Investing in a power plant boiler is a high-capital, long-term decision that influences energy production efficiency, environmental compliance, and operational cost for decades. However, boiler prices vary widely depending on type, capacity, pressure, fuel, and technology. Without a clear understanding of the cost range across boiler categories, project developers risk underbudgeting or overpaying for inappropriate solutions.

The cost range of different types of power plant boilers is broad: Pulverized Coal (PC) boilers typically cost $500–$1,200 per kW, Circulating Fluidized Bed (CFB) boilers range from $600–$1,300 per kW, Waste Heat Recovery Boilers (WHRB) from $300–$800 per kW, Biomass-fired boilers from $700–$1,500 per kW, and Gas-fired Combined Cycle boilers from $400–$900 per kW. Total plant size, pressure level, fuel type, emissions technology, and site-specific factors can greatly influence these costs.

Understanding the price structure by boiler type helps plant designers and investors align capital budgeting with performance goals. Let’s examine the detailed cost breakdowns and considerations for each type.

What Is the Cost Range of Pulverized Coal (PC) Boilers, and What Influences Their Pricing?

Pulverized coal (PC) boilers remain a mainstay in high-capacity thermal power generation across many industrial sectors and utilities. However, due to their scale, engineering complexity, and emissions compliance requirements, these systems represent one of the highest capital expenditures in boiler technology. Plant owners and procurement managers often ask: what is the true cost of a PC boiler, and why does it vary so widely between projects? Without a clear understanding of pricing ranges and cost influencers, it’s easy to either overspend or under-budget—both of which can derail project timelines and ROI.

The cost range of pulverized coal (PC) boilers typically falls between $600 and $1,500 per kilowatt (kW) of installed capacity, depending on configuration, emissions controls, fuel type, and site-specific factors. For a medium to large-scale unit (100–600 MW), this translates to a total installed cost of $60 million to over $900 million. Key cost drivers include boiler pressure rating, combustion system design, emissions control requirements, auxiliary equipment, and regional labor/material costs.

This wide range reflects not just the mechanical equipment, but also the scope of systems integration, environmental compliance packages, and the unique demands of the installation site. Understanding these cost influencers allows operators to align technical needs with budgetary realities.

All PC boilers cost roughly the same per megawatt of capacity.False

PC boiler pricing varies significantly based on pressure rating, emissions systems, fuel quality, and site-specific factors.

Typical Cost Range by Capacity Class

Let’s break down the installed capital cost of PC boilers based on their size and operational classification:

| Boiler Capacity (MW) | Cost Range per kW (USD) | Total Cost Estimate (USD) | Notes |

|---|---|---|---|

| 50–100 MW | $1,000–$1,400 | $50M–$140M | Higher unit cost due to scale |

| 100–300 MW | $850–$1,200 | $85M–$360M | Standard industrial range |

| 300–600 MW | $700–$1,000 | $210M–$600M | Economies of scale apply |

| 600–1000 MW+ | $600–$900 | $360M–$900M+ | Ultra-supercritical class units |

Key Definitions:

Subcritical Boilers: Lower pressure (<22 MPa), less efficient, lower capital cost

Supercritical Boilers: Higher pressure (>22 MPa), better efficiency, higher cost

Ultra-Supercritical: Highest pressure/temperature, premium efficiency, highest initial cost

The choice of boiler pressure rating significantly influences long-term fuel cost savings, so while ultra-supercritical designs may cost more upfront, they often deliver better lifecycle economics.

Key Factors That Influence PC Boiler Pricing

1. Pressure and Temperature Ratings

Higher pressure and temperature boilers require stronger materials, tighter tolerances, and advanced welding.

Supercritical and ultra-supercritical designs increase initial cost but reduce fuel consumption per MWh.

| Boiler Type | Steam Pressure (MPa) | Efficiency (%) | Relative Cost Increase |

|---|---|---|---|

| Subcritical | 16–18 | 36–38% | Base cost |

| Supercritical | 22–25 | 40–42% | +10–20% |

| Ultra-supercritical | >25 | 43–46% | +20–35% |

Ultra-supercritical PC boilers are more expensive to operate than subcritical ones.False

Despite higher initial cost, ultra-supercritical boilers offer higher efficiency and lower fuel costs over time.

2. Emissions Control Systems

Modern PC boilers must comply with increasingly strict air pollution standards. The cost of environmental equipment can represent 20%–35% of the total boiler cost.

| Emissions Control | Equipment Included | Cost Impact (USD/MW) | Mandatory? |

|---|---|---|---|

| SOx Control | Wet FGD system | $50k–$120k/MW | Yes (most regions) |

| NOx Control | Low-NOx burners, OFA, SCR systems | $30k–$80k/MW | Yes |

| PM Control | ESP or Baghouse | $25k–$60k/MW | Yes |

| Mercury Control | ACI injection, PAC systems | $10k–$30k/MW | Region-dependent |

| CO₂ Capture (CCUS) | Amine scrubbers or oxy-firing | $100k–$400k/MW | Optional/emerging |

In particular, carbon capture requirements can double the cost of a new plant, though subsidies and ESG incentives may offset this.

3. Auxiliary Equipment and Balance of Plant (BoP)

Beyond the boiler itself, a PC boiler plant includes:

Pulverizers (coal mills)

Forced and induced draft fans

Air preheaters

Economizers

Feedwater heaters

Water treatment systems

Ash handling and storage systems

The scope and quality of these systems influence total cost. For example, high-efficiency regenerative air preheaters or automated ash removal systems increase upfront investment but reduce long-term O&M costs.

| Auxiliary System | Cost Range (USD/MW) | Notes |

|---|---|---|

| Pulverizers & Feeders | $10k–$30k | Influenced by coal grindability |

| ID/FD Fans | $15k–$40k | Larger for high-pressure units |

| Water Treatment | $8k–$20k | Depends on feedwater source |

| Ash Handling | $10k–$25k | Dry systems cost more, reduce emissions |

4. Fuel Quality and Ash Content

Boilers designed for low-grade coal (high ash, moisture, sulfur) require:

Larger combustion zones

Enhanced slagging and fouling control

More robust material selection (tubes, shields)

This can add 10–20% to base equipment costs, and significantly more in O&M.

Boilers designed for low-grade coal cost less than those for high-grade coal.False

Low-grade coal requires larger, more complex systems to manage slagging, corrosion, and combustion inefficiency.

5. Location-Specific Factors

Labor Rates: Installation cost varies dramatically by region (e.g., $25/hr vs $150/hr)

Material Sourcing: Local steel availability, transport logistics

Regulatory Compliance: Local codes, permitting delays, inspection costs

Grid Integration: Cost of connecting to power infrastructure

For instance, the same 300 MW PC boiler may cost:

$240M in Southeast Asia (lower labor/material cost)

$390M in Western Europe or U.S. (higher compliance and labor cost)

Cost Comparison: PC Boilers vs Other Technologies (Installed)

| Technology | Cost per kW (USD) | Notes |

|---|---|---|

| PC Boiler (Subcritical) | $850–$1,200 | High emissions unless upgraded |

| PC Boiler (USC) | $1,000–$1,500 | High efficiency, best for base-load |

| CFB Boiler | $1,000–$1,400 | Fuel-flexible, lower NOx by design |

| Biomass Boiler | $1,500–$2,200 | High ash handling cost |

| Gas Turbine (CCGT) | $600–$1,000 | Lower capex, but dependent on gas |

| Nuclear (PWR/BWR) | $5,000–$8,000 | Longest payback, very high capex |

Lifecycle Cost Perspective

Even if PC boilers have high capital costs, their long operating life (30–40+ years) and low fuel cost (coal) can make them more economical than other technologies—but only at scale and with proper emissions mitigation.

| Cost Element | PC Boiler (40-year life) | Notes |

|---|---|---|

| Fuel Cost | Low | Especially with domestic coal |

| O&M Cost | Medium | Higher than gas, lower than biomass |

| Retrofit Risk | High | Older units may face high costs |

| Carbon Risk | High | Subject to carbon tax and ESG rules |

| ROI | 6–10 years | Depends on load factor and policy |

The cost of a pulverized coal boiler varies widely, but understanding its drivers—especially emissions control, pressure rating, fuel quality, and site logistics—is essential to project success. Whether you’re planning a new installation or evaluating a replacement, aligning technical specifications with budget constraints will help you make a financially sound, future-proof investment.

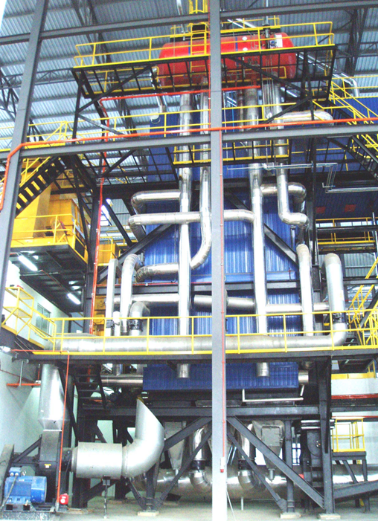

How Much Do Circulating Fluidized Bed (CFB) Boilers Cost, and What Justifies Their Investment?

Circulating Fluidized Bed (CFB) boilers are increasingly favored across power generation and industrial steam sectors for their unmatched fuel flexibility, low NOx and SOx emissions, and high combustion efficiency. However, potential buyers often ask: how much do these systems cost, and more importantly, are they worth the investment? Unlike conventional pulverized coal (PC) boilers, CFB systems require higher capital expenditure upfront—but their total cost of ownership and environmental compliance advantages often deliver superior long-term returns. Understanding what you’re paying for—and why—is essential to making a smart, strategic procurement decision.

The cost of Circulating Fluidized Bed (CFB) boilers generally ranges between $1,000 and $1,500 per kilowatt (kW) of installed capacity. For medium to large industrial applications (50–300 MW), this equates to total installed costs of $50 million to over $450 million. Despite higher initial investment compared to some alternatives, CFB boilers justify their cost through lower emissions control requirements, broad fuel compatibility, reduced O&M costs, and regulatory resilience.

CFB boilers are not just thermal assets—they are strategic infrastructure built for evolving fuel markets and tightening emissions legislation. Their value extends far beyond initial pricing when viewed from a lifecycle and sustainability perspective.

CFB boilers are only suitable for coal and cannot burn alternative fuels.False

CFB boilers are specifically designed for fuel flexibility and can burn a wide range of low-grade and alternative fuels including biomass, petcoke, and municipal solid waste.

Typical Cost Range by Capacity

| Boiler Capacity (MW) | Cost Range per kW (USD) | Total Installed Cost Estimate (USD) |

|---|---|---|

| 30–50 MW | $1,300–$1,600 | $39M–$80M |

| 100–150 MW | $1,100–$1,400 | $110M–$210M |

| 200–300 MW | $1,000–$1,300 | $200M–$390M |

| 300+ MW | $900–$1,100 | $270M–$450M+ |

These figures cover engineering, procurement, construction (EPC), auxiliary equipment, fuel handling systems, and emissions controls. However, real-world pricing may vary due to regional labor, raw material volatility, and the sophistication of emissions technologies included.

What Drives the Cost of CFB Boilers?

1. Fuel Flexibility Engineering

CFB boilers are custom-designed to burn:

Coal (bituminous, sub-bituminous, lignite)

Biomass (wood chips, agricultural waste)

Petcoke

Waste-derived fuels (RDF, MSW)

Mixed or alternative fuels

This adaptability requires:

Special refractory-lined furnaces

Advanced bed material handling

Sophisticated air distribution grids

Multiple fuel feed points

These systems cost more to build—but they protect plant economics from volatile global fuel prices and future carbon regulation.

Fuel-flexible boilers are always cheaper than fuel-specific boilers.False

Fuel-flexible systems like CFB boilers involve more complex engineering and material selection, leading to higher upfront costs.

2. Low Emissions Without Complex Retrofits

CFB boilers naturally limit NOx formation due to their lower combustion temperature (~850°C), and SO₂ can be captured in-furnace by adding limestone. This eliminates or reduces the need for:

Selective Catalytic Reduction (SCR)

Flue Gas Desulfurization (FGD)

Expensive ESP/baghouse upgrades

| Emissions Control Technology | PC Boiler (USD/MW) | CFB Boiler (USD/MW) | Savings (%) |

|---|---|---|---|

| SCR (NOx control) | $50,000–$80,000 | $10,000–$30,000 | 60–80% |

| Wet FGD (SO₂ control) | $80,000–$120,000 | $0–$40,000 (if needed) | Up to 100% |

| Baghouse/ESP | $25,000–$60,000 | $25,000–$40,000 | — |

These built-in advantages reduce compliance costs by millions of dollars over the boiler’s 30-year life.

3. Component Complexity and Material Requirements

CFB boilers operate under constant particle circulation and high turbulence, which demands:

Abrasion-resistant tubing

High-performance refractory

Robust cyclone separators

Advanced fluidization control

The design and material demands are higher than PC or biomass boilers, which partly explains the higher per-kilowatt cost.

4. Auxiliary Systems and Controls

Included in most installations:

Bed material management (silos, classifiers)

Fuel feeding systems (multiple feed ports)

Air distribution and fans

Emissions monitoring (CEMS)

DCS or PLC-based advanced control logic

More sophisticated controls improve efficiency and maintenance but add upfront cost.

CFB Boiler Cost vs. Other Technologies (Installed)

| Boiler Type | Cost per kW (USD) | Fuel Flexibility | Emissions Control Cost | Typical ROI (years) |

|---|---|---|---|---|

| CFB Boiler | $1,000–$1,500 | High | Low | 4–8 |

| Pulverized Coal (PC) | $800–$1,200 | Low | High | 6–10 |

| Gas-Fired (CCGT) | $600–$1,000 | Very Low | Low | 3–5 |

| Biomass Stoker | $1,400–$2,000 | Medium | Medium | 7–12 |

CFB boilers strike a balance between versatility and efficiency, and while not the cheapest, they are most resilient against future regulation and fuel market changes.

What Justifies Investing in a CFB Boiler?

✅ Fuel Cost Savings

By burning petcoke, waste coal, or biomass, plants can avoid high coal or gas costs. Over 20+ years, this can yield tens of millions in savings.

✅ Regulatory Compliance

Built-in SOx and NOx control reduces or eliminates retrofitting needs as environmental standards tighten globally. Plants avoid costly FGD/SCR upgrades.

✅ Long-Term Operational Stability

CFB boilers offer:

Lower fouling/slagging risk

Stable load handling

Reduced corrosion with fuel blending

Predictable maintenance cycles

This reduces downtime and emergency repair costs over decades.

✅ Low Emissions for ESG and Carbon Credits

Modern CFBs achieve:

NOx: <100 mg/Nm³

SO₂: <50 mg/Nm³ (with in-furnace sorbents)

PM: <20 mg/Nm³ (with baghouse)

These support green financing, emissions credits, and ESG reporting initiatives.

✅ Future-Proofing with Biomass Co-Firing

Many countries now mandate biomass co-firing in coal plants. CFB systems can easily integrate up to 50% biomass—compared to <10% in PC boilers.

CFB boilers require major modifications to co-fire with biomass.False

CFB boilers are specifically designed to handle mixed fuels, including high levels of biomass, with minimal modification.

Real Project Example: 150 MW CFB Boiler (Southeast Asia)

Application: Cement plant cogeneration

Fuels: 60% lignite, 30% rice husk, 10% petcoke

Installed Cost: $180 million

ROI: Achieved in 5.2 years

Emissions: NOx 85 mg/Nm³, SO₂ 35 mg/Nm³

Savings: $12M/year in fuel + $3M/year in avoided emissions penalties

The plant reports >92% availability and stable performance since commissioning in 2019.

The cost of a CFB boiler is undoubtedly higher than that of conventional systems—but the value is in its fuel flexibility, compliance-readiness, long-term efficiency, and low environmental impact. For operators facing uncertain fuel markets, rising emissions pressure, or aging coal infrastructure, CFB technology is a smart, future-focused investment that pays off across decades of operation.

What Is the Typical Cost of Biomass-Fired Power Plant Boilers, and How Do Fuel Logistics Affect Pricing?

Biomass-fired power plant boilers offer a renewable solution to the world’s energy and environmental challenges, particularly for industries and utilities aiming to reduce carbon footprints or comply with green energy mandates. However, biomass boilers come with significant capital costs, and their long-term viability depends not only on the equipment itself but heavily on fuel supply chains and logistics. Plant developers often ask: how much does a biomass boiler power system cost, and how do fuel handling and sourcing affect the final price? These questions are essential to ensuring the financial and operational success of biomass energy projects.

The typical cost of biomass-fired power plant boilers ranges from $1,400 to $2,800 per kilowatt (kW) of installed capacity. For utility-scale systems (10–100 MW), this translates to total installed costs of $20 million to $280 million. Fuel logistics—including sourcing, transportation, storage, moisture content, and regional biomass availability—can increase the overall cost by 20–40%, making them a critical factor in pricing and project feasibility.

Biomass is abundant—but not always local, uniform, or easy to handle. Unlike coal or gas plants, where fuel logistics are standardized, biomass supply chains are highly variable. Poor planning in this area can turn an otherwise efficient plant into a cost burden.

Fuel logistics have minimal impact on the cost of biomass-fired power plants.False

Fuel logistics significantly impact cost due to transport, moisture, handling equipment, and seasonal biomass availability.

Biomass Boiler Capital Cost Range by Capacity

| Power Output (MW) | Cost per kW (USD) | Estimated Total Installed Cost (USD) |

|---|---|---|

| 5–10 MW | $1,800–$2,800 | $9M–$28M |

| 10–30 MW | $1,600–$2,400 | $16M–$72M |

| 30–50 MW | $1,400–$2,000 | $42M–$100M |

| 50–100 MW | $1,300–$1,800 | $65M–$180M |

These costs include:

Boiler and combustion system

Fuel handling systems (conveyors, silos)

Steam turbine and generator

Flue gas treatment

Ash handling

Instrumentation and control

Civil and structural work

Note that small-scale biomass plants (under 10 MW) have higher per-kW costs due to reduced economies of scale.

Why Biomass Boilers Cost More Than Coal or Gas

| Boiler Type | Installed Cost per kW (USD) | Notes |

|---|---|---|

| Biomass Stoker | $1,400–$2,800 | Includes complex fuel and ash systems |

| Biomass CFB | $1,600–$2,200 | High fuel flexibility, lower emissions |

| Pulverized Coal | $800–$1,200 | Standard design, lower handling complexity |

| Gas Turbine (CCGT) | $600–$1,000 | Least capital-intensive, highest emissions |

Biomass systems require:

Larger fuel storage

Advanced feeding systems for irregular particle sizes

Moisture control systems (dryers)

More frequent ash removal

Corrosion-resistant materials due to high alkali content

All of which raise material, labor, and commissioning costs.

How Fuel Logistics Influence Total Project Cost

1. Fuel Sourcing and Availability

Biomass is regionally concentrated. Transporting wood chips or agricultural waste more than 100–150 km increases cost rapidly. Key variables:

Fuel type: wood chips, pellets, bagasse, straw, RDF

Seasonal availability: agricultural waste is not year-round

Competing users: pulp, paper, or bioethanol industries

| Fuel Type | Energy Density (kcal/kg) | Transport Cost Impact | Handling Difficulty |

|---|---|---|---|

| Wood Chips | 3,000–4,000 | Moderate | Low |

| Straw | 2,500–3,000 | High (bulky) | High (dust, fire) |

| Sawdust | 3,500–4,200 | Moderate | Moderate |

| RDF | 2,800–4,000 | Variable (waste laws) | High (emissions) |

In some regions, biomass fuel can cost as much as $70–$100 per ton if transportation and preprocessing are needed.

2. Fuel Preprocessing Requirements

Biomass is rarely “boiler-ready.” It must often be:

Sized (chipped, shredded)

Dried to <20% moisture

Blended with other materials

De-metallized (RDF, MSW fuels)

Preprocessing can add $15–$30/ton, and drying alone can consume up to 15% of the plant’s output in energy.

Raw biomass can always be fed directly into power plant boilers.False

Most biomass types require preprocessing such as drying, sizing, and contaminant removal before combustion.

3. Fuel Handling and Storage Infrastructure

Biomass fuel handling systems are more extensive than coal:

Covered conveyor systems (to avoid moisture)

Fire and dust explosion prevention

Live bottom silos

Automated stacking/reclaiming

These systems can account for 15–25% of boiler island costs.

| Component | Cost per MW (USD) | Notes |

|---|---|---|

| Fuel Storage & Silos | $20k–$50k | Climate-dependent design |

| Conveying System | $25k–$60k | Must handle irregular feedstock |

| Drying System | $50k–$100k | Needed for wet biomass (>30% moisture) |

4. Moisture and Energy Efficiency Penalty

Higher moisture means:

Lower calorific value

Higher flue gas volume

Increased fan power and corrosion risk

Moist biomass (30–50%) reduces boiler efficiency by 5–12%, forcing larger combustion chambers, bigger fans, and more emissions treatment—all increasing capital and O&M cost.

Real-World Case Example: 30 MW Biomass Plant (Eastern Europe)

Fuel: 70% wood chips, 30% straw

Moisture: Avg. 35%

Installed Cost: $2,100/kW × 30,000 kW = $63 million

Fuel Handling/Prep Cost: $12 million (19% of total)

Transport Radius: 80 km average, 120 trucks/day

Efficiency: 32% net

ROI: 7.5 years (supported by carbon credits + subsidies)

The plant faced initial cost overruns due to underestimated drying and logistics complexity, but achieved strong long-term stability due to low regional fuel cost and government-backed green tariffs.

How to Manage Biomass Boiler Costs Effectively

✅ Conduct a full fuel supply chain audit

Secure year-round contracts with local sources. Diversify by using multi-fuel capability (CFB systems).✅ Invest in moisture control

On-site drying or fuel selection dramatically affects combustion efficiency.✅ Use automation for fuel handling

Modern SCADA systems and fire safety integration reduce labor and incident risk.✅ Design for fuel variability

Stoker systems or CFB boilers are more tolerant than fixed-grate systems.✅ Plan for byproducts

Ash disposal, heat recovery, and carbon credit generation should be included in feasibility.

Biomass-fired power plant boilers are more complex and expensive than fossil fuel systems, but they unlock access to renewable energy portfolios, carbon reduction incentives, and regional biomass markets. Fuel logistics—often underestimated—can define the success or failure of a project, affecting both initial CAPEX and long-term OPEX. With the right planning and technology selection, however, biomass boilers can offer a clean, reliable, and cost-competitive energy solution for decades to come.

How Do Gas-Fired Combined Cycle Boilers Compare in Terms of Capital Cost and Efficiency?

Gas-fired combined cycle (CC) power plants are widely recognized as the benchmark for thermal efficiency and moderate capital costs in today’s power generation market. Integrating gas turbines with heat recovery steam generators (HRSGs) and steam turbines, these plants maximize energy extraction from the fuel source—typically natural gas or LNG. But how do they compare financially and operationally to other systems like coal, CFB, or biomass-fired boilers? Investors and plant developers frequently weigh their capital costs versus efficiency payback, especially as decarbonization efforts push for lower emissions and better economics.

Gas-fired combined cycle (CC) plants typically cost between $600 and $1,200 per kilowatt (kW) of installed capacity, making them among the most cost-effective fossil-based power generation technologies. Their thermal efficiency ranges from 55% to 63% (net), significantly higher than coal or biomass systems. This combination of moderate CAPEX and high efficiency makes them especially attractive in regions with stable natural gas supplies and low carbon taxes.

In essence, gas-fired combined cycle plants provide the lowest capital cost per megawatt-hour of output among thermal systems, while also offering environmental and operational advantages—provided fuel supply economics are favorable.

Combined cycle power plants are less efficient than coal-fired plants.False

Combined cycle plants are significantly more efficient than coal-fired plants, reaching thermal efficiencies over 60%, compared to 35–42% for typical coal systems.

Capital Cost Comparison: Combined Cycle vs. Other Boiler Systems

| Power Technology | Capital Cost (USD/kW) | Total Cost for 500 MW Plant (USD) | Thermal Efficiency (Net) |

|---|---|---|---|

| Gas-fired Combined Cycle | $600–$1,200 | $300M–$600M | 55%–63% |

| Pulverized Coal (PC) | $800–$1,200 | $400M–$600M | 36%–42% |

| Circulating Fluidized Bed (CFB) | $1,000–$1,400 | $500M–$700M | 37%–42% |

| Biomass Boiler | $1,400–$2,200 | $700M–$1.1B | 28%–34% |

| Nuclear | $5,000–$8,000 | $2.5B–$4B | 33%–37% |

Combined cycle systems offer the lowest cost per unit of energy output among major thermal systems, which is why they dominate new-build thermal capacity in countries with reliable gas infrastructure.

Understanding the Combined Cycle Configuration

Gas-fired CC plants consist of:

Gas Turbine: Burns natural gas to generate electricity and hot exhaust gases (500–600°C)

Heat Recovery Steam Generator (HRSG): Captures heat from exhaust to generate steam

Steam Turbine: Uses the steam to produce additional electricity

This dual-generation model dramatically boosts efficiency without burning extra fuel.

| Component | Contribution to Power Output (%) |

|---|---|

| Gas Turbine | 60–65% |

| Steam Turbine | 35–40% |

By capturing and utilizing waste heat, CC systems reduce fuel consumption per MWh by up to 40% compared to open-cycle gas or coal systems.

Efficiency Advantage: Fuel to Power

| System Type | Fuel-to-Electricity Efficiency (Net) | Notes |

|---|---|---|

| Gas Combined Cycle (2020s) | 58%–63% | Latest GTCC with advanced HRSGs |

| Supercritical Coal (USC) | 40%–42% | High-grade coal, strict control systems |

| CFB Boiler (Modern) | 38%–41% | Fuel-flexible, medium combustion temp |

| Biomass Boiler | 28%–34% | Limited by moisture, low calorific value |

| Simple Cycle Gas Turbine | 35%–39% | No heat recovery, used for peaking loads |

Higher efficiency means less fuel, fewer emissions, and lower operating costs—an especially critical advantage in regions with volatile or taxed fuel markets.

Combined cycle plants waste large amounts of energy as heat.False

Combined cycle plants are designed to recover and utilize waste heat, making them one of the most efficient power generation technologies available.

Key Factors Influencing Cost of Gas-Fired Combined Cycle Plants

1. Turbine Technology Class

F-Class (older): ~56% efficiency, lower cost

H/J-Class (latest): Up to 63% efficiency, higher cost

| Turbine Class | Cost per kW (USD) | Net Efficiency (%) |

|---|---|---|

| F-Class | $600–$900 | 55%–58% |

| H-Class | $900–$1,200 | 60%–63% |

2. Cooling System

Air-cooled condensers: Higher cost, lower efficiency in hot climates

Water-cooled systems: Lower cost, higher efficiency, but need water access

3. HRSG Complexity

Single-pressure HRSG: Cheaper, ~52% overall plant efficiency

Triple-pressure + reheat: Higher cost, boosts to 60–63%

4. Grid Integration and Peaking Flexibility

Plants designed for base-load operation are cheaper per kW, while peaking/load-following systems require:

Fast ramp-up HRSGs

Advanced DCS/SCADA systems

More turbine protection systems

This adds 10–15% to overall CAPEX but enhances revenue potential in modern power markets.

Emissions and Environmental Performance

Combined cycle plants emit:

50–70% less CO₂ per MWh than coal

Virtually zero SO₂

Low NOₓ, especially with DLN (Dry Low NOx) combustors or SCR

| Emission Type | CC Plant (g/MWh) | Coal Plant (g/MWh) |

|---|---|---|

| CO₂ | 350–450 | 800–1,100 |

| NOₓ | 25–50 | 200–500 |

| SO₂ | <1 | 800–2,000 |

This makes gas-fired combined cycle plants ideal for countries pursuing low-carbon targets without fully committing to renewables or nuclear.

Gas-fired combined cycle plants produce more greenhouse gas emissions than coal-fired plants.False

Combined cycle plants produce significantly lower CO₂ and other pollutants compared to coal-fired power plants.

O&M Cost Advantage

| Technology | O&M Cost (USD/MWh) | Notes |

|---|---|---|

| Combined Cycle | $10–$20 | Mostly preventive; low fuel prep |

| Coal | $20–$40 | Higher fuel handling and emissions |

| Biomass | $30–$50 | Complex logistics and ash disposal |

| Nuclear | $25–$35 | High staff and compliance costs |

The simplicity of fuel handling, lower ash content, and modern control systems reduce labor and maintenance intensity in CC plants.

Real-World Example: 500 MW Combined Cycle Plant (Europe)

Technology: H-Class GT + triple-pressure HRSG + water-cooled condenser

Installed Cost: ~$525 million

Efficiency: 61.2% net

Fuel: LNG

CO₂ Emissions: 370 g/kWh

Operational Flexibility: Ramps from 100 MW to 500 MW in 20 minutes

ROI Period: 6.2 years (factoring capacity payments and carbon pricing)

Gas-fired combined cycle boilers strike the optimal balance between capital efficiency, operational efficiency, and environmental performance. For regions with access to affordable gas and growing grid flexibility demands, they remain the most economically and technically viable fossil-based power solution. While they may face future decarbonization pressures, their low CAPEX and high output make them a strong strategic investment in the near to medium term.

What Are the Cost Characteristics of Waste Heat Recovery Boilers (WHRB) in Cogeneration and Process Industries?

Waste Heat Recovery Boilers (WHRBs) are key enablers of energy efficiency in cogeneration systems and process-intensive industries. Rather than letting valuable thermal energy escape as exhaust, WHRBs capture and convert it into usable steam or power. While the technology is not new, its adoption has grown rapidly due to rising energy costs and sustainability goals. A common question from plant managers and procurement engineers is: how much does a WHRB system cost, and what are the factors that influence pricing across different applications? Unlike standard boilers, WHRBs are deeply influenced by process integration, temperature profiles, and custom engineering, which make their cost structure unique.

The cost of Waste Heat Recovery Boilers (WHRBs) in cogeneration and process industries typically ranges between $300 and $900 per kilowatt (kW) of recovered thermal energy, or $1 million to $20 million for industrial-scale systems. Pricing depends heavily on the heat source temperature, gas composition, boiler design (water-tube vs fire-tube), pressure rating, materials used, and site-specific engineering requirements. Despite higher customization costs, WHRBs offer attractive paybacks—often between 2 and 5 years—by reducing fuel consumption and emissions.

Because WHRBs are “built around the process,” they are often tailored to unique site conditions and existing plant layouts. Understanding these variables is critical when budgeting for and evaluating the return on investment of a WHRB system.

Waste Heat Recovery Boilers are off-the-shelf systems with fixed pricing.False

WHRBs are highly customized based on the heat source, pressure/temperature requirements, and integration with the plant’s existing processes, leading to a wide range of costs.

Typical Cost Range by Industry and Scale

| Application/Industry | Capacity Range (Ton/hr or MWth) | Cost Range (USD/kWth) | Total System Cost (USD) |

|---|---|---|---|

| Cement Kiln (Clinker Cooler) | 15–75 TPH | $400–$700 | $2M–$10M+ |

| Steel Reheating Furnace | 10–50 TPH | $500–$850 | $3M–$12M |

| Gas Turbine WHRB (CCPP) | 50–500 TPH | $350–$650 | $4M–$20M+ |

| Glass or Ceramics Industry | 5–20 TPH | $450–$800 | $1.5M–$6M |

| Petrochemical Refineries | 20–200 TPH | $400–$900 | $5M–$18M |

Note: TPH = tons per hour of steam

MWth = Megawatts thermal (heat energy output capacity)

Key Factors Influencing WHRB Costs

1. Heat Source Temperature and Flow Rate

The higher the temperature and mass flow of the exhaust gas, the more energy can be recovered—and the more robust the boiler must be.

| Heat Source | Exhaust Temp (°C) | Impact on Cost and Design |

|---|---|---|

| Diesel Engine Exhaust | 300–450 | Moderate pressure/size |

| Gas Turbine Exhaust | 500–600 | Requires large HRSG-type units |

| Kiln/Smelter Flue Gas | 800–1000 | Needs high-grade alloys and refractory |

| Steel Furnace Exhaust | 1000–1200 | Custom designs, erosion control needed |

High-temperature sources require premium materials (e.g., Inconel, stainless steel), additional expansion joints, and air or water cooling systems, increasing capital cost by up to 30%.

All WHRBs are built with the same materials, regardless of exhaust gas characteristics.False

Material selection depends heavily on exhaust gas temperature, corrosiveness, and composition, which vary by industry.

2. Boiler Configuration

Fire-Tube WHRB: Lower cost, suitable for <20 TPH steam

Water-Tube WHRB: Higher cost, standard for >20 TPH or high pressure

Single vs Multi-Pressure Systems: Multi-pressure units (used in combined cycles) cost more but improve heat utilization

| Configuration | Suitability | Cost Range (USD/kWth) |

|---|---|---|

| Fire-Tube | Low pressure (<15 bar) | $300–$450 |

| Water-Tube | Medium–High pressure (>30 bar) | $500–$900 |

| Triple Pressure (HRSG) | CCPP > 200 MW | $800–$1,200+ |

3. Steam Parameters and Output Requirements

Generating superheated, high-pressure steam increases both material and design costs:

Higher wall thickness (pressure vessels)

Special headers and drums

Higher-grade welding and NDT requirements

Cost Impact: +10% to +25% for superheated or high-pressure (60–90 bar) units.

Additional Cost Drivers

| Cost Driver | Description | Cost Impact |

|---|---|---|

| Flue Gas Treatment | Dust filtration, scrubbers, SOx/NOx control | +$100k–$1M+ |

| Feedwater Treatment | Deaerators, softeners, chemical dosing | +$200k–$2M |

| Ductwork and Bypass Dampers | Required for system control and protection | +5–10% of system |

| Instrumentation & Controls (PLC/DCS) | Essential for safe automation | +$100k–$500k |

| Civil & Structural Integration | Foundations, pipe racks, access platforms | +$200k–$3M |

| Custom Engineering & EPC Services | Tailored design, installation, commissioning | 15–30% of equipment |

Cost Comparison: WHRB vs Conventional Boilers

| Boiler Type | CAPEX per kWth (USD) | Fuel Source | OPEX Impact | ROI Potential |

|---|---|---|---|---|

| Conventional Steam Boiler | $300–$600 | Fossil fuel | High (fuel cost) | ROI: 7–12 years |

| Biomass Boiler | $1,400–$2,200 | Agricultural waste | Medium (fuel handling) | ROI: 8–15 years |

| Waste Heat Recovery Boiler | $300–$900 | Process exhaust | Low (no fuel cost) | ROI: 2–5 years |

While WHRBs may cost as much or more than conventional boilers per kW, they recover energy without added fuel consumption, making them much more cost-effective over time.

WHRBs cost more to operate than conventional boilers.False

WHRBs require minimal operating costs since they use existing waste heat instead of burning additional fuel.

WHRBs in Cogeneration and Combined Cycle Applications

WHRBs play a critical role in combined heat and power (CHP) and combined cycle power plants (CCPPs):

In CHP, WHRBs recover heat from turbines, engines, or furnaces to supply process steam and electricity, improving plant energy efficiency to 80–90%.

In CCPPs, WHRBs (HRSGs) turn gas turbine exhaust into high-pressure steam for the steam turbine—pushing overall plant efficiency to 55–63%.

This makes them key tools for emissions reduction and energy cost minimization, justifying higher capital outlays.

Real Case Study: WHRB in Cement Kiln Plant (India)

Process: 5-stage preheater cement kiln

Exhaust Gas Temp: 400–450°C

WHRB Output: 30 TPH steam at 45 bar

Power Output via Steam Turbine: 6.5 MW

System Cost: $4.8 million

Annual Savings: $1.2 million in fuel and electricity

Payback Period: ~4 years

By avoiding new boiler fuel costs and utilizing recovered steam for both electricity and drying, the system pays back quickly while also reducing emissions.

Waste Heat Recovery Boilers (WHRBs) are highly cost-effective tools for improving energy efficiency and reducing emissions in power-intensive industries. Though their capital costs vary widely—based on process, temperature, pressure, and integration complexity—they offer some of the fastest returns on investment in thermal energy systems. For industries already generating high-temperature exhaust, a WHRB is not just a boiler—it’s an energy monetization engine.

How Do Site-Specific Factors (Location, Emissions Control, Water Treatment) Influence Final Boiler Costs?

Boiler systems—whether for power generation, process heating, or cogeneration—are capital-intensive, complex, and deeply sensitive to site-specific variables. Many plant developers or procurement teams focus solely on boiler type and capacity when budgeting, but in reality, location, emissions requirements, water treatment needs, and local infrastructure can increase total project cost by 20% to 50% or more. These factors often define whether a project remains within budget, achieves emissions compliance, or meets ROI expectations. So, when planning a new boiler installation, how do site-specific conditions shape the final price tag?

Site-specific factors significantly influence the final cost of a boiler system through additional civil engineering needs, emissions compliance technologies, water treatment complexity, logistics, labor rates, fuel handling systems, and permitting. These localized conditions can increase the total installed cost of a boiler by 25%–60% beyond the base equipment price. Accurately accounting for these factors is critical for project feasibility and lifecycle planning.

No two boiler projects are exactly alike—even with identical equipment specifications. From air quality regulations to water availability, site-specific factors transform “catalog costs” into unique engineering challenges.

Boiler pricing is mostly standardized and not significantly affected by local site conditions.False

Site-specific factors such as emissions limits, terrain, water treatment, and permitting heavily influence final boiler costs.

Key Site-Specific Factors That Influence Boiler Cost

1. Geographic Location and Accessibility

| Factor | Influence on Cost |

|---|---|

| Terrain (mountains, swamps, unstable soil) | Requires customized foundations, piling, and site prep |

| Remote/Off-grid Areas | Increases logistics, material delivery, and on-site housing |

| Urban/Confined Sites | Adds cost for noise abatement, modularization, lifting cranes |

| Weather Conditions | Requires insulation, weatherproofing, or heating systems |

Example Impact: A standard 100 TPH boiler installation in a remote mountainous region can cost 30%–50% more due to transportation, weather delays, and foundation engineering.

2. Air Quality and Emissions Compliance Requirements

Every jurisdiction has specific emissions standards for:

NOx

SO₂

CO

Particulate matter (PM)

CO₂ (carbon tax or credits)

Stricter limits require additional capital investment in emissions control systems such as:

| Emission Control Equipment | Typical Cost Range (USD/MW) | Applicability |

|---|---|---|

| Selective Catalytic Reduction (SCR) | $50,000–$100,000 | NOx reduction |

| Wet Flue Gas Desulfurization (FGD) | $80,000–$150,000 | SO₂ control |

| Baghouse or Electrostatic Precipitator (ESP) | $30,000–$80,000 | PM removal |

| Activated Carbon Injection (ACI) | $10,000–$30,000 | Hg/trace metals |

| CO₂ Capture/Sequestration (CCUS) | $200,000–$400,000+ | Emerging, optional |

Location-Based Example:

| Region | SO₂ Limit (mg/Nm³) | Additional Equipment Required |

|---|---|---|

| EU | ≤150 | Wet FGD, sorbent injection |

| India | ≤100–600 (age-based) | FGD, limestone dosing |

| China (Ultra-low) | ≤35 | FGD + ultra-clean stack |

| U.S. (EPA MACT) | ~130 | SCR + Baghouse or ESP |

Boilers with high emissions can be operated anywhere without issue.False

Many regions enforce strict emissions limits, requiring additional control systems that increase boiler cost significantly.

3. Water Availability and Treatment Requirements

Water quality and availability at the site impact both:

Boiler performance and longevity

Capital cost for treatment and conditioning

Water Quality Parameters Affecting Cost:

Total Dissolved Solids (TDS)

Hardness

Silica

Iron, chloride, sulfates

Required Equipment (Depending on Source):

| Water Source | Likely Treatment Needs | Estimated Cost (USD) |

|---|---|---|

| River or Surface Water | Clarifiers, filters, RO system | $500k–$2M+ |

| Well Water | Softening, dealkalization | $300k–$1M |

| Municipal Treated | Minimal pre-treatment | <$250k |

| Seawater (Desalination) | RO + thermal demineralization | $2M–$5M+ |

Also consider cooling water requirements for condensers in power plants—sites with limited water may require air-cooled condensers (ACCs) which cost 3–4× more than water-cooled options.

Additional Cost-Influencing Site-Specific Factors

➤ Fuel Handling Infrastructure

| Fuel Type | Infrastructure Needs | Additional Cost Impact |

|---|---|---|

| Biomass | Storage silos, drying, conveyors | High |

| Coal | Crushers, stackers, feeders | Moderate to High |

| Natural Gas | Pipeline tie-in, pressure control | Low to Medium |

| RDF/Waste | Sorting, blending, emissions | High |

Remote sites without existing fuel delivery pipelines must budget for fuel yard development, which can cost $2M–$10M+ depending on complexity.

➤ Grid Connectivity (For Power Plants)

Switchgear, transmission lines, and substations can add $5M–$20M+

Permitting and local utility integration also increase lead time and cost

➤ Permitting, Environmental Impact Assessments, and Local Regulations

Delays and changes during environmental permitting processes can lead to:

Redesign of stack height and emissions control

Additional monitoring systems (CEMS)

Noise barriers or visual impact mitigation

This can add $500k to $5M+ in unforeseen capital outlays, especially in ecologically sensitive zones or urban areas.

Real-World Example: Biomass Boiler in Southeast Asia

Project: 40 MW biomass plant near coastal town

Base Boiler Cost: $65 million

Site-Specific Add-Ons:

Water treatment from brackish source: $2.4M

Seismic foundation design: $1.6M

FGD and Baghouse for air quality: $4.1M

Fuel yard and conveyors: $5.7M

Final Installed Cost: $78.8 million (~21% increase due to site-specific factors)

Conclusion: Even with affordable biomass fuel and good grid access, site conditions added over $13 million to the project.

Summary Table: Site-Specific Boiler Cost Influencers

| Factor Category | Potential Cost Impact (%) | Notes |

|---|---|---|

| Location/Accessibility | +10–30% | Remote or urban terrain |

| Emissions Compliance | +5–25% | Region-specific limits |

| Water Treatment | +5–20% | Depends on source |

| Fuel Handling Systems | +10–30% | Complex fuels = higher cost |

| Permitting & Regulation | +2–10% | Varies by region |

| Cooling Systems | +5–15% | Air-cooled costlier |

| Grid Integration | +5–15% | Especially for large IPPs |

Boiler projects are never “plug and play.” From emissions regulations to terrain and water supply, site-specific conditions reshape your budget, timelines, and even your equipment selection. Accurately anticipating these influences ensures not only cost control, but also smoother commissioning, regulatory compliance, and long-term plant efficiency. Always start your boiler planning with a thorough site feasibility and engineering audit to uncover and quantify these hidden cost drivers.

🔍 Conclusion

Choosing the right power plant boiler isn’t about finding the cheapest system—it’s about identifying the most cost-effective solution for your energy goals, fuel availability, and compliance requirements. A comprehensive cost analysis ensures you maximize ROI while meeting performance expectations.⚡🔥📈

FAQ

Q1: What is the cost of a coal-fired power plant boiler?

A1: Coal-fired power plant boilers are among the most capital-intensive systems due to their size, emissions control requirements, and fuel handling systems. Prices generally range from $2 million to $7 million for units in the 50–300 MW capacity range. Costs increase with high-pressure systems, integrated flue gas desulfurization (FGD), and NOx reduction technologies. Ongoing maintenance and environmental compliance also add significant lifetime costs.

Q2: How much does a gas-fired power plant boiler cost?

A2: Natural gas-fired boilers, especially in combined-cycle power plants, are typically more compact and less expensive than coal units. For capacities between 50 MW and 200 MW, costs range from $1 million to $5 million, depending on efficiency levels (simple cycle vs. combined cycle), emissions systems, and integration with turbines. They are often chosen for faster deployment and cleaner combustion.

Q3: What is the cost range for biomass power plant boilers?

A3: Biomass boilers cost more than gas but less than coal systems, depending on fuel type and combustion technology. For 10–100 MW capacities, biomass boiler systems range from $2 million to $6 million, including fuel feeding, ash handling, and emission controls. Technologies like fluidized bed combustion and feedstock variability can affect pricing. Incentives and renewable energy credits may offset initial costs.

Q4: How expensive are circulating fluidized bed (CFB) boilers?

A4: CFB boilers offer excellent fuel flexibility and are often used in coal, biomass, or waste-to-energy plants. Their cost ranges from $3 million to $10 million for 100–300 MW units. Although capital-intensive, CFB boilers provide long-term savings through lower emissions, fuel versatility, and high combustion efficiency. They are especially effective where multi-fuel use or emission compliance is a priority.

Q5: What additional costs are involved beyond the boiler unit price?

A5: The total cost of a power plant boiler project includes much more than just the boiler. Additional costs include installation, structural supports, piping, controls, water treatment, flue gas systems, auxiliary equipment, and commissioning, which can add 30–70% to the base boiler price. Factors such as site conditions, fuel storage systems, permitting, and grid integration further influence total investment.

References

Power Plant Boiler Cost Guide – https://www.energy.gov/eere/femp/boiler-systems-efficiency – U.S. Department of Energy

Coal-Fired Boiler Pricing – https://www.iea.org/reports/clean-coal-technologies – International Energy Agency

Gas Boiler Cost in Power Generation – https://www.eia.gov/todayinenergy/detail.php?id=42915 – U.S. Energy Information Administration

Biomass Boiler Cost Analysis – https://www.carbontrust.com/resources/biomass-heating-guide – Carbon Trust

CFB Boiler Technology Overview – https://www.babcock.com/home/products/boilers/cfb-boilers – Babcock & Wilcox

Boiler Installation & EPC Costs – https://www.powermag.com/estimating-power-plant-construction-costs/ – POWER Magazine

Boiler Types and Industrial Applications – https://www.sciencedirect.com/science/article/pii/S0360544215012330 – ScienceDirect

Combined Cycle Boiler Cost – https://www.ge.com/gas-power/resources/education/combined-cycle-power-plant – GE Power

Boiler Emissions Compliance Costs – https://www.epa.gov/stationary-sources-air-pollution – U.S. Environmental Protection Agency

Renewable Power Plant Economics – https://www.irena.org/publications – International Renewable Energy Agency (IRENA)