Latest Innovations in Industrial Steam Boiler Design

Latest Innovations in Industrial Steam Boiler Design

Industrial steam boilers have long been the backbone of power generation, manufacturing, food processing, and chemical industries, but traditional designs often suffer from low efficiency, high emissions, and frequent maintenance challenges. With rising energy costs and stricter environmental regulations, companies are seeking advanced boiler technologies to stay competitive.

The latest innovations in industrial steam boiler design include high-efficiency heat recovery systems (economizers, condensing technology), low-NOx and ultra-low-emission combustion technologies, modular and compact boiler designs, smart control and automation systems with IoT integration, and compatibility with renewable fuels such as biomass and hydrogen blends. These advancements not only improve energy efficiency but also reduce carbon footprint, enhance operational safety, and extend equipment life.

By embracing these innovations, industries can lower operating costs, improve reliability, and ensure compliance with future energy and environmental standards.

How have advanced combustion technologies reduced emissions in modern steam boilers?

Industrial steam boilers have historically been significant contributors to NOx, SOx, CO, and particulate emissions. With tightening environmental regulations and rising fuel costs, traditional combustion systems often fail to meet compliance or efficiency demands. Left unchecked, these emissions not only increase operating costs but also expose plants to penalties and reputational risks. The solution has been the development and adoption of advanced combustion technologies that optimize flame stability, fuel-air mixing, and temperature control to minimize pollutant formation at the source.

Advanced combustion technologies—including low-NOx burners, staged combustion, flue gas recirculation (FGR), oxy-fuel systems, and digital combustion controls—have reduced boiler emissions by 40–80%. These innovations limit NOx formation, enhance fuel efficiency, and support compliance with global emission standards such as EPA, EU, and CPCB norms.

By implementing these technologies, modern steam boilers achieve both regulatory compliance and lower lifecycle costs, positioning industries for sustainable operation.

Conventional burners are sufficient to meet modern low-emission regulations.False

Conventional burners produce higher NOx and CO emissions and often cannot comply with today’s stricter regulations.

Low-NOx burners and staged combustion reduce NOx formation at the flame level.True

These technologies optimize flame temperature and oxygen distribution to suppress thermal NOx generation.

Key Combustion Technologies and Their Impact

1. Low-NOx Burners (LNB)

Improve fuel-air mixing to avoid hot spots.

Reduce thermal NOx by lowering flame temperature.

Widely used in both fire-tube and water-tube boilers.

2. Staged Combustion

Splits combustion into primary and secondary stages.

Limits oxygen availability in the first stage to suppress NOx formation.

Completes oxidation in the second stage to minimize CO.

3. Flue Gas Recirculation (FGR)

Recirculates a portion of exhaust gases into the burner.

Dilutes oxygen and lowers flame temperature, reducing NOx by up to 60%.

Common in gas-fired boilers.

4. Oxy-Fuel Combustion

Uses pure oxygen instead of air, eliminating nitrogen from the reaction.

Produces near-zero NOx and allows easier CO₂ capture.

Mostly applied in large, high-efficiency units.

5. Digital Combustion Controls

Advanced sensors and PLC/SCADA systems optimize excess air, flame shape, and fuel flow.

Improve efficiency while reducing both CO and NOx emissions.

Emission Reduction Comparison

| Technology | NOx Reduction (%) | CO Reduction (%) | Notes |

|---|---|---|---|

| Low-NOx Burner | 30–50 | 10–20 | Standard upgrade |

| Staged Combustion | 40–60 | 20–30 | Often combined with LNB |

| Flue Gas Recirculation | 50–70 | 20–25 | Widely adopted in gas-fired units |

| Oxy-Fuel Combustion | 70–90 | 40–50 | High cost, niche applications |

| Digital Controls | 10–20 | 10–15 | Continuous optimization |

Case Example: 50 TPH Water-Tube Boiler Upgrade

Original NOx emissions: ~350 mg/Nm³

With LNB + FGR: ~140 mg/Nm³ (60% reduction)

With additional staged combustion + controls: ~90 mg/Nm³ (75% reduction)

Result: Compliance with EU Industrial Emissions Directive (IED) limits (<100 mg/Nm³).

Conclusion

Advanced combustion technologies have transformed modern steam boilers from high-emission units into clean, efficient energy systems. By integrating low-NOx burners, staged combustion, FGR, oxy-fuel options, and smart controls, industries achieve both compliance and efficiency. These technologies not only cut emissions by up to 80% but also reduce fuel costs and enable future-ready carbon capture strategies.

What role do economizers, air preheaters, and condensing systems play in boosting efficiency?

One of the biggest sources of energy loss in steam boilers is wasted heat in flue gases. Traditional designs often let exhaust gases leave at high temperatures, carrying away valuable energy and forcing operators to burn more fuel to maintain steam output. This increases operational costs and emissions. The solution lies in heat recovery systems—specifically economizers, air preheaters, and condensing units—that reclaim this waste heat and feed it back into the process.

Economizers, air preheaters, and condensing systems improve boiler efficiency by 5–15% by recovering waste heat from flue gases. Economizers preheat feedwater, air preheaters raise combustion air temperature, and condensing systems extract latent heat from water vapor in exhaust, collectively reducing fuel consumption and emissions.

By integrating these systems, modern boilers achieve higher thermal efficiency, lower operating costs, and better compliance with energy-efficiency standards.

Flue gas heat recovery systems have little effect on boiler efficiency.False

Heat recovery through economizers, air preheaters, and condensing units significantly reduces fuel use and raises efficiency.

Condensing systems recover latent heat from exhaust gases, improving boiler efficiency.True

Condensing heat exchangers extract additional energy by cooling flue gases below dew point.

How Each System Boosts Efficiency

1. Economizers

Located in the flue gas path before the chimney.

Transfer waste heat to incoming feedwater.

Typical fuel savings: 4–7%.

Reduce thermal shock to boiler by preheating water.

2. Air Preheaters

Use flue gas to warm combustion air.

Hotter combustion air improves flame stability and efficiency.

Typical fuel savings: 2–4%.

Common in large water-tube boilers.

3. Condensing Heat Exchangers

Cool flue gases below the dew point (~55°C).

Recover latent heat from water vapor in exhaust.

Efficiency gain: up to 8–10% (especially with natural gas).

Require corrosion-resistant materials due to acidic condensate.

Efficiency Gains Overview

| System | Efficiency Improvement | Notes |

|---|---|---|

| Economizer | 4–7% | Feedwater preheating |

| Air Preheater | 2–4% | Hotter combustion air |

| Condensing Unit | 5–10% | Latent heat recovery |

| Combined Use | 10–15% | Common in modern designs |

Case Example: 50 TPH Gas-Fired Boiler

Base efficiency: ~82%

With economizer: ~87%

With air preheater: ~90%

With condensing heat exchanger: ~94–95%

Net fuel savings: ~10–15% (~$250,000/year in a mid-sized plant).

Conclusion

Economizers, air preheaters, and condensing systems are essential components of modern high-efficiency boilers. By recovering both sensible and latent heat from flue gases, they significantly cut fuel consumption and emissions. Plants that integrate these systems typically achieve 10–15% higher efficiency, making them vital tools for reducing lifecycle costs and meeting stringent energy regulations.

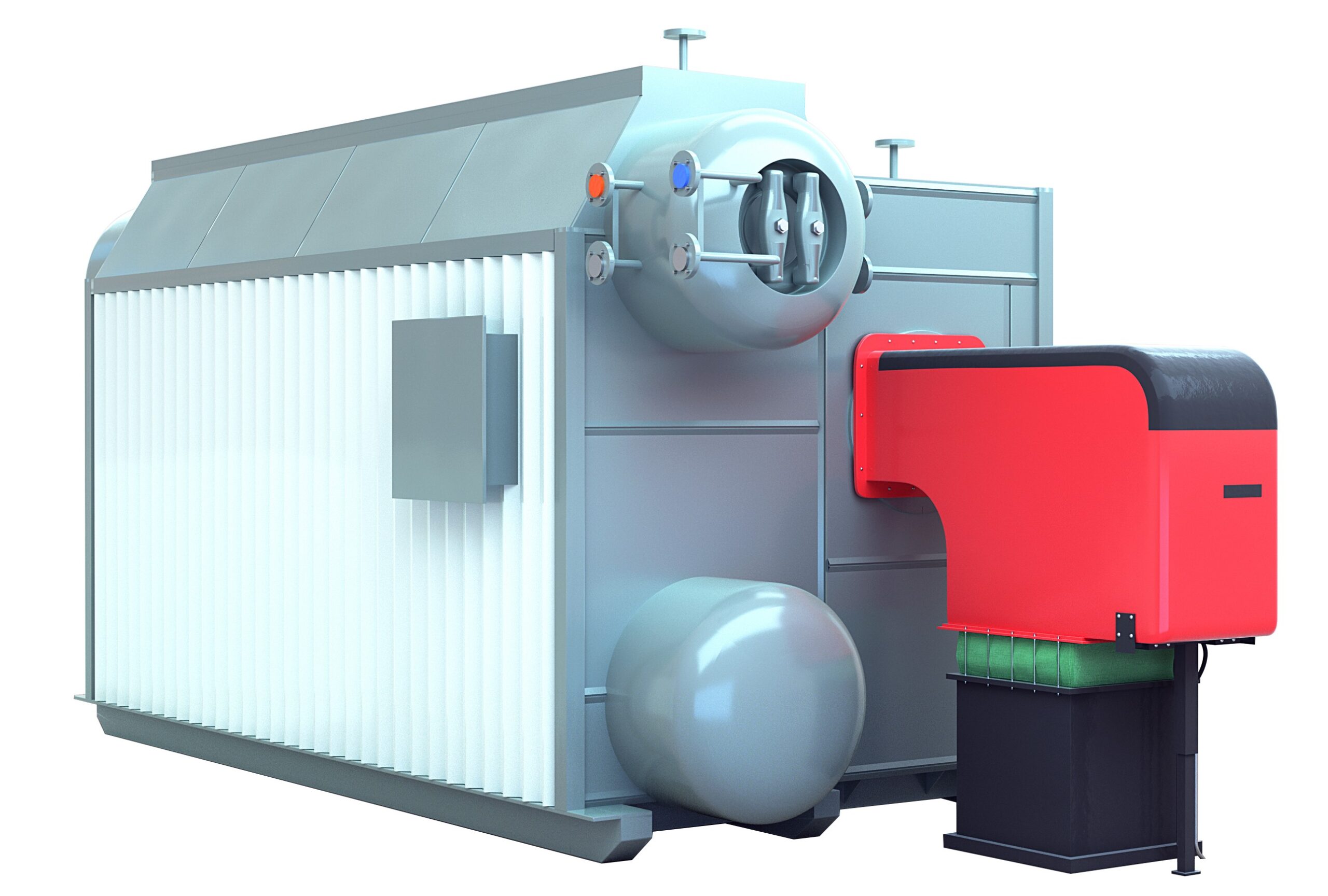

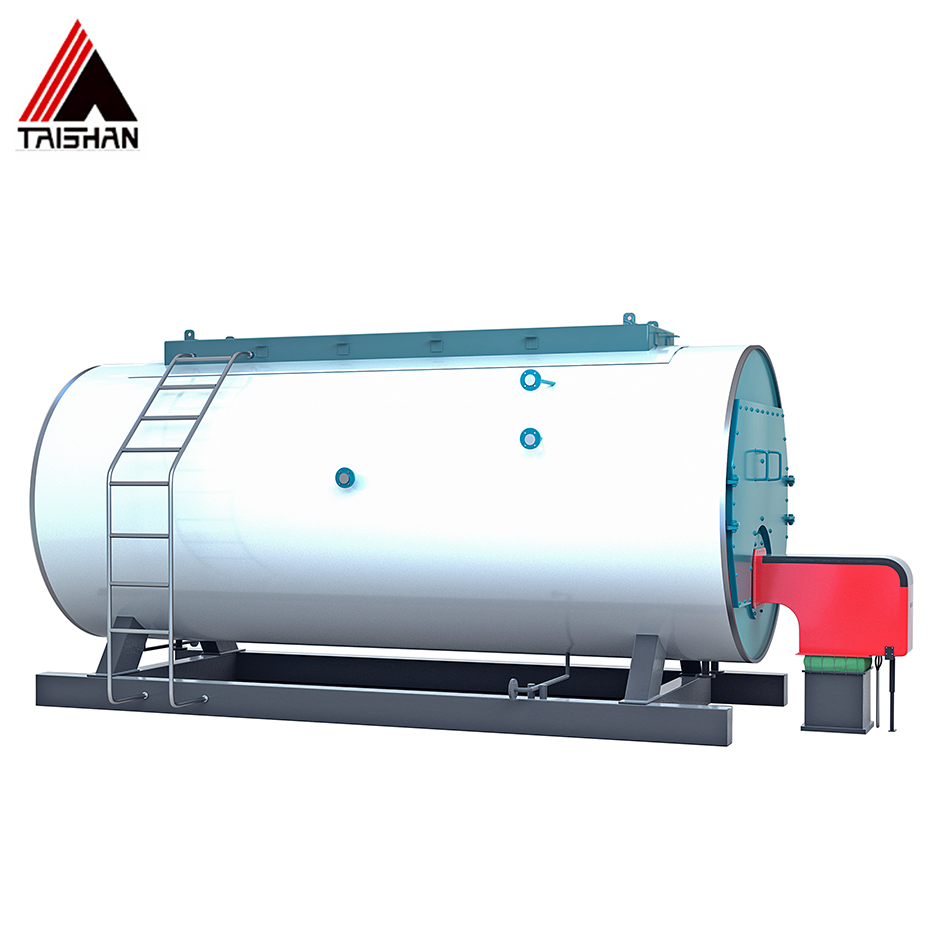

How do modular and compact boiler designs improve installation and scalability?

For decades, industrial boiler projects were defined by long installation times, heavy civil foundations, and rigid, single-unit capacity. This meant high upfront investment and limited flexibility if demand changed. Delayed commissioning often created costly downtime for plants waiting on steam supply. Modular and compact boiler designs were developed as a solution to these challenges, offering faster setup, smaller footprints, and scalable capacity expansion.

Modular and compact boiler designs reduce installation time by up to 50% by using factory-assembled, skid-mounted units that require minimal on-site work. They also improve scalability by allowing plants to add modules in parallel as steam demand grows, ensuring flexible, staged investment and improved operational efficiency.

This approach provides industries with faster project delivery, lower installation risk, and adaptable capacity planning.

Modular boilers take as long to install as conventional monolithic designs.False

Factory-assembled modular boilers require far less site fabrication, cutting installation time by months.

Compact boiler systems allow plants to scale up capacity by adding units instead of replacing existing equipment.True

Parallel modular arrangements enable cost-effective expansion and load balancing.

Key Benefits of Modular and Compact Boiler Designs

1. Accelerated Installation

Pre-engineered, skid-mounted units reduce civil works.

On-site installation typically cut from 6–9 months (conventional) to 2–4 months.

Containerized compact units can be operational in 4–8 weeks.

2. Scalable Capacity Growth

Modules (e.g., 5–30 TPH each) can be installed incrementally.

Load-sharing across modules enhances part-load efficiency.

Expansion is as simple as adding more units, avoiding major shutdowns.

3. Smaller Footprint & Mobility

Compact designs fit in tight industrial spaces or urban plants.

Easier transport using standard trucks or containers.

Suitable for relocatable or temporary installations.

4. Operational Flexibility & Reliability

Multiple modules provide redundancy—if one fails, others maintain supply.

Maintenance can be performed on individual units without halting the entire system.

Installation & Scalability Comparison

| Feature | Conventional Boiler | Modular/Compact Boiler |

|---|---|---|

| Installation Time | 6–9 months | 2–4 months (or less) |

| Footprint | Large | Compact |

| Expansion | Replace or oversize | Add parallel modules |

| Reliability | Single point of failure | Redundant operation |

| Investment Model | High upfront | Staged investment |

Case Example: 120 TPH Steam Demand

Conventional option: One 120 TPH water-tube boiler → ~12 months delivery + ~8 months installation.

Modular option: Six 20 TPH modules → ~8 months delivery + ~3 months installation.

Expansion scenario: Demand increases to 160 TPH → simply add two more 20 TPH modules, avoiding new boiler procurement.

Conclusion

Modular and compact boiler designs streamline installation and make steam generation systems more adaptable to evolving plant needs. By shortening commissioning, reducing space requirements, and enabling staged capacity growth, these designs help industries cut costs and improve reliability while future-proofing steam infrastructure.

What smart automation and IoT solutions are being applied in boiler control systems?

In traditional boiler systems, operators relied on manual checks and analog gauges to maintain safe and efficient performance. This approach was prone to delays in fault detection, inefficiencies in fuel usage, and higher maintenance costs. As industries push for greater efficiency, safety, and reliability, manual monitoring has become a limiting factor. The solution has been the integration of smart automation and IoT technologies, which allow boilers to self-optimize, predict failures, and provide real-time data for decision-making.

Smart automation and IoT solutions in boiler control systems include advanced PLC/SCADA integration, IoT-enabled sensors for temperature, pressure, and water chemistry, cloud-based monitoring platforms, predictive maintenance algorithms, and AI-driven combustion optimization. These technologies improve efficiency by 5–15%, enhance safety, and minimize downtime by enabling remote supervision and proactive interventions.

By adopting these solutions, modern steam boilers evolve into intelligent, connected assets within Industry 4.0 frameworks.

IoT solutions in boiler systems are mainly cosmetic and do not affect performance.False

IoT sensors and automation provide actionable data that improves efficiency, reliability, and safety.

Smart automation allows predictive maintenance and remote boiler monitoring.True

AI-enabled analytics detect early faults, reducing downtime and unplanned costs.

Key Smart Automation & IoT Applications

1. IoT-Enabled Sensors

Real-time monitoring of temperature, pressure, vibration, water chemistry (pH, TDS), and fuel flow.

Data transmitted to central dashboards for trend analysis.

2. PLC & SCADA Systems

Programmable Logic Controllers (PLC) automate burner management, feedwater control, and blowdown scheduling.

Supervisory Control and Data Acquisition (SCADA) systems provide centralized visualization and alarms.

3. Cloud & Remote Monitoring

Data uploaded to secure cloud platforms.

Remote access allows operators and OEMs to supervise performance globally.

Enables 24/7 diagnostics and service support.

4. Predictive Maintenance with AI

Machine learning analyzes sensor data to predict tube leaks, scaling, or burner faults before failure.

Reduces unscheduled downtime by up to 30–40%.

5. Advanced Combustion Control

AI-driven algorithms adjust air-fuel ratio, excess oxygen, and flame stability dynamically.

Improves fuel efficiency and lowers NOx and CO emissions.

Benefits of Smart Boiler Controls

| Benefit | Traditional Systems | Smart Automation & IoT |

|---|---|---|

| Efficiency | 75–85% | 85–95% |

| Monitoring | Manual, local | Real-time, remote |

| Maintenance | Reactive | Predictive & proactive |

| Safety | Operator-dependent | Automated fail-safes |

| Data Analytics | Minimal | Advanced AI-driven insights |

Example: Smart Boiler Upgrade

A 50 TPH gas-fired boiler upgraded with IoT sensors, predictive analytics, and AI combustion control achieved:

Fuel savings: ~8% annually.

NOx reduction: 25%.

Unplanned downtime: cut by 35%.

Payback period: ~2 years due to reduced fuel and maintenance costs.

Conclusion

Smart automation and IoT are revolutionizing boiler control systems. By combining real-time monitoring, predictive analytics, cloud platforms, and AI-based combustion control, boilers are becoming intelligent, self-optimizing assets. These solutions not only boost efficiency and safety but also align industrial plants with digital transformation and sustainability goals.

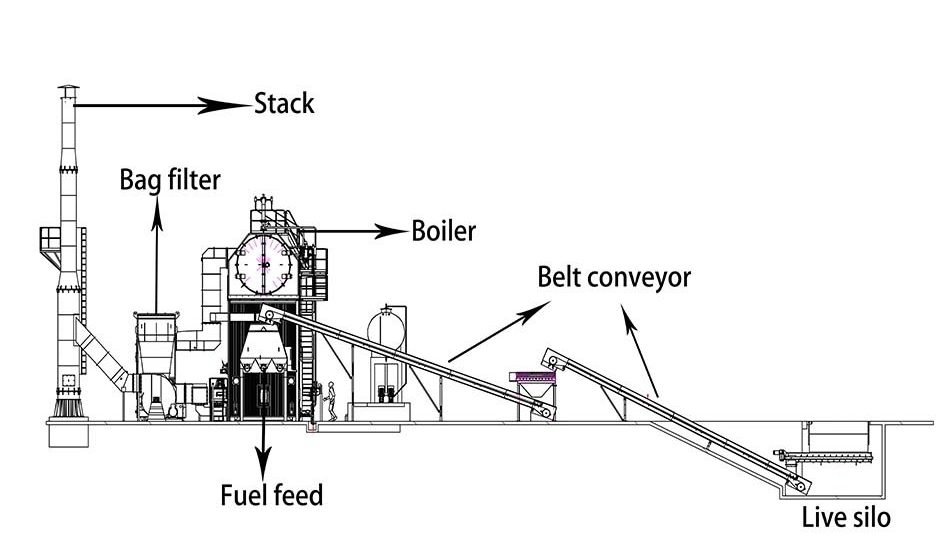

How are renewable fuels (biomass, hydrogen, waste-to-energy) integrated into boiler design?

Conventional industrial boilers were historically optimized for coal, oil, or natural gas, which are reliable but carbon-intensive fuels. As sustainability regulations tighten and industries pursue decarbonization, companies face the challenge of adopting renewable alternatives. However, burning biomass, hydrogen, or waste-derived fuels introduces unique design challenges—such as variable calorific values, higher moisture content, and combustion stability issues. To address these, boiler manufacturers are re-engineering systems with specialized designs that enable efficient, safe, and flexible use of renewable fuels.

Renewable fuels are integrated into boiler design by customizing combustion chambers, fuel feeding systems, burners, and heat recovery components to handle the unique properties of biomass, hydrogen, and waste-derived fuels. Biomass boilers require larger furnaces and advanced ash handling, hydrogen boilers need specially designed burners to manage flame speed and NOx formation, while waste-to-energy boilers integrate robust grates, advanced filtration, and corrosion-resistant alloys. These adaptations ensure efficiency, safety, and compliance with emission standards.

By adopting these design solutions, industries can transition from fossil fuels to sustainable steam generation without compromising reliability.

Hydrogen can be burned in conventional gas burners without modification.False

Hydrogen requires specially designed burners due to its high flame speed, low ignition energy, and risk of flashback.

Biomass fuels can replace coal in boilers when combustion chamber design and feeding systems are adapted.True

Biomass needs larger furnace volumes, moisture management, and ash handling systems to operate efficiently.

Fuel-Specific Boiler Design Adaptations

1. Biomass Integration

Fuel Feeding: Screw feeders, pneumatic conveyors, or chain grates for diverse biomass sizes.

Combustion Chamber: Larger furnace volumes to account for lower calorific value (~8–18 MJ/kg vs. coal’s ~24–30 MJ/kg).

Ash Handling: Automatic removal systems due to higher ash and slag formation.

Emission Control: Multi-cyclones, bag filters, or electrostatic precipitators to capture particulates.

2. Hydrogen Integration

Burner Technology: Special swirl-stabilized burners to manage hydrogen’s flame speed and prevent flashback.

NOx Control: Flue gas recirculation (FGR), staged combustion, or water injection.

Material Selection: Alloys resistant to hydrogen embrittlement.

Hybrid Flexibility: Many modern hydrogen-ready boilers can run on natural gas today and transition to 100% H₂ in the future.

3. Waste-to-Energy (WtE) Integration

Fuel Handling: Robust grates and feeding systems to handle municipal solid waste (MSW), RDF, or industrial residues.

Combustion Chamber: High turbulence zones for complete burnout of heterogeneous fuels.

Corrosion Resistance: Water walls clad with Inconel or stainless steel to withstand chlorine and alkali salts.

Emission Control: Advanced flue gas treatment including lime scrubbers, bag filters, and SCR units for dioxin, acid gas, and NOx control.

Boiler Design Comparison by Fuel

| Feature | Biomass Boiler | Hydrogen Boiler | Waste-to-Energy Boiler |

|---|---|---|---|

| Calorific Value (Fuel) | 8–18 MJ/kg | 120–142 MJ/kg | 6–12 MJ/kg (variable) |

| Furnace Design | Larger volume, low-NOx air staging | Compact, high-velocity burners | Large grate systems, robust walls |

| Main Challenge | Moisture & ash handling | Flame stability, NOx emissions | Fuel variability, corrosion |

| Key Solution | Advanced feeding & ash removal | Hydrogen-specialized burners | High-alloy materials & emission scrubbing |

Example of Hybrid Integration

A European paper mill replaced two coal boilers with biomass-waste co-firing units:

Fuel mix: 70% wood chips, 30% RDF.

Efficiency: ~84%.

CO₂ reduction: 220,000 tons/year.

Payback: ~5 years, due to avoided carbon taxes and lower fuel costs.

Conclusion

Renewable fuels can be successfully integrated into modern boiler design when fuel-specific adaptations are applied. Biomass boilers require robust fuel and ash handling, hydrogen boilers demand specialized burners and NOx control, while waste-to-energy units need durable materials and sophisticated emission treatment. Together, these innovations enable industries to meet decarbonization targets while maintaining reliable steam generation.

What safety and durability innovations enhance the long-term reliability of boilers?

Boilers operate under high temperature and pressure conditions, making them one of the most critical and risk-prone assets in industrial plants. Historically, boiler failures caused downtime, safety hazards, and costly repairs due to tube ruptures, scaling, or faulty controls. These risks limited operational efficiency and shortened equipment lifespan. To address these challenges, manufacturers have introduced safety and durability innovations that reduce accidents, extend service life, and ensure regulatory compliance.

Modern boiler reliability is enhanced through safety innovations such as redundant safety valves, automated burner management systems, flame detection, and IoT-enabled monitoring, combined with durability improvements like advanced alloys, membrane wall construction, anti-corrosion coatings, and predictive maintenance analytics. These solutions prevent catastrophic failures, extend operating cycles, and lower lifecycle costs.

Together, these innovations transform boilers into safer, more resilient, and longer-lasting assets.

Boiler safety is guaranteed solely by operator experience and manual checks.False

Modern boilers employ automated protection systems, sensors, and fail-safes that go beyond manual monitoring.

Using advanced alloys and coatings significantly extends boiler tube life under harsh conditions.True

Materials such as Inconel, stainless steel, and ceramic coatings resist corrosion, scaling, and high-temperature creep.

Key Safety Innovations in Modern Boilers

1. Automated Burner Management Systems (BMS)

Ensures proper sequencing of start-up, operation, and shutdown.

Monitors fuel-air ratio and prevents unsafe ignition.

Integrated flame scanners for early fault detection.

2. Redundant Safety Valves and Interlocks

Dual or triple valves ensure pressure relief redundancy.

Interlock systems shut down fuel supply instantly during abnormal conditions.

3. IoT-Based Safety Monitoring

Real-time sensors track pressure, temperature, vibration, water chemistry, and flame stability.

Predictive alarms prevent operator delay in responding to unsafe conditions.

4. Emergency Shutdown Systems (ESD)

Rapid depressurization and fuel cut-off.

Linked to plant-wide safety instrumented systems (SIS).

Durability Enhancements

1. Advanced Materials

Membrane water wall tubes reduce leakage points.

High-alloy steels and Inconel claddings withstand chlorine, sulfur, and hydrogen attack.

Ceramic coatings protect against slagging and scaling.

2. Water Chemistry Management

Automatic dosing systems maintain pH, hardness, and dissolved oxygen levels.

Online monitoring minimizes scaling and corrosion.

3. Thermal Stress Control

Drum and tube designs with optimized expansion joints.

Controlled ramp-up and cool-down sequences reduce fatigue.

4. Predictive and Preventive Maintenance

AI-driven analytics predict tube failure or corrosion hotspots.

Condition-based monitoring replaces fixed-interval overhauls.

Comparative Table: Traditional vs. Modern Reliability Features

| Feature | Traditional Boilers | Modern Boilers with Innovations |

|---|---|---|

| Safety Control | Manual checks | Automated BMS, IoT alarms |

| Materials | Carbon steel | Inconel, stainless, ceramic-coated |

| Corrosion Resistance | Basic treatments | Advanced coatings & alloy cladding |

| Monitoring | Periodic manual | Continuous digital monitoring |

| Lifespan | 15–20 years | 25–35 years with proper care |

Case Example

A 200 TPH circulating fluidized bed (CFB) boiler upgraded with Inconel-coated water walls and IoT monitoring achieved:

Tube failure reduction: 70% over five years.

Extended inspection cycle: from 12 to 24 months.

Operational availability: >96%.

Conclusion

Modern safety and durability innovations—ranging from automated burner controls and IoT sensors to advanced alloys and anti-corrosion coatings—significantly extend boiler reliability and safety. These technologies protect operators, reduce maintenance costs, and ensure compliance with increasingly stringent industry standards, securing the long-term value of boiler investments.

🔍 Conclusion

The future of industrial steam boilers lies in efficiency, sustainability, and digitalization. By adopting these latest design innovations, companies can not only reduce fuel consumption and emissions but also achieve smarter, safer, and more flexible operations.

📞 Contact Us

💡 Interested in upgrading to the latest boiler technology? We provide advanced design solutions, fuel conversions, and turnkey project support to help industries transition to next-generation steam boiler systems.

🔹 Contact us today to explore innovative steam boiler solutions tailored to your industry needs. 🚀🔥🌱✅

FAQ

What are the latest innovations in industrial steam boiler design?

Modern steam boiler design integrates advanced technologies to enhance performance, safety, and sustainability. Key innovations include:

Low-NOx and ultra-low-NOx burners for reduced emissions.

Condensing heat recovery systems to boost efficiency by 5–10%.

Biomass and multi-fuel capabilities for renewable energy use.

Digital twin technology for predictive maintenance and performance modeling.

Smart automation systems with IoT integration for real-time monitoring.

How is automation changing industrial steam boiler design?

Automation has shifted boilers from manual operation to intelligent control systems. Features include:

PLC and SCADA-based controls for precise operation.

Remote monitoring via cloud platforms.

AI-powered optimization of combustion and load management.

Predictive maintenance alerts, reducing downtime and costs.

What materials and construction improvements are being used in modern boilers?

High-strength, corrosion-resistant alloys extend boiler lifespan.

Improved refractory materials enhance heat retention and durability.

Modular design allows faster assembly and flexible capacity scaling.

Compact footprint designs save plant space without sacrificing output.

How do sustainability trends affect steam boiler design?

To align with global decarbonization goals, boiler manufacturers are focusing on:

Biomass, biogas, and hydrogen-ready designs.

Carbon capture and storage (CCS) compatibility.

High-efficiency heat recovery units for reduced fuel use.

Hybrid systems combining renewable energy with conventional fuel boilers.

What benefits do companies gain from adopting innovative boiler designs?

Organizations that upgrade to modern designs benefit from:

Lower fuel costs due to higher efficiency.

Regulatory compliance with stricter emission standards.

Reduced downtime thanks to predictive maintenance.

Flexibility in fuel sources, ensuring long-term sustainability.

Enhanced safety with advanced monitoring and control systems.

References

U.S. Department of Energy – Advanced Boiler Systems – https://www.energy.gov

IEA – Innovation in Industrial Energy Systems – https://www.iea.org

Babcock & Wilcox – Modern Boiler Technologies – https://www.babcock.com

Cleaver-Brooks – Boiler Design Advancements – https://www.cleaverbrooks.com

Forbes Marshall – Smart Steam Boiler Systems – https://www.forbesmarshall.com

Thermax – Sustainable Boiler Innovations – https://www.thermaxglobal.com

Spirax Sarco – Boiler Energy Efficiency Trends – https://www.spiraxsarco.com

ScienceDirect – Research on Boiler Innovation – https://www.sciencedirect.com

ResearchGate – Smart Boiler Technologies – https://www.researchgate.net

Engineering Toolbox – Boiler Performance Data – https://www.engineeringtoolbox.com

Wade Zhang

Latest Innovations in Industrial Steam Boiler Design Read More »