When planning for a new boiler project, one of the most important considerations is the total cost of a gas-fired boiler. Without a clear understanding, businesses may underestimate budgets, face delays during installation, or select a boiler that is not aligned with their operational needs.

The cost of an industrial gas-fired boiler typically ranges from $30,000 to over $300,000 depending on capacity (measured in tons/hr or BHP), steam pressure, efficiency level, and whether it is a standard packaged unit or a custom-engineered system. Additional expenses such as installation, auxiliary equipment (burner, economizer, feedwater system, control panels), and piping can bring the total installed cost to 1.5–3 times the base price. Long-term operating costs, mainly fuel and maintenance, should also be factored into the investment decision.

By evaluating both capital and operational costs, companies can ensure better ROI and reliable steam supply.

What Factors Determine the Price of an Industrial Gas-Fired Boiler?

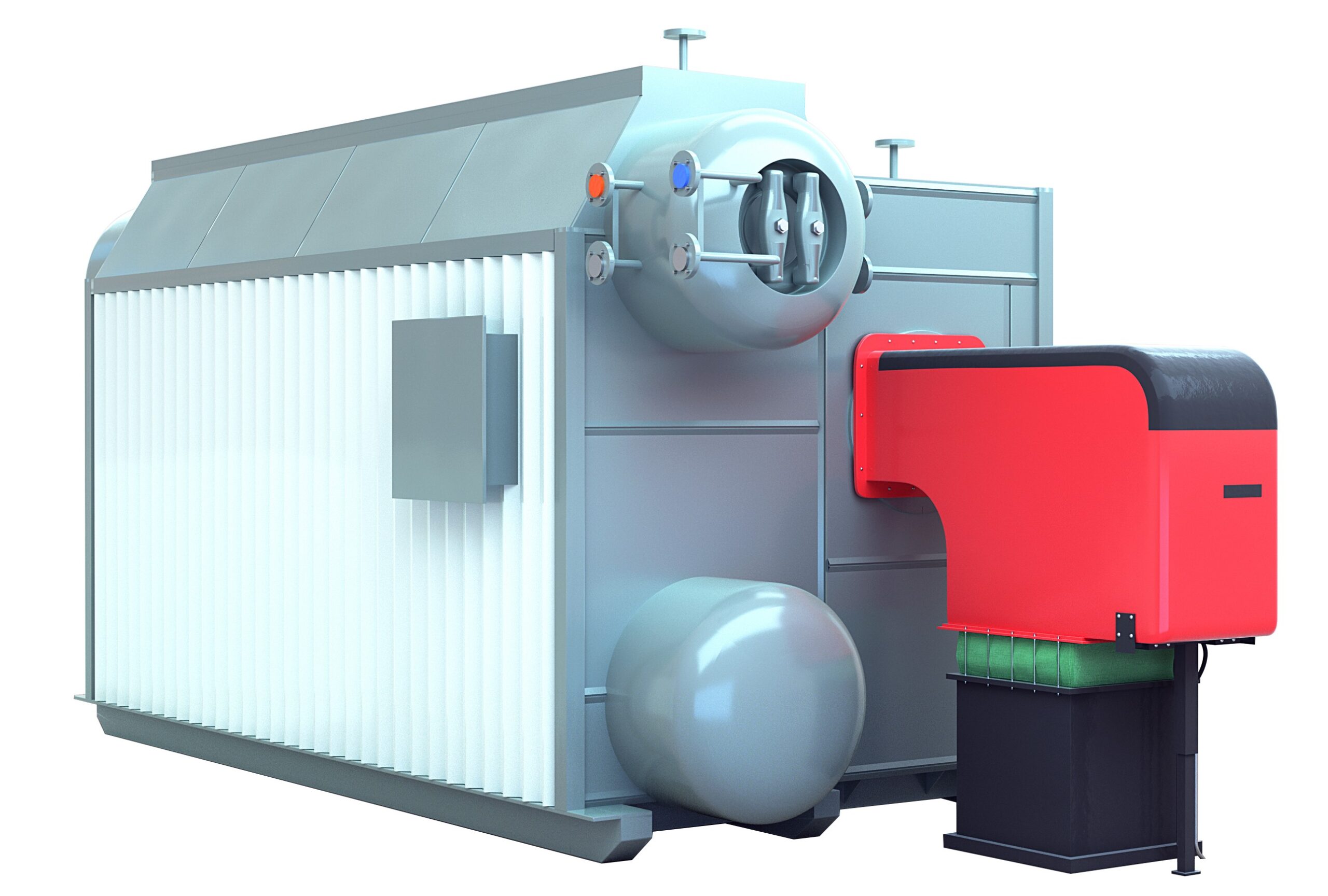

When businesses plan a boiler investment, they often focus on the unit price alone. However, the real cost of an industrial gas-fired boiler depends on multiple technical and project-specific factors. Gas-fired boilers are widely used for their high efficiency, cleaner emissions, and lower operating cost compared to coal and oil. Yet, their purchase price can vary by over 100% depending on capacity, design, and auxiliary systems.

The price of an industrial gas-fired boiler is primarily determined by its steam capacity, pressure rating, design type (fire-tube, water-tube, condensing, CFB), efficiency features (economizer, condenser, advanced controls), auxiliary systems (burner, feedwater system, stack), installation and commissioning costs, and compliance with local emission standards. Together, these factors can double or triple the base unit price.

This makes a holistic evaluation essential for accurate budgeting and lifecycle planning.

The base boiler price is the only major cost when buying a gas-fired boiler.False

Auxiliary systems, installation, and compliance costs can equal or exceed the boiler’s purchase price.

Efficiency features such as economizers and condensing designs increase upfront price but reduce lifecycle cost through fuel savings.True

They typically deliver 5–10% efficiency gains with 2–4 year payback periods.

1. Boiler Capacity & Pressure Rating

Larger capacity = higher material and fabrication costs.

High-pressure (>40 bar) systems need thicker steel, certified welding, and stricter safety standards.

Cost can rise 20–50% when moving from low to high pressure.

2. Boiler Type & Design

Fire-tube: Lower cost, suitable for ≤20 TPH, <25 bar.

Water-tube: More expensive, for larger capacities and higher pressures.

Condensing boilers: Add 10–20% to upfront cost but save fuel.

CFB gas boilers: Specialized, higher cost, for very large utility projects.

3. Efficiency Features

Economizers: Add 5–10% cost, improve efficiency 3–6%.

Condensing heat exchangers: Recover latent heat, boost efficiency to >95%.

O₂ Trim & Controls: Cost more initially, cut fuel use 2–5%.

4. Auxiliary Systems

Burner: 15–20% of project cost.

Feedwater treatment: 10–15%.

Chimney/stack: 5–8%.

Control panel/automation: 8–12%.

5. Installation & Commissioning

Adds 15–30% depending on site conditions.

Includes piping, electrical, civil works, and testing.

6. Emission Compliance

Local NOx, CO₂, and particulate standards impact design.

Low-NOx burners or SCR (selective catalytic reduction) can add 10–20% to boiler cost.

7. Cost Comparison Example

| Boiler Type | Capacity | Pressure | Base Price (USD) | Total Installed (USD) |

|---|---|---|---|---|

| Fire-Tube | 5 TPH, 16 bar | $120,000 | $220,000–$250,000 | |

| Water-Tube | 20 TPH, 40 bar | $380,000 | $650,000–$750,000 | |

| Condensing | 10 TPH, 25 bar | $260,000 | $450,000–$520,000 |

Conclusion

The cost of a gas-fired boiler is shaped by capacity, pressure, design, efficiency features, auxiliaries, installation, and compliance needs. Buyers should budget not only for the base unit but also for integration and lifecycle efficiency.

How Does Boiler Size and Steam Capacity Affect Cost?

When planning for an industrial boiler investment, boiler size and steam capacity are among the most important cost drivers. Larger boilers not only require more materials and advanced design but also need stronger infrastructure, higher-rated auxiliaries, and stricter safety compliance. This makes cost scaling non-linear—doubling the steam output does not simply double the price; it can increase by 2.5–3 times because of pressure vessel complexity and auxiliary system upgrades.

Boiler size and steam capacity directly affect cost because larger boilers require more steel, thicker pressure parts, stronger foundations, bigger burners, and higher-capacity auxiliaries. While small packaged boilers (≤5 TPH) may cost $100,000–$200,000, medium units (10–20 TPH) can range $300,000–$700,000, and large utility-scale boilers (>50 TPH) exceed several million dollars. Higher pressures (above 40 bar) further raise costs by 20–40% due to material and fabrication requirements.

This means steam demand forecasting is crucial, as oversizing increases capital and operating cost, while undersizing risks production shortfalls.

Boiler cost scales linearly with size and steam output.False

Cost increases disproportionately with larger sizes due to thicker steel, advanced welding, and auxiliary system upgrades.

Higher-capacity boilers require bigger auxiliaries such as burners, pumps, and economizers, which significantly add to total cost.True

Auxiliary system cost grows with boiler size, often making up 30–50% of installed price.

1. Why Size Affects Price

Material Use: Larger pressure vessels need exponentially more steel.

Safety Standards: Higher pressures demand certified welding and testing.

Auxiliaries: Larger units require more powerful burners, pumps, fans, and controls.

Installation Costs: Foundations, piping, and lifting requirements are more complex.

2. Typical Cost Ranges by Capacity

| Boiler Size | Steam Capacity | Pressure Range | Base Price (USD) | Total Installed (USD) |

|---|---|---|---|---|

| Small Packaged | 1–5 TPH | 10–16 bar | $100k – $200k | $180k – $300k |

| Medium Industrial | 10–20 TPH | 20–40 bar | $300k – $700k | $550k – $1M |

| Large Utility | 30–50 TPH | 40–80 bar | $800k – $1.5M | $1.5M – $3M+ |

| Utility-Scale | >50 TPH | >80 bar | $2M+ | $5M+ |

3. Example: 10 TPH vs 20 TPH Boiler

10 TPH, 25 bar: ~$380,000 base, ~$650,000 installed.

20 TPH, 25 bar: ~$650,000 base, ~$1.2M installed.

Cost nearly doubles, but per-ton steam cost decreases with larger unit (economy of scale).

4. Pressure Factor

Low-Pressure (<16 bar): Lower steel thickness, cheaper fabrication.

Medium-Pressure (20–40 bar): Adds 15–25% cost.

High-Pressure (40–100 bar): Adds 30–40% cost due to alloy steel, certifications.

Conclusion

Boiler size and steam capacity are the primary cost determinants, with larger and higher-pressure units demanding significantly higher investment. Choosing the right capacity requires balancing CAPEX, OPEX, and scalability for future demand.

What Role Do Efficiency Ratings and Emissions Standards Play in Pricing?

When evaluating a gas-fired boiler purchase, buyers often compare only the base unit price, but efficiency ratings and emissions standards can have just as much impact on total investment. Modern energy policies, rising fuel costs, and strict air-quality regulations mean that low-cost, standard-efficiency units are often no longer viable. Instead, buyers must weigh higher upfront CAPEX against lower lifecycle fuel costs and compliance-driven penalties.

Higher efficiency ratings increase boiler price by 10–25% due to advanced heat recovery technologies, while stricter emissions standards can add 15–30% for low-NOx burners, flue gas recirculation, or SCR systems. However, these features typically reduce fuel consumption by 5–12% and avoid regulatory fines, making them cost-effective over the boiler’s lifetime.

This makes efficiency and emissions compliance not just technical requirements, but strategic cost factors that directly influence ROI.

Higher-efficiency boilers always cost more but have no impact on lifecycle cost.False

Fuel savings from a 5–10% efficiency gain often pay back the premium within 2–4 years.

Stricter emission standards can add 15–30% to boiler price due to the need for low-NOx burners and after-treatment systems.True

Meeting modern environmental regulations requires advanced combustion and flue gas treatment technologies.

1. Impact of Efficiency Ratings

Standard Efficiency (80–85%): Lower cost, but higher fuel bills.

High Efficiency (88–92%): Requires economizers, adds 10–15% cost.

Condensing Efficiency (>95%): Needs corrosion-resistant heat exchangers, adds 20–25%.

| Efficiency Level | Cost Premium | Fuel Savings | Payback Period |

|---|---|---|---|

| Standard (82%) | Base price | None | N/A |

| High (90%) | +10–15% | 5–8% | 2–4 years |

| Condensing (95%) | +20–25% | 8–12% | 2–5 years |

2. Role of Emission Standards

NOx Compliance: Ultra-low NOx burners add 10–20% to boiler cost.

SO₂ / PM: Less relevant for gas but critical in dual-fuel designs.

CO₂ Reduction Goals: May require efficiency upgrades or hybridization.

After-Treatment Systems: SCR (Selective Catalytic Reduction) or FGR (Flue Gas Recirculation) add 10–15% cost.

3. Example: 10 TPH Boiler Case

Standard 82% efficiency, no emissions controls: ~$280,000 base.

90% efficiency + low-NOx burner: ~$340,000 (+21%).

95% condensing + SCR system: ~$420,000 (+50%).

Fuel savings: $30,000–50,000 per year, paying back in ~3–4 years.

4. Regulatory Pressure

Many regions (EU, US EPA, China, India) mandate <30 mg/Nm³ NOx for new boilers.

Non-compliance can result in fines, retrofits, or operating restrictions.

Forward-looking buyers prefer to invest in future-proof systems.

Conclusion

Efficiency ratings and emissions standards directly raise upfront boiler cost, but they reduce lifecycle expenses and secure compliance. Buyers must treat these as investments in operational sustainability and risk avoidance, not optional add-ons.

How Do Auxiliary Systems and Controls Influence the Total Investment?

When companies evaluate a gas-fired boiler purchase, the boiler unit price is often the first number considered. However, this represents only part of the true cost. The auxiliary systems and control package—burners, economizers, feedwater treatment, pumps, chimneys, instrumentation, and automation—can equal or exceed the price of the boiler itself. These systems are not optional; they are essential for safe, efficient, and compliant operation.

Auxiliary systems and controls typically account for 30–50% of the total installed cost of a gas-fired boiler. Burners alone can represent 15–20% of cost, economizers 5–10%, feedwater systems 10–15%, and automation 8–12%. While they increase upfront investment, they improve combustion stability, recover waste heat, ensure water quality, reduce emissions, and optimize performance—ultimately lowering lifecycle fuel and maintenance costs.

This makes auxiliaries and controls central to both budgeting and long-term ROI.

Auxiliary systems are optional extras that can be excluded to reduce boiler cost.False

Burners, feedwater systems, and controls are essential for safe operation, efficiency, and compliance.

Automation and digital controls can add 8–12% to cost but reduce fuel use and maintenance expenses by 5–10% annually.True

Smart controls optimize combustion and enable predictive maintenance, improving lifecycle economics.

1. Major Auxiliary Systems and Their Cost Role

Burner System (15–20%)

Ensures efficient combustion and low NOx.

Advanced modulating burners cost more but cut fuel waste.

Economizer (5–10%)

Recovers flue gas heat to preheat feedwater.

Improves efficiency by 3–6% with 2–3 year payback.

Feedwater System (10–15%)

Includes deaerators, pumps, water treatment.

Prevents scaling and corrosion, extending boiler life.

Stack/Chimney (5–8%)

Sized for flue gas volume and emissions control needs.

Control & Automation (8–12%)

PLC/SCADA with combustion controls and safety interlocks.

Enables monitoring, alarms, and remote operation.

2. Comparative Example – 10 TPH Gas-Fired Boiler

| Cost Component | Approx. Share | Estimated Cost (USD) |

|---|---|---|

| Boiler Base Unit | 55–65% | $240,000 |

| Burner System | 15–20% | $70,000 |

| Economizer | 5–10% | $35,000 |

| Feedwater System | 10–15% | $50,000 |

| Automation & Controls | 8–12% | $40,000 |

| Stack & Misc. | 5–8% | $25,000 |

| Total Installed Cost | 100% | ~$460,000 |

3. Impact of Controls on Lifecycle Costs

Fuel Savings: O₂ trim and load modulation reduce gas use by 3–5%.

Maintenance Reduction: Predictive alerts lower repair frequency.

Downtime Avoidance: Early fault detection prevents costly shutdowns.

Compliance Assurance: Automated reporting simplifies regulatory checks.

4. Case Study

A 20 TPH gas-fired boiler with advanced automation cost 12% more upfront, but reduced annual gas consumption by 7%. Over 10 years, this saved $1.2M in fuel costs, more than offsetting the initial premium.

Conclusion

Auxiliary systems and controls are not secondary costs—they are the foundation of boiler efficiency, reliability, and compliance. Although they increase CAPEX, they deliver payback through fuel savings, reduced maintenance, and longer boiler lifespan.

What Is the Difference in Cost Between Packaged and Custom Gas-Fired Boilers?

When deciding on a gas-fired boiler investment, one of the first questions is whether to select a packaged unit or a custom-designed system. The choice impacts not only capital cost but also installation schedule, operating flexibility, and lifecycle economics. Many end-users assume that a larger or more advanced boiler must always be custom, but advances in modular packaged solutions have blurred this line.

Packaged gas-fired boilers are typically 20–35% less expensive upfront than custom-engineered units, since they are mass-produced, skid-mounted, and require minimal site engineering. Custom-designed boilers, while 30–50% more costly, allow higher steam capacities, special fuel blends, higher pressures, and integration with complex plant systems.

The decision depends on plant size, process needs, and site constraints.

Packaged boilers are always cheaper over their lifecycle than custom boilers.False

While packaged units cost less upfront, custom systems may deliver lower fuel costs and longer lifespans in large-scale applications.

Custom-engineered gas-fired boilers can cost 30–50% more than packaged units due to site-specific engineering and auxiliary integration.True

Design customization, higher capacities, and unique compliance requirements increase cost.

1. Packaged Gas-Fired Boilers – Cost and Benefits

Cost Range: $50,000 – $500,000 (up to 30 TPH steam).

Advantages:

Lower CAPEX due to standardized design.

Factory-assembled skid (burner, controls, feedwater) minimizes installation cost.

Faster delivery (2–4 months).

Ideal for small to mid-sized plants, hospitals, food processing.

Limitations:

Typically capped at ~30 TPH and 25–40 bar pressure.

Limited customization of fuel flexibility or control systems.

2. Custom Gas-Fired Boilers – Cost and Benefits

Cost Range: $400,000 – $3,000,000+ (30–300 TPH steam).

Advantages:

Tailored to exact steam load, pressure, and redundancy requirements.

Can integrate dual-fuel capability, advanced emissions controls.

Suitable for utility-scale power and petrochemical industries.

Long service life with higher efficiency optimization.

Limitations:

Longer delivery (8–12 months).

Engineering, commissioning, and auxiliaries increase cost.

3. Cost Comparison Example – 20 TPH Steam Boiler

| Parameter | Packaged Boiler | Custom Boiler |

|---|---|---|

| Base Cost | $420,000 | $650,000 |

| Auxiliaries & Controls | Included (standard) | +$150,000 (custom) |

| Installation | $80,000 | $200,000 |

| Delivery Lead Time | 4 months | 10 months |

| Total Installed Cost | $500,000 | $1,000,000 |

4. ROI Considerations

Packaged Units: Faster ROI (1–3 years) in small plants with stable loads.

Custom Units: Longer payback (3–6 years) but better lifecycle efficiency and scalability.

Fuel Savings Impact: A 2–3% efficiency gain in a large custom boiler can save $100,000+ annually in fuel.

Conclusion

Packaged boilers minimize upfront investment and commissioning time, making them the best choice for small to medium industrial users. Custom boilers demand higher CAPEX but deliver flexibility, higher efficiency, and long-term reliability for large-scale operations. The correct choice depends on whether your priority is fast, low-cost deployment or optimized lifecycle performance.

What Long-Term Operating Costs Should Be Considered in Budgeting for Gas-Fired Boilers?

When planning for a new gas-fired boiler, most buyers focus on CAPEX (purchase + installation). However, the OPEX (operating expenses) often far exceed the initial investment over a boiler’s 20–30 year service life. Failure to account for these hidden costs leads to budget overruns, unexpected downtime, and poor ROI.

The main long-term operating costs include fuel (60–80% of lifecycle cost), maintenance and spare parts (5–10%), water and treatment chemicals (3–5%), emission compliance costs (2–5%), and labor/monitoring (5–10%). Budgeting must therefore prioritize lifecycle efficiency and reliability, not just upfront purchase price.

This perspective allows buyers to make smarter decisions about efficiency upgrades, automation, and preventive maintenance strategies.

Fuel costs account for the majority of a gas-fired boiler’s lifecycle expenses.True

Fuel typically represents 60–80% of total cost of ownership, making efficiency gains crucial.

Maintenance and spare parts can be ignored in lifecycle budgeting because they are minimal.False

Annual inspections, burner servicing, gasket replacements, and water-side cleaning contribute 5–10% of OPEX.

1. Major Long-Term Operating Cost Components

| Cost Component | Typical Share of OPEX | Description |

|---|---|---|

| Fuel Consumption | 60–80% | Natural gas, LNG, or biogas costs dominate. Even a 1% efficiency gain can save $10,000–50,000 annually in mid-size plants. |

| Maintenance & Spare Parts | 5–10% | Burner servicing, refractory repairs, valve/gasket replacements, annual inspection fees. |

| Water & Chemicals | 3–5% | Feedwater pre-treatment, demineralization, softeners, oxygen scavengers. Poor water treatment increases scaling costs. |

| Emission Compliance | 2–5% | NOx monitoring systems, low-NOx burner servicing, permits, and possible carbon credit purchases. |

| Labor & Monitoring | 5–10% | Operator salaries, digital monitoring systems, training, safety compliance. |

2. Example – 10 TPH Gas-Fired Boiler (20-Year Lifecycle)

| Cost Element | Annual Cost (USD) | 20-Year Cost (USD) | Share of Total |

|---|---|---|---|

| Fuel (natural gas @ $0.35/m³) | $280,000 | $5,600,000 | 75% |

| Maintenance & Parts | $30,000 | $600,000 | 8% |

| Water & Chemicals | $15,000 | $300,000 | 4% |

| Emission Compliance | $10,000 | $200,000 | 3% |

| Labor & Monitoring | $35,000 | $700,000 | 10% |

| Total Lifecycle OPEX | $370,000 | $7,400,000 | 100% |

3. Strategies to Manage OPEX

Invest in High Efficiency: Even a 3–5% higher efficiency rating pays back quickly through fuel savings.

Use Economizers/Condensing Tech: Reduces gas use by 5–10%.

Water Treatment Programs: Prevents scaling, reduces fuel penalties, and extends boiler life.

Automation & Remote Monitoring: Cuts labor costs and avoids costly downtime.

Planned Maintenance: Reduces emergency repair costs and keeps efficiency stable.

4. Key Insight

CAPEX for a gas-fired boiler may range from $300,000–$3M, but OPEX can exceed 10–15 times CAPEX over its service life. This makes lifecycle costing, not initial price, the critical budgeting factor.

Conclusion

When budgeting for a gas-fired boiler, long-term costs—especially fuel and maintenance—must guide investment decisions. Paying more upfront for efficiency and automation usually delivers much larger savings over the lifecycle.

🔍 Conclusion

The cost of an industrial gas-fired boiler depends on capacity, efficiency, system design, and installation scope. While the upfront investment may seem significant, choosing the right configuration can result in fuel savings, lower emissions, and reliable long-term operation.

📞 Contact Us

💡 Looking for a detailed quotation for a gas-fired boiler project? We provide cost evaluations, system customization, and turnkey installation services to match your production needs and budget.

🔹 Contact us today for a tailored gas-fired boiler solution with competitive pricing. 🏭🔥💰✅

FAQ

How much does an industrial gas-fired boiler cost?

The price depends on capacity, pressure, and design:

Small packaged gas boilers (1–5 t/h): $25,000 – $70,000

Medium capacity (6–20 t/h): $80,000 – $250,000

Large gas-fired units (20–75+ t/h): $400,000 – $1,200,000+

This excludes installation, shipping, and auxiliary systems.

What factors affect the cost of a gas-fired boiler?

Key cost drivers include:

Capacity and pressure ratings

Boiler type – fire-tube vs water-tube

Fuel efficiency level (standard vs condensing)

Auxiliary equipment – economizers, burners, feedwater systems

Automation level – basic controls vs advanced PLC/SCADA

Regulatory certifications (ASME, CE, ISO, etc.)

What are the operating costs of a gas-fired boiler?

Gas-fired boilers generally have lower operating costs than oil or coal systems due to cleaner combustion.

Natural gas consumption – 60–75% of total OPEX

Routine maintenance – burner checks, water treatment, safety valves

Labor and utilities – operators, electrical systems

Emission compliance – typically lower costs compared to oil/coal

How does efficiency impact the total cost of ownership?

Efficiency plays a critical role:

Condensing gas boilers (95%+) provide significant savings.

A 10 t/h boiler running 8,000 hrs/year at 90% efficiency can save $40,000–$90,000 annually in fuel compared to an 80% unit.

Over a 15–20 year lifecycle, efficiency reduces overall costs more than purchase price differences.

What is the total installed cost of an industrial gas-fired boiler system?

Beyond the boiler unit itself, total installed costs include:

Civil works (foundation, supports)

Auxiliary systems – pumps, economizers, water treatment

Piping, ducting, and electricals

Commissioning and testing

Typically, the installed cost = 1.5–2 times the boiler price.

References

U.S. Department of Energy – Industrial Boiler Basics – https://www.energy.gov

ASME – Boiler and Pressure Vessel Standards – https://www.asme.org

Forbes Marshall – Gas Boiler Cost Factors – https://www.forbesmarshall.com

Cleaver-Brooks – Industrial Boiler Costs – https://www.cleaverbrooks.com

Thermax – Gas-Fired Boiler Solutions – https://www.thermaxglobal.com

Babcock & Wilcox – Boiler Technologies – https://www.babcock.com

Spirax Sarco – Steam Boiler Cost Considerations – https://www.spiraxsarco.com

ResearchGate – Gas-Fired Boiler Economics – https://www.researchgate.net

ScienceDirect – Lifecycle Cost Analysis of Boilers – https://www.sciencedirect.com

Engineering Toolbox – Boiler Fuel Data and Calculations – https://www.engineeringtoolbox.com