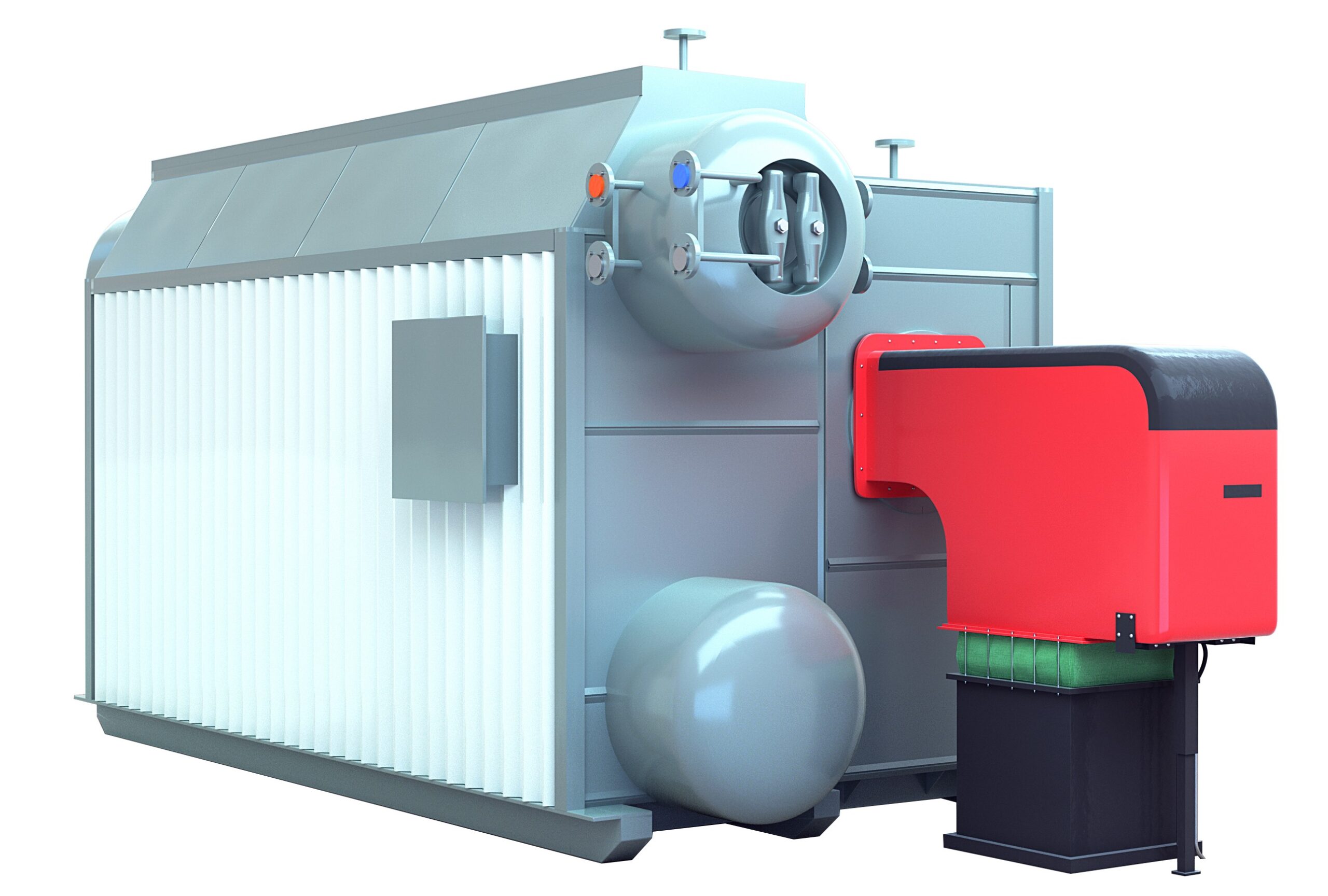

As industries seek to balance energy demand with environmental responsibility, oil-fired boilers remain widely used for their reliability and heat output. However, growing regulations on emissions and fuel sustainability have raised concerns about their environmental impact. Understanding their performance and available technologies helps determine how environmentally friendly these systems can be.

Modern industrial oil-fired boilers can be environmentally friendly when equipped with advanced combustion systems, flue gas treatment technologies, and energy-efficient designs. Low-NOx burners, condensing heat exchangers, and particulate filters significantly reduce harmful emissions such as nitrogen oxides (NOₓ), sulfur oxides (SOₓ), and soot. When operated with cleaner fuels (such as low-sulfur or bio-based oils) and high-efficiency systems, they can achieve lower emissions and higher energy utilization—making them compliant with most regional environmental regulations.

With proper design and operation, oil-fired boilers can deliver clean, efficient, and sustainable performance for various industrial applications.

What Are the Main Environmental Challenges of Traditional Oil-Fired Boilers?

Traditional oil-fired boilers have long served as reliable sources of steam and heat for industries and buildings, but in today’s context of carbon reduction and environmental accountability, they are facing growing scrutiny. The environmental challenges they pose—particularly in terms of air pollution, carbon emissions, and waste management—are significant. Uncontrolled emissions, poor fuel quality, and inefficient combustion not only reduce performance but also directly threaten compliance with modern sustainability regulations. The result is higher operating costs, potential fines, and reputational risk. The path forward lies in understanding these environmental challenges in depth and implementing mitigation strategies that align with global emission and decarbonization frameworks.

Traditional oil-fired boilers face major environmental challenges including high CO₂ emissions from fossil fuel combustion, release of harmful pollutants such as NOₓ, SO₂, CO, and particulate matter, as well as issues with waste oil disposal and water contamination. Inefficient combustion, poor fuel atomization, and outdated control systems exacerbate these impacts, resulting in reduced air quality, acid rain formation, and greater greenhouse gas intensity. Upgrading combustion systems, improving maintenance, and transitioning to low-sulfur or bio-based fuels are critical steps to mitigate these environmental problems.

Recognizing these challenges helps industries modernize their systems, ensuring both operational efficiency and compliance with tightening environmental regulations worldwide.

Oil-fired boilers produce negligible environmental pollution compared to coal-fired boilers.False

While oil-fired boilers emit less particulate matter than coal systems, they still release substantial CO₂, SO₂, and NOₓ emissions that significantly affect air quality and climate.

Switching to low-sulfur or bio-based oils can reduce emissions from oil-fired boilers.True

Low-sulfur and bio-based fuels lower SO₂ and carbon emissions, improving environmental performance and compliance with emission standards.

1. Air Emission Challenges: CO₂, NOₓ, SO₂, and PM

Combustion of fuel oil produces a complex mixture of gaseous and particulate pollutants that contribute to air quality degradation and climate change.

| Emission Type | Source Mechanism | Environmental Impact | Typical Concentration (Uncontrolled) |

|---|---|---|---|

| CO₂ (Carbon Dioxide) | Complete fuel combustion | Greenhouse gas contributing to global warming | 3.0–3.5 tons CO₂/ton of fuel |

| NOₓ (Nitrogen Oxides) | High flame temperature reaction between N₂ and O₂ | Smog formation, ozone creation, respiratory irritation | 250–450 mg/Nm³ |

| SO₂ (Sulfur Dioxide) | Oxidation of sulfur in fuel oil | Acid rain, corrosion, ecosystem damage | 800–1200 mg/Nm³ (for 1% S fuel) |

| CO (Carbon Monoxide) | Incomplete combustion | Toxic gas, health hazard | 100–300 mg/Nm³ |

| PM (Particulate Matter) | Unburnt carbon, ash, metal oxides | Airborne pollution, lung disease | 50–150 mg/Nm³ |

Fuel oil’s sulfur and nitrogen contents, combined with high combustion temperatures, make emission control a major environmental concern.

2. Fuel Quality and Composition Issues

The environmental footprint of oil-fired boilers is strongly influenced by fuel properties.

| Fuel Property | Environmental Concern | Impact on Operation |

|---|---|---|

| Sulfur Content (0.5–3%) | Generates SO₂ and sulfate particulates | Acidic condensate, corrosion |

| Nitrogen Content (0.1–0.3%) | Produces thermal and fuel NOₓ | Higher NOₓ emission rates |

| Viscosity and Ash | Incomplete combustion, PM formation | Burner fouling, efficiency loss |

| Trace Metals (Vanadium, Nickel) | Toxic ash residues | Catalyst poisoning, corrosion |

Heavy fuel oils (HFO) with high sulfur and metal content are particularly problematic for emissions and maintenance.

3. Combustion Inefficiency and Emission Intensification

Poor atomization and incomplete combustion in traditional boilers lead to elevated pollutant levels.

| Cause | Consequence | Emission Impact |

|---|---|---|

| Poor Atomizer Maintenance | Larger fuel droplets | Higher CO and soot |

| Incorrect Air-Fuel Ratio | Oxygen deficiency or excess | CO, NOₓ increase |

| Fouled Burners or Heat Surfaces | Reduced heat transfer | Increased flue temperature and fuel consumption |

| Unstable Flame Conditions | Fluctuating combustion | Irregular emissions, reduced efficiency |

Over time, such conditions can push actual emissions far above regulated limits even if the system was initially compliant.

4. Water and Waste Pollution Challenges

Oil-fired systems not only emit to air but also impact water and soil environments.

| Waste Stream | Source | Environmental Risk | Treatment Requirement |

|---|---|---|---|

| Blowdown Water | Boiler water treatment purge | Contains dissolved solids, oil, phosphates | Neutralization, oil separation |

| Oil Sludge | Incomplete fuel combustion or leakage | Hazardous waste; heavy metals | Incineration or certified disposal |

| Condensate Contamination | Fuel or oil leakage into condensate return | Equipment corrosion, water pollution | Filtration and oil separators |

Even small leaks or poor handling of waste oil residues can contaminate large volumes of water.

5. Comparative Environmental Data: Oil vs. Gas and Coal

| Fuel Type | CO₂ (kg/MJ) | SO₂ (mg/MJ) | NOₓ (mg/MJ) | PM (mg/MJ) | Typical Efficiency (%) |

|---|---|---|---|---|---|

| Coal | 95 | 1500–3000 | 200–400 | 300–800 | 80–85 |

| Heavy Fuel Oil | 75 | 600–1200 | 250–450 | 50–150 | 82–88 |

| Light Fuel Oil | 70 | 100–500 | 180–300 | 30–100 | 85–90 |

| Natural Gas | 56 | <10 | 60–120 | <10 | 90–95 |

While oil performs better than coal in terms of particulate and sulfur emissions, its carbon intensity remains significant, and its pollutants require dedicated emission controls.

6. SO₂ and NOₓ Control Requirements

| Control Method | Description | Efficiency (%) | Application |

|---|---|---|---|

| Low-Sulfur Fuel Oil | Switching to 0.5% or 0.1% sulfur content | 60–90 | Universal |

| Flue Gas Desulfurization (FGD) | Wet scrubbers removing SO₂ | 90–98 | Large installations |

| Selective Catalytic Reduction (SCR) | Catalytic NOₓ reduction with ammonia | 80–90 | Medium–large boilers |

| Low-NOₓ Burners | Reduced flame temperature design | 40–60 | Retrofit feasible |

| Water/Steam Injection | Lowers combustion temperature | 20–30 | Small-scale units |

Regulations in the EU, US, and Asia increasingly mandate such systems, especially where local air quality standards are stringent.

7. Carbon Emissions and Climate Impact

| Fuel | Carbon Emission Factor (kg CO₂/GJ) | Global Warming Impact (tCO₂/year for 10 TPH Boiler) |

|---|---|---|

| Heavy Fuel Oil | 77 | ~11,000 |

| Light Fuel Oil | 73 | ~10,200 |

| Natural Gas | 56 | ~7,800 |

These emissions make oil-fired boilers among the largest industrial stationary CO₂ sources, complicating compliance with carbon reduction targets such as the EU ETS or national Net-Zero commitments.

8. Sludge, Waste, and Soil Contamination

Oil storage and handling systems generate oil sludge and contaminated residues, which pose disposal challenges.

| Waste Type | Source | Hazard Classification | Disposal Method |

|---|---|---|---|

| Tank Bottom Sludge | Settled fuel impurities | Hazardous | Thermal treatment |

| Used Filter Residues | Filtration of oil impurities | Hazardous | Certified disposal |

| Ash Containing Metals | From high-sulfur oil combustion | Hazardous | Stabilization before landfill |

Improper disposal can contaminate groundwater and violate hazardous waste laws.

9. Compliance with Environmental Regulations

| Region | Regulation | SO₂ Limit (mg/Nm³) | NOₓ Limit (mg/Nm³) | PM Limit (mg/Nm³) |

|---|---|---|---|---|

| EU (IED Directive 2010/75/EU) | Large Combustion Plant Directive | 170–350 | 200–450 | 50 |

| USA (EPA NSPS Subpart Dc) | Clean Air Act Standards | 340 | 180 | 100 |

| China (GB13271-2014) | Emission Standard for Boilers | 200 | 150 | 30 |

| India (MoEFCC 2017) | Environmental Standards for Boilers | 600 | 400 | 100 |

Achieving compliance often requires retrofits such as FGD, low-NOₓ burners, and particulate filters.

10. Technological and Operational Mitigation Measures

| Category | Measure | Benefit |

|---|---|---|

| Fuel Management | Use ultra-low-sulfur or bio-based fuels | Reduces SO₂ and CO₂ |

| Combustion Optimization | O₂ trim control and burner tuning | Lowers CO and NOₓ |

| Heat Recovery | Add economizer and air preheater | Improves efficiency, cuts CO₂ |

| Emission Control Systems | Install FGD, SCR, and ESP | Meets air quality standards |

| Maintenance and Monitoring | Routine cleaning, leak detection | Prevents secondary pollution |

Modern control systems and cleaner fuels can reduce overall emissions by 20–40%, significantly improving sustainability.

11. Transition Toward Cleaner Alternatives

Oil-fired boilers are increasingly being replaced or hybridized with:

Natural Gas – lower CO₂ and SO₂ emissions

Biomass Blends – renewable fuel substitution (up to 20–40%)

Waste Heat Recovery Boilers – zero incremental emissions

Hydrogen-Compatible Burners – future decarbonization pathway

| Upgrade Option | CO₂ Reduction (%) | Feasibility | Typical Payback |

|---|---|---|---|

| Switch to Gas | 25–30 | High (if gas available) | 2–4 years |

| Bio-Oil Blend (20%) | 15–20 | Medium | 3–5 years |

| Add Economizer | 5–10 | High | 1–2 years |

Such measures not only address environmental challenges but also improve long-term operational economics.

12. Case Study: Environmental Improvement via Fuel and Control Upgrade

A chemical processing plant operating three 20 TPH oil-fired boilers in Southeast Asia achieved major environmental improvements after a retrofit program:

Switched from 2.5% sulfur oil to 0.5% marine-grade low-sulfur fuel.

Installed O₂ trim controls and low-NOₓ burners.

Added FGD scrubbers and bag filters.

Results:

| Parameter | Before Upgrade | After Upgrade | Reduction (%) |

|---|---|---|---|

| SO₂ (mg/Nm³) | 1150 | 180 | -84 |

| NOₓ (mg/Nm³) | 420 | 250 | -40 |

| PM (mg/Nm³) | 90 | 25 | -72 |

| CO₂ (t/year) | 34,500 | 31,000 | -10 |

The upgrade enabled compliance with national emission laws and reduced annual fuel costs by 6%, proving environmental investment yields tangible returns.

Conclusion

Traditional oil-fired boilers present substantial environmental challenges through their emissions of CO₂, SO₂, NOₓ, and particulate matter, alongside risks of waste contamination and poor combustion efficiency. These issues not only affect the environment but also threaten compliance with tightening global emission and carbon standards. The solutions lie in fuel quality improvement, modern emission control technologies, precise combustion management, and a gradual transition to cleaner or renewable fuels. By proactively addressing these factors, industries can align with sustainable operation goals and maintain regulatory approval.

How Do Modern Combustion and Emission Control Technologies Reduce Pollution?

For decades, industrial combustion systems—especially boilers and furnaces—were major contributors to air pollution, releasing carbon dioxide (CO₂), nitrogen oxides (NOₓ), sulfur oxides (SOₓ), carbon monoxide (CO), and particulate matter (PM). With tightening global environmental regulations, these emissions are no longer tolerable. Traditional combustion technologies, which rely on excess air and uncontrolled fuel burning, are inefficient and environmentally damaging. Poor combustion creates soot, incomplete oxidation, and toxic gases. Modern combustion and emission control technologies, however, have revolutionized this picture—dramatically reducing emissions, improving efficiency, and ensuring compliance with stringent international air quality standards.

Modern combustion and emission control technologies reduce pollution by optimizing the fuel–air mixing process, lowering combustion temperature, and capturing or neutralizing pollutants before they are released into the atmosphere. Techniques such as low-NOₓ burners, staged combustion, flue gas recirculation, and oxygen trim systems minimize pollutant formation at the source, while emission control devices like electrostatic precipitators (ESP), bag filters, flue gas desulfurization (FGD), and selective catalytic reduction (SCR) systems remove remaining particulates, sulfur, and nitrogen oxides from exhaust gases—achieving up to 95–99% reduction in total emissions.

Understanding how these systems interact is essential for achieving both environmental sustainability and operational efficiency in industrial energy systems.

Modern combustion systems can operate cleanly without emission controls.False

Even with advanced combustion techniques, post-combustion emission controls are required to meet modern air quality regulations.

Low-NOₓ combustion and flue gas treatment can reduce total boiler emissions by over 90%.True

Integrated low-NOₓ burners, SCR, and FGD systems can together cut particulate, sulfur, and nitrogen oxide emissions by more than 90%.

1. Combustion Optimization: Controlling the Root Cause of Emissions

Modern combustion systems focus on preventing pollutants from forming, rather than merely cleaning them afterward. The main techniques include:

| Technology | Principle | Typical Reduction (%) | Notes |

|---|---|---|---|

| Low-NOₓ Burners (LNB) | Controls flame temperature and air staging to limit NOₓ formation | 40–60 | Applicable for gas, oil, and coal boilers |

| Staged Combustion | Divides air injection into primary and secondary stages to reduce oxidation peaks | 30–50 | Reduces thermal NOₓ |

| Flue Gas Recirculation (FGR) | Recirculates cooled exhaust gas to lower flame temperature | 20–40 | Common in gas-fired boilers |

| Oxygen Trim Control (O₂ Control) | Adjusts air-to-fuel ratio continuously for complete combustion | 5–10 fuel savings, 20–30% CO reduction | Improves efficiency and reduces unburnt fuel |

| Modulating Burners | Matches burner output to demand load to prevent excessive fuel input | 10–20 efficiency gain | Prevents incomplete combustion |

| Preheated Combustion Air | Uses waste heat to preheat air for more stable combustion | Efficiency ↑ 2–4%, CO ↓ | Widely used in modern gas systems |

Through precise fuel–air ratio control and real-time feedback, these systems drastically lower CO, NOₓ, and unburned hydrocarbons while improving boiler efficiency.

2. Flue Gas Treatment: Capturing and Neutralizing Pollutants

Even optimized combustion produces residual pollutants, especially in fossil-fuel boilers. Emission control technologies target these gases and particles directly in the flue gas stream.

| System | Target Pollutant | Technology Type | Removal Efficiency (%) | Key Advantage |

|---|---|---|---|---|

| Electrostatic Precipitator (ESP) | Particulate matter (PM) | Electrical charging and collection | 95–99 | Handles large gas volumes efficiently |

| Bag Filter (Fabric Filter) | Dust and fine particles | Filtration through fabric bags | 90–98 | Captures submicron particles |

| Flue Gas Desulfurization (FGD) | SO₂ and sulfur compounds | Wet or dry chemical absorption (lime, limestone) | 90–98 | Converts SO₂ into gypsum (reusable byproduct) |

| Selective Catalytic Reduction (SCR) | NOₓ | Ammonia/urea injection with catalyst | 80–95 | High-efficiency NOₓ reduction |

| Selective Non-Catalytic Reduction (SNCR) | NOₓ | Ammonia/urea injection at high temp | 30–60 | Simple retrofit solution |

| Activated Carbon Injection (ACI) | Mercury, heavy metals | Adsorption | 70–95 | Effective for trace toxics |

The combination of LNB + FGD + SCR + ESP is considered the best available technology (BAT) for clean combustion across oil, gas, and coal boilers.

3. Integrated Control Systems and Smart Monitoring

Modern emission systems are often integrated under computerized control and monitoring platforms (CMS). These systems optimize performance through:

Real-time O₂ and CO sensors for dynamic air-fuel adjustment.

Continuous Emission Monitoring Systems (CEMS) for NOₓ, SO₂, and CO₂ tracking.

Predictive analytics using AI to forecast emission spikes and adjust combustion conditions.

Automated soot-blowing and heat-surface cleaning to sustain heat transfer and prevent energy loss.

This integration ensures sustained compliance, reduces manual intervention, and keeps emission levels consistently below permissible limits.

4. Emission Reduction Performance Comparison

| Control Stage | Example System | Pollutant Controlled | Typical Removal Efficiency (%) | Residual Emission Level (mg/Nm³) |

|---|---|---|---|---|

| Combustion Stage | Low-NOₓ Burner + O₂ Trim | NOₓ, CO | 40–60 | 200–400 |

| Intermediate Treatment | SNCR | NOₓ | +30–50 | 150–300 |

| Post-Combustion | SCR + FGD + ESP | NOₓ, SO₂, PM | 90–98 | <50 |

| Overall (Integrated) | Full BAT System | Multi-pollutant | >95 | <30 |

Integrated systems achieve compliance with even the most stringent air quality standards (e.g., EU IED, US EPA NSPS).

5. Advanced Combustion Design Innovations

Emerging design trends further minimize emissions and maximize performance:

Lean premix combustion for gas-fired boilers – uniform flame temperature, <30 ppm NOₓ.

Turbulent flame shaping – optimizes air mixing to prevent hot spots.

Hybrid fuel flexibility – allows switch between oil, gas, or biofuel to balance carbon footprint.

AI-driven flame imaging systems – continuously assess flame stability and pollutant formation.

Hydrogen-enriched combustion – near-zero CO and CO₂ emissions when blended with natural gas.

These design upgrades represent the next evolution of low-emission combustion engineering.

6. Quantitative Environmental Benefits

| Pollutant | Traditional Boiler (mg/Nm³) | With Modern Controls (mg/Nm³) | Reduction (%) |

|---|---|---|---|

| CO₂ | — | — | 10–15 (via efficiency gain) |

| CO | 300–500 | 50–100 | 80 |

| NOₓ | 400–600 | 100–200 | 70 |

| SO₂ | 1000–2000 | 50–200 | 90 |

| PM | 150–300 | 10–30 | 90 |

By combining combustion optimization with end-of-pipe treatments, overall pollutant emissions can be reduced by 90–95%, meeting the world’s strictest air quality norms.

7. Compliance with Global Standards

| Regulation | Pollutant | Emission Limit (mg/Nm³) | Applicable Systems |

|---|---|---|---|

| EU Industrial Emissions Directive (IED) | NOₓ ≤ 150, SO₂ ≤ 200, PM ≤ 20 | LNB + SCR + ESP + FGD | |

| U.S. EPA NSPS Subpart Db/Dc | NOₓ ≤ 100, SO₂ ≤ 340, PM ≤ 50 | LNB + SCR | |

| China GB13271-2014 | NOₓ ≤ 150, SO₂ ≤ 200, PM ≤ 30 | LNB + FGD | |

| India MoEFCC 2017 Standards | NOₓ ≤ 400, SO₂ ≤ 600, PM ≤ 100 | FGD + ESP |

These regulations drive industries to adopt integrated emission control strategies for full legal and environmental compliance.

8. Case Study: Integrated Combustion and Emission Control Retrofit

A petrochemical facility in the Middle East operating 50 TPH oil-fired boilers retrofitted its systems with LNB, O₂ trim control, SCR, and FGD units.

Results after 6 months:

| Parameter | Before Retrofit | After Retrofit | Improvement (%) |

|---|---|---|---|

| Boiler Efficiency | 84% | 91% | +7 |

| NOₓ (mg/Nm³) | 460 | 160 | -65 |

| SO₂ (mg/Nm³) | 950 | 150 | -84 |

| PM (mg/Nm³) | 120 | 25 | -79 |

| CO₂ Emissions | — | -8% (fuel reduction) | — |

The combined approach achieved full compliance with EU IED and local environmental standards, cutting emissions by more than 80% and saving 9% on annual fuel costs.

9. Future Outlook: Toward Ultra-Low and Carbon-Neutral Combustion

Next-generation emission reduction technologies are moving toward ultra-low and zero-emission combustion systems, including:

Hydrogen or ammonia-fired burners – near-zero CO₂ output.

Oxy-fuel combustion – uses pure oxygen, simplifying CO₂ capture.

Carbon capture, utilization, and storage (CCUS) integration – enables 90%+ CO₂ capture.

Digital twins for combustion optimization – predictive emission management.

These innovations indicate a future where industrial boilers can operate efficiently while meeting net-zero emission goals.

Conclusion

Modern combustion and emission control technologies work together to tackle pollution at both the source and the outlet. By combining advanced burner design, intelligent control systems, and high-efficiency pollutant removal technologies, industries can cut harmful emissions by over 90%, boost energy efficiency, and ensure long-term environmental compliance. This integrated approach represents the foundation of clean and sustainable industrial heat generation for the future.

Can Oil-Fired Boilers Operate on Low-Sulfur or Biofuel Alternatives?

Oil-fired boilers have long been reliable sources of thermal energy for industrial processes, district heating, and power generation. However, traditional heavy fuel oils (HFO) and medium fuel oils (MFO) contain significant sulfur and carbon content, leading to high levels of CO₂, SO₂, and particulate emissions. With global environmental regulations tightening and carbon pricing policies expanding, industries face increasing pressure to reduce their environmental footprint. The growing question is whether existing oil-fired boilers can transition to low-sulfur fuels or even bio-based alternatives without sacrificing performance or reliability. The short answer: yes—modern oil-fired boilers can operate efficiently on low-sulfur and biofuel blends with the right combustion tuning and minor system adaptations.

Oil-fired boilers can operate effectively on low-sulfur and biofuel alternatives, provided the fuel characteristics are compatible with the boiler’s burner design, atomization system, and combustion controls. Low-sulfur fuel oils (≤0.5% sulfur) dramatically reduce SO₂ emissions and corrosion risks, while biofuels—such as biodiesel (FAME), hydrotreated vegetable oil (HVO), and used cooking oil (UCO) blends—can cut net CO₂ emissions by up to 80%. In many cases, minor adjustments to burner nozzles, pumps, and control settings are sufficient to ensure stable and efficient operation.

Transitioning to these fuels not only meets environmental regulations but also enhances long-term sustainability and energy resilience.

Conventional oil-fired boilers cannot run on biofuels without complete redesign.False

Most existing oil-fired boilers can operate on biofuel blends with minor modifications to burners, pumps, and control systems.

Switching to low-sulfur or bio-based fuels reduces both sulfur dioxide and carbon emissions.True

Low-sulfur fuels cut SO₂ emissions by 70–95%, while biofuels lower net CO₂ emissions by up to 80%.

1. Low-Sulfur Fuel Oils: Cleaner Combustion and Compliance

Low-sulfur fuel oils (LSFO) and ultra-low-sulfur fuel oils (ULSFO) have become the industry standard in many regions since the implementation of the IMO 2020 sulfur cap and similar national emission standards. These fuels contain ≤0.5% sulfur (LSFO) or ≤0.1% sulfur (ULSFO), compared to 1.5–3.5% sulfur in conventional heavy fuel oils.

| Fuel Type | Sulfur Content (%) | SO₂ Emission Reduction (%) | Typical Application | Notes |

|---|---|---|---|---|

| Heavy Fuel Oil (HFO) | 2.5–3.5 | — | Legacy industrial boilers | High emissions |

| Low-Sulfur Fuel Oil (LSFO) | 0.3–0.5 | 70–85 | Industrial & marine boilers | Direct replacement |

| Ultra-Low-Sulfur Fuel Oil (ULSFO) | ≤0.1 | 90–95 | Hospitals, refineries, clean areas | Requires fine filtration |

| Marine Gas Oil (MGO) | ≤0.1 | 95 | Compact installations | High purity and stability |

Switching from HFO to LSFO/ULSFO significantly reduces SO₂, PM, and acid corrosion, improving both environmental performance and equipment lifespan.

2. Biofuel Alternatives: Toward Renewable Liquid Energy

Biofuels are derived from renewable sources such as vegetable oils, animal fats, and waste cooking oils. Unlike fossil oils, they are carbon-neutral over their lifecycle, since the carbon released during combustion is offset by carbon absorbed during biomass growth.

| Biofuel Type | Origin | Energy Content (MJ/kg) | Net CO₂ Reduction (%) | Sulfur (wt%) |

|---|---|---|---|---|

| Biodiesel (FAME) | Transesterified vegetable oils | 37–39 | 60–70 | <0.001 |

| Hydrotreated Vegetable Oil (HVO) | Catalytic hydrogenation of oils/fats | 43–44 | 75–90 | <0.001 |

| Used Cooking Oil (UCO) Blend | Recycled waste oil | 38–40 | 50–70 | <0.05 |

| Bio-Heavy Oil (BHO) | Pyrolysis of biomass residues | 35–38 | 60–80 | <0.05 |

Modern oil-fired boilers can operate on biofuel blends (10–50%) or even 100% HVO, depending on design. Biofuels not only reduce greenhouse gas emissions but also enhance combustion efficiency due to higher oxygen content in the fuel molecule, promoting more complete burning.

3. Boiler Compatibility and Required Modifications

Adapting an oil-fired boiler for low-sulfur or biofuel operation involves careful evaluation of fuel handling, atomization, and combustion systems.

The key parameters include viscosity, energy content, and combustion characteristics.

| Component | Required Adjustment | Reason |

|---|---|---|

| Burner Nozzles | Replaced or resized | To ensure proper atomization for lower viscosity fuels |

| Fuel Pumps | Calibrated or replaced | To match flow rate and pressure of lighter fuels |

| Heaters | Reduced or bypassed | Biofuels and LSFO need lower preheat temperatures (50–80°C) |

| Filters | Finer filtration (5–10 microns) | Prevents clogging due to higher oxidation tendency |

| Control System | O₂ trim or load modulation | Ensures stable air–fuel ratio for variable fuel properties |

| Material Compatibility | Check elastomers and seals | Prevents swelling or corrosion from biofuel acids |

With these adjustments, most medium and large industrial oil-fired boilers (1–50 TPH) can seamlessly operate on cleaner fuel blends.

4. Emission Performance: Comparative Analysis

| Fuel Type | CO₂ (kg/GJ) | SO₂ (mg/Nm³) | NOₓ (mg/Nm³) | PM (mg/Nm³) | CO (mg/Nm³) |

|---|---|---|---|---|---|

| HFO (3.5% S) | 77 | 1500 | 400 | 120 | 200 |

| LSFO (0.5% S) | 76 | 400 | 380 | 80 | 150 |

| HVO (100%) | 73 | <10 | 250 | <30 | 100 |

| FAME (100%) | 72 | <10 | 270 | <40 | 120 |

| Biofuel Blend (B20) | 75 | 150 | 310 | 60 | 130 |

Transitioning to ULSFO or biofuel blends can yield up to 90% SO₂ reduction, 30–40% NOₓ reduction, and 80% particulate reduction, all while maintaining comparable thermal efficiency.

5. Operational Considerations for Biofuel Usage

While biofuels are environmentally advantageous, they present unique operational characteristics:

Lower storage stability: Biofuels can oxidize and form gums; stabilizers are recommended.

Cold flow issues: Biodiesel may gel at low temperatures; blending with LSFO or heating resolves this.

Higher acidity: Requires corrosion-resistant components (stainless steel, Viton seals).

Slightly lower energy density: Increases volumetric fuel consumption by 5–8%.

Proper storage design, additive management, and combustion tuning mitigate these issues effectively.

6. Case Study: Biofuel Retrofit in an Industrial Boiler

A 25 TPH oil-fired boiler in Northern Europe was retrofitted to operate on HVO and biodiesel blends.

System modifications included new burner nozzles, O₂ trim control, and fuel preheater adjustments.

| Parameter | Pre-Retrofit (HFO) | Post-Retrofit (HVO/B20) | Improvement (%) |

|---|---|---|---|

| Boiler Efficiency | 86% | 90% | +4 |

| SO₂ (mg/Nm³) | 1100 | 40 | -96 |

| NOₓ (mg/Nm³) | 420 | 260 | -38 |

| PM (mg/Nm³) | 85 | 25 | -71 |

| CO₂ (t/year) | 9,200 | 6,800 | -26 |

The retrofit achieved EU IED emission compliance, with total annual emission reductions equivalent to removing 1,000 cars from the road.

7. Economic and Environmental Benefits

| Parameter | HFO | LSFO | HVO (B100) | B20 Blend |

|---|---|---|---|---|

| Fuel Price (USD/ton) | 600 | 720 | 1,200 | 800 |

| Maintenance Cost | High | Medium | Low | Low |

| CO₂ Reduction (%) | — | 5 | 80 | 20 |

| SO₂ Reduction (%) | — | 85 | 98 | 90 |

| Typical Payback (Years) | — | 1–2 | 3–5 | 2–3 |

While biofuels may be costlier per ton, overall savings arise from reduced maintenance, regulatory compliance, and potential carbon credit revenue.

8. Regulatory Alignment and Future Outlook

| Standard | Key Requirement | Impact |

|---|---|---|

| IMO MARPOL Annex VI (2020) | ≤0.5% sulfur limit | Drives LSFO adoption |

| EU Renewable Energy Directive (RED II) | ≥32% renewable energy by 2030 | Incentivizes biofuel blends |

| U.S. EPA RFS Program | Renewable Fuel Standard credits (RINs) | Promotes biofuel use in industry |

| ISO 8217:2023 | Standard for marine/bunker fuel oils | Includes bio-blend parameters |

Future-ready oil-fired boilers are increasingly designed for dual-fuel operation, capable of burning both fossil and renewable oils seamlessly.

9. Technological Innovations for Cleaner Liquid Fuels

Emerging advancements supporting biofuel transition include:

Smart atomizers for varying viscosity fuels

AI-controlled combustion optimization

Dual-fuel burners capable of auto-switching between oil and biofuel

On-site bio-oil reforming and blending units

Carbon capture integration for near-zero emission operation

These innovations will allow traditional oil boilers to remain viable in the low-carbon economy.

Conclusion

Yes—oil-fired boilers can and increasingly do operate on low-sulfur and biofuel alternatives. Through simple modifications to burners and controls, existing systems can achieve dramatic emission reductions and sustainability gains without replacing the entire boiler. Low-sulfur oils reduce SO₂ and corrosion, while biofuels significantly lower CO₂ and PM emissions. When combined with modern combustion control, these fuels provide a practical bridge toward carbon-neutral industrial heating.

What Role Does Efficiency Improvement Play in Lowering Environmental Impact?

Energy efficiency is the foundation of sustainable industrial operation. Every percentage point of efficiency gained in a boiler or energy system translates directly into reduced fuel consumption, lower emissions, and smaller operational costs. In a world striving toward carbon neutrality and stricter emission regulations, improving efficiency is not merely an economic decision—it is an environmental imperative. When combustion, heat recovery, and system management are optimized, a power or process plant can drastically cut its environmental footprint while maintaining output and reliability.

Efficiency improvement plays a crucial role in lowering environmental impact because it directly reduces the amount of fuel required to produce the same energy output. This results in proportionally lower emissions of carbon dioxide (CO₂), nitrogen oxides (NOₓ), sulfur dioxide (SO₂), and particulate matter. Enhancing thermal efficiency through better heat transfer, optimized combustion, advanced control systems, and waste heat recovery can reduce total greenhouse gas emissions by 10–30%, while simultaneously decreasing resource consumption and operating costs. In short, higher efficiency means cleaner, more sustainable energy generation.

Efficiency is therefore not just a performance metric—it is a vital environmental strategy. Understanding its mechanisms helps industries achieve both ecological compliance and financial optimization.

Improving boiler efficiency has no significant effect on carbon dioxide emissions.False

Boiler efficiency directly determines the amount of fuel burned; improving efficiency reduces CO₂ emissions proportionally.

Heat recovery and combustion optimization are key efficiency measures that lower environmental impact.True

These measures reduce unburned fuel losses and recover waste heat, improving energy utilization and cutting emissions.

1. The Direct Link Between Efficiency and Emissions

Boiler efficiency measures how effectively a system converts the chemical energy in fuel into useful thermal energy. When a boiler operates at higher efficiency, less fuel is needed for the same steam output, which means lower emissions per unit of energy.

| Boiler Efficiency (%) | Relative Fuel Use (%) | CO₂ Emissions (kg/MWh) | NOₓ (mg/Nm³) | SO₂ (mg/Nm³) |

|---|---|---|---|---|

| 75 | 100 | 320 | 400 | 600 |

| 80 | 94 | 300 | 370 | 560 |

| 85 | 88 | 280 | 340 | 520 |

| 90 | 83 | 260 | 310 | 480 |

| 95 | 79 | 245 | 280 | 440 |

Improving efficiency from 80% to 90% reduces fuel consumption and emissions by about 12%. In a 20 TPH (ton per hour) industrial boiler, that translates to hundreds of tons of CO₂ avoided annually.

2. Heat Loss Mechanisms and Their Environmental Cost

Boiler inefficiency arises mainly from heat losses—stack gas, radiation, and unburned fuel. Each type contributes to wasted energy and higher emissions.

| Loss Type | Typical Range (%) | Environmental Impact | Mitigation Strategy |

|---|---|---|---|

| Flue Gas Loss | 5–15 | Excess fuel burned for same heat output | Install economizers, air preheaters |

| Unburned Carbon | 1–3 | Higher CO and particulate emissions | Improve combustion and burner tuning |

| Radiation & Convection Loss | 0.5–2 | Increased heat demand | Insulate furnace and piping |

| Blowdown & Moisture Loss | 0.5–2 | Water waste and extra heating | Recover flash steam, optimize feedwater |

| Incomplete Combustion | 1–5 | CO and hydrocarbon emissions | O₂ trim control and optimized excess air |

By targeting these areas, plants can significantly reduce total energy waste and pollutant formation.

3. Efficiency and the Carbon Footprint Equation

Each unit of fuel has a defined carbon intensity. Thus, energy efficiency and carbon footprint are mathematically linked. For example, natural gas emits ~55 kg CO₂ per GJ, while coal emits ~95 kg CO₂ per GJ. If efficiency improves by 10%, CO₂ emissions per unit output fall by the same ratio.

| Fuel Type | Emission Factor (kg CO₂/GJ) | Efficiency (%) | Effective Emissions (kg CO₂/GJ useful) |

|---|---|---|---|

| Coal | 95 | 80 | 118.8 |

| Oil | 74 | 85 | 87.1 |

| Natural Gas | 55 | 92 | 59.8 |

| Biofuel (neutralized) | 0–15 | 88 | 17.0 |

| Hydrogen | 0 | 95 | 0 |

Result: Moving from coal (80%) to natural gas (92%) or adding heat recovery reduces effective CO₂ emissions by over 50%. Efficiency, therefore, is the most cost-effective carbon mitigation measure before fuel substitution.

4. Waste Heat Recovery: Turning Losses Into Gains

Waste heat recovery is among the most powerful methods to enhance efficiency and reduce environmental impact. Systems like economizers, air preheaters, and condensing heat exchangers reclaim energy from flue gases and reuse it for preheating feedwater or combustion air.

| Technology | Typical Efficiency Gain (%) | CO₂ Reduction (%) | Additional Benefits |

|---|---|---|---|

| Economizer | 3–5 | 4–6 | Reduced fuel cost |

| Air Preheater | 2–4 | 3–5 | Improved combustion stability |

| Condensing Heat Exchanger | 5–8 | 7–10 | Flue gas dew point recovery |

| Steam Turbine Backpressure Optimization | 3–6 | 5–8 | More electricity output per fuel unit |

By reclaiming 10% of wasted heat, a medium-sized plant can reduce annual CO₂ emissions by 5,000–10,000 tons depending on its capacity.

5. Advanced Control Systems for Sustained Efficiency

Modern monitoring and automation systems continuously track and optimize efficiency.

These include:

Oxygen trim control – maintains optimal air–fuel ratio.

Variable frequency drives (VFDs) – reduce fan and pump energy use.

Flue gas analyzers – ensure combustion stability.

IoT-based predictive maintenance – minimizes downtime and degradation.

| Control Type | Function | Efficiency Gain (%) | Emission Impact |

|---|---|---|---|

| O₂ Trim System | Adjusts air automatically | 1–2 | Lower NOₓ and CO |

| VFDs | Reduces motor power demand | 1–3 | Indirect CO₂ savings |

| Advanced SCADA | Integrates full plant data | 2–5 | Holistic emission reduction |

| Predictive Maintenance | Prevents fouling and leaks | 1–2 | Sustains optimal operation |

Consistent monitoring prevents long-term drift and ensures that initial design efficiency remains stable throughout the lifecycle.

6. Fouling and Clean Heat Transfer Surfaces

Efficiency losses often result from fouled heat exchangers or boiler tubes. Deposits reduce heat transfer and increase flue gas temperature, meaning more energy escapes unused.

| Deposit Type | Source | Efficiency Drop (%) | Environmental Result |

|---|---|---|---|

| Soot (carbon) | Incomplete combustion | 1–5 | More CO₂ & PM emissions |

| Scale (Ca/Mg salts) | Hard feedwater | 2–8 | Increased fuel use |

| Slagging/Ash | Solid fuel boilers | 3–10 | Higher NOₓ and unburned carbon |

| Corrosion residues | Sulfur or chloride compounds | 1–4 | More maintenance, leaks |

Regular cleaning and water treatment restore original efficiency and prevent excess fuel burning.

7. Economic and Ecological Payback

Efficiency improvement measures have fast payback times. While the initial investment may appear technical, the combined financial and environmental benefits make it one of the most attractive sustainability strategies.

| Improvement Measure | Typical Cost (USD/kW) | Efficiency Gain (%) | Payback (Years) | CO₂ Reduction (t/year for 10 MW boiler) |

|---|---|---|---|---|

| Combustion Control Upgrade | 10–20 | 2–4 | 1–2 | 800–1,200 |

| Economizer Retrofit | 25–40 | 3–6 | 2–3 | 1,500–2,000 |

| Air Preheater | 20–30 | 2–4 | 2–4 | 1,000–1,500 |

| Insulation Improvement | 5–10 | 1–2 | <1 | 400–700 |

| Condensing Recovery System | 50–70 | 5–8 | 3–5 | 2,500–3,500 |

High-efficiency operation aligns profit with environmental stewardship, fulfilling ESG and regulatory goals simultaneously.

8. Regulatory and Sustainability Implications

Governments and agencies worldwide are increasingly enforcing efficiency as part of emissions compliance.

For instance:

EU Industrial Emissions Directive (IED) mandates best available techniques (BAT) for >70% boiler efficiency.

U.S. DOE and EPA require efficiency ratings and testing for industrial boilers.

ISO 50001 energy management systems focus on continuous improvement.

Carbon offset and trading systems (EU ETS, China ETS) directly reward high-efficiency operation with emission credits.

Compliance through efficiency gains helps avoid penalties while qualifying for sustainability incentives and carbon trading advantages.

9. Case Example: Efficiency Retrofit in a 30 TPH Oil-Fired Boiler

A European textile plant retrofitted its 30 TPH boiler system with:

Flue gas economizer

O₂ trim system

VFD on feedwater pump

Soot blowing optimization

| Metric | Before Retrofit | After Retrofit | Improvement (%) |

|---|---|---|---|

| Efficiency | 82% | 91% | +11 |

| Fuel Use (ton/year) | 9,800 | 8,700 | -11 |

| CO₂ Emission (t/year) | 29,000 | 25,700 | -11.4 |

| NOₓ (mg/Nm³) | 380 | 310 | -18.4 |

| SO₂ (mg/Nm³) | 560 | 490 | -12.5 |

| Payback Period | — | 2.1 years | — |

This demonstrates that efficiency is both an environmental and financial win.

Conclusion

Efficiency improvement is the single most effective pathway to lower environmental impact in boiler and power plant systems. By reducing fuel demand, it proportionally cuts all emissions—CO₂, NOₓ, SO₂, and particulates—while improving operational stability and reducing costs. From heat recovery to digital control, every enhancement in efficiency pushes industrial systems closer to carbon neutrality and regulatory compliance. The cleaner the combustion and the smarter the control, the greener the output.

How Do International and Local Emission Standards Regulate Oil-Fired Boiler Performance?

Across the globe, oil-fired boilers have long been relied upon for industrial steam, district heating, and process energy. However, as environmental awareness and climate policies intensify, regulatory frameworks have become increasingly stringent regarding air pollutants and greenhouse gas emissions. Non-compliance not only leads to financial penalties but can also result in operational shutdowns or license revocations. For any organization running oil-fired systems, understanding and adhering to international and local emission standards is no longer optional—it is a core operational requirement to ensure both environmental responsibility and regulatory compliance.

International and local emission standards regulate oil-fired boiler performance by setting legally binding limits on pollutants such as sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide (CO), particulate matter (PM), and greenhouse gases (CO₂). These standards, enforced through frameworks like the EU Industrial Emissions Directive (IED), U.S. EPA Clean Air Act, ISO 14001, and national environmental agencies, require oil-fired boilers to adopt low-sulfur fuels, advanced combustion controls, and emission treatment systems. Compliance ensures cleaner operation, lower environmental impact, and eligibility for operation permits and sustainability certifications.

In essence, these regulations dictate how efficiently, cleanly, and safely an oil-fired boiler must operate to minimize its contribution to air pollution and climate change.

Oil-fired boilers are exempt from international emission regulations.False

All oil-fired boilers are subject to emission control laws under international and national frameworks such as the EU IED, EPA NSPS, and ISO 14001.

Compliance with low-sulfur and low-NOₓ emission standards is mandatory for industrial oil boilers.True

Environmental regulations require the use of cleaner fuels and combustion technologies to limit pollutant output.

1. Global Emission Control Frameworks for Oil-Fired Boilers

Internationally, emission standards are established by environmental authorities, technical organizations, and intergovernmental treaties. These define maximum allowable limits for key pollutants and set out testing, certification, and reporting protocols.

| Regulatory Framework | Governing Body | Key Pollutants Regulated | Applicability |

|---|---|---|---|

| EU Industrial Emissions Directive (IED) 2010/75/EU | European Commission | NOₓ, SO₂, PM, CO | All stationary combustion plants >1 MW |

| U.S. EPA Clean Air Act & NSPS (Subpart Dc) | Environmental Protection Agency (EPA) | NOₓ, SO₂, CO₂, PM | Boilers >10 MMBtu/h (~3 MW) |

| MARPOL Annex VI | International Maritime Organization (IMO) | SO₂, NOₓ | Marine and stationary boilers |

| ISO 14001 & ISO 50001 | International Organization for Standardization | Indirect control through environmental and energy management | Voluntary, for global sustainability |

| World Bank EHS Guidelines | IFC / World Bank Group | NOₓ, SO₂, PM, CO | Industrial and power plants in developing countries |

Each framework aims to reduce local air pollution and global climate impact by limiting combustion-related emissions and mandating energy efficiency improvements.

2. Key Pollutants and Typical Limit Values

Oil combustion produces several harmful emissions. Regulations specify their maximum concentration at the stack, usually in mg/Nm³ under defined oxygen conditions (often 3–6% O₂).

| Pollutant | Primary Source | Environmental Impact | Typical Limit (mg/Nm³ @ 3% O₂) |

|---|---|---|---|

| SO₂ | Sulfur in fuel | Acid rain, corrosion | 35–850 (depends on sulfur content) |

| NOₓ | High combustion temperature | Smog, ozone formation | 120–450 |

| CO | Incomplete combustion | Toxic gas, air pollution | 100–250 |

| PM (Particulate Matter) | Unburned carbon, ash | Respiratory hazard | 10–100 |

| CO₂ | Fuel carbon oxidation | Greenhouse effect | Monitored, not directly limited |

| VOCs | Unburned hydrocarbons | Ozone precursor | <50 (in stricter regions) |

Modern low-sulfur oils and biofuel blends help plants meet SO₂ and PM limits, while advanced burner design and combustion control are essential for NOₓ and CO reduction.

3. Regional Variations: EU, U.S., and Asia

Emission thresholds vary across jurisdictions depending on development level, fuel quality, and environmental policies.

| Region | Regulation | Boiler Size | NOₓ Limit (mg/Nm³) | SO₂ Limit (mg/Nm³) | PM Limit (mg/Nm³) |

|---|---|---|---|---|---|

| European Union | IED / BAT-AEL (2022) | >50 MWth | 100–200 | 35–200 | 10–30 |

| United States | EPA NSPS Subpart Db/Dc | >10 MMBtu/h | 130–260 | 260 | 43 |

| China | GB13271-2014 | >65 t/h | 150 | 200 | 30 |

| India | CPCB / MoEFCC 2017 | >25 MW | 300 | 600 | 100 |

| Japan | Air Pollution Control Law | All | 200 | 250 | 50 |

The trend is toward tightening NOₓ and SO₂ limits, particularly in the EU and China, with incentives for biofuel transition and emission control retrofits.

4. Emission Control Technologies for Compliance

To meet these regulations, oil-fired boilers employ both primary (combustion-based) and secondary (post-combustion) emission control techniques.

| Control Category | Technology | Target Pollutant | Typical Reduction (%) |

|---|---|---|---|

| Primary | Low-NOₓ Burners | NOₓ | 40–70 |

| Flue Gas Recirculation (FGR) | NOₓ | 20–50 | |

| Fuel Switching (LSFO/HVO) | SO₂, PM | 70–95 | |

| Oxygen Trim Control | CO, NOₓ | 10–20 | |

| Secondary | Selective Catalytic Reduction (SCR) | NOₓ | 80–95 |

| Wet Flue Gas Desulfurization (FGD) | SO₂ | 90–98 | |

| Electrostatic Precipitator (ESP) | PM | 95–99 | |

| Baghouse Filter | PM | 90–99 |

By combining these measures, modern oil-fired boilers can achieve multi-pollutant compliance and maintain efficiency above 90%.

5. ISO and CE Standards in Manufacturing and Operation

Compliance begins at the design stage, where certification and quality assurance standards ensure boilers meet efficiency and emission performance targets.

| Standard | Scope | Impact on Performance and Compliance |

|---|---|---|

| ISO 14001 | Environmental management system | Ensures continuous emission monitoring and improvement |

| ISO 50001 | Energy management | Optimizes efficiency, reducing emissions indirectly |

| EN 12952 / EN 12953 | European pressure equipment standards | Defines emission measurement and control integration |

| ASME BPVC Section I | Boiler and Pressure Vessel Code | Safety and performance assurance |

| CE Marking (PED 2014/68/EU) | EU certification for pressure equipment | Required for market entry and environmental safety |

Manufacturers must document emission test results, materials, and calibration procedures to demonstrate conformity with these global standards.

6. Monitoring and Reporting Obligations

Modern regulations require Continuous Emission Monitoring Systems (CEMS) and regular third-party inspections.

| Monitoring Type | Frequency | Measured Parameters | Reporting Authority |

|---|---|---|---|

| Continuous (CEMS) | Real-time | NOₓ, SO₂, CO, O₂, Flow | Local environmental bureau |

| Periodic Stack Testing | 6–12 months | PM, VOCs, opacity | Accredited testing body |

| Annual Environmental Report | Yearly | Emission totals, fuel use | National EPA or Ministry |

| ISO/EMS Audits | Annual/biannual | Compliance and improvement | Certification agency |

Non-compliance in reporting can lead to fines up to 5% of annual turnover in some jurisdictions, emphasizing the importance of traceability.

7. Emission Control Economics

While implementing emission control technologies requires capital investment, the long-term financial and environmental gains outweigh initial costs.

| System | CAPEX (USD/kW) | OPEX (USD/kW·yr) | NOₓ/SO₂ Reduction (%) | Payback (Years) |

|---|---|---|---|---|

| Low-NOₓ Burner | 15–25 | 1–2 | 50 | 1–2 |

| FGR System | 20–30 | 2–3 | 30–50 | 2–3 |

| SCR | 80–120 | 5–8 | 90 | 3–5 |

| FGD | 100–150 | 6–10 | 95 | 4–6 |

| ESP | 60–100 | 4–6 | 99 | 3–4 |

These measures enable compliance while reducing fuel waste and enhancing boiler lifespan.

8. Case Study: EU IED Compliance Retrofit

A 25 MW oil-fired boiler in Southern Europe underwent a compliance retrofit to meet EU IED 2022 limits.

| Parameter | Before Retrofit | After Retrofit | Reduction (%) |

|---|---|---|---|

| NOₓ | 410 mg/Nm³ | 160 mg/Nm³ | 61 |

| SO₂ | 550 mg/Nm³ | 120 mg/Nm³ | 78 |

| PM | 60 mg/Nm³ | 18 mg/Nm³ | 70 |

| Efficiency | 88% | 91% | +3 |

| Payback Period | — | 2.8 years | — |

By integrating a low-NOₓ burner, economizer, and partial FGD, the plant achieved full compliance while improving energy efficiency.

9. Future Regulatory Trends and Low-Carbon Transition

Global emission regulations are evolving toward carbon intensity reduction and fuel flexibility.

EU Fit for 55 and U.S. Inflation Reduction Act (IRA) target 55% GHG reduction by 2030.

Carbon border adjustment mechanisms (CBAM) will penalize carbon-intensive imports.

ISO 14067 introduces standardized carbon footprint quantification for industrial products.

Green financing and ESG frameworks increasingly link loan rates to verified emission reductions.

To stay future-ready, oil-fired boiler operators must transition toward low-sulfur, biofuel, or dual-fuel operation while maintaining high efficiency and emission monitoring accuracy.

Conclusion

International and local emission standards play a defining role in regulating oil-fired boiler performance. From the EU IED and EPA NSPS to ISO 14001, these frameworks ensure that industrial energy systems operate with minimal environmental harm. By mandating strict emission limits, continuous monitoring, and clean technology adoption, regulators drive innovation toward cleaner combustion, lower sulfur fuels, and higher efficiency. Compliance is not only about legality—it is the key to long-term sustainability, operational reliability, and global competitiveness.

What Are the Best Practices for Operating Oil-Fired Boilers Sustainably?

In an era of decarbonization and environmental accountability, oil-fired boilers—though traditionally fossil-fuel based—can still play a meaningful role in sustainable industrial energy generation. The key lies in how they are operated. Many facilities still waste significant energy due to poor maintenance, inefficient combustion, or lack of emission controls. Such inefficiencies not only drive up fuel costs but also increase greenhouse gas emissions and pollutant output. Sustainable boiler operation requires a holistic approach that integrates fuel optimization, advanced combustion control, waste heat recovery, regular maintenance, and emission monitoring. Implementing these best practices can transform a conventional oil-fired boiler into a cleaner, more efficient, and compliant energy system.

The best practices for operating oil-fired boilers sustainably include optimizing combustion through precise air–fuel ratio control, using low-sulfur or biofuel alternatives, recovering waste heat via economizers or air preheaters, maintaining clean heat transfer surfaces, and continuously monitoring emissions. Sustainable operation also involves regular tuning, water treatment, and adherence to ISO 50001 and ISO 14001 energy management systems. These practices minimize fuel use, lower CO₂, SO₂, and NOₓ emissions, extend equipment life, and ensure compliance with environmental regulations.

By adopting these practices, industrial and commercial operators can reduce operating costs and environmental impact simultaneously—achieving both profitability and sustainability in boiler operation.

Oil-fired boilers cannot be operated sustainably because of their reliance on fossil fuels.False

With efficiency optimization, low-sulfur or biofuel use, and emission controls, oil-fired boilers can achieve significant environmental improvements.

Continuous monitoring and combustion tuning are key to sustainable oil boiler operation.True

Accurate air–fuel ratio and real-time performance monitoring minimize unburned fuel and pollutant formation.

1. Fuel Quality and Selection: Foundation of Sustainability

Fuel quality directly determines combustion performance and emission levels. Using low-sulfur oil (LSFO) or ultra-low-sulfur oil (ULSFO) minimizes sulfur dioxide (SO₂) formation and corrosion. Many operators are transitioning toward biofuel blends such as biodiesel (FAME) or hydrotreated vegetable oil (HVO) to further reduce carbon intensity.

| Fuel Type | Sulfur Content (%) | CO₂ Emission (kg/GJ) | Typical Application | Sustainability Advantage |

|---|---|---|---|---|

| Heavy Fuel Oil (HFO) | 2.5–3.5 | 77 | Legacy boilers | High SO₂, low sustainability |

| Low-Sulfur Fuel Oil (LSFO) | 0.3–0.5 | 75 | Industrial & marine | 80% SO₂ reduction |

| Ultra-Low-Sulfur Fuel Oil (ULSFO) | ≤0.1 | 74 | Urban or sensitive areas | Near-zero SO₂ |

| Hydrotreated Vegetable Oil (HVO) | <0.001 | 73 | Modern retrofits | 70–90% CO₂ reduction |

| Biodiesel (B20–B100) | <0.05 | 70–72 | Retrofitted boilers | Renewable, biodegradable |

Switching from HFO to LSFO or HVO alone can reduce total emissions by up to 80% while improving combustion stability and reducing fouling.

2. Combustion Optimization: Precision Air–Fuel Control

Combustion efficiency determines how completely fuel energy converts to usable heat. Excess air or poor mixing leads to unburned fuel, CO formation, and energy loss.

| Parameter | Optimal Range | Impact of Deviation | Control Strategy |

|---|---|---|---|

| Excess Air Ratio (λ) | 1.05–1.20 | Too low → CO rise; Too high → heat loss | O₂ trim control |

| Flame Temperature | 1,300–1,500°C | Too high → NOₓ formation; too low → soot | Low-NOₓ burners |

| Atomization Pressure | 10–15 bar | Poor atomization increases PM | Burner tuning |

| Fuel Temperature | 60–90°C | Too high increases vaporization | Preheater control |

Advanced combustion management systems with O₂ trim control and real-time flue gas analysis maintain optimal efficiency continuously, cutting NOₓ emissions and saving up to 3–5% fuel annually.

3. Heat Recovery: Reusing Energy for Efficiency

Waste heat recovery is one of the most effective sustainability measures for boilers. Flue gases leaving the boiler can still contain 15–20% of total input energy, which can be recovered using economizers or air preheaters.

| Technology | Typical Efficiency Gain (%) | CO₂ Reduction (%) | Description |

|---|---|---|---|

| Economizer | 3–5 | 5–7 | Heats feedwater using flue gas |

| Air Preheater | 2–4 | 3–5 | Preheats combustion air |

| Condensing Heat Exchanger | 5–8 | 8–12 | Captures latent heat from exhaust moisture |

| Waste Heat Boiler (WHB) | 6–10 | 10–15 | Recovers exhaust energy for steam generation |

Implementing one or more recovery systems can raise overall boiler efficiency to 90–94%, significantly reducing both fuel consumption and CO₂ output.

4. Maintenance and Cleaning: Preventing Efficiency Loss

Even the most advanced boiler loses performance if neglected. Deposits on heat surfaces increase thermal resistance, causing higher flue gas temperatures and wasted fuel.

| Deposit Type | Source | Impact on Efficiency | Recommended Maintenance |

|---|---|---|---|

| Soot | Incomplete combustion | -1% efficiency per 1mm deposit | Daily/weekly soot blowing |

| Scale | Poor water treatment | -2–8% efficiency loss | Softening, chemical dosing |

| Corrosion | Sulfur compounds | Tube leaks, energy loss | LSFO and pH control |

| Slag/Ash | Fuel impurities | Heat transfer blockage | Routine cleaning & inspection |

A consistent maintenance schedule can recover up to 10% efficiency and extend boiler life by several years.

5. Emission Control Technologies: Cleaner Operation

Sustainable operation involves controlling pollutants beyond efficiency. Modern oil-fired boilers employ integrated systems for NOₓ, SO₂, and particulate matter mitigation.

| System | Target Pollutant | Reduction (%) | Operating Principle |

|---|---|---|---|

| Low-NOₓ Burner | NOₓ | 50–70 | Staged combustion lowers peak temperature |

| Flue Gas Recirculation (FGR) | NOₓ | 30–50 | Recirculates cool flue gas to dilute O₂ |

| Wet Scrubber (FGD) | SO₂ | 90–98 | Uses alkaline slurry to absorb sulfur gases |

| Electrostatic Precipitator (ESP) | PM | 95–99 | Electrostatic charge collects fine particles |

| Activated Carbon Filter | VOCs | 80–95 | Adsorbs organic compounds |

Combining two or more systems ensures full regulatory compliance and cleaner exhaust quality.

6. Water Treatment and Blowdown Control

Water chemistry plays a critical sustainability role. Poor water treatment leads to scale buildup, corrosion, and chemical waste.

| Parameter | Recommended Range | Sustainability Benefit |

|---|---|---|

| Feedwater Hardness | <0.1 ppm | Prevents scale, extends tube life |

| pH Level | 8.5–9.5 | Prevents corrosion |

| Total Dissolved Solids (TDS) | <3,000 ppm | Reduces blowdown frequency |

| Blowdown Rate | 2–5% | Balances efficiency and water conservation |

Automated blowdown controllers and condensate recovery can save up to 10% water and energy, aligning with ISO 14046 water footprint goals.

7. Automation, Monitoring, and Data Analytics

Digitalization has become central to sustainable operation. Modern Boiler Management Systems (BMS) and Continuous Emission Monitoring Systems (CEMS) integrate AI-driven analytics for predictive optimization.

| System | Function | Benefit |

|---|---|---|

| BMS (Boiler Management System) | Controls combustion and safety interlocks | Stable operation, minimal human error |

| CEMS | Monitors NOₓ, SO₂, CO, O₂ | Real-time compliance assurance |

| SCADA | Supervisory control and data acquisition | Centralized efficiency tracking |

| AI Predictive Analytics | Detects fouling and fuel deviation | Preventive maintenance |

| O₂ Trim & VFD Integration | Dynamically adjusts fan and fuel | 2–5% energy savings |

These technologies provide transparency, traceability, and optimized operation for long-term environmental performance.

8. Operator Training and Energy Management Systems

Human expertise remains critical. Even the most advanced system can waste fuel if operated poorly. Regular training ensures operators understand combustion principles, safety, and sustainability goals.

| Certification | Governing Body | Key Focus Area |

|---|---|---|

| ISO 50001 | International Organization for Standardization | Energy performance optimization |

| ISO 14001 | ISO | Environmental management and monitoring |

| Boiler Operation Certification | Local government or energy bureau | Safe and efficient operation |

| EMS Auditing | Accredited bodies | Continuous improvement process |

Embedding efficiency awareness into daily operation can yield 1–3% performance improvement purely through procedural optimization.

9. Sustainability Metrics and Continuous Improvement

True sustainability is measurable. Regular audits and benchmarking help identify long-term improvements.

| Metric | Unit | Target/Benchmark | Environmental Relevance |

|---|---|---|---|

| Fuel-to-Steam Ratio | kg fuel/ton steam | <60 (oil-fired) | Energy efficiency |

| CO₂ Intensity | kg CO₂/kWh | <0.25 | Climate impact |

| NOₓ Emission | mg/Nm³ | <200 | Air quality |

| SO₂ Emission | mg/Nm³ | <100 | Acid rain prevention |

| Water Reuse Rate | % | >80 | Water conservation |

Tracking these indicators ensures that sustainability is not static but a continuous improvement journey.

10. Case Study: Sustainable Retrofit in a 20 TPH Oil Boiler

A manufacturing facility in Southeast Asia retrofitted its 20 TPH boiler for sustainable operation:

Installed economizer and low-NOₓ burner

Switched to HVO-biodiesel blend (B30)

Integrated O₂ trim control and CEMS

| Parameter | Before Retrofit | After Retrofit | Improvement (%) |

|---|---|---|---|

| Efficiency | 84% | 91% | +7 |

| Fuel Use | 1,000 L/hr | 910 L/hr | -9 |

| CO₂ (t/year) | 9,400 | 8,550 | -9 |

| NOₓ (mg/Nm³) | 370 | 190 | -49 |

| SO₂ (mg/Nm³) | 530 | 70 | -87 |

| Payback | — | 2.3 years | — |

This demonstrates that sustainability and profitability can coexist when guided by engineering precision and policy alignment.

Conclusion

Sustainable operation of oil-fired boilers is not a single modification—it is an integrated discipline combining clean fuels, precise combustion control, heat recovery, maintenance, and digital monitoring. When executed correctly, these measures drastically cut fuel use and emissions while enhancing reliability and extending equipment life. In essence, a sustainably operated oil-fired boiler becomes a bridge between traditional energy and a low-carbon future.

🔍 Conclusion

While older oil-fired boilers had significant environmental drawbacks, modern systems designed with low-emission combustion, efficient heat recovery, and cleaner fuels can meet today’s environmental standards. When properly maintained, they offer a balance between reliability, efficiency, and ecological responsibility.

📞 Contact Us

💡 Looking for an environmentally friendly oil-fired boiler solution? We offer low-NOx, high-efficiency, and biofuel-compatible boiler systems tailored to your environmental and operational needs.

🔹 Contact us today for eco-efficient industrial boiler solutions that meet global standards. 🌿🔥🏭✅

FAQ

Q1: Are industrial oil-fired boilers environmentally friendly?

A1: Traditional oil-fired boilers are less environmentally friendly compared to natural gas or biomass alternatives due to higher carbon emissions and sulfur content in fuel oil. However, modern oil-fired boilers have made significant progress in emission control and fuel efficiency. Equipped with low-NOx burners, flue gas treatment systems, and condensing technology, they can greatly reduce harmful pollutants and improve energy utilization rates. When operated and maintained properly, modern oil-fired boilers can achieve over 90% thermal efficiency, making them a more sustainable choice for industries that require high heat capacity and reliability.

Q2: What are the main environmental impacts of oil-fired boilers?

A2: The key environmental impacts include carbon dioxide (CO₂), nitrogen oxides (NOₓ), and sulfur dioxide (SO₂) emissions, which contribute to global warming and acid rain. Additionally, incomplete combustion can release particulate matter and unburned hydrocarbons. However, by using low-sulfur or ultra-low-sulfur fuel oils, implementing advanced combustion controls, and maintaining proper burner calibration, these emissions can be significantly minimized. Regular emissions monitoring also ensures compliance with local environmental regulations and reduces the ecological footprint.

Q3: How can industries reduce the environmental footprint of oil-fired boilers?

A3: To reduce environmental impact, industries can adopt several strategies:

Switch to low-sulfur fuel oil or bio-based oils to cut SO₂ and CO₂ emissions.

Install flue gas desulfurization (FGD) and Selective Catalytic Reduction (SCR) systems for cleaner exhaust.

Upgrade to condensing boiler models that recover waste heat from exhaust gases.

Implement smart combustion controls for optimized air-fuel ratios.

Conduct regular maintenance to prevent soot buildup and ensure efficient combustion.

These practices not only enhance eco-friendliness but also lower operational costs and extend boiler life.

Q4: How do modern oil-fired boilers compare to gas or biomass boilers in terms of sustainability?

A4: Modern oil-fired boilers are less sustainable than gas or biomass units, but they remain viable in regions where gas infrastructure is unavailable. Gas-fired boilers emit lower CO₂ and virtually no SO₂, while biomass boilers can be carbon-neutral when sourced sustainably. However, high-efficiency oil boilers equipped with emission reduction technologies can still meet strict environmental standards. They offer a balance between performance, fuel availability, and compliance in industrial settings that rely on heavy or distillate fuels.

Q5: What regulations govern emissions from industrial oil-fired boilers?

A5: Industrial oil-fired boilers are subject to strict environmental regulations globally. In the U.S., the EPA’s Clean Air Act enforces emission limits on NOₓ, SO₂, CO₂, and particulates. The European Union’s Industrial Emissions Directive (IED) sets similar standards, requiring periodic emission testing and reporting. Many countries also mandate Continuous Emission Monitoring Systems (CEMS) and energy efficiency certifications to ensure compliance. These regulatory frameworks encourage manufacturers to design cleaner, more efficient systems and promote sustainable industrial practices.

References

EPA Industrial Boilers and Process Heaters Regulations – https://www.epa.gov/boilers – U.S. Environmental Protection Agency

EU Industrial Emissions Directive (IED) – https://environment.ec.europa.eu/ – European Commission

ASME Boiler and Pressure Vessel Code (BPVC) – https://www.asme.org/ – ASME

Carbon Trust – Energy Efficiency in Boilers – https://www.carbontrust.com/ – Carbon Trust

International Energy Agency – Clean Heating Technologies – https://www.iea.org/ – IEA

ISO 50001 Energy Management Systems – https://www.iso.org/iso-50001-energy.html – ISO

NOx and SOx Emission Reduction Techniques – https://www.energy.gov/ – U.S. Department of Energy

Condensing Boiler Efficiency Studies – https://www.engineeringtoolbox.com/ – Engineering Toolbox

Global Industrial Boiler Market Analysis – https://www.marketsandmarkets.com/ – Markets and Markets

Clean Combustion and Emission Control Technologies – https://www.sciencedirect.com/ – ScienceDirect