/water circuits |

| Drum Design | Often none (direct flow) | Steam and mud drums with internal baffles |

| Tube Expansion | Rolled into headers or welded | Fully welded with end caps or stub tubes |

| Access & Maintenance Ports | Limited hatches, small inspection doors | Manholes, access doors, soot blower ports |

| Mounting Base | Skid-mounted or floor-mounted | Foundation-supported with seismic anchoring |

| Heat Transfer Area (per TPH) | ~30–40 m²/Ton | 60–90 m²/Ton |

Industrial boilers are built for modular cleaning, inspection, and component replacement during long lifespans and rigorous service cycles.

📆 Service Life Expectations

| Factor | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Design Life (avg) | 10–15 years | 25–35 years |

| Duty Cycle | Intermittent or seasonal | Continuous (24/7/365) |

| Corrosion Resistance | Basic coatings or anodizing | Internal linings, deaeration, alloy components |

| Expected Downtime | Seasonal or annual maintenance | Scheduled shutdowns for overhaul |

| Repairability | Limited (often replace vs. repair) | High—tubes, refractory, valves replaceable |

A commercial boiler is considered a disposable asset in many buildings, whereas an industrial boiler is treated as a critical capital investment.

🧪 Metallurgical and Structural Integrity Comparison

| Performance Metric | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Tensile Strength of Shell | ~400–450 MPa | 550–700+ MPa |

| Creep Resistance at High Temp | Low | High (Mo-alloys, Cr-moly steels) |

| Thermal Cycling Tolerance | Moderate | High |

| Corrosion Allowance | ~1 mm wall loss over life | 2–4 mm (extra thickness or alloy) |

| Fatigue Life (cycles) | Low (~10⁴–10⁵ cycles) | Very high (~10⁶–10⁷ cycles) |

🏭 Real-World Example: Boiler Lifespan & Construction Specs

| Facility | Boiler Type | Shell Material | Design Life | Pressure Rating |

|---|---|---|---|---|

| Small Hospital | 500 kW condensing | Carbon steel (5 mm) | ~12 years | 6 bar |

| Commercial Office Tower | 1.5 MW fire-tube | Mild steel + aluminum fins | ~15 years | 8 bar |

| Textile Mill (Medium Scale) | 10 TPH water-tube | SA-516 Gr.70 + SA-210 | ~25–30 years | 18 bar |

| Power Plant (Cogeneration) | 150 TPH HRSG | SA-387 alloy, Inconel | 35+ years | 110 bar |

These differences in build quality and material selection reflect the end-use expectations—comfort heating vs. mission-critical process performance.

Conclusion

The differences in materials, construction, and service life between commercial and industrial boilers are substantial. Commercial boilers are built for simplicity, ease of installation, and moderate duty. Industrial boilers are engineered for strength, endurance, and reliability, capable of withstanding high temperatures and pressures for decades. Their thicker shells, high-alloy tubes, and certified fabrication standards ensure long-term performance in demanding environments—from petrochemicals to food processing to energy.

How Do Control Systems and Compliance Standards Vary Between Commercial and Industrial Boilers?

When selecting a boiler, it’s easy to focus on hardware—pressure ratings, output, and fuel type. But the true intelligence and safety of a boiler lies in its control system and regulatory compliance. For commercial boilers, controls are designed to be user-friendly, plug-and-play, and integrated with building systems. In contrast, industrial boilers require robust, programmable logic controllers (PLC), real-time monitoring, and strict adherence to international safety codes. If the wrong level of control or non-compliant system is chosen, the results can include process failures, safety violations, or legal shutdowns.

Commercial boilers use simplified digital control panels and often integrate with BMS (Building Management Systems), while industrial boilers are equipped with advanced PLC- or SCADA-based systems that control, monitor, and protect high-pressure, high-capacity operations. Compliance standards also differ: commercial boilers follow ASME Section IV and local codes, whereas industrial boilers must comply with ASME Section I, NFPA, ISO, PED, and emissions standards like EPA Title V or EU IED.

These differences affect installation complexity, operating safety, and ongoing inspection obligations.

Industrial boilers require more sophisticated control systems and stricter code compliance than commercial boilers.True

Due to their higher pressure, temperature, and energy potential, industrial boilers are subject to more rigorous control and safety standards including SCADA automation and ASME Section I design.

A commercial boiler control system can be reused in industrial applications if needed.False

Commercial boiler control systems lack the interlocks, alarm layers, and process logic necessary for safe operation in industrial environments.

🔧 Control System Differences

| Feature | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Control Type | Digital controller (thermostatic or PLC-lite) | Full PLC or SCADA-based system |

| User Interface | Touchscreen or dial-based | HMI + Remote workstation |

| Automation Level | Pre-set cycles and time control | Fully automated with feedback and PID loops |

| Remote Access | Via BMS/BACnet | VPN/industrial protocols (Modbus, OPC-UA, Profibus) |

| Alarm Handling | Basic local alerts | Multi-tiered alarms, real-time alerts to operators |

| Start-Up & Shutdown | Timed sequence or manual start | Sequenced startup with interlocks, safety interlocks |

| Data Logging | Limited | Continuous trend logging, performance data storage |

| Redundancy | Often not included | Dual-sensor logic, backup controls |

Industrial boilers require control systems that can actively prevent catastrophic events like overpressure, dry fire, or feedwater failure using real-time diagnostics.

📜 Compliance Standards Comparison

| Regulation Category | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Pressure Vessel Code | ASME Section IV or UL 795 | ASME Section I, EN 12952, IBR (India), GB150 (China) |

| Combustion Safety | ANSI Z21.13, NFPA 85 (partial) | Full NFPA 85, IEC 61511 (SIS), API 520 |

| Control Panel Safety | UL 508A (North America) | UL 508A + ATEX, IECEx (in hazardous areas) |

| Electrical Safety | NEC, CSA | NEC, IEC 60204, EMC/EMI compatibility |

| Water Treatment Standards | ASHRAE, local health codes | ISO 5667, ASTM D1193, boiler-specific feedwater specs |

| Emissions Compliance | Local AQMD, EPA under 10 MMBTU/hr | EPA Title V, EU IED, CPCB (India), CEMS required |

| Inspection Requirements | Annual visual/local code-based | ASME NBIC inspections, state pressure vessel inspection |

| Operator Certification | Often not required | Required in many regions for >50 HP boilers |

Industrial boilers are subject to third-party certifications, documented test procedures, and traceable logs. This adds cost but ensures safety.

🧰 Functional Capabilities in Controls

| Function | Commercial Control Panel | Industrial Boiler PLC/SCADA |

|---|---|---|

| Fuel-air ratio control | Manual or pre-set | Automatic, dynamic O₂ trim |

| Water level management | Float switch or probe | Dual-element level control |

| Stack temp monitoring | Optional | Real-time with trend analysis |

| Combustion optimization | Basic burner feedback | Integrated fuel efficiency optimization |

| Safety shutdown logic | Basic over-temp/low-water trips | Multi-layer interlocks and fail-safes |

| Boiler sequencing (multi-unit) | Manual or BMS | Load-dependent auto sequencing |

| Emissions logging and reporting | Rare | Continuous via CEMS and SCADA |

🔍 Real-World Example: Pharmaceutical Plant vs. School Heating System

| Facility Type | Boiler Type | Controls Used | Compliance Needs |

|---|---|---|---|

| Public School | 2×300 kW fire-tube | Touchscreen controller, BACnet | ASME IV, local building codes |

| Pharmaceutical Factory | 20 TPH water-tube | PLC/SCADA with remote HMI | ASME I, NFPA 85, ISO 9001, FDA audit logs |

In regulated industries like pharmaceuticals and food, automated control documentation is required for compliance verification.

🏗️ Installation and Operational Implications

| Aspect | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Startup Time | Minutes | Up to hours (warm-up, purge) |

| Training Required | Minimal | Operator certification needed |

| Maintenance Alerts | Basic LED or screen message | Predictive maintenance systems |

| Integration with Plant Systems | Simple HVAC/BMS | Full industrial system integration |

| Cybersecurity Features | Limited or none | VPN-secured, role-based access |

Conclusion

The difference between commercial and industrial boiler control systems and compliance standards is foundational. Commercial boilers are plug-and-play, ideal for space heating and hot water, and follow building-focused regulations. Industrial boilers operate under far greater thermal and operational stress, needing advanced automation and strict adherence to codes like ASME Section I, NFPA, ISO, and EPA emissions limits. Investing in the right level of control intelligence and regulatory readiness ensures long-term performance, safety, and legal compliance.

When Should You Upgrade From a Commercial Boiler to an Industrial Solution?

Many facilities begin with commercial boilers due to their lower upfront costs and ease of installation. However, as your business grows—whether in manufacturing, food production, healthcare, or energy services—those same systems may become underpowered, unsafe, or inefficient for evolving operational demands. If your current boiler is frequently overloaded, causes pressure drops, fails inspection, or struggles to support new processes, it may be time to upgrade to an industrial-grade boiler solution.

You should upgrade from a commercial to an industrial boiler when your facility requires higher steam capacity (>3 TPH), higher pressure (>10 bar), continuous 24/7 operation, or integration with process-critical systems. This shift is also necessary if your commercial system no longer meets safety codes, fuel flexibility needs, or emissions compliance.

Upgrading ensures improved reliability, performance, and regulatory alignment, especially in high-demand applications.

Upgrading to an industrial boiler is necessary when operating pressure or output requirements exceed commercial capabilities.True

Industrial boilers are designed for higher capacities, pressures, and duty cycles that commercial systems are not built to handle.

A commercial boiler can meet industrial needs if it's run in parallel with multiple units.False

While modular commercial systems may extend capacity, they still lack the pressure handling, process integration, and safety systems needed in true industrial applications.

🔧 Key Indicators It’s Time to Upgrade

| Warning Sign | Why It Matters |

|---|---|

| Frequent low-pressure alarms or tripping | Boiler is undersized for load or out of spec |

| Extended runtime (>16–20 hours/day) | Shortens lifespan of commercial units not rated for heavy use |

| Plans to expand or add steam-intensive processes | May exceed flow, temp, and pressure capacity |

| Failed inspection due to pressure/temperature ratings | Commercial code no longer sufficient |

| Process demands precise steam control | Requires advanced automation only found in industrial systems |

| Maintenance costs are rising fast | Commercial boilers degrade faster under high stress |

| Fuel flexibility is now a requirement | Industrial boilers can handle gas, oil, biomass, or dual-fuel |

| Regional emissions limits are tightening | Need SCRs, low-NOx burners, CEMS—industrial-only features |

📊 Technical Limits Comparison: Commercial vs. Industrial

| Specification | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Steam Output | Up to 3 TPH (~10 MMBTU/hr) | 10–300+ TPH |

| Operating Pressure | Max ~10 bar (145 psi) | 10–160+ bar |

| Max Temp (Steam/Water) | ~180°C | Up to 540°C |

| Continuous Duty | Light to medium (~16 hrs/day) | Heavy (24/7 for decades) |

| Fuel Options | Gas, electric, light oil | Gas, oil, coal, biomass, hybrid |

| Control System | BMS, basic touchscreen | PLC/SCADA, advanced safety logics |

| Code Compliance | ASME Section IV | ASME Section I, NFPA, ISO, IBR |

🏭 Application Thresholds That Require Industrial Boilers

| Facility Type | Application | Threshold That Triggers Upgrade |

|---|---|---|

| Food Processing Plant | Pasteurization, sterilization, drying | >3 TPH steam, precise pressure temp control |

| Textile Mill | Dyeing, printing, calendaring | >10 bar pressure, 10+ hours daily operation |

| Chemical Plant | Reaction heating, solvent distillation | Critical pressure/temperature requirements |

| Power Plant | Turbine drive, cogeneration | 40–300 TPH steam, high superheat temps |

| Pharma Factory | GMP steam, CIP systems | High purity steam, automated quality controls |

| District Heating | Long-run hot water/steam distribution | >5 MW demand, seasonal 24/7 operation |

If your plant has growing production lines, added shifts, or energy optimization goals, an industrial boiler becomes the only sustainable choice.

⚙️ Key System Differences Upon Upgrading

| System Feature | Commercial | Industrial |

|---|---|---|

| Burner/Combustion System | Pre-mix or staged gas burner | Modulating, dual-fuel, O₂-trim enabled |

| Feedwater Management | Softener or basic preheat | Deaerator, multi-stage pump system |

| Blowdown Control | Manual or basic timed | Automatic TDS/continuous blowdown system |

| Emissions Monitoring | Usually absent | CEMS, opacity monitor, NOx analyzers |

| Safety Valves and Shutdowns | Over-temp/low-water | ASME/NBIC certified logic with interlocks |

| Boiler Sequencing (multi-boiler) | Manual or BMS-driven | Load-sharing with intelligent logic |

| Fuel-to-Steam Efficiency | 80–90% (non-condensing) | 85–95% with heat recovery options |

💸 Cost and ROI Considerations

| Cost Factor | Commercial Boiler | Industrial Boiler |

|---|---|---|

| Initial Equipment Cost | $20,000 – $100,000 | $100,000 – $1.5 million+ |

| Installation & Commissioning | $10,000 – $40,000 | $50,000 – $300,000+ |

| Annual O&M Cost | $2,000 – $10,000 | $10,000 – $100,000+ |

| Efficiency Savings Potential | Limited | High via economizers, FGR, etc. |

| Emissions Penalty Avoidance | Not always required | Often critical to avoid fines |

| Lifespan | 10–15 years | 25–35 years |

| Payback Period | 4–7 years | 3–6 years (with energy optimization) |

Many facilities find that the upfront cost is quickly offset by lower downtime, better energy efficiency, and emissions compliance.

🔐 Compliance & Safety Triggers for Upgrade

| Regulatory Trigger | Resulting Requirement |

|---|---|

| >10 bar steam generation | ASME Section I (industrial only) |

| >3 TPH or >1,000 kW output | High-pressure boiler designation |

| Hazardous location classification | Explosion-proof controls (ATEX/IECEx) |

| EPA/CPCB emissions thresholds | Require SCR, ESP, CEMS monitoring |

| FDA/GMP audit requirements | Clean steam generator + auto logging |

| NBIC/Third-party inspection needed | Industrial design code required |

Conclusion

If your operations are outgrowing the capabilities of a commercial boiler, it’s not just about size—it’s about safety, performance, efficiency, and compliance. Upgrading to an industrial boiler is the responsible, future-proof move when your business reaches a point where steam becomes mission-critical. With higher capacities, smart controls, and robust certifications, industrial boilers protect your output, workforce, and regulatory standing.

🔍 Conclusion

While they may look similar externally, commercial and industrial boilers are built for fundamentally different workloads and environments. Selecting the right type depends on your heat load, operational intensity, safety regulations, and future scalability. Understanding these differences ensures safe, efficient, and cost-effective system performance.

📞 Contact Us

💡 Not sure if you need a commercial or industrial boiler? We provide engineering assessments, load analysis, and system recommendations to help you choose the right boiler class for your application.

🔹 Let our experts guide you to the right boiler solution—commercial or industrial. 🔍🔥🏭✅

FAQ

What is the main difference between commercial and industrial boilers?

The primary difference lies in scale, capacity, and application:

Commercial boilers are designed for light-duty use in places like schools, offices, hospitals, and apartment buildings.

Industrial boilers are heavy-duty systems built for large-scale production, such as in power plants, chemical processing, manufacturing, and refineries.

Industrial boilers handle higher pressures, temperatures, and continuous loads, while commercial units serve smaller-scale heating and hot water needs.

How do the capacities of commercial and industrial boilers compare?

Commercial boilers: 100,000 to 3,000,000 BTU/hr

Industrial boilers: 10 to 1,000+ horsepower (HP) or 345,000 to 34,500,000+ BTU/hr

Industrial boilers are often custom-designed to handle specific process loads, including steam generation, power cogeneration, and thermal oil systems.

Are there differences in boiler design and construction?

Yes. Design differences include:

Commercial boilers:

Often pre-packaged and compact

May use cast iron or copper heat exchangers

Primarily hot water-based

Industrial boilers:

Larger and often modular

Built with heavy-duty steel

Use fire-tube or water-tube designs for steam or high-temperature applications

Industrial designs prioritize durability, scalability, and long operating lifespans.

What are the typical applications for each type?

Commercial boilers:

HVAC heating for buildings

Domestic hot water supply

Small-scale radiant heating

Industrial boilers:

Steam for manufacturing or sterilization

Process heating in food, textile, paper, and chemical industries

Power generation (in cogeneration plants)

Industrial applications demand higher energy output and process integration.

How do maintenance and operational requirements differ?

Commercial boilers:

Easier to operate

Typically maintained by in-house facility teams

Less frequent inspections and lower compliance standards

Industrial boilers:

Require licensed boiler operators

Subject to strict regulatory inspections (ASME, EPA, etc.)

Need routine monitoring, chemical treatment, and professional servicing

Industrial systems are more complex, with higher maintenance and safety standards.

References

Cleaver-Brooks – Commercial vs. Industrial Boilers – https://www.cleaverbrooks.com

Hurst Boiler – Boiler Types and Applications – https://www.hurstboiler.com

Spirax Sarco – Steam vs. Hot Water Systems – https://www.spiraxsarco.com

Powerhouse – Choosing the Right Boiler – https://www.powerhouse.com

Miura Boilers – Industrial vs. Commercial Explained – https://www.miuraboiler.com

Thermodyne Boilers – Industrial Boiler Design – https://www.thermodyneboilers.com

BioEnergy Consult – Industrial Heating Systems – https://www.bioenergyconsult.com

ASHRAE – Boiler Efficiency Standards – https://www.ashrae.org

EPA – Boiler Emissions & Compliance – https://www.epa.gov

IEA – Boiler Performance in Industry – https://www.iea.org