How to Improve the Efficiency of Coal-Fired Boilers: Practical Guide

How to Improve the Efficiency of Coal-Fired Boilers: Practical Guide

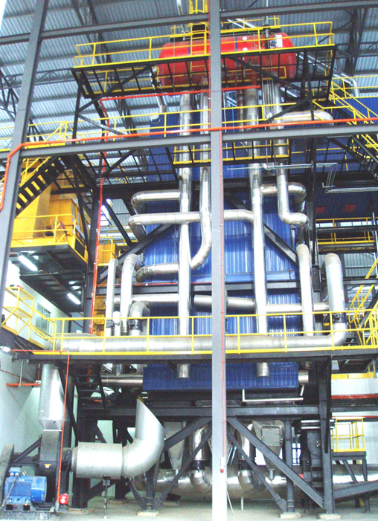

Coal-fired boilers remain a backbone of power generation and heavy industry, but they are often criticized for low efficiency, high fuel costs, and environmental impact. If not optimized, these boilers waste large amounts of energy and create higher emissions, directly affecting profitability and compliance.

The efficiency of coal-fired boilers can be improved through measures such as installing economizers and air preheaters for heat recovery, optimizing combustion with advanced burners and air-fuel control, using high-quality coal or blended fuels, ensuring proper feedwater treatment, reducing heat losses through insulation, and implementing regular maintenance and soot blowing. Additionally, digital monitoring, automation, and retrofitting emission control systems help sustain higher efficiency while meeting environmental regulations.

By combining design improvements with operational best practices, industries can achieve lower fuel consumption, reduced emissions, and long-term cost savings.

How Does Combustion Optimization Improve Coal-Fired Boiler Efficiency?

One of the biggest challenges in operating a coal-fired boiler is burning fuel completely and efficiently. Poor combustion leads to higher unburned carbon in ash, wasted fuel, excessive emissions, and unstable steam output. Plants struggling with rising fuel costs and stricter regulations often overlook the huge potential of combustion optimization as a cost-effective way to improve efficiency without major equipment upgrades.

Combustion optimization improves coal-fired boiler efficiency by ensuring precise fuel-air mixing, reducing excess air, stabilizing flame conditions, and enhancing heat transfer. Advanced optimization techniques can cut unburned carbon losses, lower auxiliary power consumption, and increase boiler efficiency by 1–3 percentage points, translating into significant annual fuel savings.

This means that relatively small adjustments in combustion tuning and control can produce millions of dollars in fuel savings for large utility boilers over their operating life.

Increasing excess air always increases boiler efficiency.False

Too much excess air carries heat away in flue gases, lowering efficiency. Optimal control balances complete combustion with minimal heat loss.

Combustion optimization can reduce fuel consumption in coal-fired boilers.True

By lowering unburned carbon losses and reducing excess air, optimized combustion reduces coal use for the same steam output.

Key Elements of Combustion Optimization

1. Fuel-Air Ratio Control

Proper proportioning of primary, secondary, and tertiary air streams.

Reduces unburned carbon (UBC) in fly ash and bottom ash.

Typical savings: 0.5–1.5% coal reduction.

2. Burner and Air Distribution Adjustment

Correcting burner tilt, swirl, and secondary air damper settings.

Enhances flame stability and reduces localized slagging.

Efficiency gain: 0.5–1%.

3. Real-Time Combustion Monitoring

O₂ analyzers and CO monitors in flue gas.

Adaptive control reduces excess air from 25% to ~15%, improving efficiency.

| Condition | Excess Air (%) | Boiler Efficiency (%) |

|---|---|---|

| Poorly tuned | 25–30% | 83–84% |

| Optimized | 15–20% | 85–87% |

4. Advanced Optimization Systems

Neural network or AI-based models analyze furnace conditions in real time.

Optimize mill loads, air distribution, and excess O₂ simultaneously.

Can yield 2–3% net heat rate improvement.

Example Case Study

A 300 MW coal-fired power plant implemented advanced combustion optimization software:

Baseline boiler efficiency: 84.5%

After optimization: 86.8%

Coal savings: ~20,000 tons/year

Payback period: less than 12 months

5. Secondary Benefits of Combustion Optimization

Lower Emissions: Reduced CO, NOx, and particulate matter.

Reduced Maintenance: Less slagging and fouling extend tube life.

Improved Load Flexibility: Stable flame supports low-load operation.

Lower Auxiliary Power Use: Optimized ID/FD fans save electricity.

Conclusion

Combustion optimization is one of the most cost-effective methods to improve coal-fired boiler performance. With careful air-fuel ratio control, burner tuning, and advanced monitoring systems, plants can achieve 1–3% efficiency gains, reduce fuel costs, lower emissions, and extend equipment life—all with relatively modest investment.

What Role Do Economizers and Air Preheaters Play in Energy Recovery?

Coal-fired boilers are inherently energy-intensive, and a large portion of energy input is lost as hot flue gases leaving the stack. Without proper heat recovery, plants waste fuel, pay higher operating costs, and face unnecessary emissions. This is where economizers and air preheaters come in: they are essential energy recovery devices that capture waste heat and return it to the steam cycle.

Economizers and air preheaters improve energy recovery in coal-fired boilers by transferring heat from flue gases to feedwater and combustion air, respectively. Economizers raise feedwater temperature, reducing fuel consumption, while air preheaters warm incoming combustion air to enhance flame stability and efficiency. Together, they can boost overall boiler efficiency by 5–10% and significantly cut fuel costs.

This means that even though these systems add to the capital cost, they quickly pay back through reduced coal use and improved boiler performance.

An economizer increases fuel consumption because it adds resistance to flue gas flow.False

Although it adds minor pressure drop, the heat recovered by an economizer preheats feedwater, reducing fuel demand and improving efficiency.

Air preheaters improve combustion efficiency by heating the air supplied to burners.True

Warmer combustion air enhances coal ignition, flame stability, and fuel-air mixing, which reduces unburned carbon losses.

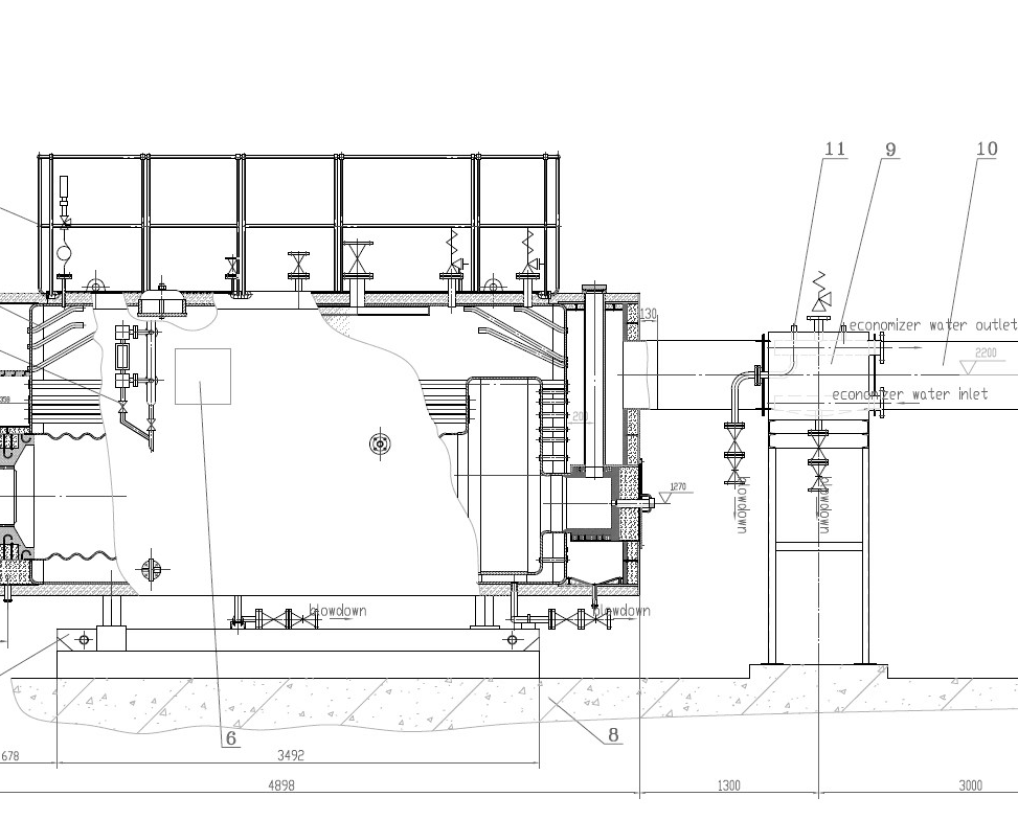

1. Economizers – Feedwater Heat Recovery

Function: Located in the flue gas path after the boiler bank, they use waste heat to preheat feedwater before entering the steam drum.

Benefits:

Saves 3–6% fuel consumption.

Reduces thermal shock in boiler tubes.

Enhances overall efficiency.

| Parameter | Without Economizer | With Economizer |

|---|---|---|

| Feedwater Temp | 105 °C | 150 °C |

| Boiler Efficiency | 82% | 86% |

| Coal Use (per ton steam) | 140 kg | 130 kg |

2. Air Preheaters – Combustion Air Heat Recovery

Function: Extract heat from flue gases to raise the temperature of combustion air entering burners.

Types:

Recuperative (tubular) – uses heat exchanger tubes.

Regenerative (rotary Ljungström) – rotating matrix absorbs and transfers heat.

Benefits:

Improves flame stability and coal ignition.

Reduces unburned carbon and excess air.

Saves 2–4% coal consumption.

| Parameter | Without APH | With APH |

|---|---|---|

| Combustion Air Temp | 25 °C | 180 °C |

| Boiler Efficiency | 83% | 86% |

| Unburned Carbon in Ash | 6% | 3% |

3. Combined Energy Recovery Impact

When both devices are used together, efficiency gains are cumulative:

Economizer + Air Preheater → 5–10% overall efficiency improvement.

Payback time often < 2 years in coal-fired plants.

| Device | Efficiency Gain | Typical Fuel Savings | Payback Period |

|---|---|---|---|

| Economizer | 3–6% | 10–20 kg coal/t steam | 1–2 years |

| Air Preheater | 2–4% | 5–12 kg coal/t steam | 1–1.5 years |

| Combined | 5–10% | 15–30 kg coal/t steam | < 2 years |

4. Secondary Advantages

Emission Reduction: Lower CO₂ per ton of steam.

Improved Boiler Life: Reduced stress from temperature gradients.

Operational Flexibility: Better low-load performance.

Conclusion

Economizers and air preheaters are essential energy recovery systems in coal-fired boilers. By preheating feedwater and combustion air, they cut fuel consumption, raise efficiency by up to 10%, and deliver rapid payback. Any modern coal-fired boiler aiming for cost and environmental competitiveness should integrate both.

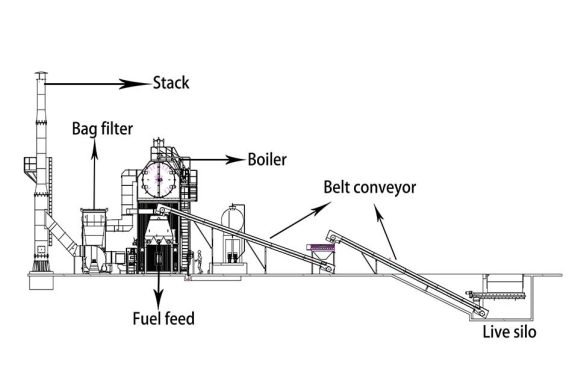

How Does Fuel Quality and Coal Preparation Affect Boiler Performance?

One of the most underestimated drivers of coal-fired boiler performance is fuel quality. Plants often struggle with slagging, fouling, unstable flame, low efficiency, and high emissions not because of poor boiler design but due to inconsistent coal quality or inadequate coal preparation. Using unsuitable coal without pretreatment can shorten boiler life, increase O&M costs, and cause costly unplanned outages.

Fuel quality and coal preparation directly affect combustion stability, heat transfer, efficiency, slagging tendency, and emission levels in coal-fired boilers. Higher calorific value, lower ash, and controlled moisture improve efficiency, while proper coal sizing and washing reduce unburned carbon, fouling, and maintenance costs. Consistent, well-prepared coal ensures stable steam output and optimal boiler performance.

This means that investing in coal quality control and preparation systems often yields better returns than oversizing or overengineering the boiler itself.

High-moisture coal improves combustion efficiency because water vapor increases heat transfer.False

Moisture in coal absorbs latent heat during evaporation, reducing net boiler efficiency.

Coal washing and preparation reduce ash and improve combustion efficiency.True

Coal washing removes impurities, lowers ash, improves heating value, and reduces slagging and particulate emissions.

1. Key Coal Quality Parameters Impacting Boiler Performance

| Coal Property | Effect on Boiler Performance | Impact if Poor Quality |

|---|---|---|

| Calorific Value (CV) | Determines energy per kg of coal | Low CV → higher fuel consumption |

| Moisture Content | Affects ignition and flame temperature | High → efficiency loss, unstable flame |

| Ash Content | Influences slagging, fouling, and maintenance | High → reduced heat transfer, erosion |

| Sulfur Content | Impacts SO₂ emissions and corrosion risk | High → environmental compliance cost |

| Volatile Matter | Affects ignition and combustion stability | Too low → hard ignition; too high → smoke, CO |

| Grindability Index (HGI) | Determines ease of pulverization | Low → high mill power, poor fineness |

2. Role of Coal Preparation in Optimizing Boiler Performance

Crushing & Sizing: Ensures uniform particle size for complete combustion (typically < 75 µm for pulverized coal).

Coal Washing: Removes rocks, ash, and sulfur compounds.

Efficiency gain: 1–3%.

Reduces particulate and SO₂ emissions.

Blending: Mixing high- and low-quality coals to achieve target CV and ash balance.

Drying (for lignite/sub-bituminous): Reduces moisture, improves ignition, and increases efficiency.

| Coal Type | Raw Efficiency Potential | With Preparation | Efficiency Gain |

|---|---|---|---|

| Lignite (35% moisture) | 75–78% | 80–82% | +4–6% |

| Bituminous (moderate ash) | 83–85% | 86–88% | +2–3% |

| Anthracite (hard to ignite) | 80–83% | 83–85% | +1–2% |

3. Real-World Example

A 200 MW power station switched from raw lignite to dried and partially washed lignite:

Boiler efficiency increased from 77% → 82%.

Coal consumption reduced by 80,000 tons/year.

Payback period of coal preparation system: ~18 months.

4. Secondary Impacts of Better Fuel Quality

Lower Emissions: Reduced SO₂, NOx, and particulates.

Extended Boiler Life: Less slagging and tube erosion.

Reduced Maintenance Costs: Fewer sootblowing and ash handling issues.

Stable Steam Supply: Improved flame stability supports grid reliability.

Conclusion

Fuel quality and coal preparation are as important as boiler design in determining overall efficiency, emissions, and operating costs. Investing in coal washing, drying, and proper sizing not only reduces fuel consumption but also protects equipment and ensures compliance. Inconsistent fuel quality is a hidden cost driver that many plants cannot afford to ignore.

Why Is Proper Insulation and Minimization of Heat Loss Critical for Efficiency?

One of the most overlooked factors in boiler performance is heat loss through uninsulated or poorly insulated surfaces. Even the most advanced boiler design with economizers and air preheaters cannot reach peak efficiency if heat escapes through boiler walls, piping, or storage tanks. This wasted energy not only drives up fuel consumption but also increases greenhouse gas emissions and raises plant operating costs.

Proper insulation and minimization of heat loss are critical for efficiency because they prevent unnecessary thermal losses from boiler surfaces, piping, and ancillary systems. Good insulation reduces fuel consumption, lowers emissions, improves workplace safety, and ensures stable steam supply. In many cases, proper insulation can increase overall boiler efficiency by 2–5% and pay for itself in under two years.

This means that insulation is not just a passive protection measure, but a powerful energy efficiency investment with fast returns.

Heat loss from boiler surfaces is negligible and does not affect efficiency.False

Uninsulated surfaces can lose 5–20% of total heat, significantly lowering efficiency. Proper insulation prevents this loss.

Insulation on steam piping helps sustain steam temperature and reduce fuel consumption.True

By minimizing radiation and convection losses, insulated piping delivers steam at higher temperature and pressure with less reheating required.

1. Major Sources of Heat Loss in Boilers

Radiation & Convection Losses: Heat escaping from boiler shells, doors, valves, and flanges.

Uninsulated Steam Lines: Steam temperature drops lead to condensation and efficiency loss.

Hot Water & Feedwater Tanks: Surface heat loss increases fuel demand to maintain set temperature.

Blowdown & Vent Systems: Energy lost in hot discharge if not recovered.

| Surface Type | Without Insulation (Heat Loss %) | With Proper Insulation (Heat Loss %) |

|---|---|---|

| Boiler Shell | 2–5% | <1% |

| Steam Piping | 3–8% | <1.5% |

| Hot Water Tanks | 2–4% | <0.5% |

2. Benefits of Proper Insulation

Fuel Savings: 2–5% reduction in coal, oil, or gas use.

Lower Emissions: Reduced CO₂ and NOx per unit of steam.

Safety: Insulated surfaces reduce workplace burns.

System Stability: Higher and more consistent steam temperatures.

Extended Equipment Life: Less condensation, corrosion, and stress.

3. Real-World Example

A textile factory with a 10 TPH steam boiler retrofitted proper insulation on steam lines, hot water tanks, and boiler shells:

Annual coal consumption reduced by 450 tons.

Fuel cost savings: $55,000 per year.

Payback period: 14 months.

4. Advanced Insulation Practices

Material Selection: Mineral wool, ceramic fiber, calcium silicate based on temperature.

Cladding: Aluminum or steel jacketing prevents moisture penetration.

Insulation Thickness: Optimized using economic thickness calculations.

Heat Loss Audits: Infrared thermography identifies hidden hot spots.

| Insulation Material | Max Service Temp (°C) | Thermal Conductivity (W/m·K) | Typical Application |

|---|---|---|---|

| Mineral Wool | 700 | 0.04 | Boiler walls, piping |

| Calcium Silicate | 650 | 0.06 | High-pressure piping |

| Ceramic Fiber | 1,200 | 0.10 | Furnace linings, burners |

Conclusion

Proper insulation is not a luxury—it is a critical efficiency strategy. By minimizing thermal losses, plants can save millions in annual fuel costs, improve safety, and reduce emissions. For many industrial facilities, insulation is one of the fastest-return energy investments available.

How Do Automation and Real-Time Monitoring Sustain High Efficiency?

Many plants invest heavily in advanced boilers, burners, and heat recovery systems, but still struggle with efficiency decline over time. The culprit is often manual operation and lack of continuous performance oversight. Without precise controls, boilers run with excess air, fuel imbalance, and fluctuating steam pressure—leading to wasted energy, high emissions, and unstable production.

Automation and real-time monitoring sustain high boiler efficiency by continuously optimizing combustion, steam conditions, and auxiliary systems based on real-time data. Automated controls adjust fuel-air ratio, burner load, and feedwater supply dynamically, while monitoring systems track performance, detect inefficiencies, and support predictive maintenance. This prevents efficiency drift, reduces fuel waste, and ensures long-term optimal operation.

In other words, automation locks in efficiency gains, ensuring the boiler operates at peak performance every day, not just after manual tuning.

Once optimized, boiler efficiency remains constant without monitoring or automation.False

Efficiency naturally drifts due to fuel variability, fouling, and load changes. Continuous monitoring and automation are required to maintain optimal performance.

Automated combustion control reduces excess air and improves efficiency.True

Automation fine-tunes air-fuel ratio in real time, minimizing heat loss in flue gases while ensuring complete combustion.

1. Key Automation Functions in Boilers

Combustion Control: Balances air and fuel in real time, reducing unburned carbon and excess O₂.

Drum Level Control: Ensures stable feedwater supply to maintain pressure and avoid carryover.

Burner Management System (BMS): Automates startup/shutdown and ensures safety.

Load Control: Matches steam generation to process demand with minimal fluctuation.

Emission Control Integration: Adjusts NOx burners and flue gas recirculation automatically.

| Automation Level | Typical Features | Efficiency Gain |

|---|---|---|

| Basic | Manual settings + fixed excess air | Baseline |

| Semi-Automated | O₂ trim + pressure control | +1–2% |

| Advanced (DCS/PLC) | Real-time air/fuel ratio, load balancing | +2–4% |

| Smart/AI Systems | Predictive combustion optimization | +3–5% |

2. Real-Time Monitoring Systems

Sensors & Analyzers: O₂, CO, NOx, flue gas temperature, and steam flow.

Performance Dashboards: KPIs like efficiency, heat rate, and fuel use.

Condition Monitoring: Detects fouling, slagging, or mill imbalance early.

Predictive Analytics: Uses trends to schedule maintenance before failures.

3. Case Study Example

A 150 TPH coal-fired boiler upgraded with real-time monitoring and AI-based combustion optimization:

Baseline efficiency: 84.2%

Post-automation efficiency: 87.5%

Annual coal savings: 25,000 tons

Payback period: 11 months

4. Secondary Benefits of Automation

Lower Emissions: Reduced CO₂ and NOx per unit steam.

Improved Safety: Automatic trip protection reduces operator risk.

Stable Steam Supply: Supports sensitive industrial processes.

Reduced Operator Workload: Less manual intervention required.

Conclusion

Automation and real-time monitoring are not just add-ons—they are core enablers of sustainable efficiency. By dynamically adjusting combustion and steam conditions while detecting inefficiencies early, these systems prevent costly performance degradation and ensure consistent savings over the boiler’s lifetime.

What Maintenance Practices Help Maintain Peak Performance in Coal-Fired Boilers?

Coal-fired boilers are highly efficient when properly designed, but their performance naturally declines over time due to slagging, fouling, wear, and component misalignment. Neglecting maintenance results in higher fuel consumption, lower efficiency, unstable steam supply, more unplanned shutdowns, and non-compliance with emission standards. To sustain peak performance, regular and systematic maintenance practices are essential.

The key maintenance practices that help maintain peak performance in coal-fired boilers include regular sootblowing, tube cleaning, fuel preparation checks, burner inspection, water chemistry control, refractory and insulation repair, air and flue gas path maintenance, and predictive monitoring of critical components. Consistent maintenance prevents efficiency loss, extends equipment life, and reduces operating costs.

This means that peak performance is not a one-time achievement but an outcome of disciplined, ongoing maintenance strategy.

Sootblowing and tube cleaning are unnecessary if the boiler is operating normally.False

Even during normal operation, ash and slag deposits reduce heat transfer, so periodic cleaning is critical for maintaining efficiency.

Water chemistry control prevents scaling and corrosion in boiler tubes.True

Proper feedwater treatment reduces scale formation, corrosion, and tube failures, ensuring high efficiency and reliability.

1. Combustion System and Burner Maintenance

Inspect and adjust burners to ensure proper fuel-air mixing.

Calibrate air dampers and registers.

Check coal mills for wear, balance, and fineness.

Result: Stable flame, reduced unburned carbon, and lower excess air requirements.

2. Heat Transfer Surface Cleaning

Sootblowers remove ash and slag from superheater, reheater, and economizer tubes.

Manual or chemical cleaning may be needed for stubborn deposits.

Regular cleaning improves heat transfer efficiency by 2–5%.

| Condition | Heat Transfer Efficiency | Boiler Efficiency |

|---|---|---|

| Fouled tubes | 70–75% | 80–82% |

| Clean tubes | 90–95% | 85–87% |

3. Water-Side Maintenance

Maintain correct water chemistry (pH, dissolved oxygen, TDS).

Use de-aerators and chemical dosing to prevent corrosion.

Regularly inspect for leaks, scaling, or pitting.

Benefit: Reduced tube failures and extended boiler life.

4. Refractory, Insulation, and Sealing

Repair cracks in refractory to avoid flame impingement and heat loss.

Inspect and upgrade insulation to reduce radiation losses.

Ensure doors, hatches, and flanges are well sealed.

5. Air and Flue Gas Path Checks

Inspect ID/FD fans and ducts for leaks and efficiency.

Calibrate O₂ analyzers and emission sensors.

Ensure proper draft balance to avoid backflow or excess air.

6. Predictive and Condition-Based Maintenance

Use infrared thermography to detect hot spots.

Apply vibration monitoring on rotating equipment (fans, mills).

Employ real-time monitoring for efficiency and emissions.

Enables proactive repairs before costly failures.

7. Scheduled Overhauls

Annual or biennial major inspections of pressure parts, drums, and headers.

Nondestructive testing (NDT) for cracks, thinning, or weld integrity.

Replacement of worn-out tubes, burners, and fans.

Case Example

A 300 MW coal-fired unit implemented systematic cleaning and predictive monitoring:

Baseline efficiency: 83.5%

After 12 months of disciplined maintenance: 86.2%

Annual coal savings: 22,000 tons

Avoided 3 forced outages, saving $1.2M in downtime costs.

Conclusion

Coal-fired boiler efficiency cannot be maintained through design alone—it requires structured maintenance practices. Regular cleaning, inspection, water chemistry management, and predictive monitoring ensure boilers deliver stable, safe, and efficient operation throughout their life cycle.

🔍 Conclusion

Improving the efficiency of coal-fired boilers requires a holistic approach combining better design, operational optimization, and proactive maintenance. Plants that implement these strategies enjoy higher energy savings, reduced emissions, and longer equipment life.

📞 Contact Us

💡 Looking to upgrade or optimize your coal-fired boiler system? We offer efficiency audits, retrofitting solutions, and turnkey upgrades tailored to coal-based operations.

🔹 Contact us today to maximize the efficiency and performance of your coal-fired boiler. ⚙️🔥🏭✅

FAQ

How can the efficiency of a coal-fired boiler be improved?

Efficiency can be improved through:

Combustion optimization – Adjusting air-to-fuel ratio for complete fuel burn.

Fuel quality control – Using coal with consistent calorific value and lower moisture.

Soot blowing & cleaning – Preventing slagging and fouling in heat exchange surfaces.

Heat recovery systems – Installing economizers and air preheaters to capture waste heat.

Insulation upgrades – Reducing radiation and convection heat losses.

Real-time monitoring – Using sensors and automation to maintain optimal performance.

Why does coal quality affect boiler efficiency?

Coal with high moisture or ash content reduces combustion efficiency because:

More energy is wasted evaporating water.

Excess ash leads to fouling, slagging, and reduced heat transfer.

Switching to washed coal, low-ash coal, or blending fuels can raise efficiency by 2–5%.

What role does flue gas heat recovery play?

Installing economizers and air preheaters allows heat from flue gases to be reused:

Economizers preheat feedwater, reducing fuel input.

Air preheaters warm combustion air, improving fuel burn.

These systems can improve overall efficiency by 3–7%.

Can automation improve coal boiler performance?

Yes. Advanced control systems use AI and IoT sensors to:

Continuously monitor combustion and emissions.

Adjust dampers, burners, and feed rates in real time.

Detect inefficiencies before they cause major fuel losses.

Automation can increase efficiency by 5–10% while reducing manual intervention.

Are there long-term strategies for higher efficiency?

Yes, some include:

Retrofitting to supercritical or ultra-supercritical designs (higher pressure/temperature).

Switching to fluidized bed combustion (CFB) for fuel flexibility and better efficiency.

Hybridization with biomass or natural gas co-firing to cut emissions and fuel costs.

Carbon capture integration for future sustainability requirements.

References

U.S. Department of Energy – Improving Coal Boiler Efficiency – https://www.energy.gov

ASME – Boiler Performance Optimization – https://www.asme.org

Spirax Sarco – Combustion and Boiler Efficiency – https://www.spiraxsarco.com

Forbes Marshall – Fuel Efficiency in Boilers – https://www.forbesmarshall.com

Babcock & Wilcox – Coal Boiler Upgrades – https://www.babcock.com

IEA – Efficiency in Fossil Fuel Boilers – https://www.iea.org

ScienceDirect – Coal Combustion Optimization – https://www.sciencedirect.com

ResearchGate – Heat Recovery in Steam Boilers – https://www.researchgate.net

Cleaver-Brooks – Boiler Efficiency Improvement – https://www.cleaverbrooks.com

Engineering Toolbox – Boiler Heat Loss Analysis – https://www.engineeringtoolbox.com

Wade Zhang

How to Improve the Efficiency of Coal-Fired Boilers: Practical Guide Read More »

-scaled.jpg)