Cost Range of Different Types of Industrial Gas-Fired Boilers

When planning an industrial boiler investment, understanding the cost differences between various gas-fired boiler types is critical. Whether you’re running a manufacturing plant, processing facility, or commercial energy system, boiler costs can significantly impact both upfront capital expenditure and long-term operating budgets. However, prices vary widely depending on capacity, technology, and features—so what should you expect?

The cost range of industrial gas-fired boilers varies significantly based on type: fire-tube boilers typically range from $20,000 to $100,000, water-tube boilers from $100,000 to over $1 million, condensing boilers from $30,000 to $150,000, and modular or packaged systems can range from $50,000 to $500,000. Final pricing depends on capacity, pressure, materials, efficiency, and customization.

A boiler’s sticker price tells only part of the story. To make a smart investment, it’s essential to compare boiler types by total cost of ownership, not just initial purchase price. Here’s what to know about the cost structures of different industrial gas boiler systems.

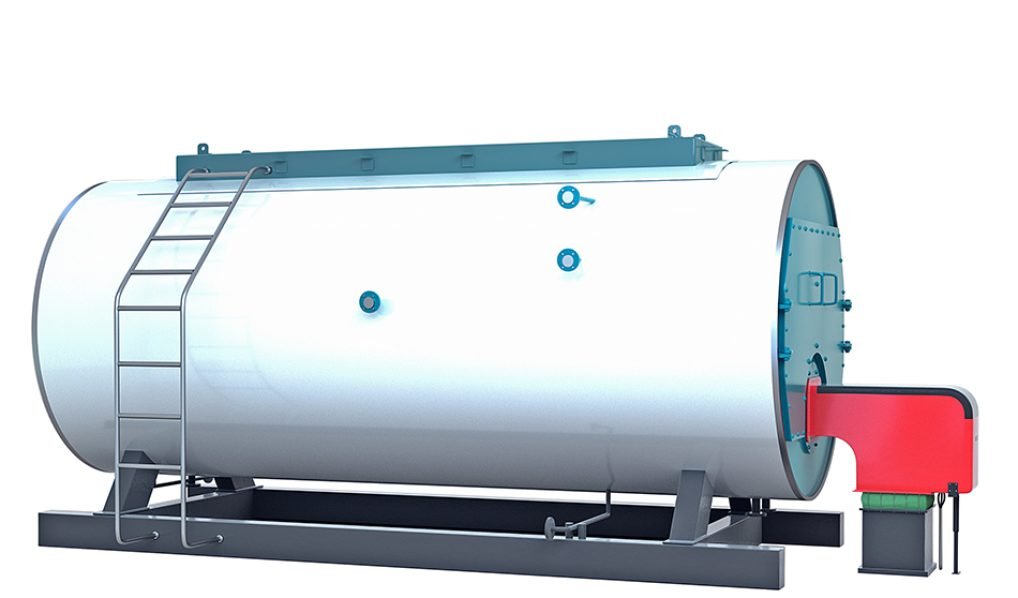

What Is the Typical Cost of Fire-Tube Gas-Fired Boilers, and What Applications Suit Them?

Fire-tube gas-fired boilers remain a workhorse of industrial and commercial heating systems thanks to their reliability, compact size, ease of operation, and relatively low capital cost. However, selecting the right model requires careful balancing of initial investment, operating efficiency, and load requirements. Misjudging boiler size or application suitability can result in excessive fuel costs or underperformance. Therefore, understanding what these boilers cost and where they perform best is essential for making an informed investment.

The typical cost of fire-tube gas-fired boilers ranges from $20,000 to $150,000 depending on capacity (from 1 to 25 tons/hour), pressure rating, efficiency level, and added features such as economizers or control automation. These boilers are best suited for low-to-medium pressure steam and hot water applications in food processing, hospitals, commercial buildings, textile factories, and light manufacturing operations. Their simple design makes them ideal for consistent heat demands, especially where space and budget are limited.

Fire-tube boilers offer solid ROI, minimal maintenance complexity, and widespread applicability across industries with steady thermal loads.

Fire-tube gas-fired boilers are typically lower in cost and complexity compared to water-tube boilers.True

They are built for low-to-medium pressure, lower steam capacity applications with easier maintenance.

Fire-tube boilers are unsuitable for most commercial applications.False

They are widely used in commercial sectors like hospitals, laundry services, and food processing.

💰 Fire-Tube Gas-Fired Boiler Cost Overview

| Boiler Capacity (Ton/hr) | Typical Output (kW) | Estimated Price Range (USD) | Common Use Case |

|---|---|---|---|

| 1–2 TPH | 700–1,400 kW | $20,000–$40,000 | Small laundry or clinic |

| 3–6 TPH | 2,100–4,200 kW | $45,000–$70,000 | Food processing, mid-size hotel |

| 8–10 TPH | 5,600–7,000 kW | $80,000–$110,000 | Textile factory, large hospital |

| 12–15 TPH | 8,400–10,500 kW | $110,000–$150,000+ | Brewery, large school campus |

Note: Price includes burner, shell, control panel, valves; excludes installation, water treatment, and flue systems.

🧪 Example: Cost Breakdown of a 5 TPH Fire-Tube Boiler

| Item | Estimated Cost (USD) |

|---|---|

| Boiler shell with tubes | $30,000 |

| Gas burner (fully modulating) | $8,000 |

| Control & safety instrumentation | $6,000 |

| Economizer (optional) | $5,000 |

| Skid mounting & accessories | $3,000 |

| Total | $52,000 |

Installation typically adds 15–25% of equipment cost depending on site complexity.

🔍 Ideal Applications for Fire-Tube Gas Boilers

| Sector | Why It’s Suitable |

|---|---|

| Hospitals & Clinics | Consistent steam/hot water needs, space constraints |

| Textile Factories | Steady process heat demand, medium-pressure steam needed |

| Hotels & Resorts | Hot water generation, laundry, kitchen steam |

| Food & Beverage Plants | Batch processing, sterilization, CIP systems |

| Educational Campuses | Central heating and cafeteria applications |

| Pharmaceutical Units | Low-to-mid pressure steam for jacketed vessels, cleaning |

Fire-tube boilers are ideal for facilities operating <20 bar steam pressure, with stable load curves.

⚙️ Fire-Tube vs. Water-Tube Boiler Comparison

| Parameter | Fire-Tube Boiler | Water-Tube Boiler |

|---|---|---|

| Pressure Range | Up to 25 bar (typical) | Up to 160 bar |

| Capacity | Up to ~25 TPH | >25 TPH possible |

| Thermal Efficiency | 80–90% (with economizer) | 85–95% (with superheaters/recovery) |

| Footprint | Compact | Larger, more complex layout |

| Startup Time | Short (20–60 min) | Long (90+ min) |

| O&M Complexity | Low | Higher (specialized training needed) |

| Cost (Initial) | Lower ($20k–$150k) | Higher ($100k–$500k+) |

Choose fire-tube when you need lower cost, simplicity, and reliable steam generation below 20–25 TPH.

📈 Efficiency and Features Worth Investing In

| Feature | Benefit | Added Cost (Approx) |

|---|---|---|

| Economizer | 3–5% fuel savings by recovering flue heat | $3,000–$10,000 |

| O₂ Trim Controls | Optimizes combustion air for higher efficiency | $2,000–$6,000 |

| Fully Modulating Burners | Matches output to demand for fuel economy | $2,500–$8,000 |

| PLC + SCADA Controls | Remote monitoring, data logging | $3,000–$10,000 |

| Skid-Mounted Design | Eases installation and footprint | $1,000–$4,000 |

Small investments in controls and recovery equipment can yield fast ROI from fuel savings.

✅ Fire-Tube Boiler Selection Checklist

Is your pressure requirement under 25 bar?

Does your steam or hot water demand remain fairly constant?

Is natural gas or LPG available and economical in your area?

Do you have space constraints or require a simple layout?

Are installation costs a key decision factor?

Do you require modular expansion options in the future?

Would a quicker startup time benefit your operation?

Are you targeting a low O&M cost solution?

If most answers are yes, a fire-tube boiler is likely your best fit.

Fire-tube gas-fired boilers strike a cost-effective balance of simplicity, efficiency, and adaptability—making them ideal for many commercial and industrial users. While they’re not suited to ultra-high-pressure or superheated applications, they remain the go-to technology for stable load environments requiring up to ~25 TPH of steam or hot water.

How Much Do Water-Tube Gas-Fired Boilers Cost, and Why Are They Used for High-Capacity Operations?

For large-scale industrial and power generation facilities, demanding steam outputs and high operating pressures require more than conventional fire-tube systems can offer. Enter water-tube gas-fired boilers—designed for high-pressure, high-capacity applications, these advanced systems offer superior heat transfer, faster response times, and the ability to generate superheated steam. However, with these advantages come higher capital investment and technical complexity, making cost estimation and application analysis critical in project planning.

Water-tube gas-fired boilers typically cost between $100,000 and $500,000 or more depending on capacity (10 to 150+ tons/hour), pressure rating (20 to 160 bar), burner type, and control systems. These boilers are used for high-capacity operations because they can safely operate at high steam pressures and temperatures, offer fast steam generation, and support continuous loads in industries like power generation, petrochemicals, refineries, steel mills, and district heating plants.

Water-tube boilers deliver unmatched performance, pressure tolerance, and thermal efficiency for energy-intensive applications.

Water-tube gas-fired boilers are preferred for high-capacity, high-pressure operations.True

Their design allows for higher pressure handling, larger output, and rapid steam generation.

Water-tube boilers are cheaper and simpler than fire-tube boilers.False

Water-tube boilers are more expensive and technically complex, but offer higher performance.

💰 Water-Tube Gas Boiler Cost Overview by Capacity

| Boiler Capacity (Ton/hr) | Steam Output (kW) | Estimated Cost (USD) | Application Example |

|---|---|---|---|

| 10–15 TPH | 7,000–10,500 kW | $100,000–$180,000 | Industrial food or textile plant |

| 20–35 TPH | 14,000–24,500 kW | $200,000–$300,000 | Petrochemical processing |

| 50–75 TPH | 35,000–52,500 kW | $300,000–$450,000 | Large chemical plant or district heating plant |

| 100+ TPH | 70,000+ kW | $500,000–$1,000,000+ | Thermal power plants, paper mills |

Pricing includes basic pressure vessel, high-efficiency gas burner, and control panel. Superheaters, economizers, and auxiliary systems add extra.

🧪 Case Study: 50 TPH Water-Tube Boiler in a Refinery

Industry: Petroleum Refining

Boiler Type: D-type gas-fired water-tube boiler

Capacity: 50 tons/hour at 80 bar pressure

Fuel: Natural gas with low NOx burner

Key Features:

Superheater and economizer

Full automation with PLC + DCS integration

Continuous blowdown and water treatment system

Cost: $430,000 (excluding installation and piping)

Application: Steam reforming, thermal cracking, and process heating

Results:Rapid load response to variable refinery demand

NOx emissions < 60 mg/Nm³

15-year service life with scheduled maintenance

🔍 Why Choose Water-Tube Gas-Fired Boilers?

| Technical Advantage | Explanation |

|---|---|

| High-Pressure Operation | Can safely operate at 100–160 bar |

| High-Capacity Steam Output | Ideal for loads exceeding 20 TPH |

| Fast Steam Generation | Thin tubes and large surface area enable quicker startup |

| Compact for Output | Despite high output, vertical orientation saves floor space |

| Superheated Steam | Supports turbines or high-process-temperature applications |

| Better Safety Profile | Less water stored under pressure reduces explosion risk |

📊 Fire-Tube vs. Water-Tube Boiler at Scale

| Feature | Fire-Tube Boiler | Water-Tube Boiler |

|---|---|---|

| Max Capacity | ~25 TPH | 10 to 200+ TPH |

| Max Pressure | Up to ~25 bar | Up to 160+ bar |

| Steam Quality | Saturated | Saturated or superheated |

| Response Time | Moderate | Fast |

| Maintenance Complexity | Low | High (requires skilled staff) |

| Cost Range | $20,000–$150,000 | $100,000–$1,000,000+ |

| Ideal Application | Commercial, small industry | Power plants, heavy industry |

⚙️ High-Value Features That Impact Water-Tube Boiler Cost

| Feature | Purpose | Estimated Cost Add-on (USD) |

|---|---|---|

| Superheater | Raises steam temp for turbine or high-temp process | $10,000–$50,000 |

| Economizer | Recovers flue gas heat to improve efficiency | $5,000–$25,000 |

| Low NOx Burner | Meets environmental compliance | $5,000–$20,000 |

| PLC/DCS Automation | Advanced control, safety, and diagnostics | $8,000–$40,000 |

| Water Treatment System | Prevents scaling, corrosion, and fouling | $10,000–$30,000 |

These components are essential for performance, safety, and long-term savings.

✅ Checklist: Is a Water-Tube Boiler the Right Fit?

Is your steam requirement above 20 tons/hour?

Do you require pressures above 25–30 bar?

Does your operation need superheated steam for turbines or high-temp processes?

Are you in a mission-critical industry (e.g., power, chemicals, petrochemicals)?

Can you support skilled maintenance staff and advanced controls?

Are you planning a long-lifecycle CAPEX project with future expansion potential?

Do your environmental permits require low NOx, SOx, and CO emissions?

If most answers are “yes,” a water-tube boiler is the appropriate choice for your application.

Water-tube gas-fired boilers are premium thermal assets, engineered for the most demanding industrial and power applications. Though their upfront cost is higher, their performance, longevity, and compliance capabilities make them a smart long-term investment—especially where steam capacity, high pressure, and efficiency are non-negotiable.

What Is the Cost Range of Condensing Gas-Fired Boilers, and How Do They Impact Energy Savings?

As commercial and industrial facilities face increasing energy costs and stricter emissions targets, condensing gas-fired boilers have gained popularity for their ability to deliver high thermal efficiency—often exceeding 95%. Although these systems have a higher upfront cost than conventional gas boilers, they often yield a rapid return on investment through fuel savings, lower emissions, and utility incentives. However, understanding their true cost and when they make economic sense is essential for buyers aiming to optimize long-term operational efficiency.

Condensing gas-fired boilers typically cost between $5,000 and $60,000 depending on capacity (50 kW to 2,000 kW), application complexity, and additional features such as modulation and smart controls. These boilers increase energy savings by recovering latent heat from flue gases that would otherwise be lost in traditional systems. By condensing water vapor and utilizing the released heat, they achieve thermal efficiencies of 92%–98%, significantly reducing natural gas consumption, especially in systems with low return water temperatures.

Condensing boilers are ideal for buildings and processes with consistent hot water needs and low-temperature heating loops, making them a top choice for schools, office buildings, hospitals, and light industry.

Condensing gas boilers are more efficient than traditional boilers because they recover latent heat from exhaust gases.True

They condense water vapor in flue gas, using its heat to warm the return water, boosting thermal efficiency.

Condensing boilers always operate at 98% efficiency, regardless of system design.False

Their efficiency depends on return water temperature, typically highest below 55°C.

💰 Cost Range of Condensing Gas-Fired Boilers

| Boiler Size (kW) | Typical Output (MBH) | Estimated Cost (USD) | Suitable Application |

|---|---|---|---|

| 50–150 kW | 170–510 MBH | $5,000–$12,000 | Residential buildings, small offices |

| 200–500 kW | 680–1,700 MBH | $12,000–$25,000 | Schools, clinics, mid-sized facilities |

| 600–1,000 kW | 2,000–3,400 MBH | $25,000–$45,000 | Hotels, large commercial buildings |

| 1,100–2,000 kW | 3,750–6,800 MBH | $45,000–$60,000+ | Hospitals, manufacturing, district heat |

Costs exclude installation, venting, water treatment, and integration with BMS (building management systems).

📊 Condensing vs. Non-Condensing Boiler Energy Efficiency Comparison

| Boiler Type | Thermal Efficiency (%) | Fuel Savings Potential | Flue Gas Temp (°C) | CO₂ Emissions Reduction |

|---|---|---|---|---|

| Non-Condensing Boiler | 80–88% | Baseline | 130–180°C | Low |

| Condensing Gas Boiler | 92–98% | 10–15%+ | 50–70°C | Medium to High |

| Condensing + Controls | Up to 99% in optimized loops | 15–20%+ | 45–55°C | High |

Greater savings occur when systems operate below 55°C return water temperature.

🧪 Case Study: Energy Savings with a 500 kW Condensing Boiler

Facility: Public Secondary School

Previous System: 500 kW cast-iron gas boiler (85% efficiency)

Upgrade: 500 kW fully modulating condensing boiler (96% peak efficiency)

Operation: Heating and hot water with return temp of 45°C

Gas Savings: ~75,000 m³ annually

Cost Savings: $18,000/year based on $0.24/m³ gas price

Installation Cost: $22,000 (including retrofits and controls)

ROI: Payback in 1.2 years

Other Benefits:

Reduced flue stack temperature by 65%

CO₂ emissions reduced by ~135 tons/year

Integration with weather compensation controls

⚙️ Key Features That Influence Condensing Boiler Cost & Efficiency

| Feature | Function | Cost Impact |

|---|---|---|

| Modulating Burner | Matches output to demand, reduces short cycling | +$2,000–$5,000 |

| Integrated Controls (BMS-ready) | Supports remote optimization and diagnostics | +$1,000–$3,000 |

| Aluminum or Stainless Steel HX | Efficient heat transfer and corrosion resistance | Standard |

| Low NOx Burner (<30 ppm) | Meets air quality regulations in urban zones | +$1,000–$2,000 |

| Condensate Neutralization Kit | Prevents acidic drain damage | +$500–$1,200 |

| Weather Compensation Sensor | Adjusts output to outside temperature changes | +$300–$700 |

These features enhance performance and compliance, especially in commercial retrofits.

🔍 Applications Best Suited to Condensing Gas Boilers

| Application | Why It’s Ideal |

|---|---|

| Schools and Colleges | Continuous low-temp heating loops, fast payback |

| Office Buildings | Zonal heating with modulating demand |

| Hospitals and Clinics | Domestic hot water + space heating + 24/7 operation |

| Hotels and Hospitality | Centralized hot water and heating with part-load benefits |

| Light Industrial | Space and process heating with clean fuel requirements |

| District Heating Loops | Low return temperature favors condensing efficiency |

When paired with hydronic systems and low return temperatures, condensing boilers excel.

✅ Condensing Boiler Selection Checklist

Do you operate with hot water return temps < 55°C?

Are you replacing a system with >15 years of age or low efficiency?

Is your heating demand steady or partially modulating?

Do you seek emissions reductions or qualify for green incentives?

Is your facility gas-connected and operating year-round?

Can you install corrosion-resistant venting and condensate drainage?

Would smart controls and zone modulation reduce energy use?

If you answered “yes” to most, a condensing boiler offers high ROI and future compliance assurance.

Condensing gas-fired boilers present a cost-efficient path to high-efficiency heating and are increasingly favored in sustainability-driven retrofits and new installations. Though initial costs are higher than traditional units, the long-term energy and emissions savings—especially when combined with modern controls—make them a smart investment for forward-thinking building managers and engineers.

How Do Modular and Packaged Boiler Systems Compare in Cost and Scalability?

Choosing between modular and packaged boiler systems is a critical decision that affects not just initial investment, but also long-term operational flexibility, maintenance strategy, and capacity expansion potential. Each system type offers unique benefits depending on the project’s size, complexity, scalability requirements, and space constraints. A mismatch can lead to overinvestment in capacity or costly retrofits when future expansion is required.

Modular boiler systems typically consist of multiple smaller boiler units connected to act as a single system, allowing precise load matching and easy scalability. These systems generally cost $60,000–$500,000+ depending on the number of modules and their capacity. Packaged boilers, on the other hand, are pre-engineered, single-unit solutions costing $25,000–$250,000+, and are ideal for facilities with predictable loads and limited need for future expansion. Modular systems offer superior scalability and redundancy, while packaged boilers provide a simpler, more cost-effective solution for consistent operations.

Both systems can be gas, oil, or biomass-fired—but their configuration and application impact cost and future-proofing significantly.

Modular boiler systems allow better scalability and load flexibility than packaged boilers.True

Their multi-unit design enables phase-wise capacity increase and improved efficiency under part-load conditions.

Packaged boilers are less expensive upfront but harder to expand or upgrade later.True

Packaged systems are compact and turnkey but typically fixed in capacity, requiring full replacement for major expansions.

💰 Cost Comparison: Modular vs. Packaged Boilers

| System Type | Capacity Range (kW) | Typical Cost (USD) | Best Use Case |

|---|---|---|---|

| Modular Boiler System | 500–10,000+ kW | $60,000–$500,000+ | Facilities with fluctuating or growing loads |

| Packaged Boiler | 200–5,000 kW | $25,000–$250,000+ | Stable-load industries, commercial buildings |

Prices exclude installation, building integration, water treatment, and emissions systems.

📊 Operational Scalability & Cost Efficiency Comparison

| Feature | Modular Boiler System | Packaged Boiler System |

|---|---|---|

| Scalability | High – modules added as needed | Low – fixed output, hard to expand |

| Redundancy | Excellent – units can operate independently | Limited – full outage if failure occurs |

| Part-Load Efficiency | High – only required modules run | Moderate – may short-cycle |

| Startup Time | Fast (due to small unit sizes) | Slower for large single systems |

| Space Flexibility | Modular installation possible | Skid-mounted, more compact footprint |

| Initial Capital Cost | Higher upfront due to multi-unit design | Lower due to single-unit simplicity |

| O&M Costs | Slightly higher – more units to maintain | Lower – fewer components |

| Lifecycle Cost Flexibility | High – easy to replace individual units | Low – complete system upgrades required |

Modular systems win on adaptability, while packaged units are better for predictable, consistent loads.

🧪 Case Study: Modular vs. Packaged Boiler Deployment

Facility Type: Food Processing Plant

Location: Mid-sized town, USA

Initial Load: 2,500 kW, expanding to 4,000 kW in 5 years

Option 1: Modular Boiler System

3 × 1,000 kW modules + expansion space

Cost: $195,000 (3 modules + controls)

Outcome: Smooth load modulation, expansion with 1 more module in Year 4

ROI: 4 years due to part-load fuel savings

Option 2: Packaged Boiler

1 × 4,000 kW single unit

Cost: $150,000

Outcome: Overcapacity in early years; lower efficiency at partial load

ROI: 6 years due to higher fuel use and retrofit costs in Year 5

Conclusion: Modular system justified higher initial cost due to operational flexibility and staged expansion.

📈 Energy & Performance Optimization Potential

| System Component | Modular Boiler System Benefit | Packaged Boiler System Benefit |

|---|---|---|

| O₂ Trim & Smart Controls | Enhanced in each module for fine-tuned combustion | Centralized control – easier to manage |

| BMS Integration | Multi-point data logging and demand tracking | Limited unless high-end controls added |

| Burner Modulation | Each unit modulates independently | Single burner may not match partial load well |

| Heat Recovery/Economizers | Modular configuration allows staged heat recovery | Compact economizer usually included |

With modular systems, multiple control loops allow real-time load balancing and higher savings in part-load environments.

🧩 Which System Is Best for You?

| Scenario | Recommended System Type |

|---|---|

| Fluctuating or seasonal heat demand | Modular Boiler System |

| Stable 24/7 industrial process | Packaged Boiler |

| Anticipated future load expansion | Modular Boiler System |

| Small commercial facility with tight space | Packaged Boiler |

| Need for high redundancy/uptime | Modular Boiler System |

| Budget-sensitive short-term solution | Packaged Boiler |

Always weigh future expansion needs against current operational simplicity.

✅ Boiler System Selection Checklist

Is your heat/steam load variable or growing over time?

Do you require load redundancy and minimal downtime?

Will the system be integrated with advanced building or process controls?

Is your available space modular-installation friendly?

Do you require a fast, low-cost turnkey heating solution?

Is part-load fuel efficiency a critical factor for your OPEX?

Do your utility incentives favor energy-efficient modular designs?

Answering “yes” to the first four favors modular systems. “Yes” to the last three may favor packaged boilers.

Modular and packaged boiler systems both have distinct cost structures and performance advantages. For complex, growing, or variable-load environments, modular systems provide flexibility and higher long-term efficiency. For simpler, stable operations with limited budgets or small spaces, packaged boilers offer a practical, reliable solution.

What Factors Most Influence the Final Cost of an Industrial Gas-Fired Boiler?

Selecting an industrial gas-fired boiler is a major capital investment that affects operational efficiency, environmental compliance, and total lifecycle costs. Many companies make the mistake of comparing only the base purchase price, overlooking a host of technical, regulatory, and design-related variables that can drive the total system cost up by 50% or more. Poor planning can lead to underperforming systems, regulatory fines, or even premature boiler failure.

The final cost of an industrial gas-fired boiler is most influenced by factors such as steam capacity, pressure and temperature requirements, thermal efficiency, burner and emissions technology, control system sophistication, and compliance with local environmental and safety regulations. Additional cost drivers include boiler type (fire-tube or water-tube), custom engineering needs, fuel supply infrastructure, installation complexity, and after-sales service packages. These components collectively determine both the upfront and long-term operating costs.

Understanding these key influences ensures accurate budgeting and long-term return on investment (ROI) from your boiler project.

Boiler capacity and pressure rating are among the largest contributors to final boiler system cost.True

Larger capacities and higher pressures require more robust materials, larger components, and complex safety systems.

All gas-fired boilers cost roughly the same per ton regardless of application.False

Final cost depends on pressure class, combustion system, controls, and compliance needs.

💰 Key Cost Drivers of Industrial Gas-Fired Boilers

| Cost Factor | Impact on Total Cost | Details |

|---|---|---|

| Boiler Capacity (TPH/kW) | High | Larger units require more steel, tubes, insulation |

| Pressure & Temp Rating | High | High-pressure designs need thicker drums and safety valves |

| Boiler Type | Moderate to High | Water-tube more expensive than fire-tube |

| Thermal Efficiency | Moderate | Higher efficiency systems cost more upfront |

| Burner Technology | High | Low-NOx, modulating burners are premium priced |

| Emission Control Systems | Moderate to High | SCRs, ESPs, or FGR systems add significant cost |

| Automation & Controls | Moderate | PLC/SCADA systems vary by complexity |

| Fuel Type Compatibility | Low to Moderate | Natural gas vs. LPG, biogas blending |

| Installation Complexity | High | Tight spaces, roof lifts, pipe rerouting increase costs |

| Custom Engineering | High (if required) | Special metallurgy, explosion-proofing, etc. |

| Support Services | Moderate | Commissioning, training, warranties |

🧪 Real-World Boiler Cost Breakdown: 10 TPH, 16 bar Gas-Fired Water-Tube

| Component | Estimated Cost (USD) |

|---|---|

| Pressure Vessel + Shell & Tubes | $75,000 |

| Modulating Low-NOx Burner (Natural Gas) | $12,000 |

| Economizer + Flue Gas Heat Recovery Unit | $9,000 |

| PLC-Based Combustion Management System | $6,000 |

| Blowdown Tank + Water Treatment Add-ons | $8,500 |

| Emissions Monitoring & Compliance Module | $4,500 |

| Installation (on-site piping + wiring) | $15,000 |

| Freight, Taxes, Customs | $7,500 |

| Total Estimated System Cost | $137,500 |

Optional features such as condensate recovery, dual-fuel capabilities, and oxygen trim could push the total over $150,000.

📊 How Capacity and Pressure Impact Cost (Illustrative Chart)

| Boiler Capacity (TPH) | Pressure Rating (bar) | Estimated Cost (USD) |

|---|---|---|

| 2 | 10 | $25,000–$35,000 |

| 5 | 16 | $50,000–$80,000 |

| 10 | 16 | $120,000–$150,000 |

| 20 | 40 | $180,000–$300,000 |

| 50 | 60+ | $400,000–$700,000 |

Costs rise exponentially with increased pressure and capacity due to material and safety design needs.

⚙️ Efficiency and Burner Options: Impact on Cost & ROI

| Efficiency Range | Burner Type | Additional Cost | Savings Potential |

|---|---|---|---|

| 85–88% | On/Off or 2-stage | Base price | Low fuel savings, common in older models |

| 90–93% | Fully modulating | +$2,000–$5,000 | 5–8% fuel reduction, fast ROI in large loads |

| 94–98% | Condensing + O₂ trim | +$6,000–$12,000 | Up to 15% gas savings, low emissions |

Higher efficiency options often pay back in <3 years depending on runtime and fuel price.

✅ Industrial Gas Boiler Procurement Checklist

Have you defined exact steam capacity and pressure/temperature needs?

Do you know your expected runtime and operating hours?

Is high thermal efficiency a priority to reduce fuel consumption?

Are you in a region with strict NOx or CO₂ regulations?

Do you need dual-fuel capability or plan to use biogas blends?

Will the boiler be installed in a space-limited area or rooftop?

Is integration with a building management or SCADA system required?

Do you need custom engineering (corrosive fluids, offshore, ATEX)?

Is long-term service and warranty support critical to your team?

Each “yes” likely increases complexity—and cost—so include these in your budgeting and RFQ.

Choosing an industrial gas-fired boiler involves much more than the unit price. The true cost includes design complexity, installation, fuel system integration, emission controls, and smart operation. However, a well-specified boiler will provide decades of reliable and cost-efficient service, especially if sized and configured for your unique application.

How Can Buyers Reduce Costs Without Compromising Quality or Performance When Procuring Industrial Boilers?

Procuring an industrial boiler system is a high-stakes investment. But in pursuit of cost savings, some buyers make the mistake of focusing solely on upfront price—resulting in performance issues, higher fuel bills, or compliance failures down the line. Others overpay for unnecessary features or overengineered systems. The real challenge is to strategically lower cost without sacrificing thermal efficiency, emissions compliance, system lifespan, or operational reliability.

Buyers can reduce industrial boiler costs without compromising quality or performance by applying smart procurement strategies such as right-sizing the boiler, optimizing specifications for actual load conditions, using modular or pre-engineered systems, negotiating total value instead of just unit price, leveraging local fabrication and supplier competition, and prioritizing lifecycle cost analysis over capital cost alone. Engaging in performance-based contracts, bundling services, and utilizing energy incentives can further minimize total expenditure while maintaining long-term value.

Cost-effective procurement is not about buying cheap—it’s about buying smart and ensuring every dollar supports the system’s real-world performance and durability.

Choosing the lowest-cost boiler model often leads to higher lifecycle expenses due to inefficiency or poor reliability.True

A cheaper boiler may lack critical features like modulating burners or emissions controls, increasing fuel and maintenance costs.

Negotiating boiler procurement based on lifecycle value rather than initial price can reduce long-term operating costs.True

Lifecycle analysis accounts for fuel, maintenance, and downtime, often justifying premium features that save money over time.

💡 Top 10 Strategies to Reduce Boiler Procurement Costs Without Sacrificing Quality

| Strategy | How It Saves Money Without Performance Loss |

|---|---|

| 1. Right-Size the Boiler | Avoid overspending on unnecessary capacity that increases fuel costs |

| 2. Choose Packaged or Modular Systems | Factory-assembled units reduce installation time and engineering fees |

| 3. Optimize Pressure and Steam Specs | Specify only as much pressure and temp as the process truly requires |

| 4. Use Fuel-Flexible Designs | Prepare for future fuel pricing shifts (biogas-ready or dual-fuel) |

| 5. Avoid Over-Specifying Materials | Choose proven, cost-effective alloys unless exotic conditions demand more |

| 6. Apply for Efficiency Incentives | Use government or utility rebates to reduce capex on high-efficiency systems |

| 7. Compare Multiple Bids Objectively | Standardize RFQs to ensure apples-to-apples pricing on technical specs |

| 8. Negotiate Service Bundles | Secure installation, commissioning, and maintenance as a package |

| 9. Consider Local or Regional Suppliers | Lower logistics, tariffs, and support costs while ensuring fast access |

| 10. Focus on Lifecycle Cost (LCC) | Use total cost over 15–20 years, not just upfront cost, to guide decision |

📊 Lifecycle Cost Comparison: Low-Cost Boiler vs. Optimized High-Efficiency System

| Metric | Low-Cost Basic Boiler | Optimized High-Efficiency Boiler |

|---|---|---|

| Purchase Price | $75,000 | $110,000 |

| Thermal Efficiency | 84% | 94% |

| Annual Fuel Cost (natural gas) | $130,000 | $116,000 |

| Maintenance Cost (avg/yr) | $8,000 | $5,000 |

| Expected Lifecycle (years) | 15 | 20 |

| 15-Year Total Cost of Ownership | $395,000 | $386,000 |

👉 Despite a higher initial cost, the efficient boiler saves $9,000 over 15 years—and reduces emissions.

🧪 Case Example: Strategic Specification for a 6 TPH Boiler Project

Client: Medium-sized textile plant

Initial RFQ Result:

6 TPH, 16 bar fire-tube boiler with advanced burner

Quoted price from top vendor: $128,000

Revised Strategy:

Reduced design pressure to 12 bar (based on actual need)

Switched to modular twin 3 TPH configuration for better efficiency

Used local controls and sourced burner domestically

Final price: $102,000

Savings: $26,000 without affecting capacity, emissions, or safety

✅ Boiler Procurement Cost Reduction Checklist

Have you matched boiler capacity to actual peak and average load demands?

Are you optimizing—not overengineering—pressure and temperature specifications?

Are you standardizing bids to avoid cost inflation from non-uniform specifications?

Can you bundle services like training, installation, and water treatment to get better pricing?

Are you qualifying local suppliers or regional fabricators to reduce delivery and service costs?

Have you calculated total cost of ownership (TCO) over at least 10–15 years?

Are you comparing feature cost vs. performance benefit (e.g., modulating burners, economizers)?

Have you explored government or utility rebates for high-efficiency, low-emission systems?

Are you leveraging competitive negotiation rather than simply accepting the first quote?

🛠️ Quality-Preserving Cost Controls in Boiler Design

| Feature | Impact on Performance | Cost Control Strategy |

|---|---|---|

| Burner Type | Directly affects fuel use | Choose domestic brand with proven performance |

| Heat Exchanger Surface | Affects efficiency | Optimize—not oversize—based on actual duty cycle |

| Controls & Automation | Improves O&M and safety | Use scalable PLC system over DCS for mid-size plants |

| Emissions Controls | Required for compliance | Use Low-NOx burners instead of expensive SCRs when possible |

Don’t eliminate core features—instead, customize design around actual operating conditions to control cost.

Reducing boiler procurement cost without sacrificing performance is entirely achievable with thoughtful planning, competitive supplier engagement, and a lifecycle mindset. Strategic buyers know that value, not just price, ensures efficiency, reliability, and environmental compliance over decades of operation.

🔍 Conclusion

Choosing the right boiler means balancing price with performance, lifecycle efficiency, and application suitability. By understanding how each boiler type aligns with your process requirements and budget, you’ll make a cost-effective and future-ready decision.🔥📈✅

FAQ

Q1: What is the typical cost range for industrial gas-fired boilers?

A1: The cost of industrial gas-fired boilers varies widely based on boiler type, capacity, efficiency, and system complexity. Entry-level units like small fire-tube boilers (up to 1,000 HP) can cost $50,000 to $150,000, while mid-sized water-tube boilers range from $200,000 to $500,000. Large custom high-capacity or high-pressure gas boilers can exceed $1 million. Costs also depend on materials, automation features, emissions controls, and installation scope.

Q2: How do fire-tube and water-tube boilers differ in cost?

A2: Fire-tube boilers are generally less expensive upfront and are ideal for low to medium pressure applications. Their cost typically ranges from $50,000 to $300,000, depending on size and capacity. Water-tube boilers are suited for high-pressure and high-capacity operations and come with higher design and engineering complexity, resulting in a broader price range of $200,000 to $1 million+. However, water-tube units offer faster steam generation and better efficiency for large-scale operations.

Q3: What is the price range of condensing gas-fired boilers?

A3: Condensing boilers, known for high efficiency (up to 98%), generally cost more than non-condensing models due to advanced heat exchanger technology. For industrial-scale units, pricing starts around $80,000 and can exceed $250,000, depending on capacity. Despite the higher initial investment, condensing boilers offer significant long-term fuel savings and reduced emissions, making them a smart choice for energy-conscious facilities.

Q4: What additional costs should be considered beyond the boiler unit price?

A4: In addition to the boiler itself, total project cost includes installation, piping, controls, emissions systems, water treatment equipment, commissioning, and training. These can add 30–60% to the base boiler price. For example, a $300,000 boiler may result in a total installed cost of $450,000 to $500,000. Site-specific factors like permitting, retrofit requirements, and utility infrastructure may further influence total expenses.

Q5: How can facilities control or reduce boiler investment costs?

A5: Facilities can reduce boiler costs by choosing standardized units over custom builds, optimizing boiler size to match load requirements, selecting efficient models with available rebates or tax incentives, and bundling auxiliary equipment in procurement contracts. Buying from reputable manufacturers with strong support can also prevent costly operational issues later. Life cycle cost analysis helps justify higher upfront investment in energy-efficient models through long-term savings.

References

Boiler Pricing Overview – https://www.cleaverbrooks.com/reference-center/boiler-selection-guide.aspx – Cleaver-Brooks

Fire-Tube vs Water-Tube Boiler Costs – https://www.powerhouse.com/boiler-education/firetube-vs-watertube-boiler – Powerhouse Equipment

Condensing Boiler Cost Benefits – https://www.viessmann-us.com/en/knowledge/condensing-boilers.html – Viessmann

Cost Factors in Boiler Installation – https://www.energy.gov/eere/femp/boiler-systems-efficiency – U.S. Department of Energy

Boiler Project Budgeting Tips – https://www.abma.com/buying-guide – American Boiler Manufacturers Association

High-Efficiency Industrial Boiler Systems – https://www.miuraboiler.com/advantage/energy-efficiency – Miura Boiler

Industrial Boiler Types and Costs – https://www.hurstboiler.com/boilers/gas_oil_fired/ – Hurst Boiler

Boiler Capital and Operating Costs – https://www.sciencedirect.com/science/article/abs/pii/S0360544214006397 – ScienceDirect

Boiler Retrofit and Total Project Cost – https://www.babcock.com/home/resources/whitepapers/ – Babcock & Wilcox

Life Cycle Cost Analysis for Boilers – https://www.energy.gov/eere/femp/life-cycle-cost-analysis – U.S. Department of Energy