As global pressure mounts to reduce carbon emissions and transition to sustainable energy systems, industrial biomass boilers are increasingly being adopted in renewable energy projects. Yet, many businesses and project developers still question how these systems integrate into larger green initiatives and whether they offer a practical and scalable solution. Understanding their applications can help unlock new opportunities in the decarbonization of heat and power.

Industrial biomass boilers are applied in renewable energy projects to convert organic waste materials—such as wood chips, agricultural residues, and energy crops—into heat or steam for power generation, industrial processes, or district heating. They enable carbon-neutral energy production, reduce reliance on fossil fuels, and contribute to circular economy strategies.

If you’re exploring sustainable technologies for industrial or municipal energy systems, biomass boilers can be a central component. Let’s examine how they are deployed across various renewable energy applications and what makes them effective.

How Do Industrial Biomass Boilers Support Renewable Heat and Power Generation?

Amid rising energy prices and urgent carbon reduction mandates, industries are under pressure to decarbonize their thermal and power systems. Fossil fuels, while traditionally reliable, now come with high environmental costs, regulatory burdens, and price volatility. This is where industrial biomass boilers offer a compelling alternative. By converting organic waste and renewable biomass into heat and electricity, these systems help industries transition to sustainable energy without compromising performance. They not only meet strict emissions requirements but also offer energy security through the use of local, renewable fuel sources.

Industrial biomass boilers support renewable heat and power generation by converting organic materials such as wood chips, agricultural waste, and energy crops into thermal energy or steam. This steam can be used directly for industrial processes or to drive turbines for electricity generation. Unlike fossil fuels, biomass is considered carbon-neutral because the CO₂ released during combustion is offset by the CO₂ absorbed during plant growth. Biomass boilers thus offer a reliable, scalable, and environmentally responsible solution for renewable energy generation in both industrial heat and combined heat and power (CHP) systems.

Industrial biomass boilers are key enablers of the global shift to renewable energy, providing a sustainable alternative to coal, oil, and gas in high-heat industrial applications.

Biomass boilers reduce net CO₂ emissions by using carbon-neutral fuels.True

Biomass absorbs CO₂ during its growth, and releases it during combustion, resulting in a closed carbon cycle.

Biomass boilers cannot produce electricity, only heat.False

Biomass boilers generate steam that can drive turbines for electricity in cogeneration or CHP systems.

🔍 How Biomass Boilers Work in Renewable Energy Systems

| Component | Function |

|---|---|

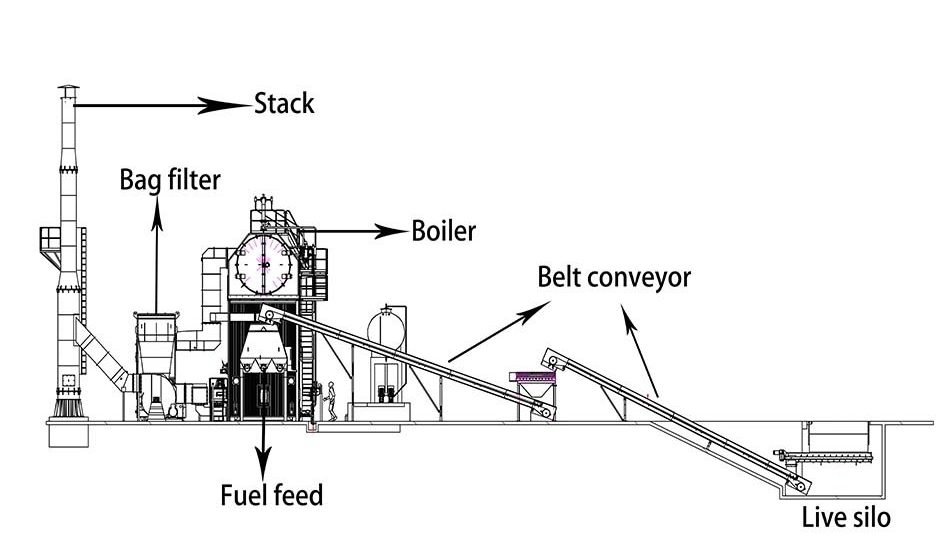

| Fuel Feeding System | Delivers biomass (e.g., chips, pellets) to combustion chamber |

| Combustion Chamber | Burns biomass to produce hot gases |

| Heat Exchanger | Transfers heat from combustion gases to water or steam |

| Steam Drum & Piping | Collects and routes generated steam to process or turbine |

| Turbine Generator (CHP) | Converts high-pressure steam into electricity (optional) |

| Flue Gas Cleaning | Reduces particulate and gaseous emissions to meet environmental laws |

Depending on the configuration, the system may produce just heat (thermal) or both heat and power (CHP).

📊 Biomass vs Fossil Fuels for Industrial Energy

| Metric | Biomass Boiler | Fossil Fuel Boiler |

|---|---|---|

| CO₂ Emissions (Net) | Near Zero (Carbon-Neutral) | High (Carbon-Positive) |

| Renewable Status | Yes | No |

| Fuel Cost Stability | High (local sourcing) | Low (global market dependent) |

| Heat-to-Power Capability | Yes (via CHP systems) | Yes, but less sustainable |

| Government Incentives | Eligible (carbon credits, RECs) | Often penalized (carbon taxes) |

| Sustainability Profile | High | Low |

🧪 Case Study: Biomass Boiler for Renewable CHP in Pulp Mill

Location: Nordic Pulp & Paper Plant

System Installed: 35 TPH biomass boiler with CHP system

Fuel: Wood waste and bark (~25% moisture content)

Outputs:

28 MW thermal energy

7 MW electric power

Benefits:CO₂ emissions reduced by 85,000 tons/year

$2.1M/year in fossil fuel savings

Received carbon credit revenue under EU ETS

Improved local energy security with own waste as fuel

Lesson: Biomass boilers can serve as powerful industrial-scale renewable energy solutions with strong economic returns.

⚙️ Renewable Energy Contribution of Biomass Boilers

| Function | How It Supports Renewable Energy Goals |

|---|---|

| Thermal Heat Supply | Replaces fossil fuel heat with renewable biomass combustion |

| Electricity Generation | Enables cogeneration or biomass power plants (CHP) |

| Waste Recycling | Converts agri-forestry waste into energy, reducing landfill and methane |

| Energy Autonomy | Local sourcing of fuel reduces dependency on volatile fossil fuel markets |

| Carbon Reduction | Supports carbon neutrality and Scope 1 emissions reductions |

| Grid Stabilization | Supplies distributed power generation, especially in remote/off-grid areas |

📈 Biomass Boiler Efficiency and Output Characteristics

| Boiler Type | Fuel | Thermal Efficiency (%) | Electric Output Potential (CHP) |

|---|---|---|---|

| Grate-Fired Boiler | Wood chips, husks | 78–85% | 10–25% of thermal input |

| Fluidized Bed Boiler | Mixed biomass, RDF | 85–89% | 20–30% (higher combustion control) |

| Gasification Boiler | Wood pellets, chips | 80–88% | Up to 30% with gas turbine pairing |

| Combined Biomass CHP | Wood waste + heat exch. | ~80% thermal, ~20% electric | Dual output: heat + electricity |

✅ Checklist for Biomass Boiler Renewable Integration

What is the thermal demand of your facility (in TPH or MW)?

Is electricity generation (CHP) required?

Is suitable biomass fuel locally available?

Can the boiler support multi-fuel adaptability (for seasonal biomass)?

Are emissions control systems included (e.g., ESP, baghouse, scrubbers)?

Is your plant eligible for carbon credits, RECs, or green energy incentives?

Will the biomass boiler be integrated with grid or internal power systems?

📋 Government Incentives for Biomass Energy

| Country/Region | Program | Incentive Type |

|---|---|---|

| EU | RED II, ETS | Feed-in tariffs, carbon allowances |

| USA | Renewable Energy Production Tax Credit (PTC) | Tax relief, green bonds |

| India | SATAT, MNRE Subsidies | Capex subsidies, biomass procurement |

| China | Biomass Feed-in Tariff Scheme | Guaranteed tariffs per kWh |

| Canada | Clean Fuel Regulations (CFR) | Credit trading, low-carbon fuel use |

Industrial biomass boilers stand at the crossroads of energy efficiency, emissions reduction, and renewable integration. They offer industries a resilient and future-ready solution to meet heat and power needs—without depending on fossil fuels. With biomass boilers, renewable energy is no longer a concept. It’s a proven, scalable technology already powering thousands of industrial facilities worldwide.

What Types of Biomass Fuels Are Used in Renewable Energy Projects, and How Are They Sourced?

Biomass fuels are the foundation of renewable heat and power systems—but not all biomass is created equal. For renewable energy projects to succeed, the type, quality, and supply chain of the biomass fuel must be carefully selected and managed. An unsuitable or inconsistent biomass fuel can lead to combustion instability, efficiency losses, equipment damage, and emissions non-compliance. On the other hand, the right biomass fuel—sourced sustainably and processed correctly—can power a boiler or CHP system with low carbon emissions, high thermal efficiency, and strong ROI.

The main types of biomass fuels used in renewable energy projects include wood chips, wood pellets, agricultural residues (such as rice husk, straw, and bagasse), energy crops (like miscanthus and switchgrass), and organic waste (such as manure or food waste). These fuels are sourced through forestry operations, agricultural byproducts, dedicated biomass plantations, or waste recycling systems. Effective sourcing ensures consistent quality, reliable supply, and minimal environmental impact—critical for stable and efficient biomass boiler operation.

Choosing the right fuel is not just about availability—it’s about sustainability, performance, and process compatibility.

Biomass fuels like wood chips and rice husk are renewable and widely used in industrial energy generation.True

These fuels are sourced from forestry and agriculture, providing sustainable alternatives to fossil fuels.

Biomass fuel quality does not affect boiler performance significantly.False

Fuel moisture, calorific value, and particle size directly influence combustion efficiency and emissions.

🔍 Overview: Common Biomass Fuels and Their Properties

| Fuel Type | Source | Moisture (%) | Calorific Value (kcal/kg) | Availability |

|---|---|---|---|---|

| Wood Chips | Forest thinning, sawmills | 20–50% | 3,200–4,200 | High (forestry regions) |

| Wood Pellets | Compressed sawdust/shavings | 6–10% | 4,600–4,900 | Medium to high |

| Rice Husk | Rice mills | 8–15% | 3,000–3,500 | Seasonal/agricultural |

| Bagasse | Sugar processing | 40–50% (wet) | 2,200–2,800 | High (sugar belts) |

| Straw/Biomass Bales | Wheat, barley, maize stalks | 12–20% | 3,200–3,700 | Abundant post-harvest |

| Miscanthus/Switchgrass | Energy crops (plantations) | 15–20% | 4,000–4,500 | Planned cultivation |

| Biogas (from waste) | Food, manure, organic waste | Saturated gas | ~20 MJ/m³ | Continuous (digesters) |

📈 Fuel Suitability for Renewable Energy Systems

| Fuel Type | Thermal Systems (Boiler) | CHP Systems (Steam/Turbine) | Direct Heating Systems | Biogas Engines |

|---|---|---|---|---|

| Wood Chips | ✔️ High | ✔️ Medium | ✔️ High | ❌ Not suitable |

| Wood Pellets | ✔️ High | ✔️ High | ✔️ High | ❌ Not suitable |

| Rice Husk | ✔️ Medium | ✔️ Low to Medium | ✔️ Medium | ❌ Not suitable |

| Bagasse | ✔️ High | ✔️ Medium | ✔️ Medium | ❌ Not suitable |

| Straw | ✔️ Medium | ✔️ Low to Medium | ✔️ Medium | ❌ Not suitable |

| Biogas | ❌ | ✔️ Via gas engine/turbine | ❌ | ✔️ High |

🧪 Case Study: Biomass Fuel Switching for Efficiency

Industry: Textile Manufacturer, Southeast Asia

Original Fuel: Low-grade wood bark (35% moisture)

Problem: High flue gas loss, inconsistent steam generation

Change: Switched to rice husk with 12% moisture content

Result:

Boiler efficiency increased from 74% to 84%

Steam cost reduced by 16%

Stabilized combustion, improved product quality

Sourced rice husk from three local mills with seasonal contract

Lesson: Fuel consistency and moisture control are crucial to biomass boiler performance.

🌱 How Biomass Fuels Are Sourced

| Fuel Type | Primary Sourcing Method | Key Considerations |

|---|---|---|

| Wood Chips | Sawmills, logging residue, plantation thinnings | Requires drying, uniform size, transportation volume |

| Wood Pellets | Pelletizing plants (from sawdust/shavings) | Densified, stored easily, ideal for automated systems |

| Agricultural Residues | Post-harvest collection of husks, stalks, straw | Seasonal availability, storage, sometimes baled or loose |

| Bagasse | Directly from sugar mills during crushing season | High moisture, often used on-site with special handling |

| Energy Crops | Planned plantations on marginal lands | Long-term contracts, consistent yield |

| Biogas | From anaerobic digesters fed with food/manure waste | Continuous supply, requires gas storage and purification |

Sourcing strategy depends on location, volume need, and fuel price volatility.

⚙️ Biomass Fuel Quality Parameters

| Parameter | Impact on Boiler Operation |

|---|---|

| Moisture Content | Higher moisture = more heat loss, reduced combustion temp |

| Ash Content | High ash = more slagging, cleaning, disposal issues |

| Calorific Value | Determines fuel input needed for same steam output |

| Size Uniformity | Affects feeding, combustion uniformity |

| Chlorine/Silica | Can cause corrosion or slagging at high temps |

Boiler design must match the fuel’s combustion characteristics.

✅ Biomass Fuel Selection Checklist

Is the fuel locally available with low transportation cost?

Can it be supplied year-round or only seasonally?

What is the moisture content (target <20% for efficiency)?

Does your boiler support multi-fuel or specific feedstock only?

Is there a fuel storage and drying system available?

Are there any handling challenges (dust, clumping, high ash)?

Does the fuel qualify for carbon credits or renewable incentives?

📋 Regional Trends in Biomass Fuel Usage

| Region | Most Common Fuels | Availability Level |

|---|---|---|

| Europe | Wood pellets, forestry residues | High (certified biomass) |

| North America | Wood chips, sawmill waste, pellets | High (export and domestic) |

| Southeast Asia | Rice husk, palm kernel shell, bagasse | High (agriculture-based) |

| Latin America | Sugarcane bagasse, eucalyptus chips | High (sugar/forestry) |

| India | Rice husk, mustard stalk, bagasse | Seasonal |

| Africa | Forestry waste, crop residues | Medium (collection limited) |

Biomass fuels are not generic commodities—they are regionally, seasonally, and process-specific energy sources. Understanding their characteristics and sourcing dynamics is essential to the reliable and efficient operation of biomass boilers. Whether you’re powering a food plant or a biomass CHP unit, your fuel choice will define your system’s emissions, costs, and uptime.

How Are Biomass Boilers Integrated into Combined Heat and Power (CHP) Systems?

As energy-intensive industries and municipalities seek more efficient and sustainable energy systems, combined heat and power (CHP)—also known as cogeneration—has emerged as a powerful solution. When fueled by biomass, CHP systems not only provide carbon-neutral energy but also deliver exceptional fuel-to-energy conversion efficiency. However, integrating a biomass boiler into a CHP system requires precise engineering, matching of thermal and electrical loads, and advanced control systems to optimize performance and emissions.

Biomass boilers are integrated into CHP systems by using the steam generated from biomass combustion to drive a steam turbine that produces electricity, while the residual heat from the steam cycle is recovered and used for industrial processes, district heating, or domestic hot water. This cogeneration process maximizes the energy extracted from biomass fuel—typically achieving overall efficiencies of 75–90%—and reduces carbon emissions compared to fossil-fueled alternatives. Proper integration involves synchronized steam pressure control, turbine-condensate management, and heat recovery optimization.

Biomass CHP transforms renewable fuel into both power and process heat, reducing waste and increasing energy independence.

Biomass boilers can be effectively integrated into CHP systems to produce both heat and electricity.True

Steam generated by the biomass boiler drives a turbine for power while residual heat is recovered for heating or industrial processes.

CHP integration is only possible with fossil fuel systems, not biomass.False

Biomass boilers can be designed for high-pressure steam suitable for cogeneration applications.

🔍 Components of a Biomass CHP System

| Component | Function in CHP Integration |

|---|---|

| Biomass Boiler | Burns organic material to generate high-pressure steam |

| Steam Turbine Generator | Converts thermal energy from steam into electrical power |

| Condenser or Heat Exchanger | Recovers residual steam heat for process use or district heating |

| Feedwater System | Recycles condensate and feeds water back to the boiler |

| Fuel Handling & Storage | Ensures continuous biomass supply to combustion system |

| Control & Monitoring System | Balances power and heat output, maintains operational stability |

📈 Energy Flow in a Biomass CHP System

| Step | Energy Conversion Stage | Efficiency (%) |

|---|---|---|

| 1 | Biomass combustion to steam | ~85% thermal |

| 2 | Steam drives turbine to generate electricity | ~20–25% electrical |

| 3 | Residual heat recovered for thermal use | ~50–65% thermal |

| Total | Combined heat and power utilization | 75–90% overall |

CHP systems maximize fuel usage by recovering what would otherwise be waste heat.

🧪 Case Study: Industrial Biomass CHP at a Food Processing Facility

Project: 5 MW Biomass CHP System

Fuel: Wood chips and rice husk

Boiler Type: Water-tube, high-pressure (35 bar) biomass boiler

Steam Output: 25 TPH

Electric Output: 5 MW

Thermal Output: 12 MW for process steam and hot water

Key Outcomes:

Reduced fossil energy consumption by 95%

80% reduction in CO₂ emissions (~30,000 tons/year)

12-year ROI, accelerated by carbon credit income

Reliable power during grid outages

Lesson: Properly integrated biomass CHP delivers resilience, savings, and sustainability for energy-intensive operations.

⚙️ Design Considerations for Biomass CHP Integration

| Design Element | Importance |

|---|---|

| Steam Pressure & Temperature | Must be suitable for turbine operation (typically >30 bar) |

| Fuel Quality Consistency | Essential for stable combustion and predictable output |

| Load Matching | System should align with thermal and electrical demand curves |

| Emissions Control Systems | Bag filters, ESPs, FGR to comply with regulatory standards |

| Condensate Recovery | Increases efficiency and reduces water consumption |

| Automation & Monitoring | Real-time control of steam flow, turbine load, and safety |

📊 Comparison: Biomass Boiler vs Biomass CHP

| Feature | Biomass Boiler Only | Biomass CHP System |

|---|---|---|

| Heat Generation | ✔️ | ✔️ |

| Electricity Generation | ❌ | ✔️ |

| Fuel Efficiency | 75–85% | 80–90% |

| Application Scope | Process heating only | Heating + power + cooling |

| Emissions Compliance | Required | Required + power grid standards |

| Investment Cost | Lower | Higher (but better ROI long-term) |

✅ Integration Checklist for Biomass CHP Projects

Does your site have simultaneous heat and power demand?

Is steam pressure high enough to drive a turbine (typically ≥30 bar)?

Can biomass fuel be supplied reliably and consistently year-round?

Is there space and infrastructure for turbine and heat recovery systems?

Will the CHP system qualify for feed-in tariffs or green incentives?

Is the system automated for real-time demand balancing?

Can the facility recover condensate to improve thermal efficiency?

🌱 Incentives and ESG Benefits of Biomass CHP

| Benefit Area | Details |

|---|---|

| Carbon Neutrality | CO₂ absorbed during plant growth offsets combustion emissions |

| Grid Independence | On-site power reduces exposure to grid outages and prices |

| Green Energy Credits | Earn renewable energy certificates (RECs), carbon credits |

| Sustainability Ratings | Improves ESG scoring for corporate reporting |

| Waste Utilization | Burns agricultural and forestry residues that would otherwise be landfilled |

Biomass boilers integrated into CHP systems are renewable powerhouses—turning waste and organic fuel into reliable, dual-purpose energy. With fuel flexibility, modular configurations, and growing policy support, they provide an economically and environmentally sound solution for industries, campuses, and communities seeking energy resilience and sustainability.

What Role Do Biomass Boilers Play in District Heating and Community Energy Systems?

As cities, towns, and remote communities search for ways to decarbonize their heating systems and reduce reliance on fossil fuels, biomass boilers have emerged as a key solution in the expansion of district heating and community energy networks. These systems replace dozens or hundreds of individual boilers with centralized renewable heating, improving efficiency, cutting emissions, and lowering energy bills for households and public buildings. Biomass boilers are especially suitable because they can run on locally sourced, renewable fuels, which keeps energy spending within the community and supports energy resilience.

Biomass boilers serve as the central heat source in district heating and community energy systems by producing hot water or steam from renewable biomass fuels and distributing it through insulated underground pipes to multiple buildings. These centralized systems provide efficient, low-carbon heating for residential, commercial, and institutional users. Biomass boilers are ideal for district heating due to their ability to burn wood chips, pellets, or agricultural residues at high efficiency, while offering stable, controllable heat output and eligibility for government renewable energy incentives.

By using biomass boilers, communities can cut heating emissions by over 90%, reduce energy poverty, and strengthen local economies.

Biomass boilers can supply renewable heat to entire communities through district heating systems.True

They centralize heat generation and distribute hot water or steam to multiple buildings via insulated pipe networks.

Biomass district heating is only suitable for rural areas, not urban zones.False

Biomass-based district heating has been successfully implemented in both rural villages and urban neighborhoods.

🔍 What Is a Biomass-Based District Heating System?

| Component | Function in Community Heating |

|---|---|

| Central Biomass Boiler Plant | Burns biomass to generate hot water or steam for distribution |

| Heat Distribution Network | Insulated underground pipes transport thermal energy to buildings |

| Heat Exchangers/Substations | Transfer heat to building systems (radiators, hot water tanks) |

| Control System | Regulates flow and temperature, adapts to user demand |

| Fuel Storage and Handling | Stores and feeds biomass fuel into the boiler |

| Backup Heat Source | Gas or electric boiler for redundancy or peak demand |

Biomass district heating is often implemented with combined heat and power (CHP) for additional electricity generation.

📊 Use Cases: Where Biomass Boilers Support Community Energy

| Setting | Typical Heat Demand | Biomass Role |

|---|---|---|

| Small Towns (1,000–10,000 ppl) | 1–5 MW thermal | Primary boiler for community heating network |

| University Campuses | 2–10 MW | Heat for dorms, labs, cafeterias |

| Eco-Housing Developments | 0.5–3 MW | Low-carbon central heating |

| Hospitals & Municipal Buildings | 1–8 MW | 24/7 reliable renewable heat |

| Rural Villages | 0.5–2 MW | Affordable heating with local biomass |

🧪 Case Study: Biomass District Heating in Austria

Location: Mureck, Austria (Population: ~1,500)

System: 3 MW biomass district heating plant

Fuel: Wood chips from local forests

Network Length: 13 km

Buildings Served: 200+ homes, school, municipal offices, swimming pool

CO₂ Savings: 2,000+ tons per year

Economic Impact: Local jobs in forestry, fuel processing, and maintenance

Result: Over 90% of the town’s heating demand met by renewable, affordable heat with predictable fuel pricing.

⚙️ Technical and Economic Benefits of Biomass District Heating

| Advantage | Explanation |

|---|---|

| Low-Carbon Heating | Biomass is carbon-neutral, offsetting fossil-based CO₂ emissions |

| Fuel Cost Stability | Biomass prices are less volatile than oil/gas |

| High Efficiency | Centralized generation avoids small boiler inefficiencies |

| Local Job Creation | Forestry, fuel supply, plant operation |

| Grid Independence | Community control over energy production |

| Ease of Regulation | One central boiler is easier to monitor for emissions compliance |

📈 Biomass District Heating Efficiency Overview

| Efficiency Metric | Typical Value |

|---|---|

| Boiler Thermal Efficiency | 80–90% (depending on fuel & moisture) |

| Distribution Losses | 5–15% (well-insulated networks) |

| Building-Level Efficiency | 95–98% (modern heat exchangers) |

| Overall System Efficiency | 70–85% |

CHP configurations further boost total system efficiency to 85–90%.

✅ Planning Checklist for Biomass in Community Energy

Is there a consistent demand for heating or hot water in the area?

Can a central boiler be located within reasonable distance of end users?

Is there local biomass fuel available at sustainable volumes?

Can you install a distribution network (pipes, exchangers, meters)?

Are there funding mechanisms (RECs, green bonds, subsidies) available?

Are zoning or emissions regulations compatible with biomass combustion?

Is there community or stakeholder buy-in for renewable heating?

🌍 Government Incentives for Community Biomass Heating

| Region | Programs Supporting Biomass District Heating |

|---|---|

| EU | RED III, Just Transition Fund, Cohesion Funds |

| UK | Renewable Heat Incentive (RHI), Green Heat Network Fund |

| Canada | Low Carbon Economy Fund, NRCan support |

| USA | USDA REAP, Community Wood Energy Grant |

| India | Biomass Energy Programme, Rural Heating Initiatives |

Many programs support design, equipment purchase, and fuel supply chains.

Biomass boilers bring renewable, affordable, and resilient heat to entire communities—turning local organic matter into sustainable energy. When paired with district heating systems, they simplify infrastructure, lower per-household costs, and reduce carbon footprints at scale. From small towns to urban redevelopment zones, biomass is playing a key role in building low-carbon energy futures that are owned and operated by the communities they serve.

How Do Biomass Boilers Contribute to Carbon Neutrality and Sustainable Waste Management?

Climate change is driving urgent global action, and industries are under pressure to decarbonize their energy systems while managing rising waste volumes. Traditional fossil fuel boilers not only release high amounts of CO₂, but also rely on finite resources and contribute to escalating emissions taxes. Meanwhile, landfilling agricultural or forestry waste creates methane—a greenhouse gas 25 times more potent than CO₂. This is where biomass boilers present a sustainable dual solution, converting waste into clean, usable energy while significantly reducing the net carbon footprint of heat and power generation.

Biomass boilers contribute to carbon neutrality by utilizing organic materials—such as wood chips, crop residues, and biowaste—that absorb CO₂ during their growth. When combusted, these fuels release that same amount of CO₂, creating a closed carbon loop. Additionally, biomass boilers help manage agricultural, forestry, and industrial organic waste sustainably by diverting it from landfills or open burning. This not only reduces methane and particulate emissions but transforms waste into renewable energy, supporting both climate targets and circular economy goals.

Through responsible sourcing and emissions control, biomass boilers enable industries and municipalities to turn waste into carbon-neutral energy.

Biomass combustion is considered carbon-neutral because the CO₂ released equals the amount absorbed during plant growth.True

Unlike fossil fuels, biomass originates from renewable sources that participate in the natural carbon cycle.

Biomass boilers increase landfill waste by creating ash and residue.False

Biomass boilers significantly reduce landfill waste by converting organic material into energy and generating minimal ash, often reused in agriculture.

🔍 How Biomass Boilers Achieve Carbon Neutrality

| Process Step | Carbon Impact |

|---|---|

| Plant Growth | Absorbs CO₂ from the atmosphere via photosynthesis |

| Biomass Harvest & Transport | Small emissions if managed sustainably |

| Combustion in Boiler | Releases absorbed CO₂ back into the atmosphere (net-zero cycle) |

| Ash Residue | Less than 3–5%, often used as soil amendment or brick filler |

| New Growth Cycle | Continues the absorption process |

This loop forms the basis of the carbon neutrality claim for sustainably sourced biomass.

📊 Biomass Boiler vs Fossil Fuel CO₂ Emissions (Per MWh Thermal)

| Fuel Type | CO₂ Emissions (kg/MWh) | Lifecycle Emissions with Sustainable Practices |

|---|---|---|

| Coal | 330–350 | High, from extraction to combustion |

| Natural Gas | 200–250 | Moderate, includes methane leakage |

| Biomass (Wood Chips) | ~10–30 | Largely offset by regrowth and closed carbon loop |

| Biomass (Ag Waste) | ~20–40 | Net zero if displacing open burning or landfilling |

Biomass lifecycle emissions are minimal when fuels are locally sourced and sustainably managed.

🧪 Case Study: Industrial Biomass Boiler for Waste Reuse and Emissions Reduction

Facility: Agro-processing Plant (India)

Original Problem: 200 tons/month of rice husk waste disposed via open burning

Solution: Installed 6 TPH biomass boiler burning husk

Results:

80% of thermal energy now derived from in-house agri-waste

Eliminated over 2,500 tons of CO₂ annually

Improved local air quality by reducing particulate emissions

Reduced fuel purchase cost by 60%

Conclusion: Biomass boilers can simultaneously solve emissions and waste management challenges.

⚙️ Types of Waste Utilized by Biomass Boilers

| Waste Source | Biomass Fuel Type | Boiler Compatibility |

|---|---|---|

| Forestry Residues | Wood chips, bark, sawdust | Grate-fired or fluidized bed |

| Agricultural Waste | Rice husk, wheat straw, bagasse | Fluidized bed, high-moisture-tolerant boilers |

| Industrial Organic Waste | Pulp sludge, food waste pellets | Specialized multi-fuel boilers |

| Energy Crops | Miscanthus, switchgrass | Pellet or chip-fed systems |

| Urban Biowaste | RDF pellets (refined), biogas from digesters | CHP or gasification boilers |

Most biomass boilers today are multi-fuel capable, enhancing flexibility and resilience.

♻️ Biomass Boilers as Tools for Circular Waste Management

| Waste Management Benefit | How Biomass Boilers Help |

|---|---|

| Waste Reduction | Divert biomass from landfill or open burning |

| Energy Recovery | Transform waste into usable heat or electricity |

| Soil Restoration | Reuse ash residue as nutrient-rich soil additive |

| Cost Saving | Reduce waste disposal fees and energy procurement costs |

| Environmental Compliance | Meet solid waste diversion and emission targets |

Biomass boilers align with zero waste and circular economy principles.

📈 Efficiency & Emissions Profile of Modern Biomass Boilers

| Parameter | Performance Range |

|---|---|

| Boiler Thermal Efficiency | 80–90% (depends on fuel & design) |

| Particulate Emissions | <50 mg/Nm³ with proper filters |

| CO₂ Net Emissions | Near Zero (sustainable sources) |

| Ash Generation | 2–5% of input fuel |

| NOx/SOx | Much lower than coal or oil |

Advanced systems use ESP, bag filters, and scrubbers to meet stringent emission norms.

✅ Biomass Boiler Contribution to Global Climate Goals

| Sustainable Development Goal (SDG) | Biomass Boiler Contribution |

|---|---|

| SDG 7: Affordable Clean Energy | Provides decentralized, renewable thermal energy |

| SDG 12: Responsible Consumption | Utilizes waste streams as energy inputs |

| SDG 13: Climate Action | Reduces net GHG emissions and supports carbon neutrality |

| SDG 11: Sustainable Cities | Powers clean district heating and public facilities |

| SDG 9: Industry Innovation | Enables green retrofits and sustainable industrial practices |

Biomass boilers are more than just heating equipment—they are integral tools in the global fight against climate change and landfill overflow. By harnessing the energy potential of organic waste and closing the carbon loop, biomass systems allow industries and municipalities to achieve real-world sustainability targets with proven, scalable technologies.

What Are the Key Considerations for Designing and Scaling Biomass Boiler Systems in Renewable Projects?

With governments, corporations, and municipalities investing heavily in renewable energy infrastructure, biomass boiler systems are increasingly recognized as a reliable, carbon-neutral foundation for thermal energy and combined heat and power (CHP) applications. However, the success of a biomass-based renewable project hinges not just on fuel availability, but on the correct design, scalability, and long-term operability of the system. If poorly designed, a biomass boiler can face problems such as fuel handling inefficiencies, low combustion stability, emissions non-compliance, and high maintenance costs—especially when scaled for industrial or district energy use.

The key considerations for designing and scaling biomass boiler systems in renewable projects include correct sizing based on heat and power demand, fuel type and quality compatibility, combustion technology selection (grate, fluidized bed, gasification), emissions control integration, scalability through modular design, efficient fuel handling systems, and automation for load flexibility. These systems must also comply with environmental regulations, ensure lifecycle cost-effectiveness, and adapt to seasonal or long-term shifts in fuel supply and energy usage.

Thoughtful planning during the design phase is essential to ensure scalability, efficiency, and sustainability throughout the biomass project lifecycle.

Biomass boiler systems must be carefully designed and scaled to match energy demand and fuel logistics.True

Proper design ensures efficiency, compliance, and operational reliability in renewable energy projects.

Biomass boiler systems can be designed the same way as fossil fuel boilers without modification.False

Biomass systems require different combustion, fuel handling, and emissions strategies due to their unique fuel properties.

🔍 Core Design and Scaling Elements for Biomass Boiler Systems

| Design Parameter | Importance in Renewable Projects |

|---|---|

| System Sizing (MW/Ton Steam) | Must match load profile and seasonal variations |

| Fuel Type Compatibility | Impacts combustion system, emissions, and boiler lifespan |

| Combustion Technology | Determines efficiency, fuel flexibility, and scalability |

| Heat vs Power Balance (CHP) | Optimizes energy output in cogeneration projects |

| Scalability Options | Modular boilers enable phased growth and easier maintenance |

| Emission Control Systems | Essential for regulatory compliance (dust, NOx, SOx, CO) |

| Automation & Controls | Critical for load matching, efficiency optimization, and safety |

| Ash Handling & Recovery | Affects operational continuity and waste management |

| Water Treatment & Blowdown | Extends boiler life and reduces scaling or corrosion |

📈 Design Strategy for Biomass Boiler Scalability

| Scaling Approach | Best Use Case | Design Benefit |

|---|---|---|

| Single Large Boiler | Large industrial plants with constant load | High efficiency, centralized control |

| Modular Multi-Boiler | District heating or variable load systems | Redundancy, load flexibility, phased expansion |

| CHP Integration | Facilities needing both power and heat | Increased ROI, carbon savings |

| Hybrid Systems (Bio+Gas) | Backup for peak demand or low fuel season | Enhanced reliability, fuel diversification |

Modular designs also facilitate installation in constrained spaces and support future capacity upgrades.

🧪 Case Study: Biomass System Design for an Urban District Energy Project

Location: Northern Europe

Project: Biomass CHP Plant for Mixed-Use Community

Initial Design: 2 x 4 MW biomass boilers (modular) + 1 MW electric output via steam turbine

Fuel: Wood chips with 35% moisture (sourced locally)

Features:

Automatic fuel feeding + buffer silo

ESP for dust control

Weather-based load modulation

Remote monitoring SCADA

Scalability: Designed for third boiler module by Year 5

Impact:

Heating for 1,200 homes and 5 public buildings

CO₂ reduction of 8,500 tons/year

15-year design lifespan with 20% buffer capacity for expansion

Lesson: A scalable and flexible biomass design ensures long-term viability in dynamic community environments.

📊 Fuel and Combustion Technology Selection Matrix

| Fuel Type | Recommended Combustion Tech | Design Notes |

|---|---|---|

| Wood Chips (20–40% MC) | Moving grate / fluidized bed | Robust handling, needs moisture control |

| Wood Pellets (<10% MC) | Fixed grate / underfed burner | Consistent combustion, automated systems |

| Straw / Ag Waste | Vibrating grate / fluidized bed | High ash, silica; slag prevention critical |

| Bagasse (wet) | High-moisture compatible system | Often used in sugar mills; requires dryers |

| RDF / Mixed Biowaste | Fluidized bed / gasification | Advanced air control, high emissions filtering |

Fuel preparation and feedstock management must be integrated into boiler plant design.

⚙️ Emissions Control and Compliance Integration

| Pollutant | Mitigation Technology | Design Integration Point |

|---|---|---|

| Particulates (PM) | Bag filters, electrostatic precipitator (ESP) | Post-combustion gas stream |

| NOx | Flue Gas Recirculation (FGR), staged combustion | Burner design and air staging |

| SOx | Use of low-sulfur fuels or scrubbers | Fuel selection and flue gas scrubber system |

| CO | Oxygen trim control + burner tuning | Integrated combustion control system |

Compliance with ISO 14001, EU MCPD, or local EPA standards is essential for project permitting.

✅ Biomass Boiler Design Checklist for Renewable Projects

Have you calculated peak and seasonal heat/power demand?

Is the boiler system designed for the specific fuel(s) available locally?

Does the system allow for scaling or modular expansion?

Are combustion and control technologies appropriate for emission limits?

Is CHP integration necessary or viable for project ROI?

Are automation, remote monitoring, and SCADA systems included?

Is there a fuel logistics and storage plan matched to burn rate and supply chain?

Are ash disposal or reuse strategies in place?

Does the project meet all environmental permitting requirements?

Have you performed a lifecycle cost analysis including CAPEX and OPEX?

📋 Lifecycle Cost Elements in Biomass System Design

| Cost Component | Impact on Scaling Decision |

|---|---|

| Capital Cost (CAPEX) | Increases with emissions systems, CHP integration |

| Fuel Cost | Depends on sourcing distance, preprocessing, availability |

| Operation & Maintenance | Varies with complexity, ash volume, automation level |

| Emissions Compliance | Required filters and documentation add cost |

| Downtime Risk | Modular systems reduce downtime losses |

| Incentives/Carbon Credits | Can significantly improve ROI over project lifespan |

Modular and right-sized systems often provide the best balance of performance and cost.

Designing and scaling biomass boiler systems in renewable energy projects is a multidisciplinary challenge that must account for energy engineering, fuel logistics, environmental regulations, and long-term community or industrial energy needs. Success lies not only in combustion efficiency but in how well the system integrates with real-world usage patterns, growth projections, and policy frameworks.

🔍 Conclusion

Industrial biomass boilers are not just a low-carbon alternative—they’re a powerful tool for sustainable development. When integrated thoughtfully, they enhance energy security, improve waste valorization, and provide reliable heat and power in diverse renewable energy projects.🌿🔥📉

FAQ

Q1: How do industrial biomass boilers support renewable energy goals?

A1: Industrial biomass boilers play a key role in renewable energy projects by using organic materials—like wood chips, agricultural waste, or energy crops—as fuel to generate heat and power. Unlike fossil fuels, biomass is renewable and can be replenished through sustainable agriculture or forestry practices. Biomass combustion is considered carbon-neutral when managed responsibly, as the CO₂ released is reabsorbed during the growth of the biomass feedstock. This supports low-emission energy generation and aligns with global decarbonization and climate action goals.

Q2: What types of renewable energy projects use biomass boilers?

A2: Biomass boilers are used across a wide range of renewable energy applications including district heating systems, combined heat and power (CHP) plants, industrial processing facilities, and agricultural operations. In district heating, they supply hot water or steam to entire communities. In CHP systems, they simultaneously generate electricity and heat, improving energy efficiency. In industries like food processing, paper, or textiles, biomass boilers replace fossil fuels for process heat with a sustainable alternative.

Q3: What are the advantages of using biomass boilers in renewable energy projects?

A3: Advantages include reduced greenhouse gas emissions, lower dependence on fossil fuels, and the ability to use locally sourced or waste biomass materials, which enhances energy security. Biomass boilers also create a beneficial use for agricultural residues and wood waste, helping reduce landfill use. In CHP applications, their high efficiency translates into better resource utilization. Additionally, many countries offer subsidies, feed-in tariffs, or renewable energy credits for biomass-based systems.

Q4: How is fuel sustainability ensured in biomass energy projects?

A4: Sustainability depends on the sourcing and management of biomass fuel. Responsible practices include using certified sustainable forestry products, utilizing agricultural residues without disrupting soil health, and adhering to environmental standards. Lifecycle assessments and carbon accounting help verify that biomass operations provide genuine emission reductions. Supply chain logistics also play a role—local sourcing reduces transportation emissions and supports regional economies.

Q5: What technologies enhance the efficiency of biomass boilers in renewable systems?

A5: Advanced technologies such as fluidized bed combustion, gasification, and automated feed systems enhance biomass boiler efficiency. Integrated emission control systems—including cyclones, scrubbers, and electrostatic precipitators—ensure compliance with air quality regulations. In CHP setups, cogeneration improves fuel use efficiency up to 80–90%. Real-time monitoring and smart controls also optimize combustion, fuel input, and heat recovery for maximum output with minimal waste.

References

Biomass and Renewable Energy – https://www.energy.gov/eere/bioenergy/biomass-energy – U.S. Department of Energy

Renewable Heat with Biomass Boilers – https://www.carbontrust.com/resources/biomass-heating-guide – Carbon Trust

Biomass CHP Systems – https://www.epa.gov/chp/biomass-combined-heat-and-power-catalog-technologies – U.S. Environmental Protection Agency

Biomass Fuel Sustainability – https://www.ieabioenergy.com/ – IEA Bioenergy

District Heating with Biomass – https://www.sciencedirect.com/science/article/abs/pii/S0301421516301272 – ScienceDirect

Biomass Boiler Efficiency Improvements – https://www.hurstboiler.com/boilers/solid_fuel_fired/ – Hurst Boiler

Biomass Emissions and Compliance – https://www.babcock.com/home/products/emissions-control/ – Babcock & Wilcox

Combined Heat and Power Overview – https://www.energy.gov/eere/amo/combined-heat-and-power-basics – U.S. Department of Energy

Biomass Lifecycle Emissions – https://www.ucsusa.org/resources/biomass-carbon-neutral – Union of Concerned Scientists

Sustainable Bioenergy Guidelines – https://www.fao.org/bioenergy/en/ – Food and Agriculture Organization (FAO)