When purchasing an industrial boiler, many buyers are unsure what exactly is included in the standard supply package—leading to miscommunication, unexpected add-ons, or delays during installation. Without a clear scope of supply, it’s easy to overlook critical components or assume certain systems are included when they are not. This can result in cost overruns, integration issues, and commissioning failures.

A standard industrial boiler package typically includes the boiler unit (pressure vessel and heat exchanger), burner system, control panel, feedwater inlet connections, safety valves, blowdown connections, mounting frame, and insulation. Most packages also come with basic instrumentation, wiring terminals, pressure gauges, level indicators, and flue gas outlets. Optional items like economizers, feedwater tanks, deaerators, and blowdown separators are often offered separately or under an extended scope.

Knowing exactly what comes with the boiler ensures smooth coordination with civil works, electrical systems, and auxiliary equipment planning. Below, we break down the full details of a typical supply scope.

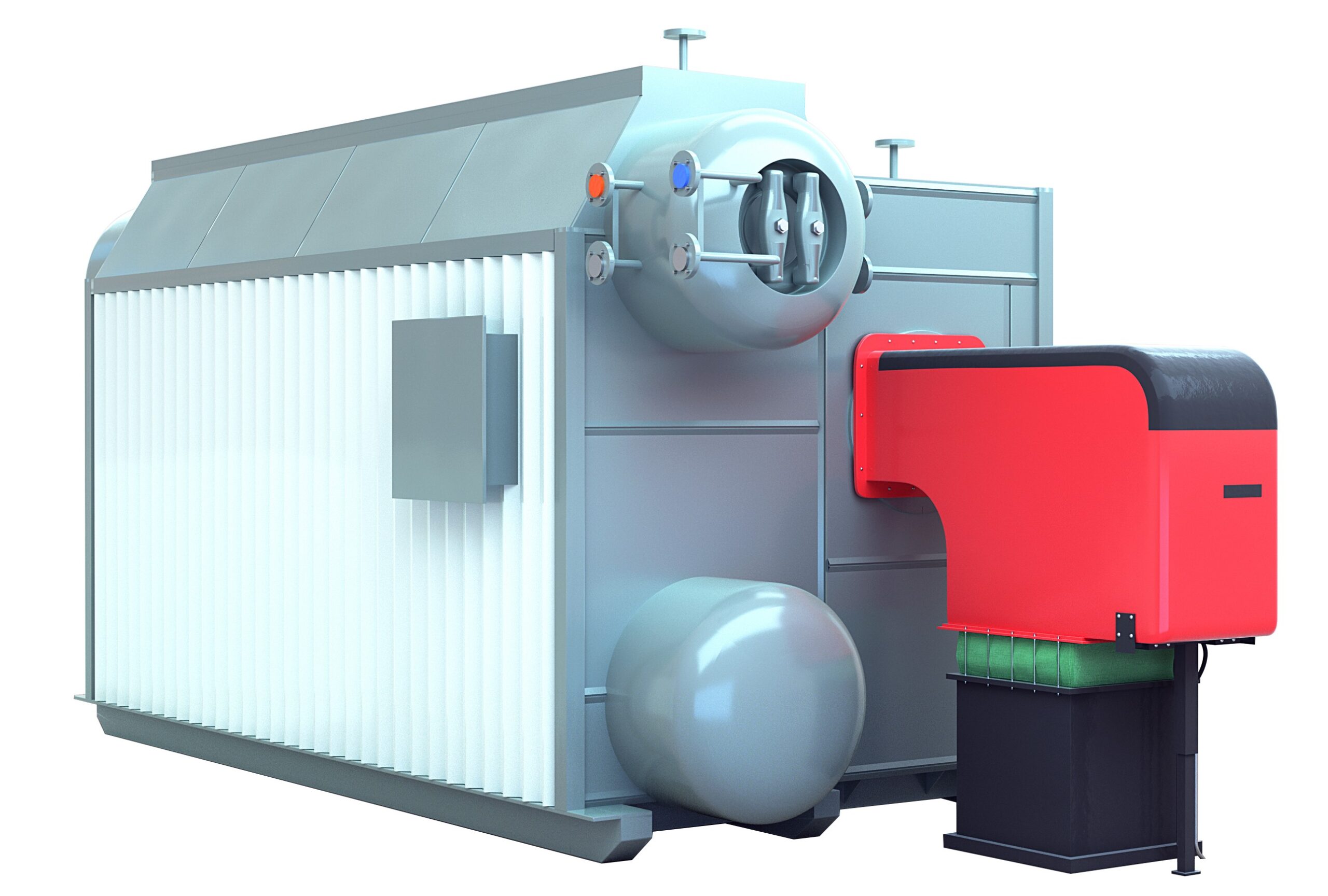

What Are the Core Components Included in a Standard Industrial Boiler Package?

When you order an industrial boiler, you’re not just getting a pressure vessel. You’re investing in a complete, interdependent system that must generate steam or hot water safely, efficiently, and reliably. Whether your application is food processing, chemicals, textiles, or pharmaceuticals, a standard boiler package includes several essential components that work together to ensure proper combustion, heat exchange, water circulation, and control.

A standard industrial boiler package includes the pressure vessel, burner system, feedwater pumps, control panel, safety valves, water level controls, steam header, blowdown system, and optionally, an economizer and deaerator. These components are pre-engineered and matched to operate as one efficient unit.

Each component plays a critical role in energy output, safety, and operational stability.

Industrial boiler systems require multiple core components beyond just the boiler shell.True

The boiler alone cannot operate without supporting systems like pumps, valves, burners, and controls integrated into a complete package.

Core Components of a Standard Industrial Boiler System

| Component | Function |

|---|---|

| Boiler Pressure Vessel | Heats water into steam using fuel combustion or electric power |

| Burner Assembly | Combines fuel and air in the right ratio for combustion (gas, oil, biomass) |

| Control Panel (PLC/HMI) | Regulates temperature, pressure, safety trips, and alarm systems |

| Feedwater Pump(s) | Circulates treated water into the boiler against system pressure |

| Steam Header/Outlet | Distributes steam to process lines or heating systems |

| Safety Valves | Prevent overpressure conditions—critical for operator safety |

| Water Level Controls | Maintain safe water level inside the boiler to prevent dry firing |

| Blowdown System | Removes sludge and dissolved solids from the boiler water |

| Economizer (Optional) | Recovers exhaust heat to preheat feedwater, increasing efficiency |

| Deaerator (Optional) | Removes oxygen and gases from feedwater to prevent corrosion |

Visual Overview of Boiler Package Components

| System Section | Main Equipment Included |

|---|---|

| Combustion System | Burner, fuel train (valves, regulators), air blower |

| Steam Generation | Pressure vessel, steam drum, water tubes or fire tubes |

| Feedwater System | Pumps, flow meters, check valves, control valves |

| Control & Safety | PLC/HMI, sensors, safety relays, alarms, trip circuits |

| Efficiency Enhancements | Economizer, condensate recovery, insulation |

| Maintenance Access | Manholes, sight glasses, drain valves, sample ports |

Optional Add-ons Depending on Application

| Optional Component | Use Case |

|---|---|

| Water Treatment Skid | Pre-treatment of raw water for scale/corrosion control |

| Blowdown Tank/Separator | Safely cools and vents hot blowdown water |

| Flue Gas Monitoring | Tracks NOx, SOx, and CO levels for compliance |

| Remote Monitoring Kit | Enables cloud-based performance tracking and alerts |

| Skid-Mounted Design | Entire system preassembled for plug-and-play installation |

Example: 4-Ton Gas-Fired Steam Boiler Package Includes

Horizontal fire tube boiler with 4-pass design

Natural gas burner with modulating control

Touchscreen PLC control panel

Dual feedwater pumps with auto-switch

Steam outlet header with 2 isolation valves

Condensate return unit

Safety valves, float-type water level controller, flame scanner

Economizer for 6% fuel savings

Factory skid mounting for fast installation

Final Word

A standard boiler package is far more than just the boiler shell—it’s a coordinated system engineered for safe and efficient steam production. Every component is chosen to match the boiler’s size, fuel, and application needs.

What Combustion and Control Systems Are Typically Provided?

Efficient fuel usage and safe boiler operation rely heavily on advanced combustion systems and intelligent control systems. In industrial boiler packages, these systems are not optional—they’re essential for performance, safety, emissions compliance, and automation. Whether firing with gas, oil, or biomass, a well-matched combustion and control setup ensures that fuel burns cleanly and the boiler operates reliably under changing load conditions.

Typical combustion and control systems provided in industrial boilers include a modulating burner (gas/oil/dual-fuel), fuel train, flame monitoring system, air-fuel ratio controller, PLC or HMI control panel, safety interlocks, and combustion optimization features such as O₂ trim and VFD blowers.

Together, these systems deliver reliable heat, maximize efficiency, and protect personnel and equipment from unsafe conditions.

Industrial boilers are equipped with modulating combustion systems and programmable control panels.True

Combustion and control systems are critical for achieving efficiency, safety, and emissions compliance in boiler operation.

Combustion Systems Typically Included

| Component | Function |

|---|---|

| Burner (Gas/Oil/Biomass) | Mixes fuel and air, ignites flame, and modulates flame size based on load |

| Fuel Train | Includes valves, regulators, filters, pressure switches for safe fuel delivery |

| Air Blower (w/ VFD) | Supplies combustion air at required volume and pressure |

| Flame Detector | Monitors flame presence (UV/IR sensors or ionization probes) |

| Ignition System | Starts combustion using pilot or electronic spark system |

| Air/Fuel Ratio Controller | Adjusts combustion mixture for efficiency and emissions control |

| Low-NOx/Ultra-Low-NOx Features | Reduce nitrogen oxide emissions using special burners or FGR |

Control Systems Typically Provided

| Control Feature | Description |

|---|---|

| PLC-Based Control Panel | Programmable controller automates boiler functions and safety logic |

| Touchscreen HMI Interface | User interface for monitoring temperature, pressure, alarms, and settings |

| Modulating Control Logic | Adjusts burner output based on real-time steam demand |

| Safety Interlocks & Trips | Shutdown system for overpressure, flame failure, low water, or fuel errors |

| Remote Monitoring Capability | Optional cloud access or SCADA integration for diagnostics |

| O₂ Trim System (Optional) | Optimizes combustion by adjusting airflow based on exhaust oxygen level |

| Historical Data Logging | Stores performance, alarm, and maintenance data for analysis |

Typical Combustion & Control System Workflow

Startup – Control panel checks safety conditions (fuel pressure, water level, air flow)

Ignition – Spark ignites fuel-air mixture; flame scanner confirms ignition

Modulation – PLC adjusts burner flame size via control valves and blower motor

Feedback – Pressure/temperature sensors send data to PLC; O₂ sensor adjusts air trim

Safety Monitoring – Real-time fault detection; instant shutdown on unsafe conditions

User Interaction – Operator views or adjusts settings via touchscreen interface

Example: Natural Gas Boiler with Standard Combustion/Control Package

| System Component | Specification |

|---|---|

| Burner Type | Fully modulating gas burner with low-NOx design |

| Fuel Train Components | Manual shutoff, solenoid valves, pressure switches, filter |

| PLC Brand | Siemens S7 or Allen-Bradley (customizable) |

| HMI Screen | 7″ or 10″ touchscreen with multilingual display |

| Sensors Integrated | Steam pressure, stack temperature, water level, flame presence |

| Safety Protocols | ANSI/NFPA85 compliant logic with auto-reset interlocks |

| Optional Add-Ons | Oxygen trim system, VFD for fan motor, remote access gateway |

Why These Systems Matter

Increase efficiency by up to 5–10% through precise flame control

Reduce fuel costs with optimized air/fuel ratios

Ensure compliance with NOx, CO, and safety codes

Protect your investment with smart, preventive shutdown features

Enable remote supervision and faster troubleshooting

Tip: Choose a supplier who offers factory-tested combustion and control systems, so your startup and tuning process is fast, smooth, and code-compliant.

Final Word

An industrial boiler is only as good as its burner and brain. Combustion and control systems are what make your boiler safe, efficient, and intelligent. They handle the heat—literally and digitally.

Are Safety Devices and Monitoring Instruments Part of the Standard Supply?

Safety is non-negotiable in industrial boiler systems. These high-pressure, high-temperature units operate in environments where failure can lead to serious injury, equipment damage, or production shutdowns. That’s why modern boiler packages are delivered with a full set of pre-installed safety devices and monitoring instruments. These components ensure the system operates within safe parameters and provides early warnings before any critical failure occurs.

Yes, safety devices and monitoring instruments are included in the standard supply of industrial boiler systems. These typically include pressure relief valves, low-water level cutoffs, flame detectors, pressure and temperature gauges, safety interlocks, and alarm systems—all factory-integrated for compliance and operational security.

These components are not add-ons—they are core to both regulatory approval and safe commissioning.

Industrial boilers come with essential safety and monitoring devices as standard components.True

Boilers must comply with international safety codes, which require integrated monitoring and protection systems before operation.

Common Safety Devices in a Standard Boiler Package

| Device | Function |

|---|---|

| Safety Relief Valve | Automatically releases steam to prevent overpressure |

| Low Water Cutoff | Shuts down burner when water level is unsafe |

| Flame Detector (UV/IR) | Monitors presence of flame—trips burner if flame is lost |

| Pressure Limit Control | Stops burner if steam pressure exceeds setpoint |

| High Temperature Cutout | Protects against overheating in hot water or thermal oil boilers |

| Blowdown Valve System | Removes impurities and prevents pressure build-up in the boiler drum |

| Gas Leak Detectors (optional) | Detects fuel gas leakage near burner system |

| Emergency Stop Switch | Manual shutdown option in case of abnormal conditions |

Standard Monitoring Instruments Included

| Instrument | Purpose |

|---|---|

| Pressure Gauge | Displays boiler steam or water pressure in real-time |

| Thermocouples/RTDs | Measure temperature at key points (flue, drum, feedwater, etc.) |

| Water Level Sight Glass | Provides visual confirmation of boiler water level |

| Level Transmitter | Sends continuous water level signal to PLC for display and control |

| Oxygen Sensor (optional) | Monitors stack O₂ for combustion tuning and efficiency |

| Control Panel Alarms | Indicates faults like low pressure, high temp, or flame failure |

Boiler Control Panel Safety Interface Functions

Alarm Logging

Visual and Audible Alerts

Automatic Burner Lockout

Interlock Logic Testing

Safety Reset Function (supervised)

Regulatory Standards That Mandate Safety Devices

| Code or Standard | Region or Use | Safety Requirements Covered |

|---|---|---|

| ASME Section I & CSD-1 | USA | Pressure, water level, combustion safeguards |

| CE PED / EN12953 | EU | Pressure vessel and burner protection |

| NFPA 85 | Combustion safety | Flame failure, purging, fuel shut-off |

| API 560 / ISO 4126 | Process industries | Relief devices, pressure integrity |

Real-Life Example: Safety Package in a 6-Ton Gas Boiler

Included Devices:

– 2x Spring-loaded safety valves (ASME certified)

– Dual water level controls (1 for control, 1 for cutoff)

– UV flame scanner for main burner

– Manual-reset high-pressure switch

– Pressure gauge + stack temperature sensor

– HMI with password-protected reset features

Final Word

Boiler safety isn’t optional—it’s engineered into every standard unit. From flame sensors to emergency shutdowns, these systems protect both people and plant assets. With all key safety devices and monitoring tools included from the start, you can operate with confidence and compliance.

Which Auxiliary Systems Are Optional or Offered Under Extended Scope?

While a standard industrial boiler package includes the pressure vessel, burner, controls, and core safety features, many facilities require additional systems to improve efficiency, ensure water quality, recover energy, or support specific fuels. These auxiliary systems—though not always standard—can be critical for long-term reliability, environmental compliance, and lifecycle cost reduction. They are typically offered as optional add-ons or under extended EPC scope, depending on your application needs.

Auxiliary systems offered under extended scope include water treatment systems, deaerators, economizers, condensate recovery units, blowdown separators, fuel handling systems (for biomass/oil/gas), flue gas scrubbers, and emission monitoring devices. These components enhance boiler performance, protect internal components, and reduce operational costs.

They can be bundled into turnkey packages or added as custom modules.

Auxiliary systems like economizers and water treatment skids are commonly offered as optional items in boiler projects.True

These systems are not always standard, but they significantly improve efficiency, longevity, and compliance, so they are offered as part of extended project scope.

Optional Auxiliary Systems and Their Functions

| Auxiliary System | Function and Benefit |

|---|---|

| Water Treatment Skid | Pre-treats feedwater to prevent scaling and corrosion; includes softeners, RO units, dosing systems |

| Deaerator System | Removes dissolved oxygen and gases from feedwater to protect against corrosion |

| Economizer | Recovers heat from flue gas to preheat feedwater—boosts thermal efficiency by 5–7% |

| Condensate Recovery Unit | Collects and reuses steam condensate—reduces makeup water and energy loss |

| Fuel Handling System | Biomass feeders, oil pumping skids, gas train manifolds—ensures reliable fuel delivery |

| Blowdown Separator Tank | Cools and vents blowdown water safely; avoids damage to drains or sewers |

| Emissions Control Devices | Reduces NOx, SOx, particulates—includes SCR, bag filters, FGR systems |

| Chimney or Stack Systems | Designed per emission dispersion requirements; includes dampers and sampling ports |

| Compressed Air System | Supports burner purge, actuator control, or instrumentation needs |

| Backup Power Supply (UPS) | Ensures control system or pumps stay online during grid failure |

Commonly Requested Auxiliary Packages by Industry

| Industry | Auxiliaries Typically Included |

|---|---|

| Food & Beverage | Deaerator, softening system, condensate recovery |

| Pharmaceutical | RO water treatment, blowdown separator, stack emissions monitoring |

| Textiles | Economizer, condensate recovery, fuel skids |

| Chemical Processing | Deaerator, FGR system, dual-fuel burner, emission scrubbers |

| Power Generation | Full water treatment plant, economizer, SCR unit, soot blowers |

Add-on Integration Options in EPC Projects

| Integration Level | Available in EPC Turnkey Scope? | Note |

|---|---|---|

| Pre-piped and wired skid units | ✅ Yes | Fast installation with minimal site labor |

| Fully automated auxiliaries | ✅ Yes | Integrated into main PLC or SCADA |

| Modular expansions | ✅ Yes | Future-ready systems designed with expansion in mind |

| Civil foundation for auxiliaries | ✅ Yes | Included in EPC base if scope is defined early |

Real Project Example

Client: Paper mill in Southeast Asia

Boiler: 12-ton biomass steam boiler

Auxiliaries Included:

– Chain grate fuel feeder system

– Water softening plant with auto-regeneration

– Deaerator and condensate recovery tank

– Economizer for 7% fuel savings

– PLC integration for full auxiliary control

Final Word

Auxiliary systems are often what transform a basic boiler into a high-efficiency, low-maintenance, and regulation-compliant thermal solution. They’re not mandatory for every application, but in many cases, they’re the smart investment for long-term performance.

What Documentation, Certifications, and Spare Parts Are Included in Delivery?

When your industrial boiler system arrives on-site, you’re not just receiving a piece of equipment—you’re receiving a fully documented, certified, and ready-to-operate thermal system. Proper documentation and a complete spare parts package are critical for regulatory compliance, warranty activation, installation, training, and long-term maintenance. Without them, even a high-quality boiler can face delays in commissioning or legal hurdles in certain jurisdictions.

A standard industrial boiler delivery includes a comprehensive documentation package (with manuals, drawings, certificates), all required legal certifications (ASME, CE, PED, etc.), and a basic startup spare parts kit. Extended spare parts lists and digital documents are also available under EPC or customized supply scopes.

This ensures your team can install, operate, maintain, and certify the system with full confidence.

Industrial boiler deliveries include essential documents, certifications, and a basic spare parts kit.True

These are required to meet code regulations, validate warranties, and ensure the boiler can be installed and maintained safely.

Standard Documentation Included in Boiler Delivery

| Document Type | Purpose |

|---|---|

| Operation & Maintenance Manual | Guides daily operation, control use, and safety routines |

| Installation Manual | Shows how to position, connect, and commission the boiler |

| As-Built Drawings | Includes P&ID, GA (General Arrangement), and electrical layout diagrams |

| Wiring Diagrams | Shows control panel wiring, sensor connections, and interlocks |

| Spare Parts List | Identifies all replaceable components and part numbers |

| Commissioning Checklist | Guides technician through safe system startup steps |

| Warranty Certificate | States coverage period, conditions, and claim procedures |

| Inspection Test Plans (ITP) | Shows factory quality checks and results for traceability |

Certifications Typically Supplied

| Certificate Type | Compliance Standard | Applies To |

|---|---|---|

| ASME U-Stamp | ASME Section I | Pressure vessels (main boiler body) |

| CE Marking | PED 2014/68/EU | Boilers supplied in the European Union |

| PED Module B / D / H | Pressure Equipment Directive | Ensures conformity of design/manufacturing |

| ISO 9001 Certificate | Quality Management System | Manufacturer’s quality compliance |

| Material Test Certificates (MTCs) | EN10204 / ASTM | Pressure parts like tubes, plates, drums |

| Third-Party Inspection Report | TUV, SGS, or Bureau Veritas | Confirms boiler passed factory inspection |

| Combustion Test Report | Factory burner test data | Proves emissions and performance specs |

Typical Spare Parts Kit (Startup Package)

| Component | Qty | Purpose |

|---|---|---|

| Burner Ignition Electrode | 1–2 pcs | Backup for ignition failure |

| Gasket/O-Ring Set | Full set | For manholes, valves, sensors |

| Pressure & Temp Sensors | 1 set | Replacement sensors for startup or testing |

| Water Level Controller Float | 1 pc | Critical spare for low-water cutoff |

| Safety Valve Spring | 1 pc | Backup part to ensure pressure relief function |

| Fuses / Relays | 2–3 pcs | Electrical panel spares |

| Sight Glass Assembly | 1 set | For water level visual confirmation |

Extended Spare Parts Package (Optional with EPC)

Burner nozzle kits

Motor and fan bearings

Extra feedwater pump

Flame detector sensor head

PLC I/O modules

Pneumatic actuator parts

Cleaning brushes and tools

Pressure switches and solenoid valves

Final Checklist Upon Delivery

| Item | Included |

|---|---|

| Operation & Maintenance Manual | ✅ |

| GA and P&ID Drawings | ✅ |

| Control Wiring Diagram | ✅ |

| Boiler Pressure Test Certificate | ✅ |

| CE/ASME Compliance Docs | ✅ |

| Startup Spare Parts | ✅ |

| Digital Document Copy (USB/Cloud) | Optional |

Final Word

Every industrial boiler delivery is backed by critical documents, certifications, and parts that enable fast, legal, and trouble-free installation and operation. These elements are as important as the hardware itself.

How Should Buyers Verify and Align Scope of Supply with Project Requirements?

One of the most common reasons for project delays, cost overruns, or technical mismatches in industrial boiler installations is a poorly defined or misunderstood scope of supply. If the buyer’s project needs and the supplier’s offer aren’t fully aligned early on, it can lead to missing components, last-minute upgrades, or compliance issues during inspection. That’s why verifying and aligning the scope of supply with your exact site and process requirements is absolutely essential before finalizing the purchase order.

To verify and align the boiler scope of supply, buyers should carefully review technical specifications, compare the offered equipment list with project requirements, confirm inclusion of all critical components, cross-check with P&ID and layout drawings, and conduct a joint scope clarification meeting with the supplier before order confirmation.

This step ensures that nothing critical is overlooked and that both sides have a shared understanding of deliverables.

Scope verification involves technical comparison, drawing review, and supplier clarification.True

This ensures the purchased system matches actual project requirements and avoids costly rework or delays.

Key Steps to Verify and Align Scope of Supply

| Verification Step | What to Do |

|---|---|

| 1. Review Buyer’s Technical Specs | Re-express performance goals: capacity, pressure, fuel type, emissions limits |

| 2. Check Supplier’s Quotation Line-by-Line | Compare each item against your specifications and checklist |

| 3. Examine GA and P&ID Drawings | Ensure piping, valves, tanks, and instrumentation match your plant layout |

| 4. Confirm Included Components | Pressure parts, controls, auxiliaries, safety devices, electrical scope |

| 5. Clarify Interfaces and Exclusions | Who supplies platforms, cabling, foundations, cranes? |

| 6. Request a Scope Clarification Matrix | A tabular summary that clearly defines included vs. excluded items |

| 7. Hold a Technical Clarification Meeting | Invite your project engineer, consultant, and supplier’s technical lead |

| 8. Document Final Agreement in PO or Contract | Lock the verified scope into a written, signed contract |

Scope Clarification Matrix Sample

| System/Item | Included in Supply? | Comments |

|---|---|---|

| Boiler Pressure Vessel | ✅ Yes | Horizontal 10-ton steam boiler, ASME-stamped |

| PLC & Touchscreen Panel | ✅ Yes | Allen-Bradley with full I/O and alarm system |

| Water Softener System | ❌ No | Offered optionally; buyer to confirm |

| Economizer | ✅ Yes | Provided with 5% fuel savings estimate |

| Civil Foundation Design | ❌ No | Buyer’s responsibility |

| Stack/Chimney | ✅ Yes | 15m stack, flanged and painted |

| Commissioning Services | ✅ Yes | 3 days of on-site tuning and training |

Common Oversights to Avoid

Assuming auxiliaries like deaerators, softeners, or blowdown tanks are included by default

Not specifying the electrical scope (e.g., cables, MCC panels, field wiring)

Ignoring instrumentation detail (are pressure gauges and transmitters included?)

Failing to address compliance documents (ASME, CE, emissions testing)

Overlooking transport and delivery terms (e.g., FOB vs. DAP vs. CIF)

Best Practices for Alignment

Use a checklist or RFQ template with tick-boxes for every critical item

Request the supplier’s “scope confirmation sheet” or BOM early in negotiations

Assign a dedicated technical reviewer on the buyer side before PO placement

Ask for revision-controlled drawings and documentation lists

Ensure all parties are aligned on installation and startup responsibilities

Final Word

When scope clarity exists, everything else flows smoothly—from design and delivery to installation and operation. Aligning the scope upfront saves time, avoids disputes, and ensures your project is delivered on time and as expected.

🔍 Conclusion

Understanding the standard scope of supply for an industrial boiler helps ensure smooth project execution, accurate budgeting, and system compatibility. While the core boiler unit and control system are standard, auxiliaries, accessories, and integration elements often require separate consideration or negotiation.

📞 Contact Us

💡 Need a complete boiler supply package tailored to your operation? We offer standard and custom-configured boiler systems, with clear scope definitions, technical documentation, and modular add-ons.

🔹 Let us deliver a boiler system that’s complete, compatible, and ready for rapid installation. 📦🔥🛠️✅

FAQ

What is typically included in the standard scope of supply for an industrial boiler package?

A standard industrial boiler package usually includes the essential components required for startup and operation, such as:

Boiler pressure vessel or shell

Burner assembly (gas/oil/dual-fuel)

Combustion chamber

Steam drum or water drum

Boiler mountings (safety valves, level gauges, pressure gauges)

Control panel with programmable logic controller (PLC)

Feedwater system (pumps, valves, deaerator—if applicable)

Blowdown system

Insulation and cladding

Economizer or air preheater (optional, based on order)

Wiring and instrument cabling (within skid limits)

Foundation bolts and base frame

Manufacturers often ship the unit skid-mounted or modular for easier on-site assembly.

Are control systems included in the standard boiler supply?

Yes. Most industrial boiler packages include:

Integrated PLC-based control panel

HMI touchscreen interface

Instrumentation for pressure, temperature, and water level

Safety interlocks and alarms

Remote monitoring interface (optional in some cases)

Control systems are designed to automate operation, ensure safety, and optimize performance.

What optional items can be added beyond the standard scope?

Optional add-ons or upgrades may include:

Water treatment systems (softeners, RO, chemical dosing)

Chimney and ductwork

Condensate recovery systems

Boiler feed tanks or deaerators

Modular housing/enclosures

Low-NOx burners or emission control systems

Stack economizers for energy recovery

Spare parts kits and tool sets

These are typically quoted separately based on project needs and compliance requirements.

Is documentation part of the boiler package supply?

Absolutely. Standard boiler packages include a complete documentation set, such as:

General arrangement drawings

P&I diagrams (Piping and Instrumentation)

Wiring schematics

Operation & maintenance manuals

Inspection and testing certificates (e.g., ASME, CE)

Factory acceptance test (FAT) reports

Some suppliers may also offer 3D models and digital twins for EPC or BIM integration.

What utilities and connections are required on-site?

To install and operate the supplied boiler package, you typically need:

Fuel line connection (natural gas, oil, etc.)

Water inlet and steam outlet piping

Electrical power supply

Drainage and blowdown piping

Flue gas stack or chimney system

Final integration, commissioning, and piping beyond skid limits are often site responsibilities unless turnkey service is included.

References

Cleaver-Brooks – Boiler System Packages – https://www.cleaverbrooks.com

Hurst Boiler – Standard Equipment List – https://www.hurstboiler.com

Powerhouse – What’s in a Boiler Package? – https://www.powerhouse.com

Miura Boilers – Modular Boiler Systems – https://www.miuraboiler.com

Thermodyne – Industrial Boiler Scope of Supply – https://www.thermodyneboilers.com

Spirax Sarco – Boiler Control Systems – https://www.spiraxsarco.com

Indeck Boilers – Complete Boiler Packages – https://www.indeck.com

IEA – Boiler System Design Guidelines – https://www.iea.org

BioEnergy Consult – Steam Boiler System Overview – https://www.bioenergyconsult.com

DNV – Boiler Packaging and Compliance Standards – https://www.dnv.com