Upfront and Long-Term Costs of an Industrial Biomass Boiler

Upfront and Long-Term Costs of an Industrial Biomass Boiler

Industrial biomass boilers are increasingly adopted for their renewable fuel usage, carbon neutrality, and potential cost savings. However, investing in a biomass boiler involves more than just the equipment price. Without a full understanding of the upfront and long-term costs, companies may face budget overruns, unexpected operational expenses, or inefficient system performance. A well-informed investment requires analyzing both the capital expenditure and the total cost of ownership (TCO) over the boiler’s lifecycle.

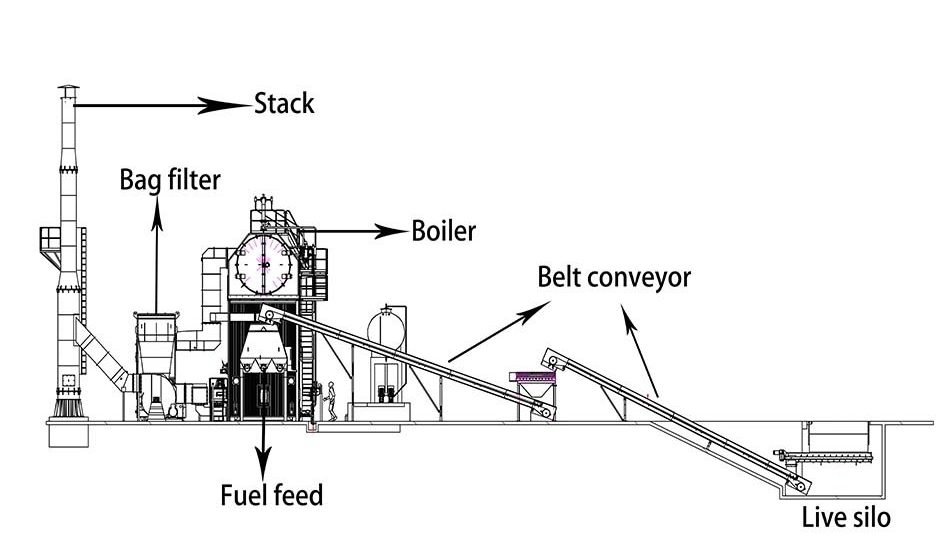

The upfront costs of an industrial biomass boiler include the equipment purchase, installation, site preparation, fuel storage and handling systems, emissions controls, and permitting. Long-term costs involve fuel sourcing and transportation, ash disposal, regular maintenance, equipment cleaning, emissions monitoring, and operator training. While fuel costs are often lower than fossil fuels, maintenance and logistics are typically higher. Over a lifespan of 15–25 years, a properly optimized biomass boiler can deliver competitive energy at a lower environmental cost—if lifecycle costs are carefully managed.

Here’s a breakdown of the key financial components to help you make a cost-effective investment.

-scaled-r3gfus8l0p2gl106z0ksl6rqq0kqjrbuwda948iv2c.jpg)

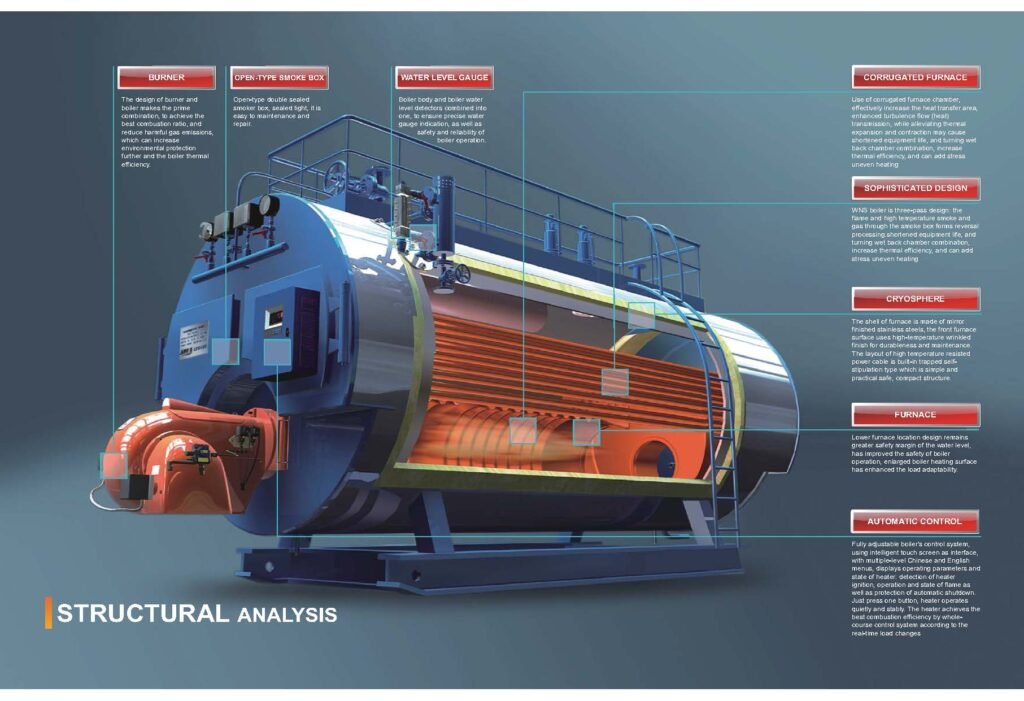

What Are the Typical Upfront Costs of Purchasing and Installing a Biomass Boiler?

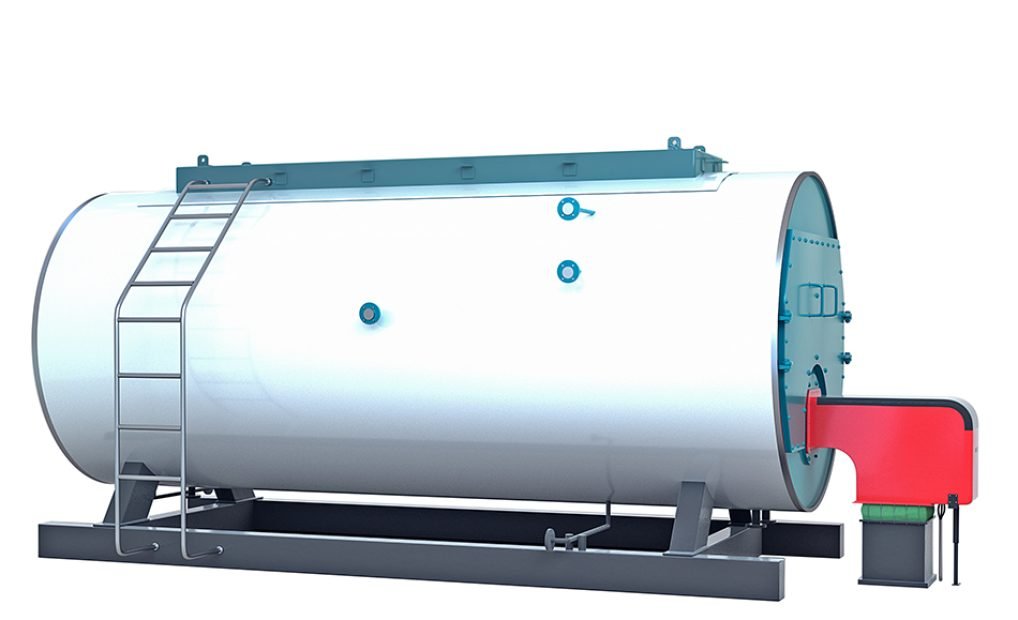

Biomass boilers are a popular choice for facilities seeking renewable heat or steam generation using wood chips, pellets, agricultural waste, or other organic materials. However, the transition to biomass involves more than just the boiler unit—it requires specialized fuel handling, combustion, ash disposal, emissions controls, and civil works. This makes the upfront cost higher than traditional fossil-fueled boilers. Understanding these capital costs helps businesses, industries, and institutions accurately plan energy investments and assess long-term feasibility.

The typical upfront cost of purchasing and installing a biomass boiler ranges from $350,000 to over $5 million depending on capacity, automation level, emissions compliance, and supporting infrastructure. Small-scale systems (100–500 kW thermal) cost between $350,000 and $750,000 installed, while mid-scale commercial and industrial systems (1–5 MW or 1.5–7.5 TPH) range from $1.2 to $3.5 million. Large biomass CHP plants or district heating boilers (10+ TPH) can exceed $5 million when including fuel storage, feeding systems, ash handling, and flue gas treatment.

Choosing biomass means budgeting not just for energy—but for a complete sustainable energy ecosystem.

Biomass boiler installations require higher upfront costs due to complex fuel logistics and emissions controls.True

Systems must accommodate bulk fuels, ash disposal, and air quality standards, increasing overall capital requirements.

🔧 Typical Upfront Cost Breakdown for Biomass Boiler Projects

| System Component | Cost Range (USD) | % of Total Cost |

|---|---|---|

| Boiler Unit (Grate/FBC) | $200,000 – $2,500,000 | 25–40% |

| Fuel Storage and Conveying System | $80,000 – $600,000 | 10–20% |

| Combustion & Control System | $50,000 – $300,000 | 5–10% |

| Ash Handling System | $40,000 – $300,000 | 5–8% |

| Emission Control Equipment (cyclone, baghouse, scrubber) | $100,000 – $800,000 | 10–20% |

| Water Treatment (if steam plant) | $50,000 – $250,000 | 3–6% |

| Piping, Civil Works, Foundations | $150,000 – $600,000 | 10–15% |

| Automation, PLC/SCADA Integration | $30,000 – $200,000 | 3–5% |

| Installation & Commissioning Labor | $100,000 – $500,000 | 10–15% |

Total Installed Cost (Small to Medium Scale):

100–500 kWth: $350,000 – $750,000

1–5 MWth (1.5–7.5 TPH): $1.2M – $3.5M

10+ MWth (10+ TPH): $4.5M – $7.5M+

Upfront costs for biomass boilers are significantly influenced by fuel type and storage automation.True

Bulkier fuels like wood chips require more robust feeding systems than pellets, increasing cost.

📉 Cost Comparison: Biomass vs. Other Boiler Types

| Boiler Type | Installed Cost per MWth | Main Cost Drivers |

|---|---|---|

| Gas-Fired Boiler | $250,000 – $500,000 | Simple burner, low emissions equipment |

| Oil-Fired Boiler | $400,000 – $700,000 | Burner and tank systems |

| Coal-Fired Boiler | $700,000 – $1.2M | Fuel and ash handling + emissions control |

| Biomass Boiler | $900,000 – $1.5M | Fuel logistics, ash, emissions compliance |

Although biomass has higher upfront costs, fuel cost savings and environmental compliance advantages may yield better ROI in the long run.

🧪 Case Study: 3 TPH Biomass Boiler for Food Processing Plant

Project Details:

Output: 3 TPH saturated steam

Fuel: Rice husk and wood chips

6,000 operating hours per year

Cost Breakdown:

Boiler system (grate type): $800,000

Fuel handling + bunker: $250,000

ESP and cyclone dust collector: $400,000

Ash system: $80,000

Civil works + piping: $320,000

Commissioning: $150,000

Total Installed Cost: ~$2 million

Compared to oil-fired alternative: $1.2 million installed

Estimated fuel savings/year: $210,000

Simple Payback: ~3.8 years

Fuel savings from biomass systems can offset higher capital investment in under 5 years for high-use applications.True

Biomass fuels are cheaper and more stable in price than fossil fuels, leading to strong long-term financial returns.

📋 Cost Factors That Influence Capital Budget

| Factor | Influence on Cost |

|---|---|

| Fuel Type (chips vs. pellets) | Bulkier fuels = more storage and feeding gear |

| Fuel Moisture Content | Wet fuels need larger combustion chambers |

| Emission Standards (SOx, NOx) | Stricter rules = baghouses or scrubbers |

| System Automation Level | Full PLC/SCADA control adds upfront cost |

| Onsite Space Constraints | Tight sites raise civil and layout costs |

A well-scoped project balances performance needs with compliance and layout realities.

Summary

Biomass boiler systems require higher upfront investment than conventional boilers due to their complex fuel logistics, ash disposal, and emissions control requirements. Installed costs for small to medium systems typically range from $350,000 to over $3 million, with larger plants exceeding $5 million. While the capital outlay is substantial, long-term fuel savings and regulatory incentives often offset the initial expense within 4–7 years. When budgeting for biomass, it’s not just about buying a boiler—it’s about building a sustainable thermal system that can support your operation for decades.

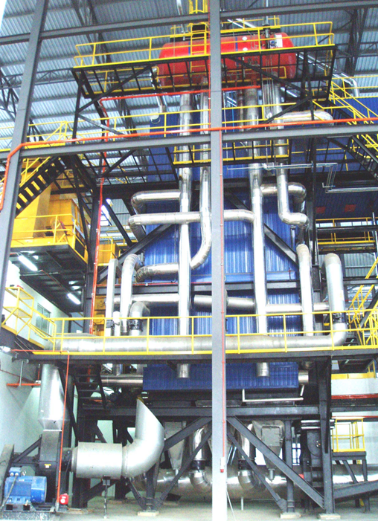

How Do Fuel Storage, Conveyor, and Ash Handling Systems Add to Capital Cost?

In a biomass boiler system, the core boiler unit is just one part of the infrastructure. Fuel logistics and ash disposal play an equally important role—especially given the volume, weight, and variability of solid biofuels like wood chips, pellets, rice husks, or agricultural waste. These systems must be robust, automated, and tailored to the specific fuel and combustion characteristics. As a result, fuel storage silos, conveyors, feeders, and ash handling systems can add 20% to 40% to the total installed capital cost—and more in some configurations.

Fuel storage, conveyor, and ash handling systems significantly add to the capital cost of biomass boiler installations because they require durable mechanical equipment, automation, safety controls, and civil infrastructure. Fuel systems must accommodate variable moisture, bulk density, and flow characteristics, while ash systems must manage abrasive, high-temperature residues. Depending on fuel type and boiler capacity, these support systems can cost $300,000 to over $1.5 million, representing 20%–40% of total project cost. Their design also affects operational efficiency, labor needs, and safety.

Biomass isn’t just burned—it must be stored, moved, and managed efficiently, and that comes with substantial capital implications.

Biomass boiler support systems for fuel and ash handling often account for up to 40% of the total installed cost.True

These systems are required to move, meter, and dispose of large volumes of solid fuel and ash safely and reliably.

🧱 Breakdown of Fuel & Ash System Components and Their Costs

| System Component | Purpose | Typical Cost Range (USD) | % of Total Capex |

|---|---|---|---|

| Fuel Storage (silos/bunkers) | Stores wood chips, pellets, or husks | $80,000 – $600,000 | 10–15% |

| Fuel Feeding Conveyors | Transports biomass to boiler | $50,000 – $300,000 | 5–10% |

| Automatic Fuel Metering | Regulates feed rate based on load/temperature | $30,000 – $150,000 | 3–5% |

| Ash Conveyors (bottom/fly) | Moves hot ash to silo or bin | $40,000 – $250,000 | 4–7% |

| Ash Silo/Storage System | Collects and stores ash before disposal | $30,000 – $200,000 | 3–5% |

| Ash Cooling or Quenching | Reduces temperature for handling safety | $20,000 – $80,000 | 1–3% |

| Dust Control Systems | Prevents airborne particulate from conveyors | $25,000 – $100,000 | 2–4% |

Total Additional Capital Range (Mid-Sized System): $300,000 – $1.5 million+

These are non-optional systems, especially for high-capacity or continuously operated biomass plants.

📊 Example Project Cost Breakdown: 3 TPH Biomass Boiler (Wood Chip)

| Component | Installed Cost (USD) | % of Total Cost |

|---|---|---|

| Boiler + Burner | $800,000 | 40% |

| Fuel Storage + Feed System | $360,000 | 18% |

| Ash Handling System | $180,000 | 9% |

| Emission Control | $350,000 | 17% |

| Civil + Installation + SCADA | $330,000 | 16% |

| Total CapEx | $2.02 million | 100% |

Support systems account for 27% of this total.

Fuel and ash logistics in biomass systems require high-capacity, reliable mechanical components and custom design.True

Biomass is variable and bulky, requiring larger, more robust handling systems than liquid or gas fuels.

⚠️ Key Design Factors That Affect System Cost

| Factor | How It Increases Cost |

|---|---|

| Fuel Type (chips vs. pellets) | Chips need larger conveyors, anti-bridging feeders |

| Storage Automation (silos vs. manual tipping) | Silos with automatic extraction cost more but reduce labor |

| Fuel Moisture & Flowability | Wet or sticky fuels require special conveyor design |

| Continuous Operation | Redundant conveyors and larger ash bins needed |

| Indoor vs. Outdoor Storage | Covered fuel bunkers or weatherproofing required |

| Ash Volume (high-ash fuels) | More robust disposal systems and increased storage |

🧪 Case Study: Agricultural Plant Using Rice Husk

System Capacity: 2 TPH

Fuel: Rice husk (low density, high ash)

Fuel Storage: Horizontal covered bunker, 100 m³

Conveyor: Inclined belt with screw feeder to furnace

Ash Handling: Dual-screw cooled system with bagging station

Costs:

Fuel handling system: $290,000

Ash system: $170,000

Boiler & core: $650,000

Total Installed CapEx: $1.35 million

Support systems = ~34% of total cost

📋 Best Practices to Optimize Cost of These Systems

| Strategy | Cost Benefit |

|---|---|

| Design for modularity | Easier upgrades and future scaling |

| Select fuel with low ash | Reduces ash handling system requirements |

| Optimize layout (shorter conveyors) | Less infrastructure and energy use |

| Automate feeding but monitor usage | Reduces labor cost, improves consistency |

| Choose dual-function silos (storage + metering) | Saves space and component cost |

Fuel and ash systems must be scaled to match boiler size, fuel type, and expected runtime.True

Improper sizing leads to frequent blockages, wear, and downtime—impacting both OPEX and efficiency.

Summary

Fuel storage, conveyor, and ash handling systems significantly increase the capital cost of a biomass boiler installation—often by $300,000 to over $1.5 million, depending on system size, automation, and fuel type. These systems are vital for feeding the boiler reliably and disposing of ash safely. Underinvesting in them leads to operational headaches, inefficiency, and higher long-term maintenance. When planning a biomass project, remember: your system is only as reliable as your fuel and ash logistics—and they must be budgeted and built to last.

What Are the Recurring Fuel, Logistics, and Operating Expenses Over Time for Biomass Boiler Systems?

Biomass boiler systems may offer long-term savings and sustainability benefits, but their recurring operating expenses are multifaceted. These include not only fuel procurement but also logistics, labor, maintenance, and system efficiency losses. Unlike liquid fuels, biomass is a bulky, solid, and sometimes moisture-laden fuel that must be stored, conveyed, metered, and combusted efficiently. These realities translate into ongoing costs that can rival or even surpass fossil fuel systems if not properly managed.

Recurring fuel, logistics, and operating expenses for biomass boiler systems typically range from $50 to $120 per MWh of thermal energy produced, depending on fuel type, boiler efficiency, labor structure, and automation. Annual fuel costs often make up 60% to 80% of total operating expenses, with logistics (delivery, storage, handling) contributing another 10%–20%. Maintenance, water treatment, ash disposal, and labor account for the remaining 10%–20%. For a mid-sized 2–5 TPH biomass boiler running 6,000 hours per year, total recurring costs may reach $300,000 to $750,000 annually.

Biomass is affordable fuel—but managing it is a logistics-driven, labor-sensitive process.

Fuel and logistics are the dominant recurring operating costs in biomass boiler systems.True

Due to the low energy density and bulkiness of biomass, fuel sourcing, delivery, and handling form the largest share of annual expenditures.

🔁 Annual Recurring Cost Breakdown (for 3 TPH Biomass Boiler, 6,000 hrs/year)

| Cost Component | Annual Cost Estimate (USD) | % of Total OPEX |

|---|---|---|

| Fuel (wood chips/pellets) | $180,000 – $450,000 | 60–75% |

| Fuel Delivery & Handling | $30,000 – $80,000 | 10–15% |

| Ash Handling & Disposal | $8,000 – $25,000 | 2–5% |

| Labor (operators, techs) | $50,000 – $120,000 | 10–15% |

| Routine Maintenance | $30,000 – $60,000 | 5–10% |

| Water Treatment (steam) | $8,000 – $20,000 | 2–4% |

| Total Operating Expense | $300,000 – $750,000 | 100% |

Biomass fuel price stability helps control long-term OPEX, but logistics costs remain highly location-dependent.True

Local fuel availability and transport distance significantly affect total fuel cost per ton.

🌿 Fuel Costs Over Time: Key Variables

| Variable | Impact on Fuel Expense |

|---|---|

| Fuel Type | Pellets cost more than chips, but burn cleaner |

| Moisture Content | Wet fuel = more tons needed per MWh |

| Calorific Value (GCV) | Low-energy fuels require more volume |

| Local Sourcing | Shorter distance = lower delivery cost |

| Seasonal Availability | Prices may rise during winter or harvest seasons |

Typical Biomass Prices (Delivered):

Wood chips: $40–$80/ton

Wood pellets: $90–$150/ton

Agricultural residues: $30–$60/ton

At 65–80% boiler efficiency, this translates to:

$45–$110 per MWh thermal

🧪 Example: 2 TPH Biomass Boiler Using Wood Chips

| Parameter | Value |

|---|---|

| Operating Hours/Year | 6,000 |

| Fuel Use (wood chips) | ~6,000 tons/year |

| Delivered Price | $55/ton |

| Annual Fuel Cost | $330,000 |

| Other O&M (labor, handling) | ~$120,000 |

| Total Annual Recurring Cost | ~$450,000 |

If the same boiler used pellets at $110/ton, total annual cost could rise by $330,000, showing how fuel type and sourcing dominate costs.

📋 How Logistics Affects Cost and Efficiency

| Logistics Element | Cost Impact |

|---|---|

| Delivery Frequency (trucks/week) | More deliveries = higher transport fees |

| Onsite Storage | Larger silos/bunkers reduce cost volatility |

| Fuel Handling Automation | Reduces labor but raises capex |

| Fuel Quality Management | Cleaner fuel reduces maintenance |

Fuel moisture and particle size variability can increase both logistics and maintenance expenses in biomass systems.True

Handling inconsistent biomass requires more frequent cleaning and equipment upkeep.

📈 Trends in Biomass OPEX vs. Fossil Fuels

| Fuel Type | Annual Cost Stability | Emissions Cost Risk | Handling Complexity |

|---|---|---|---|

| Natural Gas | Volatile pricing | High (CO₂ tax) | Low |

| Oil | High cost, volatile | High (CO₂ + NOx) | Low |

| Coal | Moderate cost | Very high compliance | High |

| Biomass | Moderate cost, stable | Low (carbon neutral) | High |

Despite handling challenges, biomass is often favored for carbon neutrality and regulatory compliance, especially in carbon tax regions.

Summary

Biomass boiler systems may be fuel-efficient, but their total operating expenses hinge on more than just fuel cost. Logistics, moisture management, handling systems, ash disposal, labor, and maintenance all contribute to a complex cost structure. Annual recurring expenses range from $300,000 to $750,000 or more, depending on system size and automation level. To keep costs predictable and performance high, operators must optimize fuel sourcing, delivery frequency, and operational efficiency. In the biomass world, it’s not just what you burn—it’s how you manage everything around it.

How Do Maintenance, Cleaning, and Operator Training Impact Lifecycle Costs of Biomass Boiler Systems?

In biomass boiler operations, performance and cost aren’t only driven by the fuel burned—but by how well the system is cleaned, maintained, and operated over time. These “soft costs” often receive less attention than capital and fuel expenses, but they can significantly affect the Total Cost of Ownership (TCO), efficiency, downtime, and system lifespan. Poor maintenance leads to fouling, scaling, ash buildup, and premature failures, while under-trained staff can cause combustion imbalances and avoidable breakdowns. When done right, preventive maintenance, regular cleaning, and skilled operation can lower lifecycle costs by 10–30%.

Maintenance, cleaning, and operator training directly impact lifecycle costs by preventing system degradation, avoiding unplanned downtime, and sustaining high thermal efficiency. Scheduled cleaning and inspections keep heat transfer surfaces clear of soot and ash, which reduces fuel consumption and protects components. Skilled operators reduce the risk of malfunctions, optimize combustion, and detect issues early. Over a 20-year lifecycle, well-maintained and properly operated biomass boilers can save hundreds of thousands of dollars in avoided repairs, fuel waste, and labor inefficiencies.

In thermal systems, clean operation and trained oversight aren’t just best practices—they are profit protection tools.

Preventive maintenance and trained operators can lower biomass boiler lifecycle costs by up to 30%.True

They reduce repair frequency, extend component life, and minimize energy waste, which adds up significantly over decades.

🔧 Lifecycle Cost Impact by Category (20-Year View)

| Category | Poor Practice Cost (USD) | Optimized Cost (USD) | Potential Savings |

|---|---|---|---|

| Unplanned Repairs | $800,000 – $1.2 million | $300,000 – $500,000 | $300K – $900K |

| Fuel Efficiency Loss | $2.5 – $3.5 million | $1.8 – $2.3 million | $700K – $1.2M |

| Component Replacement (burners, fans) | $600,000 – $1M | $300,000 – $600,000 | $300K – $400K |

| Downtime Production Loss | $1M – $2.5 million | $400,000 – $900,000 | $600K – $1.6M |

| Total Lifecycle Savings | — | — | $2 – $4 million+ |

These savings can outweigh the cost of the boiler itself—underscoring the ROI of disciplined maintenance and training.

🧹 Importance of Cleaning and Fouling Control

| Cleaning Activity | Frequency | Benefit |

|---|---|---|

| Tube brushing / soot removal | Weekly to monthly | Maintains thermal transfer |

| Ash bin/silo emptying | Weekly | Prevents overflow & buildup |

| Cyclone/baghouse inspection | Monthly to quarterly | Sustains emissions compliance |

| Combustion chamber vacuuming | Monthly | Reduces clinker formation |

| Heat exchanger cleaning | Annually | Restores energy recovery capacity |

Even 1 mm of soot can cause up to 10% fuel efficiency loss.

Ash and soot buildup on heat transfer surfaces increases fuel consumption by reducing thermal efficiency.True

These deposits act as insulation, forcing more fuel to achieve the same heat output.

👷 Operator Training and Its ROI

| Training Area | Impact on Lifecycle Cost |

|---|---|

| Combustion optimization | Reduces unburned fuel, CO, soot |

| Startup/shutdown procedures | Prevents thermal shock, wear |

| Sensor and alarm interpretation | Enables early problem detection |

| Water chemistry management | Prevents scaling and corrosion |

| Fuel handling and feeding | Avoids clogs, fire hazards |

Well-trained operators can reduce fuel use by 5%–10%, avoid 2–4 unplanned shutdowns per year, and extend boiler life by 3–5 years.

Training operators in biomass combustion and system response improves efficiency and reduces unplanned maintenance.True

Skilled staff optimize combustion, react quickly to faults, and handle fuel variability better.

📊 Case Study: Lifecycle Cost Comparison

Facility A (No Training, Minimal Maintenance):

20 TPH biomass boiler

Fuel efficiency: 68%

Annual repairs: $85,000

Downtime: 12 days/year

Lifecycle cost (20 years): ~$28 million

Facility B (Trained Staff + Preventive Cleaning):

20 TPH biomass boiler

Fuel efficiency: 78%

Annual repairs: $40,000

Downtime: 4 days/year

Lifecycle cost (20 years): ~$23 million

Savings: $5+ million

📋 Best Practices for Lifecycle Cost Control

| Practice | Description |

|---|---|

| Create a preventive maintenance schedule | Base it on OEM and runtime data |

| Track cleaning intervals with logs | Identify patterns in fouling |

| Use infrared or stack sensors | Detect hidden heat loss or airflow issues |

| Conduct quarterly operator refresher training | Keep staff sharp and compliant |

| Budget annually for training + maintenance | Ensure funding isn’t cut reactively |

Summary

Maintenance, cleaning, and operator training are key cost levers in the lifecycle of a biomass boiler system. These elements directly affect efficiency, availability, component durability, and compliance. Facilities that neglect these areas face higher fuel costs, shorter equipment lifespan, and frequent operational interruptions. In contrast, disciplined programs lead to fuel savings, extended system life, and smoother operations—with savings that often total millions of dollars over two decades. In biomass boiler management, smart habits save hard cash.

What Role Do Emissions Control and Compliance Systems Play in Long-Term Budgeting?

In biomass boiler systems, staying compliant with air quality and environmental regulations isn’t optional—it’s central to long-term cost management and system viability. As global and regional environmental standards tighten, emissions control systems like cyclones, baghouses, scrubbers, and continuous emissions monitoring systems (CEMS) become critical line items in both capital and operating budgets. These systems ensure your facility meets limits for particulate matter (PM), CO, NOₓ, SO₂, and VOCs—protecting you from fines, operational suspensions, or forced retrofits. Over a 20-year lifecycle, emissions control and compliance management can account for 10% to 20% of total boiler system cost.

Emissions control and compliance systems play a pivotal role in long-term budgeting by introducing significant up-front capital investments and recurring operational costs tied to environmental performance. These systems ensure regulatory compliance, avoid penalties, and maintain operating permits. While initial installation may cost $100,000 to over $1 million, ongoing expenses—including maintenance, reagent replenishment, monitoring calibration, and reporting—can add $20,000 to $100,000 or more annually. In regulated markets, these costs must be included in total cost of ownership (TCO) and amortized into financial planning.

In the era of sustainability and carbon accountability, compliance isn’t a cost to cut—it’s a cost to plan for.

Emissions control and compliance systems are essential for permitting and long-term operation of biomass boiler plants.True

They are required by law and prevent penalties, shutdowns, or loss of environmental certification.

🏭 Typical Emissions Systems and Budget Impact

| Component | Purpose | Installed Cost (USD) | Annual O&M (USD) |

|---|---|---|---|

| Cyclone Separator | Pre-separation of large particulates | $50,000 – $150,000 | $5,000 – $15,000 |

| Baghouse Filter | Fine particulate filtration (PM <10µm) | $100,000 – $500,000 | $10,000 – $25,000 |

| Wet/Dry Scrubber | SO₂ or acid gas removal | $150,000 – $750,000 | $15,000 – $40,000 |

| SNCR or SCR System | NOₓ reduction (optional in some regions) | $300,000 – $900,000 | $25,000 – $60,000 |

| CEMS (Continuous Monitoring) | Tracks CO, NOₓ, PM, O₂ in real time | $40,000 – $120,000 | $8,000 – $20,000 |

| Stack Sampling & Reporting | Regulatory compliance and audits | Included in O&M | $5,000 – $15,000 |

For a 3–5 TPH biomass boiler, total installed emissions system cost: $300,000 – $1.2 million

Annual emissions-related O&M: $30,000 – $100,000

📊 Emissions-Related Cost Share in Lifecycle Budget (20-Year Span)

| Lifecycle Budget Area | Cost (USD) | % of TCO |

|---|---|---|

| Boiler + Core Systems | $2.5 – $5 million | 40–55% |

| Fuel Supply & Logistics | $6 – $10 million | 35–45% |

| Emissions Control (CAPEX + OPEX) | $1 – $2.5 million | 10–15% |

| Labor + Maintenance (non-emissions) | $1.5 – $3 million | 10–15% |

Emissions compliance is a top 3 lifecycle cost category, not just a minor addition.

Over a 20-year period, emissions-related expenses can exceed $2 million for medium-sized biomass boilers.True

Between installation, maintenance, and compliance reporting, these systems represent a major OPEX and CAPEX component.

🧪 Case Study: Biomass Boiler with Baghouse + Scrubber + CEMS

Facility: Industrial processing plant with 4 TPH biomass steam boiler

Location: EU, under strict PM and SO₂ limits

| Emissions Compliance Element | Cost |

|---|---|

| Baghouse Filter (fabric) | $320,000 |

| Wet Scrubber (lime injection) | $460,000 |

| CEMS Unit | $85,000 |

| Installation & Integration | $180,000 |

| Total Emissions CAPEX | $1.05 million |

| Annual Reagents & Filter Media | ~$28,000/year |

| CEMS Calibration & Reporting | ~$12,000/year |

Total 20-Year Emissions Cost: ~$1.7 million

Avoided Fines/Shutdowns: Estimated $300,000 – $500,000

📋 Compliance Considerations for Budget Planning

| Factor | Budget Impact |

|---|---|

| Local Emissions Limits | Defines scope of controls needed |

| Fuel Type & Composition | Affects PM, SO₂, NOₓ output |

| Boiler Size and Load Factor | Drives CEMS & reagent consumption |

| Automation Integration (PLC/SCADA) | Eases reporting, adds upfront cost |

| Inspection and Re-Certification | Recurring fees every 1–3 years |

Some jurisdictions require quarterly stack testing—budget $5,000–$10,000/year minimum.

🌍 Emissions and Regulatory Trends Affecting Future Budgets

Tighter PM10 and PM2.5 thresholds

Expanded CO₂ and carbon credit policies

Real-time emissions dashboards required in EU/UK

Higher penalties for non-compliance in Asia and Latin America

Forward-looking budgeting should include a 10–20% emissions cost buffer to account for policy tightening over 10–20 years.

Planning for emissions control upgrades now avoids costly retrofits when regulations tighten later.True

Designing modular, scalable systems upfront reduces future disruption and capital shock.

Summary

Emissions control and compliance systems are non-negotiable components of biomass boiler planning—and their impact on long-term budgeting is substantial. While they add $300,000 to $1.2 million in capital costs and $30,000 to $100,000 in annual O&M, they are essential to maintain operating permits and avoid penalties. Over a 20-year period, these costs often exceed $2 million and must be accounted for in any credible TCO model. In sustainable energy systems, compliance is a cost of doing business—and a safeguard for uninterrupted operation.

How Can ROI and TCO Be Calculated to Assess Long-Term Investment Value of Biomass Boiler Systems?

When evaluating a biomass boiler investment, decision-makers must go beyond the initial price tag and consider the entire financial footprint of the system. This means calculating both Total Cost of Ownership (TCO)—all expenses over the boiler’s life—and Return on Investment (ROI)—how fast the system pays back and how much value it generates. These two metrics help compare biomass systems to alternatives like gas or oil-fired boilers, and support long-term financial and sustainability planning.

ROI (Return on Investment) and TCO (Total Cost of Ownership) are essential tools for assessing the long-term value of a biomass boiler investment. TCO includes all costs over the system’s lifetime—CAPEX, OPEX, fuel, maintenance, labor, emissions compliance, and decommissioning. ROI compares the total benefits (like fuel savings or revenue from steam production) to the total cost, usually expressed as a percentage or payback period. These calculations help quantify project feasibility, determine breakeven points, and guide capital allocation.

A biomass boiler’s value isn’t defined by what you pay today—but by how it performs financially over 20–30 years.

ROI and TCO calculations are essential for evaluating the long-term investment value of biomass boiler systems.True

They provide a complete financial picture, allowing owners to compare options and make informed, sustainable decisions.

📊 Step-by-Step TCO Calculation (Total Cost of Ownership)

TCO = CAPEX + (OPEX × Lifespan) + Compliance Costs + Decommissioning

| Cost Category | Example Value (USD) | Notes |

|---|---|---|

| CAPEX (Initial Investment) | $2.5 million | Boiler + installation + emissions |

| OPEX (Annual Operating Costs) | $300,000 – $700,000 | Fuel, labor, maintenance, chemicals |

| Lifespan | 20 years | Industry average |

| Compliance + Monitoring | $30,000/year × 20 = $600,000 | Emissions, stack testing, permits |

| Decommissioning (est.) | $100,000 – $200,000 | End-of-life dismantling & disposal |

TCO Estimate (20-Year, Mid-Sized Boiler):

$2.5M + ($500K × 20) + $600K + $150K = $13.75 million

💰 Step-by-Step ROI Calculation

✅ Simple ROI Formula:

ROI (%) = (Net Benefit ÷ Total Investment) × 100

✅ Payback Period Formula:

Payback (years) = Total Investment ÷ Annual Savings

🧪 ROI Example: Biomass vs. Oil-Fired Boiler

| Parameter | Biomass Boiler | Oil-Fired Boiler |

|---|---|---|

| CAPEX | $2.5 million | $1.2 million |

| Annual Fuel Cost | $330,000 | $850,000 |

| Annual OPEX (excluding fuel) | $160,000 | $120,000 |

| Annual Savings (fuel + emissions) | $480,000 | — |

| Payback Period | 2.5M ÷ 480K = ~5.2 yrs | — |

| 20-Year ROI | ($480K × 20) ÷ 2.5M = 384% | — |

Despite higher capital cost, fuel savings provide strong returns within 5–6 years, especially in high-fuel-cost regions.

Biomass systems often achieve payback in under 6 years through fuel savings compared to oil or LPG systems.True

Cheaper biomass fuel offsets the higher capital investment over time.

📋 TCO vs. ROI: Side-by-Side Analysis

| Metric | What It Tells You | Used For |

|---|---|---|

| TCO | Lifetime financial burden | Budget forecasting, risk analysis |

| ROI (%) | Profitability from investment | Investment comparison, performance |

| Payback Period | Time to recover investment | Project feasibility, loan planning |

| NPV/IRR | Time-value adjusted return | Advanced investment modeling |

For a financially sound biomass project, aim for:

TCO below $15M (20-year scope)

ROI above 250%

Payback < 7 years

📉 Factors That Affect ROI & TCO

| Factor | TCO Impact | ROI Impact |

|---|---|---|

| Fuel Type & Price Stability | High (lower is better) | High (greater savings) |

| Boiler Efficiency | High (efficiency = lower TCO) | High |

| Automation Level | Higher CAPEX but lower OPEX | Positive long-term |

| Labor and Maintenance Practices | Moderate | Significant (avoids failures) |

| Emissions Compliance Stringency | Moderate to high | May reduce savings margin |

Boiler efficiency and fuel type are the most influential factors in long-term ROI for biomass systems.True

They directly affect both recurring costs and achievable savings.

🔁 Tips for Accurate ROI and TCO Analysis

Use realistic fuel cost escalation (e.g., 2%/year)

Include maintenance, training, and cleaning costs

Factor in emissions compliance changes over 20 years

Don’t forget downtime risk or part replacement cycles

Use Net Present Value (NPV) for deeper analysis

Create comparison models with fossil fuel alternatives

Summary

Calculating ROI and TCO is essential for determining the long-term financial viability of biomass boiler investments. While capital costs may be high, the fuel savings, compliance benefits, and lifecycle efficiency of biomass often deliver strong returns—especially when projected over 20–30 years. A clear financial model ensures that decisions are based not on the cheapest option upfront, but on the most valuable option long term. For industrial users, schools, or utilities, a high-ROI biomass system can fund itself—and then fuel savings for years to come.

🔍 Conclusion

The cost of an industrial biomass boiler goes far beyond the initial purchase. While the fuel cost per unit energy is generally lower than oil or gas, factors like fuel quality variability, ash management, and system maintenance must be considered when evaluating total ownership cost. By conducting a full lifecycle cost analysis, including installation, fuel, upkeep, and regulatory compliance, businesses can ensure their investment in biomass technology delivers long-term environmental and economic benefits.

📞 Contact Us

💡 Need help calculating the full cost of a biomass boiler project? Our team offers feasibility studies, TCO assessments, and customized cost modeling to help you plan confidently.

🔹 Contact us today and invest in a biomass boiler system that’s efficient, cost-effective, and built to last. 🌱🔥💰

FAQ

What is the average upfront cost of an industrial biomass boiler?

Upfront costs typically range from $150,000 to $1.5 million, depending on boiler size, type (grate, fluidized bed, etc.), automation, emissions controls, and whether it supports multi-fuel operations. Installation costs (civil works, piping, feed systems) add $100,000–$500,000.

What are the long-term fuel costs for a biomass boiler?

Biomass fuel cost depends on type and region.

Wood chips: $40–$70/ton

Wood pellets: $150–$250/ton

Agri-waste/energy crops: $30–$80/ton

Annual fuel costs for mid-size units can range from $100,000 to $500,000, influenced by fuel quality and moisture content.

How much does long-term maintenance cost?

Maintenance tends to be 5–8% of the capital cost per year, due to:

Ash handling system upkeep

Tube cleaning

Refractory replacement

Fuel feeding system maintenance

Over a 20-year lifespan, expect $300,000–$800,000+ in total maintenance costs.

What hidden or indirect costs should be considered?

Fuel storage infrastructure and drying systems

Permitting and emissions compliance (especially for particulate matter)

Operator training due to more complex fuel handling

Emission control systems (e.g., cyclones, baghouses)

Fuel supply logistics, especially for variable biomass

How do biomass boilers compare in total cost of ownership (TCO)?

While upfront costs are higher than gas/oil boilers, biomass systems benefit from lower and stable fuel prices, renewable energy incentives, and carbon credits. Over 20+ years, they offer competitive or even lower TCO—especially where biomass is locally sourced and regulations favor carbon neutrality.

References

Industrial Biomass Boiler Cost Overview – https://www.energy.gov

Biomass Fuel Cost and Supply Guide – https://www.bioenergyconsult.com

Total Cost of Ownership for Biomass Systems – https://www.researchgate.net

Biomass Boiler Installation and Operating Costs – https://www.sciencedirect.com

Emission Compliance Costs for Biomass Boilers – https://www.epa.gov

Wood Chip vs. Pellet Cost Comparison – https://www.eia.gov

Boiler Maintenance and Lifecycle Analysis – https://www.mdpi.com

IEA Biomass Boiler Economics Report – https://www.iea.org

Renewable Heat Incentive and Carbon Credits – https://www.energysavingtrust.org.uk

ASME Biomass Boiler Standards and Cost Trends – https://www.asme.org

Wade Zhang

Upfront and Long-Term Costs of an Industrial Biomass Boiler Read More »

-1024x768.jpg)

-scaled.jpg)