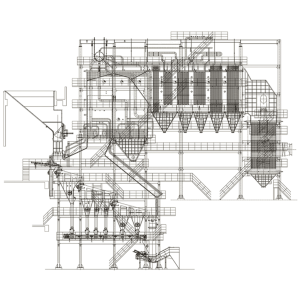

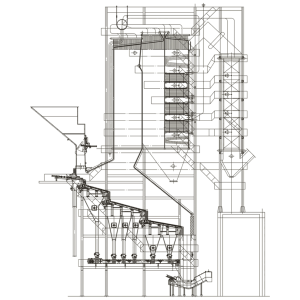

CFB Biomass Boiler

Waste heat boilers refer to boilers that utilize the waste heat generated during industrial production processes to produce steam or hot water. They are primarily used to cool high-temperature process gases and control the temperature of industrial process gases while simultaneously recovering the waste heat generated during the production process. They are widely applied in the waste heat recovery processes of industries such as petrochemical production, metallurgy, machinery, papermaking, building materials, etc.

Overview

Waste Heat Recovery Boiler (WHRB)

Waste heat recovery boiler (WHRB) is a type of boiler that captures and utilizes the heat produced as a byproduct of industrial processes or from other sources of waste heat, such as exhaust gases from gas turbines, diesel engines, incinerators, or other thermal equipment. Instead of allowing this heat to escape unused into the atmosphere, a WHRB recovers it and converts it into useful energy, typically in the form of steam or hot water.

Waste heat recovery boilers play a crucial role in energy conservation and sustainability efforts across various industries, including power generation, oil and gas, chemical processing, cement production, and manufacturing. They offer a cost-effective way to harness untapped energy resources and contribute to more sustainable industrial practices.

Standards & Certifications:

Types

Waste Heat Recovery Boiler (WHRB)

Waste heat recovery boiler (WHRB) is a type of boiler that captures and utilizes the heat produced as a byproduct of industrial processes or from other sources of waste heat, such as exhaust gases from gas turbines, diesel engines, incinerators, or other thermal equipment. Instead of allowing this heat to escape unused into the atmosphere, a WHRB recovers it and converts it into useful energy, typically in the form of steam or hot water.

Waste heat recovery boilers play a crucial role in energy conservation and sustainability efforts across various industries, including power generation, oil and gas, chemical processing, cement production, and manufacturing. They offer a cost-effective way to harness untapped energy resources and contribute to more sustainable industrial practices.

Vertical garbage

- Structure and Space Requirements: Vertical incinerators typically have a higher structure and occupy less ground space;

- Combustion Efficiency: Vertical incinerators, due to their gravity-assisted feeding systems, may offer better combustion efficiency in certain situations.

Horizontal Garbage Incinerators

- Structure and Space Requirements: Horizontal incinerators cover a larger area but are not as tall.

- Maintenance and Operation: Horizontal incinerators are generally easier to maintain and operate, especially when dealing with large volumes or less pre-treated waste.

Feature

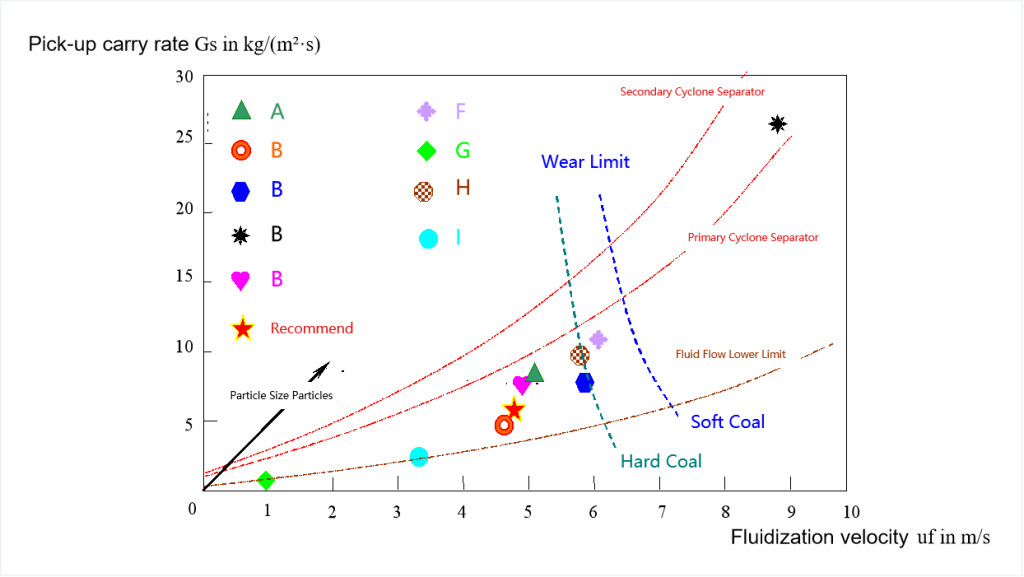

High heat efficiency reach 90-92%, load range in 30%-110%, 850-900℃ low burning temperature on bed inhibits NOx generation, good desulfurizing in furnace.

1. Wide Fuel Adaptability

2. Energy efficient

3. Environmental friendly

· Low SO₂ Pollutant Emission

· Capable of Burning Low-Quality Fuel

· Good Utilization Performance of Ash and Slag

4. Good Load Adjustment

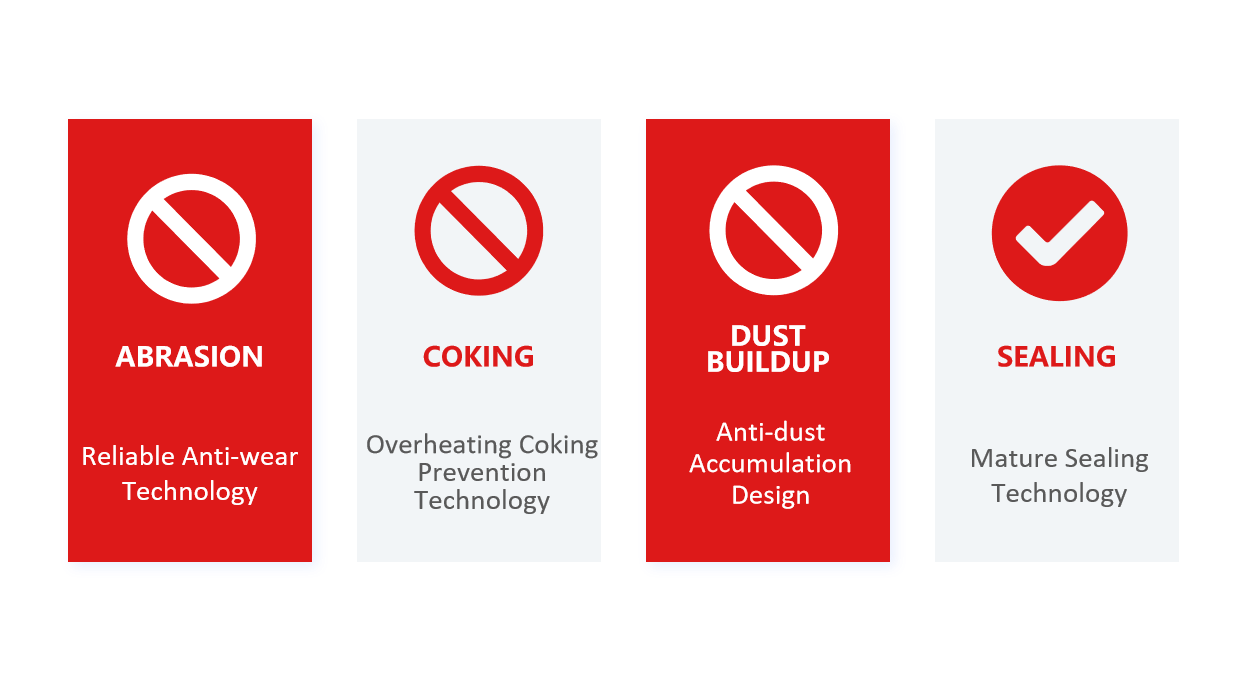

5. Safe & Reliable Operation

· Annual Operating Time >7500 Hours

· Continuous Operation Time >4500 Hours

· Annual Operating Time 3-4 years

Application

Power

Central Heating

Textile

Rubber & Tires

Paper industry

Food & Beverage

Palm Oil Mill

Steel Mill

Case & Customers

Why Choose Us?

Leading coal, biomass and waste to energy solution provider.

- Covering Entire Project Lifecycle A-Z Service.

- Ranked top in China's industrial boiler industry for 10 consecutive years.

- World first largest-capacity high-efficiency pulverized coal industrial boiler.

- China's first largest-capacity ultra-low nitrogen gas boiler.

- China largest-capacity pulverized coal boiler.

- China largest-capacity biomass power generation boiler.

- Independently developed and produced the world's first 110KV/10KV dual-circuit high-voltage direct-entry 40MV electric storage boiler.

10403+ Units

Boliers Experience

8035+ Satisfied

Global Customers

1000+ EPC

Services Experience

Since 1978

Company History

sales@coalbiomassboiler.com

Phone

Office. 0086-538-6619637

Office. 0086-538-6619632

Mob. +86-15265380805

+86-15265380805

+86 15265380805

Address

No. 1169 Beitianmen Street, High-tech Zone, Taian, Shandong, China