How to Assess After-Sales Support and Maintenance Services for Industrial Biomass Boilers

How to Assess After-Sales Support and Maintenance Services for Industrial Biomass Boilers

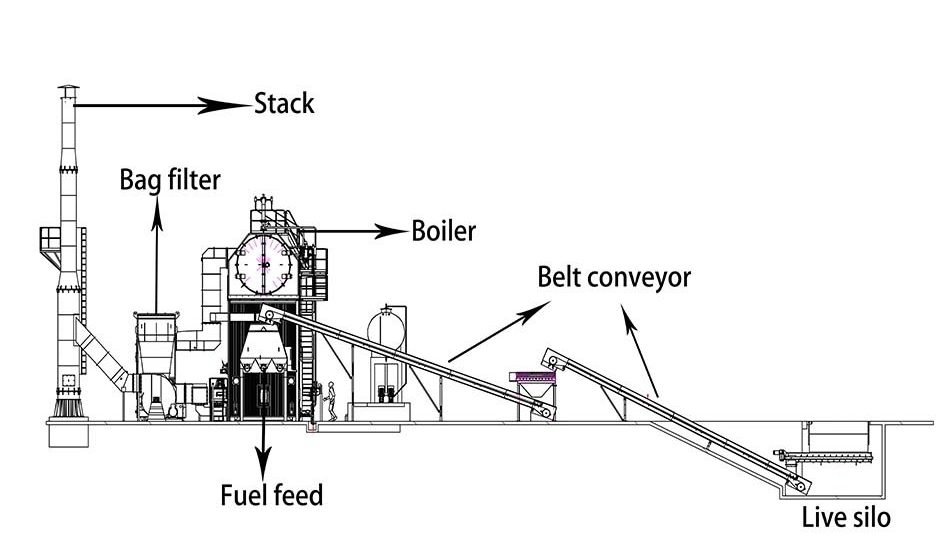

Industrial biomass boilers are an effective solution for sustainable energy generation, but they require specialized and consistent after-sales support due to the variability of fuel types, combustion conditions, ash content, and emissions control systems. Without strong post-installation service, issues like slagging, poor combustion, downtime, and regulatory violations can significantly increase operating costs and reduce boiler lifespan.

To assess after-sales support and maintenance services for industrial biomass boilers, evaluate the supplier’s preventive maintenance protocols, remote monitoring capabilities, spare parts inventory, emergency response times, technician training, refractory and ash-handling expertise, and long-term performance guarantees. Ask about service contracts, operator training, fuel testing services, and historical uptime performance. A trusted supplier should offer full lifecycle support tailored to the unique operational challenges of biomass fuel systems.

Here’s a comprehensive guide to evaluating a supplier’s service capability.

What Types of Service Agreements Are Available (Basic Inspection, Full Maintenance, Performance-Based)?

Biomass-fired boilers face unique challenges—such as fuel variability, high ash content, refractory wear, and emissions complexity—that require structured, proactive, and fuel-informed maintenance. Without the right service agreement in place, boiler owners are left exposed to unpredictable downtime, combustion inefficiency, and regulatory risk. The solution lies in selecting the right type of service contract to match the plant’s operational needs, fuel quality, and production criticality.

Buyers must ask suppliers to clearly define the service agreement options available—typically categorized as basic inspection, full maintenance, and performance-based—and understand the scope of coverage, frequency of service, spare parts availability, technical support terms, and performance KPIs. Contracts should align with the complexity of the biomass system and the expected runtime hours.

Service isn’t a cost—it’s a safeguard. Choose it wisely.

Structured service agreements tailored to biomass boiler operation are critical for managing fuel-related risks, maintaining efficiency, and ensuring emissions compliance.True

Biomass fuels introduce operational variability. Maintenance contracts that proactively address fouling, ash buildup, and combustion control prevent outages and stabilize long-term performance.

Common Biomass Boiler Service Contract Types Explained

1. Basic Inspection Agreement – Entry-Level Oversight and Support

| Scope | Features | Ideal For |

|---|---|---|

| Annual or semi-annual visit | Visual inspection, combustion check, report issuance | Plants with skilled in-house O&M teams |

| Includes trip log review | Emissions drift check, visual grate wear assessment | Low-load or standby biomass systems |

| Advisory only | No parts or tuning included | Fuel quality stable or batch-mode |

Ask:

Is the inspection report digitally formatted for ISO audits?

Are refractory inspections or sensor checks included?

Can you assist in preparing for local compliance audits?

2. Full Maintenance Contract – All-Inclusive Preventive Service

| Scope | Features | Ideal For |

|---|---|---|

| Quarterly or monthly visits | Full cleaning, tuning, lubrication, thermal scan | Base-load biomass steam generation plants |

| Spare parts coverage | Grate bars, nozzles, actuators, thermocouples | Continuous-use or high-ash fuel plants |

| Emissions tuning and reporting | CEMS calibration support, O₂/CO/NOₓ tuning | Plants under strict environmental oversight |

| Emergency support | Guaranteed response within 48 hours | Critical uptime environments |

Ask:

Are burner curves and air/fuel ratios adjusted each visit?

Does your technician carry spare parts for on-the-spot repairs?

Are scheduled cleaning routines adapted to our biomass grade?

3. Performance-Based Contract – Guaranteed Results Linked to KPIs

| Scope | Features | Ideal For |

|---|---|---|

| Contract linked to boiler uptime, efficiency, or emissions | Shared risk model based on runtime hours or fuel consumption | High-reliability users (IPPs, district heating, continuous process industries) |

| Real-time performance monitoring | Remote diagnostics, dashboard alerts, predictive alerts | Digital-ready plants with SCADA access |

| Incentives for high availability | Penalties/bonuses tied to performance | ESG or uptime contract-regulated facilities |

Ask:

What KPIs are included—efficiency, uptime, emissions, maintenance intervals?

How are fuel variations (e.g., moisture shifts) accounted for?

Is downtime response covered under the contract or separately?

Contract Comparison Table

| Feature | Basic Inspection | Full Maintenance | Performance-Based |

|---|---|---|---|

| Site visits/year | 1–2 | 4–12 | 6–12 + remote |

| Spare parts | Not included | Included (select items) | Fully included |

| Remote monitoring | Optional add-on | Often included | Required |

| Uptime KPIs | ❌ | Informational only | Contractual target (e.g., ≥95%) |

| Report generation | Manual | Scheduled + dashboard | Auto-generated, real-time |

Example: 20 TPH Biomass Boiler Service Agreement Case

Fuel: Mixed sawdust + rice husk (18–28% moisture)

Service Plan: Full Maintenance Contract

Included:

Monthly site visit with combustion diagnostics and refractory thermal mapping

Ash system inspection + scraper chain lubrication

Grate bar wear replacement every 6 months

Emergency response under 24 hours

CEMS recalibration and NOₓ tuning every quarter

Access to emissions dashboard with daily NOₓ trendline

Results:

Unplanned shutdowns reduced from 3.8/year to 0.5/year

Steam-to-fuel ratio improved by 7.2%

Emissions consistently below 135 mg/Nm³ for NOₓ and 25 mg/Nm³ for CO

Summary

Biomass fuels change with every truckload—your service plan shouldn’t. Whether you need a light inspection, a full-service lifecycle shield, or a performance-guaranteed partnership, make sure your contract matches your operation. Ask for clarity, KPIs, and real-world case proof. Choose not just service, but assurance. Choose biomass support built for variability, uptime, and regulatory peace of mind.

How Do You Handle Spare Parts and Consumables for Fuel Feed, Combustion, and Ash Systems?

Biomass boiler operations depend on mechanical systems that endure constant wear, abrasion, corrosion, and thermal cycling—especially in fuel feeding, combustion, and ash extraction zones. Without proper spare parts planning and consumable inventory, failures in a single screw feeder, grate, or ash conveyor can halt the entire steam supply chain, trigger emissions excursions, or even damage refractory linings.

Buyers must ask biomass boiler suppliers how they manage spare parts and consumables—especially for high-wear systems such as fuel screw conveyors, combustion air nozzles, grate bars, refractory modules, and ash extraction components. This includes parts availability, stocking options, delivery timelines, digital tracking, and replacement schedules.

Reliability isn’t built into steel alone—it’s stocked on your shelf and tracked in your logs.

Timely availability of spare parts and consumables for biomass boiler fuel, combustion, and ash systems is essential to prevent unplanned downtime and operational losses.True

Due to high wear from abrasive fuels, parts like screw conveyors, nozzles, and grates must be replaced proactively to maintain combustion performance and ensure safe operation.

Key Spare Parts Management Areas to Ask Your Supplier

1. How Are Fuel Feeding Components Supported?

| Component | Wear Risk | Parts to Track |

|---|---|---|

| Fuel screw conveyors | Abrasion, jamming | Shafts, bearings, seals, drive motors |

| Rotary airlocks | Ash buildup, jamming | Vanes, seals, couplings |

| Chain/bucket elevators | Dust ingress, misalignment | Chains, sprockets, buckets |

Ask:

Do you recommend stocking entire assemblies or critical wear kits?

What’s the typical lifetime (hours/tons) for screw flights in our fuel type?

Are motors and couplings standardized or custom-sized?

2. What Is the Grate and Combustion Parts Supply Strategy?

| Component | Failure Mode | Recommended Spares |

|---|---|---|

| Grate bars | Thermal cycling, fuel ash fusion | Alloy-cast bar sets by row or section |

| Air nozzles | Ash impingement, warping | Ceramic/SS nozzles, O-rings, seat washers |

| Primary/secondary air dampers | Warping, actuator slip | Actuator kits, damper blades, sensors |

Ask:

Are grates modular for partial replacement?

Can you deliver ceramic nozzles pre-matched to our row IDs?

Do you offer a combustion tuning kit (nozzles + seals + gaskets)?

3. How Are Ash Handling Parts Managed?

| System | Critical Components | Failure Points |

|---|---|---|

| Bottom ash conveyor | Trough liner, drag chain | Chain wear, sprocket rounding |

| Fly ash hopper | Rapping motors, filter elements | Motor failure, bag blinding |

| Rotary unloader | Seal ring, vanes, gearhead | Leakage, torque slippage |

Ask:

What is the ash removal motor’s MTBF under high-ash fuels?

Are baghouse filters provided in sets with barcode labels?

Can you auto-replenish filters based on runtime?

4. What Are the Parts Stocking and Delivery Terms?

| Spare Type | Stocking Method | Lead Time (Typical) |

|---|---|---|

| Critical parts (motors, grates) | On-site consignment or contract | 1–3 days (in-region) |

| Consumables (gaskets, filters) | Yearly or bi-annual kits | Delivered quarterly |

| Large parts (gearboxes, fans) | Reserved at regional warehouse | 4–8 weeks |

| Digital inventory | QR-tagged BOM + reorder alerts | Real-time mobile access |

Ask:

Do you offer a digital spare parts management system?

Can spares be bundled with service contracts or preventive kits?

Are obsolete or upgraded parts automatically flagged?

5. Do You Provide Parts Replacement Schedules and Predictive Planning?

| Tool | Function |

|---|---|

| Runtime counter linked to SCADA | Triggers part replacement alerts |

| Visual inspection checklist | Identifies fatigue, warping, cracking |

| Predictive service dashboard | Combines run hours, ash rate, temperature trends |

| Illustrated parts manual | 3D exploded views with codes for reordering |

Ask:

Do you provide expected life charts for major assemblies?

Can we access parts forecasts based on our actual fuel blend?

Are parts kits optimized by runtime or calendar-based intervals?

Example: Spare Parts Kit for 15 TPH Biomass Boiler

Fuel: Sawdust + palm kernel shell blend (ash 7.2%, 23% moisture)

Stocked On-Site:

Grate bars: 12% annual replacement rate (per burner row)

Ceramic air nozzles: 25% attrition/year

Fuel screw shaft + coupling kit: 1 spare per 8,000 hours

Bottom ash drag chain set: Full length every 3 years

Filter bags (PTFE): Full change every 12–18 months

Digital Tools:

QR-coded BOM matched to boiler serial number

Parts dashboard linked to service intervals and usage logs

Monthly reorder report + alert email for low inventory levels

Summary

Biomass burns hard—and it wears harder. Your supplier’s spare parts system must anticipate that reality with smart stocking, predictive replacement, and responsive logistics. Ask not just what parts they offer, but how, when, and with what support they deliver them. Choose a spare parts system as strong as the boiler itself. Choose proactive logistics. Choose parts that arrive before failure. Choose combustion without compromise.

What Is Your Response Time for Emergency Support, and Do You Offer 24/7 Assistance?

Biomass boilers are subject to fuel variability, mechanical stress, and ash accumulation—making them more prone to unplanned shutdowns, fuel feeder blockages, flame loss, or refractory failure. When a fault occurs, your ability to recover operations quickly depends entirely on the speed and quality of your supplier’s emergency response. Every hour offline means production losses, compliance risk, and fuel waste.

Buyers must ask biomass boiler suppliers to clearly define their emergency support terms—including guaranteed response times, hotline availability, field engineer dispatch protocol, and the availability of 24/7 assistance. Support terms should also cover fault diagnosis procedures, digital access to controls, escalation hierarchy, and availability of spare parts for urgent repair.

When you’re facing a shutdown, only one metric matters: how fast your supplier shows up—with solutions.

Rapid emergency response and 24/7 support access are essential for minimizing downtime and avoiding production and environmental losses in biomass boiler operations.True

Biomass boiler failures often occur due to ash bridging, fuel flow disruption, or emissions drift. Timely support prevents extended outages and safety risks.

Key Emergency Support Elements You Must Clarify

1. What Are Your Remote Support and Diagnostic Capabilities?

| Remote Support Type | Expected Response | What It Includes |

|---|---|---|

| 24/7 technical hotline | ≤2 hours response | First-line troubleshooting |

| VPN-based diagnostics | <1 hour login (if contracted) | PLC review, sensor faults, trip logs |

| SCADA remote viewing | Real-time data access | Alarm status, emissions levels |

| SMS/Email alert system | Auto-alarm forwarding | Critical events push notifications |

Ask:

Is your hotline staffed by boiler-specific engineers?

Can you access our control system remotely?

Are remote resets or parameter tuning permitted under warranty?

2. What Is the Guaranteed Field Engineer Response Time?

| Response Type | In-Region Target | Typical Outside Timeframe |

|---|---|---|

| On-site engineer (critical failure) | ≤24–48 hours | 48–72 hours (remote or rural) |

| Parts + engineer combo dispatch | ≤72 hours with spare delivery | Pre-contract required |

| Weekend/emergency visit | Available with surcharge or SLA | Must be pre-authorized |

Ask:

Do you have regional service bases for field deployment?

Is the response time SLA-backed or “best effort”?

Do you offer priority support under extended service contracts?

3. Do You Support 24/7 Assistance and What Does It Cover?

| Support Coverage | Available Under |

|---|---|

| 24/7 hotline support | All service tiers or with subscription |

| Emergency field visits | Only with premium service contract or add-on |

| 24/7 parts dispatch | Contracted clients or key accounts only |

| SCADA/VPN support after hours | Requires pre-configured access + consent |

Ask:

Is 24/7 support included in our default service plan?

Are nighttime or holiday response terms different?

What incidents are prioritized for overnight dispatch?

4. What Is the Fault Escalation and Closure Workflow?

| Step | Timeline | Responsibility |

|---|---|---|

| Fault report received | Within 15 minutes | Plant operator logs via hotline or web |

| Support assigned | <30 minutes | Senior technician or remote engineer |

| Root cause diagnosis | <2 hours for digital | On-site only if unresolved |

| Follow-up report + closure | Within 48–72 hours | Field engineer or account manager |

Ask:

Are service events logged in a digital portal?

Do you issue post-event debriefing with action plan?

Can you provide monthly incident history for audit?

5. Do You Offer Emergency Spare Parts and On-Demand Kits?

| Spare Part Support | Terms |

|---|---|

| Pre-packed emergency kits | Supplied on consignment or contract |

| Courier shipping | 24–72 hours from regional depot |

| Rental/replacement burners or controls | Select models only |

Ask:

Can critical spares be shipped same-day?

Do you pre-stock emergency items at our site?

Are spare parts mapped to fault types for rapid matching?

Example: Emergency Response Record – 12 TPH Biomass Boiler, Thailand

Issue: Ash screw jam + flame loss on night shift

Support Flow:

22:48 – Alarm logged, SCADA auto-sends to supplier support

23:05 – Hotline engineer diagnoses trip via remote login

00:34 – On-site operator guided to clear obstruction and purge ash

01:20 – Boiler restarted under remote supervision

10:00 – Field engineer dispatched for post-event inspection

Total Downtime: 2.5 hours

Parts used: None (issue resolved remotely)

Summary

In biomass combustion, time is steam—and steam is money. Don’t wait until your feeder jams, your flame dies, or your NOₓ trips a shutdown alarm. Ask your supplier what real emergency support looks like: how fast they respond, what’s included, and how they’ll protect your uptime 24/7. Choose not just a boiler vendor, but an emergency-ready service partner. Choose support that starts when the fault does—not after. Choose presence. Choose preparedness. Choose round-the-clock reliability.

What Monitoring Tools and Automation Systems Do You Provide for Real-Time Performance Tracking?

Biomass boilers present significant control challenges due to fuel variability, moisture fluctuations, and combustion unpredictability. To operate safely, efficiently, and within emissions limits, these systems must be continuously monitored, automatically adjusted, and transparently logged. That’s where real-time automation and performance tracking tools make the difference between reactive troubleshooting and proactive efficiency.

Buyers must ask suppliers about the automation platform (PLC, HMI), monitoring instruments (O₂, CO, steam, fuel flow, emissions), data visualization (SCADA or dashboards), remote access capabilities, and whether the system provides alerts, diagnostics, and performance KPIs in real time. These tools ensure visibility, safety, and compliance throughout the boiler’s lifecycle.

A modern boiler must do more than burn biomass—it must understand itself.

Integrated monitoring and automation systems are essential for optimizing combustion, preventing faults, and ensuring emissions compliance in biomass boiler operations.True

Real-time visibility into oxygen, fuel flow, and thermal efficiency enables early detection of inefficiencies or failures, especially under variable biomass fuel conditions.

What to Look For in a Monitoring and Automation System

1. What PLC and HMI Platforms Are Offered?

| Component | Function | Popular Brands |

|---|---|---|

| PLC (Programmable Logic Controller) | Burner logic, interlocks, air/fuel ratio | Siemens, Schneider, Allen-Bradley |

| HMI (Human-Machine Interface) | Touchscreen control, alarm handling | Weintek, ProFace, Siemens |

| RTU or Edge Gateway | For isolated or cloud-linked systems | Modbus/OPC/IoT-ready |

Ask:

Is the PLC logic modular for fuel-specific adaptation?

Is the HMI multilingual and touchscreen-enabled?

Can settings be remotely accessed for tuning or resets?

2. What Sensors and Instruments Are Installed for Performance Monitoring?

| Sensor Type | Purpose |

|---|---|

| O₂ analyzer | Optimize excess air for combustion efficiency |

| CO analyzer | Detect incomplete combustion and firebox drift |

| Fuel flowmeter | Track kg/hour of biomass feed |

| Steam output sensors | Measure energy conversion and demand match |

| Bed temp / flue gas temp | Ensure combustion zone control |

| Pressure differential (baghouse, economizer) | Detect fouling or maintenance needs |

Ask:

Are sensors linked to alarm triggers for trip events?

Can sensor readings be trended historically?

Are sensors field-replaceable and calibrated on-site?

3. What Real-Time Dashboards and Visualizations Are Available?

| Dashboard Feature | Use Case |

|---|---|

| Efficiency tracker | Live boiler thermal performance (% HHV/LHV) |

| Alarm log viewer | Timestamped fault investigation |

| Emissions panel | NOₓ, SO₂, CO readings (linked to CEMS or sensors) |

| Fuel moisture/flow | Alerts for wet/sluggish feed affecting flame |

| Steam-to-fuel ratio | KPI for operator performance tracking |

Ask:

Is the dashboard accessible remotely (cloud or app)?

Can multiple boilers be viewed in a single interface?

Can reports be exported (CSV, Excel, PDF) for audits?

4. What Automation Functions Are Available for Control?

| Control Function | Benefit |

|---|---|

| O₂ trim control | Adjusts air fan speed based on real-time excess air |

| Fuel-air ratio logic | Matches burner output to feed variation |

| PID tuning auto-adjustment | Maintains stable output during load swings |

| Burner modulation | Avoids flame extinction at low demand |

| Ash system logic | Triggers cleaning based on runtime or ash % trends |

Ask:

Is combustion tuning adaptive to fuel grade or manual only?

Are auto-cleaning systems programmable based on ash trend data?

Can safety shutdowns be tested via simulation?

5. Do You Provide Remote Monitoring, Reporting, and Alerts?

| Remote Feature | Utility |

|---|---|

| VPN-secured PLC access | Troubleshoot without site visit |

| Email/SMS alert system | Operator and manager notifications |

| Daily or weekly report auto-export | For compliance and performance logs |

| Remote burner tuning (optional) | Adjust curves for emissions or moisture variation |

Ask:

Can multiple users have different access levels (operator, engineer, auditor)?

Are alerts prioritized (warning vs critical)?

Is a mobile app available for off-site status checking?

Example: 12 TPH Biomass Boiler Monitoring Suite

Fuel: Coffee husk + sawdust (19–24% moisture)

PLC: Siemens S7-1500

HMI: 10” touchscreen, multilingual

Sensors Installed:

O₂ + CO in flue gas

Fuel belt scale with CV compensation

Steam pressure and output

Baghouse ΔP sensor

Ash bin fill level sensors

Visualization:

Efficiency dashboard with real-time HHV-based curve

NOₓ trend line from CEMS API

Operator shift performance logs

Auto-email of steam/fuel KPIs daily at 6:00 AM

Summary

Biomass combustion requires precision, and precision requires visibility. Choose a supplier who not only builds strong boilers—but equips them with smart eyes, ears, and logic. Ask for real-time analytics, sensor integration, and full automation that adapts to your fuel and load. Choose not just a firebox—but a feedback loop. Choose the biomass boiler that doesn’t just burn clean—it thinks smart. Choose control built for combustion. Choose insight built for uptime.

Do You Offer Biomass Fuel Analysis, Combustion Tuning, and Refractory Inspection Services?

Biomass boiler performance hinges on three dynamic variables: fuel quality, combustion stability, and refractory integrity. Variations in ash content, moisture levels, and calorific value can quickly throw combustion out of tune, increase emissions, cause slagging, or damage furnace linings. Routine operations without biomass fuel analysis, combustion tuning, and refractory inspection quickly degrade efficiency and elevate maintenance costs.

Buyers must ask the supplier whether they offer a full suite of diagnostic and tuning services—including proximate/ultimate fuel testing, burner/air ratio tuning, flame shape optimization, and infrared or manual refractory inspections. These services must be scheduled periodically or triggered by performance drift, and included in service contracts or available on-demand.

Precision in fuel, flame, and firebrick isn’t optional—it’s operational insurance.

Fuel analysis, combustion tuning, and refractory inspection services are essential to optimize performance and prevent failure in biomass boiler systems.True

Biomass fuels are inconsistent by nature. Adjusting combustion settings and monitoring refractory health prevents costly downtime and ensures emissions compliance.

Key Diagnostic and Optimization Services to Request

1. Do You Offer Biomass Fuel Analysis and Testing?

| Test Type | Purpose |

|---|---|

| Proximate analysis | Moisture, volatile matter, fixed carbon, ash |

| Ultimate analysis | Carbon, hydrogen, nitrogen, sulfur, oxygen |

| Ash fusion temperature | Predict slagging and clinker risk |

| HHV/LHV measurement | Calorific value for tuning feed rate |

| Bulk density + particle size | Feeder and combustion consistency |

Ask:

Do you offer on-site sampling or lab-based testing?

Can analysis reports be tied to combustion performance trends?

How often should fuel be re-tested for consistent operation?

2. What Combustion Tuning Services Are Provided?

| Tuning Element | Target Benefit |

|---|---|

| Primary/secondary air calibration | Optimal excess air for fuel burn completeness |

| Burner nozzle cleaning/replacement | Flame shape control and CO reduction |

| Grate speed and fuel bed depth tuning | Slagging avoidance, complete combustion |

| CO and O₂ trim tuning | Fuel savings and emissions reduction |

| Flame scanner calibration | Trip avoidance and flameout protection |

Ask:

Is tuning performed after every fuel change or seasonally?

Do you provide combustion curve reports before/after tuning?

Can tuning be done remotely via SCADA or only on-site?

3. Do You Conduct Refractory Inspections and Maintenance?

| Inspection Method | Findings |

|---|---|

| Visual inspection | Cracks, spalls, wear zones |

| Thermal camera mapping | Hot spots, insulation loss, bridging detection |

| Thickness gauge (manual) | Lining erosion or uneven wear |

| Expansion joint assessment | High-risk leakage or detachment |

Ask:

Is thermal imaging included in your annual service plan?

Are refractory maps archived digitally for comparison?

Can you conduct minor patch repairs during inspection?

4. How Are These Services Delivered—Contract, Schedule, or On-Demand?

| Service Type | Delivery Options |

|---|---|

| Fuel analysis | Initial commissioning + quarterly or fuel change |

| Combustion tuning | Quarterly or fuel quality variation |

| Refractory inspection | Annually or during shutdown |

Ask:

Are these services bundled in your full maintenance contracts?

Do you support training for in-house staff on combustion tuning?

Are post-service reports included with photos and sensor logs?

5. Example Service Record – 20 TPH Biomass Boiler (Rice Husk + Wood Chips)

Service Package: Quarterly Optimization + Annual Refractory Audit

Fuel Testing:

Moisture: 18.6% (avg)

Ash content: 14.2%

HHV: 13.9 MJ/kg

Ash fusion: 1190°C

Combustion Tuning Actions:

Adjusted secondary air dampers by 8%

Replaced 12 nozzles with ceramic tips

Optimized CO level from 65 → 23 mg/Nm³

Increased efficiency by 4.1% after tuning

Refractory Findings:

Rear wall hot zone (thermal delta +65°C)

Repaired 0.8 m² patch during planned outage

Next inspection scheduled in 11 months

Summary

Biomass combustion isn’t “set and forget”—it’s “monitor, tune, and inspect.” Choose a supplier that delivers fuel-informed, combustion-optimized, and refractory-protected service—not just during breakdowns, but proactively throughout your boiler’s life. Ask for fuel labs, burner experts, and thermal scanners—not just spares. Choose combustion support that adapts to your feedstock. Choose uptime through understanding. Choose tuning that saves fuel and firebrick alike.

What Training Programs Are Available for Operators and On-Site Maintenance Staff?

Operating a biomass boiler is not just about pushing buttons—it’s about understanding combustion dynamics, fuel variability, emissions control, and mechanical systems under real-world pressures. Without structured training, even the best boiler technology is at risk of human error, emissions violations, or avoidable downtime. For safe, efficient, and consistent performance, operators and maintenance teams must be trained to master the boiler’s unique challenges.

Buyers must ask their boiler supplier what formal training programs are available for on-site teams, including operator certification, maintenance skills development, SCADA use, emissions compliance, and emergency handling. Training should cover startup/shutdown protocols, troubleshooting, preventive maintenance, tuning, and safety systems—delivered through classroom, on-site, and digital modules.

Skilled people protect steam, emissions, uptime—and investment.

Structured operator and maintenance training programs are essential to ensure safe, efficient, and compliant operation of biomass boilers.True

Without proper training, biomass boiler operators may mishandle fuel variability, damage refractory, or cause inefficient combustion—leading to unnecessary downtime and higher emissions.

Key Training Program Components to Ask About

1. What Training Topics Are Covered for Operators?

| Module | Core Focus |

|---|---|

| System overview | Boiler anatomy, fuel system, flue path |

| Startup/shutdown | Purge logic, burner ignition, load control |

| SCADA interface | Alarms, KPIs, parameter changes |

| Emissions monitoring | O₂/CO/NOₓ readings, CEMS data handling |

| Alarm handling | Safety trips, auto/manual intervention |

| Fuel handling | Moisture, ash content, bridging risks |

Ask:

Is operator training modular by skill level?

Can sessions be tailored for fuel-specific challenges?

Are classroom and on-site formats both available?

2. What Skills Are Taught to Maintenance Personnel?

| Maintenance Area | Key Learning |

|---|---|

| Refractory inspection | Visual signs, thermal hotspots, patching |

| Air/fuel system | Grate cleaning, fan maintenance, actuator alignment |

| Sensor calibration | O₂/CO probe handling, SCADA diagnostics |

| Ash system upkeep | Screw inspection, gear lubrication, hopper alarms |

| Burner inspection | Nozzle erosion, ignition probe checks |

Ask:

Are technicians taught fault tracing from alarm logs?

Do training modules include step-by-step maintenance SOPs?

Can your engineers supervise live maintenance during training?

3. How Is Training Delivered (Formats and Scheduling)?

| Delivery Mode | Description |

|---|---|

| On-site classroom | Slides, manuals, Q&A, safety briefings |

| Hands-on practical | In-boiler and control room drills |

| SCADA simulation | Fault scenarios, trip handling, tuning |

| Online portal | Refresher videos, manuals, certification test |

| OEM workshop (optional) | Advanced courses at supplier facility |

Ask:

How many sessions are included with boiler delivery?

Can training be repeated for shift changes or new hires?

Do you offer mobile or tablet-based learning modules?

4. Is There a Certification or Assessment Process?

| Assessment Type | Purpose |

|---|---|

| Written exam | Theory verification |

| Simulation test | Control room action handling |

| Hands-on evaluation | Mechanical and safety task execution |

| Attendance-based certificate | ISO or audit evidence |

Ask:

Are pass/fail records and scores documented?

Is certification valid for multiple years?

Do you provide plant-specific completion records?

5. Can Training Be Integrated into Service Contracts?

| Contract Type | Training Option |

|---|---|

| Commissioning phase | Full handover package + training |

| Annual service contract | Refreshers for operators and techs |

| Performance-based service | Mandatory operator competency evaluation |

Ask:

Can training be scheduled before annual shutdowns?

Are updated manuals and troubleshooting guides included?

Can training logs be used for compliance audits?

Example: Biomass Boiler Operator Training Plan – 10 TPH System (Fuel: Palm Kernel Shell + Sawdust)

Training Duration: 5 days (post-commissioning)

Format: 50% classroom + 30% hands-on + 20% SCADA simulation

| Day | Topic |

|---|---|

| Day 1 | System layout, fuel variability, refractory risks |

| Day 2 | Burner ignition, air-fuel ratio, emissions panel |

| Day 3 | SCADA control + alarm simulation exercises |

| Day 4 | Maintenance team drill: grates, nozzles, fans |

| Day 5 | Written and practical exams, certificate issue |

Result:

14 personnel trained (3 shifts)

100% pass rate, 3 maintenance technicians certified in refractory patching

Emissions drift reduced by 22% in first 60 days post-training

Summary

Your biomass boiler’s best efficiency guarantee is not just a curve—it’s the people running it. Choose a supplier who builds skills, not just systems. Ask for fuel-adaptive training, SCADA-based simulation, and certification your team can trust. Choose training that equips—not just informs. Choose instruction built for combustion, compliance, and confidence. Choose a workforce ready for every shift. Choose operational certainty through education.

🔍 Conclusion

Effective after-sales support for biomass boilers goes beyond routine inspections—it includes fuel-specific tuning, emissions monitoring, and predictive maintenance. By choosing a supplier with a structured service model and proven field expertise, you ensure operational reliability, compliance, and cost efficiency throughout the boiler’s lifecycle.

📞 Contact Us

💡 Need help reviewing or optimizing service plans for your biomass boiler? Our team provides support benchmarking, maintenance strategy development, and lifecycle performance consulting.

🔹 Partner with a service team that understands your fuel, your system, and your long-term goals. 🌱🛠️✅

FAQ

What should be included in a complete after-sales support package for biomass boilers?

A reliable supplier should offer:

Installation and commissioning assistance

Operator training and safety documentation

24/7 technical support

Remote monitoring or diagnostics (if available)

Spare parts supply and long-term support (10–15 years)

These services reduce downtime and optimize boiler operation.

What specific maintenance services are critical for biomass boilers?

Maintenance must address biomass-specific needs:

Fuel feeder and auger system inspection

Ash removal system cleaning and alignment

Refractory maintenance (due to variable combustion conditions)

Flue gas cleaning systems (cyclone, baghouse, scrubber)

Moisture and fuel sensor calibration

Routine maintenance ensures consistent combustion and reduces emissions.

How responsive is the service team in case of breakdowns or emergencies?

Ask the supplier:

What is your average response time for service calls?

Do you have local or regional service technicians?

Can you provide emergency support outside standard business hours?

Prompt service minimizes production losses and protects system integrity.

Are spare parts readily available and how long are they supported?

Ensure the supplier:

Keeps critical parts in stock (motors, grates, actuators, sensors)

Provides OEM-certified spares to maintain performance

Offers long-term parts availability (10–15+ years)

Has an efficient logistics network for global dispatch

Lack of spares can cause extended downtimes and costly outages.

What value-added services enhance long-term performance?

Look for:

Predictive maintenance programs using data logs

Performance audits and optimization reports

System upgrades and control retrofits

Fuel consulting to help adjust settings based on biomass variation

These extras help maximize ROI and ensure regulatory compliance.

References

ASME Guidelines for Boiler Maintenance and Service – https://www.asme.org

EPA Biomass Boiler Emissions and Maintenance Compliance – https://www.epa.gov

Biomass Boiler Maintenance Strategies – IEA Bioenergy – https://www.ieabioenergy.com

DOE Industrial Boiler Service Support Guidelines – https://www.energy.gov

Predictive Maintenance Technologies for Biomass Boilers – https://www.sciencedirect.com

Boiler Refractory and Fuel System Inspection Tools – https://www.bioenergyconsult.com

Smart Monitoring Systems for Biomass Combustion – https://www.automation.com

Spare Parts and Supply Chain Planning – https://www.researchgate.net

Boiler Warranty Terms and Service Contract Models – https://www.trustpilot.com

OEM Recommendations for Biomass Boiler Servicing –