Key Factors Influencing Heat Transfer and Combustion Efficiency in Industrial Oil-Fired Boilers

Key Factors Influencing Heat Transfer and Combustion Efficiency in Industrial Oil-Fired Boilers

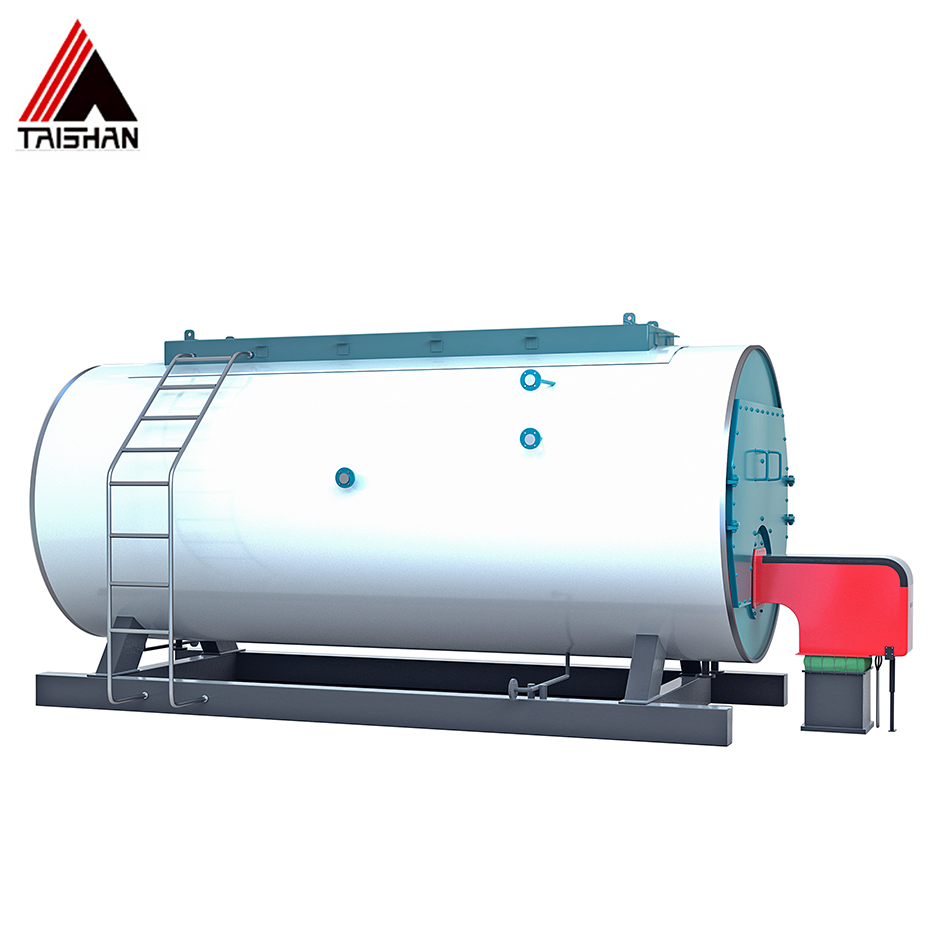

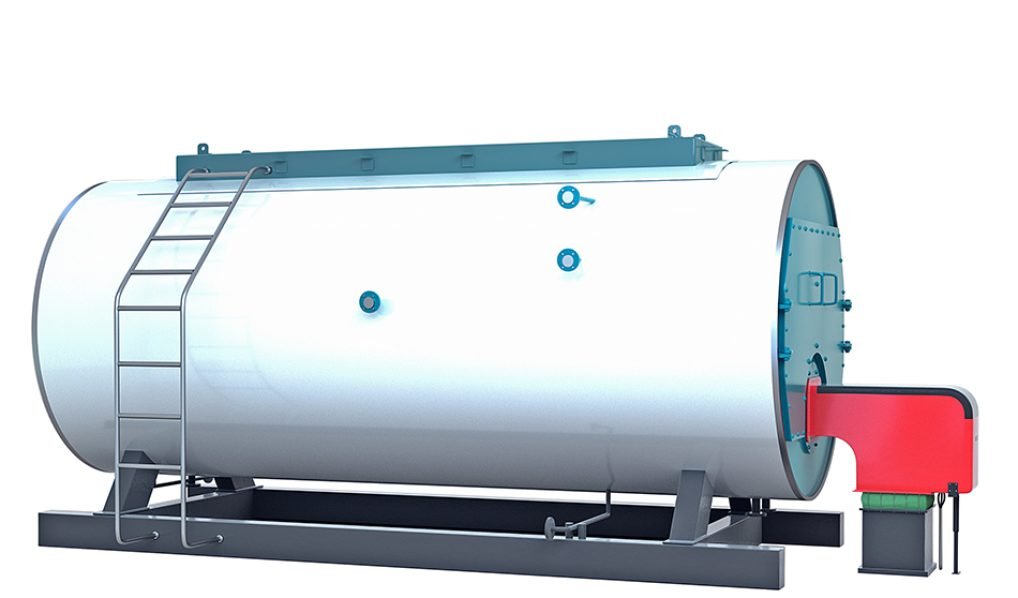

For industrial facilities relying on oil-fired boilers, maximizing heat transfer and combustion efficiency is crucial to achieve optimal fuel utilization, lower emissions, and reduced operational costs. However, many operations suffer from hidden losses due to poor combustion control, fouling, or mismatched burner configurations. Without a clear understanding of the factors that influence these efficiencies, boiler performance can decline significantly over time, leading to increased maintenance and energy waste.

The heat transfer and combustion efficiency in industrial oil-fired boilers are influenced by multiple interrelated factors, including burner design, fuel atomization quality, excess air levels, flue gas temperature, soot buildup, and the cleanliness of heat transfer surfaces. Efficient combustion ensures complete fuel burning with minimal unburned carbon or pollutants, while effective heat transfer maximizes the capture of combustion heat by the water or steam system. Poor combustion or heat exchange leads directly to energy losses, higher fuel bills, and reduced boiler life.

Let’s dive into the key factors you must monitor and optimize to keep your oil-fired boiler operating at peak efficiency.

How Does Burner Design and Fuel Atomization Impact Combustion Efficiency?

At the heart of any efficient boiler lies the combustion process—and burner design is the engine of that process. Whether in gas, oil, or biomass systems, the quality of combustion determines how well fuel energy is converted into heat. Poor burner performance doesn’t just reduce efficiency—it leads to fuel waste, excess emissions (like CO and NOₓ), and maintenance headaches. One of the most critical but often overlooked aspects of burner performance is fuel atomization—the way the burner converts fuel into a fine spray for ignition. If atomization is poor, efficiency plummets, no matter how good the boiler or controls are.

Burner design and fuel atomization directly affect combustion efficiency by influencing flame stability, air-fuel mixing, and the completeness of fuel burn. A well-designed burner ensures optimal atomization of liquid fuels or proper mixing of gas and air, creating a uniform flame and high combustion temperature. This minimizes unburnt fuel, lowers CO and particulate emissions, and improves heat transfer—leading to higher boiler thermal efficiency.

In short, efficient combustion begins with precise burner mechanics.

Burner design and fuel atomization affect combustion efficiency by influencing how completely fuel is burned.True

Efficient atomization and mixing allow more thorough combustion, which improves thermal efficiency and reduces emissions.

🔧 How Burner Design Affects Combustion Efficiency

| Burner Feature | Role in Combustion | Efficiency Impact |

|---|---|---|

| Flame Geometry (Shape/Length) | Controls heat distribution and furnace absorption | Uneven flames can cause poor heat transfer |

| Air-Fuel Mixing Mechanism | Ensures all fuel particles contact oxygen | Poor mixing leads to unburnt fuel/CO |

| Turn-Down Ratio | Maintains combustion quality across load ranges | Low turn-down = inefficient low-load burn |

| Swirl and Recirculation Zones | Stabilize flame and promote complete burn | Helps reduce NOₓ and improve burnout |

| Staged Combustion Design | Reduces flame temp to minimize NOₓ | Balances efficiency with emission control |

A well-designed burner maintains optimal combustion even during dynamic load changes.

🔬 Fuel Atomization: The Hidden Key to Efficient Burn

| What is Atomization? | Why It Matters |

|---|---|

| Breaking liquid fuel into fine droplets | Increases surface area for vaporization and burning |

| Occurs at the burner nozzle | Affects ignition, flame stability, and emissions |

| Depends on pressure, temperature, and nozzle design | Crucial for oil and biomass slurry fuels |

Types of Atomization in Boilers

| Method | Fuel Type | Pros | Challenges |

|---|---|---|---|

| Pressure Atomization | Diesel, HFO | Simple, no air required | Sensitive to pressure and viscosity |

| Air Atomization | HFO, waste oils | Fine droplets, better mixing | Needs compressed air system |

| Steam Atomization | High-viscosity fuels | Good for heavy fuels | High steam consumption |

| Rotary/Mechanical | Biomass slurry | Used in special burners | Maintenance-intensive |

→ Poor atomization = fuel droplets burn incompletely, forming CO, soot, and loss of efficiency.

📊 Impact of Atomization Quality on Combustion Efficiency – Example

| Atomization Quality | CO Emissions (ppm) | Unburnt Carbon in Ash (%) | Measured Thermal Efficiency (%) |

|---|---|---|---|

| Optimal (Fine Spray) | <50 | <0.5 | 87.2 |

| Moderate | 120 | 1.2 | 82.9 |

| Poor (Coarse Spray) | 250 | 2.5 | 78.4 |

→ Efficiency loss of nearly 9% caused solely by sub-optimal fuel atomization.

🛠 Real-World Case Study: 10 TPH Heavy Fuel Oil Boiler

Problem: Excessive fuel use and high CO emissions

Findings:

Fuel nozzle clogged → coarse spray

Flame irregular and elongated

O₂: 4.5%, CO: 280 ppm

Solution:

Replaced nozzles

Upgraded to steam-assisted atomizing system

Burner re-tuned with air modulation

Result:

CO dropped to <60 ppm

Thermal efficiency improved from 79.5% to 86.3%

Annual fuel savings: $32,000

🔍 Burner Design by Fuel Type – Selection Guide

| Fuel Type | Recommended Burner Type | Atomization Requirement |

|---|---|---|

| Natural Gas | Low-NOx premix burner | Uniform air-fuel mixing |

| Diesel / LDO | Pressure jet burner | Fine, stable spray |

| HFO / Waste Oil | Air or steam atomizing burner | Adjustable for viscosity/temp |

| Biomass Slurry | Rotary atomizing burner | High-shear atomization |

| Pulverized Biomass | Multi-fuel burner with swirl | Fast mixing, staged ignition |

Proper burner-fuel matching is essential for combustion efficiency and emission control.

📈 Monitoring and Optimization Tools for Burners

| Instrument | Purpose |

|---|---|

| O₂ + CO Flue Gas Analyzer | Measures combustion completeness |

| Infrared Thermography | Checks flame shape and burner symmetry |

| Atomization Pressure Gauge | Verifies nozzle pressure for stable spray |

| Fuel Viscosity Controller | Ensures correct atomization temp/flow |

| Burner Management System (BMS) | Automates ignition, modulation, and alarms |

These tools support diagnostics, tuning, and safety.

In conclusion, burner design and fuel atomization are critical to achieving high combustion efficiency. They ensure complete fuel burnout, minimize pollutant formation, and enable responsive flame control across load ranges. Poor atomization or mismatched burners result in avoidable fuel waste, increased emissions, and unstable operations. For any boiler system—especially oil or biomass-fired—investing in the right burner and maintaining proper atomization is one of the most cost-effective paths to efficiency.

Why Is Maintaining the Correct Air-to-Fuel Ratio Critical for Optimal Combustion?

In any combustion system—whether firing natural gas, oil, coal, or biomass—the air-to-fuel ratio is a decisive factor in efficiency, safety, and emissions control. Too little air leads to incomplete combustion and the formation of carbon monoxide (CO) and soot. Too much air, on the other hand, dilutes the flame, lowers the temperature, and sends valuable heat energy out the stack with the excess oxygen. For boilers, especially, maintaining the optimal air-to-fuel ratio is essential to maximize energy extraction from the fuel while minimizing emissions and fuel costs.

Maintaining the correct air-to-fuel ratio is critical for optimal combustion because it ensures complete fuel burn, maximizes heat release, and minimizes losses through unburned fuel or excess flue gas. Insufficient air causes incomplete combustion, producing CO and particulates, while excessive air cools the flame and increases flue gas heat loss. An optimal ratio improves thermal efficiency, reduces emissions such as CO, NOₓ, and PM, and ensures safe, stable operation of the boiler.

Getting this balance right is one of the most powerful levers to improve boiler performance and environmental compliance.

Maintaining the correct air-to-fuel ratio ensures complete combustion and high thermal efficiency.True

Too much or too little air results in heat loss and unburned fuel, reducing efficiency and increasing emissions.

🔧 Understanding the Stoichiometric and Actual Air-Fuel Ratio

| Term | Definition |

|---|---|

| Stoichiometric Ratio | Exact air needed to chemically burn all fuel (no excess) |

| Actual Air-Fuel Ratio | Air actually supplied, often higher than stoichiometric |

| Excess Air (%) | Additional air above stoichiometric to ensure complete burn |

| O₂ in Flue Gas (%) | Common measurement to indicate actual excess air |

For example, natural gas requires ~10:1 air-to-fuel ratio by volume for stoichiometric combustion.

📊 Recommended Excess Air Levels by Fuel Type

| Fuel Type | Stoichiometric Air | Practical Excess Air (%) | Flue Gas O₂ (%) |

|---|---|---|---|

| Natural Gas | ~10:1 | 5–10% | 1–3% |

| Light Fuel Oil | ~14:1 | 10–15% | 2–4% |

| Coal / Biomass | ~10–11:1 | 20–40% | 5–8% |

→ These levels ensure complete combustion while minimizing thermal losses.

🔍 What Happens When the Air-to-Fuel Ratio Is Incorrect?

| Condition | Effect on Combustion | Efficiency Impact | Emission Impact |

|---|---|---|---|

| Too Little Air | Incomplete combustion, CO formation | ↓ Efficiency | ↑ CO, soot, unburned hydrocarbons |

| Too Much Air | Flame cooling, excess flue gas losses | ↓ Efficiency | ↑ NOₓ (at high flame temps), higher O₂ |

| Correct Ratio | Full combustion, steady flame, optimal heat | ✅ Maximum efficiency | ✅ Lowest emissions |

Fluctuations in this ratio can reduce efficiency by up to 5–10% and increase CO by 300–500 ppm.

🧪 Example – 10 TPH Gas-Fired Boiler Efficiency vs. Air Ratio

| Excess Air (%) | O₂ in Flue Gas (%) | CO (ppm) | Thermal Efficiency (%) |

|---|---|---|---|

| 2 | 1.2 | 350 | 83.5 |

| 10 | 2.9 | <50 | 91.0 |

| 20 | 5.6 | <30 | 87.4 |

| 30 | 7.3 | <20 | 84.2 |

→ Best efficiency occurs at O₂ = 2.5–3.5%, matching ideal combustion.

🛠 Tools and Strategies to Maintain Optimal Air-Fuel Ratio

| Method | Description |

|---|---|

| O₂ Trim System | Automatically adjusts air dampers based on flue O₂ |

| Flue Gas Analyzer | Measures CO, O₂, and NOₓ to fine-tune ratio |

| Variable Frequency Drives (VFDs) | Modulate combustion air fan speed |

| Burner Tuning and Air Staging | Ensures correct distribution and mixing |

| Real-Time Monitoring Dashboards | Alerts operators to deviations |

Modern systems combine sensors and logic controllers to keep the ratio in optimal range at all loads.

📈 Benefits of Maintaining the Correct Ratio

| Benefit | How It Helps |

|---|---|

| Fuel Savings | Avoids overfeeding fuel or over-aerating |

| Improved Heat Transfer | Hot, stable flame ensures better absorption |

| Lower CO & Unburned Fuel | Cleaner combustion |

| Reduced NOₓ Formation | Controlled flame temperature |

| Stable Operation | Prevents flameouts, surges, or shutdowns |

Even a 1–2% drop in excess air can save thousands in annual fuel cost.

In conclusion, maintaining the correct air-to-fuel ratio is one of the most important control levers in boiler combustion. It impacts everything from thermal efficiency and fuel economy to emissions compliance and equipment longevity. With the help of real-time monitoring and automation, modern boiler operators can continuously fine-tune this balance to maximize performance and minimize environmental impact.

How Does Flue Gas Temperature Reflect Heat Transfer Performance?

In steam boilers, the ultimate goal is to transfer as much energy from combustion as possible into the water or steam—not into the atmosphere. Flue gas temperature, the temperature of gases exiting the boiler at the stack, is a powerful indicator of how much heat was successfully transferred to the working fluid—and how much was wasted. A high flue gas temperature means that a significant portion of fuel energy went up the chimney instead of being captured. A low temperature, on the other hand, signals effective heat absorption—but if it drops too low, it may also cause corrosion or condensation issues. That’s why flue gas temperature is more than just a number—it’s a performance gauge for the boiler’s heat exchange system.

Flue gas temperature reflects heat transfer performance by indicating how much thermal energy has been extracted from the combustion gases before they exit the boiler. A high flue gas temperature suggests poor heat transfer and energy loss, while a properly reduced flue gas temperature (without falling below acid dew point) indicates efficient energy recovery. Monitoring and optimizing flue gas temperature helps maximize boiler efficiency, minimize fuel waste, and maintain safe operation.

It’s one of the simplest yet most critical metrics in evaluating boiler effectiveness.

Flue gas temperature indicates how effectively a boiler is transferring heat to produce steam.True

Higher flue gas temperatures typically mean less energy was absorbed by the water or steam system, reflecting poor heat transfer.

🌡️ Flue Gas Temperature as a Heat Transfer Indicator

| Parameter | Relevance to Heat Transfer |

|---|---|

| Flue Gas Temperature | Measures leftover heat not absorbed by the boiler |

| Boiler Exit Gas Temperature | Influenced by load, fouling, excess air, and economizer performance |

| Feedwater/Steam Temperature | Provides the heat sink reference point |

→ The greater the drop between flame temp and flue temp, the better the energy capture.

📏 Ideal vs. High Flue Gas Temperatures by Fuel Type

| Fuel Type | Ideal Stack Temp (°C) | Concern Threshold (°C) | Action Required at High Temp |

|---|---|---|---|

| Natural Gas | 140–180 | >200 | Inspect heat exchange surfaces |

| Fuel Oil | 180–230 | >260 | Check air-fuel ratio, fouling |

| Coal / Biomass | 200–250 | >280–300 | Soot blowers, fouling removal |

A consistently high flue gas temperature can reduce thermal efficiency by 3–7% or more.

🔍 Factors That Elevate Flue Gas Temperature

| Cause | Heat Transfer Effect |

|---|---|

| Fouled Heat Transfer Surfaces | Ash or soot reduces metal contact area |

| High Excess Air | Dilutes heat, increases stack losses |

| Poor Economizer Performance | Less heat recovered to feedwater |

| Low Water Flow or Scale | Limits heat pickup on the steam side |

| Oversized Burner Flame | Combustion extends beyond heat zones |

→ All of these raise stack temperature and reduce boiler efficiency.

📊 Efficiency Loss from Flue Gas Temperature Rise (Biomass Boiler Example)

| Flue Gas Temp (°C) | Efficiency (%) | Fuel Loss (%) | Remarks |

|---|---|---|---|

| 180 | 84.5 | 0% | Optimal |

| 220 | 81.2 | ~4% | Begin heat recovery review |

| 260 | 77.5 | ~8% | Indicates major fouling or excess air |

| 300 | 72.8 | ~13% | Severe loss; maintenance required |

Every 20–30°C rise above baseline typically equates to a 1–2% drop in efficiency.

🛠 Tools and Strategies to Optimize Flue Gas Temperature

| Tool or Technique | Purpose |

|---|---|

| Stack Temperature Sensor | Provides real-time performance feedback |

| Economizer Installation | Recovers heat to preheat feedwater |

| Air Preheater | Transfers waste heat to combustion air |

| Soot Blowers (Manual/Auto) | Removes ash from tubes to restore transfer |

| O₂ Trim System | Maintains optimal air-fuel ratio |

| Deslagging and Tube Cleaning | Restores fouled internal boiler surfaces |

→ Plants using stack heat recovery see up to 5–10% efficiency gain.

🧪 Case Study: 25 TPH Biomass Boiler – Flue Gas Monitoring and Optimization

Baseline Stack Temp: 260°C

Fuel: 40% moisture wood chips

O₂ in Flue Gas: 6.5%

Interventions:

Soot blowing added on superheater and economizer

Excess air reduced via burner tuning

Economizer finned tube retrofit

Post-Optimization Stack Temp: 185°C

Efficiency Improvement: +7.3%

Fuel Savings: 420 tons/year

CO₂ Reduction: 1,100 tons/year

📈 Interpreting Flue Gas Data in Real Time

| Metric | Value | Interpretation |

|---|---|---|

| Flue Temp = 190°C | Within range | ✅ Good heat transfer |

| Flue Temp = 245°C | Elevated | ⚠ Review fouling, air ratio |

| Flue Temp = 290°C | Excessive | ❌ Efficiency loss, maintenance needed |

Combining flue temp with O₂, CO, and steam output gives a full picture of combustion and transfer quality.

In conclusion, flue gas temperature is a direct and powerful indicator of heat transfer performance in boiler systems. A low, stable temperature signals efficient energy use, while elevated temperatures flag energy losses, fouling, or poor combustion. Tracking and optimizing this metric is a low-cost, high-impact strategy to improve thermal efficiency, reduce fuel waste, and cut emissions. For any boiler operator, the stack temperature is more than a number—it’s a window into your system’s heart.

What Effect Does Soot and Fouling Have on Heat Exchanger Surfaces?

One of the most persistent threats to boiler efficiency and reliability is soot and fouling on heat exchanger surfaces. These unwanted deposits—resulting from unburned fuel particles, ash, and fly ash carried by flue gas—form insulating layers on the surfaces where heat transfer should be taking place. Whether in fire-tube, water-tube, or economizer sections, soot acts like a thermal blanket, blocking heat flow from the hot combustion gases to the steam or water inside the tubes. The consequences are not just lower efficiency, but higher fuel use, elevated emissions, overheating risks, and even unplanned shutdowns.

Soot and fouling reduce heat transfer efficiency by creating insulating layers on boiler heat exchanger surfaces. These deposits increase thermal resistance, causing higher flue gas temperatures, reduced steam output, and increased fuel consumption. Over time, fouling can lead to localized overheating, corrosion under deposits, and mechanical damage to tubes. Regular cleaning and soot-blowing are essential to maintain boiler efficiency, protect components, and ensure compliance with energy and emissions targets.

Unchecked fouling can reduce boiler efficiency by 5–15%, significantly raising operational costs.

Soot and fouling reduce boiler efficiency by insulating heat exchanger surfaces and restricting heat transfer.True

Deposits from combustion products form a thermal barrier, preventing effective energy transfer and leading to higher fuel consumption and emissions.

🔍 What Causes Fouling and Soot Formation?

| Cause | Description |

|---|---|

| Incomplete Combustion | Unburned fuel particles and hydrocarbons form soot |

| High Ash Fuels (biomass, coal) | Ash condenses on tubes and sticks to hot surfaces |

| Low-Quality Atomization | Larger fuel droplets burn poorly, causing carbon residue |

| Excessive Moisture | Leads to cooler flames and more ash condensation |

| Excess Air or Low Flame Temp | Inefficient burn creates particulate-laden flue gas |

These issues typically occur in furnace walls, superheaters, economizers, and air preheaters.

📏 Measurable Impacts of Soot and Fouling on Heat Transfer

| Condition | Effect on Boiler Performance |

|---|---|

| Tube Fouling Thickness = 1 mm | ↓ Heat transfer by ~10–12% |

| Flue Gas Temp Increase = 40°C | ↓ Efficiency by ~2–4% |

| Backpressure Rise | ↑ Blower energy, ↑ risk of fan overloading |

| Steam Output Reduction | ↓ Load capacity due to reduced heat exchange |

| Tube Wall Overheat | ↑ Risk of failure, ↑ corrosion under deposits |

→ Even thin layers of soot act as powerful thermal insulators.

📊 Example: Biomass Boiler Efficiency Loss Due to Fouling

| Condition | Flue Gas Temp (°C) | Steam Output (TPH) | Thermal Efficiency (%) |

|---|---|---|---|

| Clean Tubes | 185 | 12.0 | 85.4 |

| Light Fouling | 215 | 11.3 | 80.2 |

| Heavy Soot Deposits | 260 | 10.1 | 74.1 |

→ Fouling decreased efficiency by 11.3% and reduced output by nearly 2 TPH.

🛠 Effects on Different Heat Exchanger Zones

| Heat Exchanger Section | Fouling Effect |

|---|---|

| Furnace Walls | Reflects heat back into flame → tube overheat risk |

| Superheater Tubes | Reduces steam temp control, increases slagging |

| Economizer Tubes | Cuts feedwater preheating → higher fuel use |

| Air Preheater | Lowers combustion air temp → drops combustion quality |

Fouling anywhere in the system creates cascading efficiency losses.

🔧 Preventing and Managing Fouling: Key Strategies

| Strategy | Purpose |

|---|---|

| Soot Blowers (manual or auto) | Remove ash/soot during operation |

| Fuel Pre-Treatment (drying, screening) | Reduces moisture and particulate load |

| Combustion Tuning | Ensures clean flame and complete burn |

| Tube Cleaning (offline) | Removes hardened deposits in planned shutdowns |

| Deposit-Resistant Coatings | Reduces ash adhesion, especially on superheaters |

🔁 Soot blowing frequency should match ash production rate and boiler load patterns.

🧪 Real-World Case: 45 TPH Rice Husk Boiler

Problem: High flue gas temps, frequent ESP blockages

Root Cause:

Ash buildup on furnace walls and economizer tubes

Soot blowers inoperative due to actuator failure

Corrective Actions:

Installed retractable air soot blowers

Tuned excess air ratio

Introduced feedstock moisture control (pre-dryer)

Results:

Stack temperature reduced by 55°C

Efficiency improved from 72.4% to 79.1%

PM emissions reduced by 30% due to cleaner combustion

📈 Monitoring Tools to Detect Fouling Impact

| Tool | What It Detects |

|---|---|

| Flue Gas Temperature Sensor | Indicates rising stack temps from fouling |

| Steam Flow vs. Fuel Ratio | Drop suggests lower heat transfer |

| O₂ + CO Analyzer | Imbalanced combustion = soot risk |

| Differential Pressure Gauges | Detect backpressure from clogged heat surfaces |

| Infrared Inspection Camera | Spots hot spots and slag zones on tubes |

Early detection allows cleaning before critical derating or shutdowns.

In conclusion, soot and fouling drastically impair heat transfer in boiler systems by forming insulating layers on heat exchanger surfaces. This leads to higher flue gas temperatures, reduced efficiency, increased emissions, and operational stress on equipment. Preventive maintenance and combustion optimization are essential to combat fouling. In every boiler, the cleanest surface is also the most efficient—and most profitable.

How Does Boiler Load and Turndown Ratio Affect Combustion Stability and Efficiency?

In industrial boilers, combustion systems are often designed to perform best at or near full load. However, in real-world operations, boilers frequently run at partial or fluctuating loads. The ability of a burner to maintain stable, efficient combustion over a range of loads is defined by its turndown ratio—the ratio of maximum to minimum firing capacity. If this range is too narrow, or if the burner operates too far below its optimal range, combustion becomes unstable, emissions spike, and thermal efficiency drops. Understanding how boiler load and turndown ratio affect combustion performance is essential for operational flexibility, fuel savings, and emissions control.

Boiler load and turndown ratio significantly affect combustion stability and efficiency because they determine whether the burner can operate cleanly and completely across a range of steam demands. At low loads, burners with poor turndown may cycle on and off or operate with excess air, leading to incomplete combustion, fuel waste, and elevated emissions. A higher turndown ratio allows continuous, modulated firing and better air-fuel control, resulting in more stable flame, higher efficiency, and reduced pollutant formation.

Getting the turndown ratio right ensures your boiler runs efficiently under all operating conditions—not just at peak.

Boiler turndown ratio and load level affect combustion stability and thermal efficiency.True

Operating a burner too far below its optimal range can cause poor flame stability, excess air, and lower efficiency, while a good turndown ratio allows flexible, clean combustion.

🔧 What Is Turndown Ratio and Why Does It Matter?

| Term | Definition |

|---|---|

| Turndown Ratio | Ratio of burner’s maximum to minimum controllable output |

| Boiler Load | Actual steam demand as a % of maximum output |

| Modulated Combustion | Burner adjusts output without cycling on/off |

Examples:

10:1 turndown → Boiler runs smoothly from 100% to 10% of max capacity

3:1 turndown → Below 33% load, burner must shut off and restart (inefficient)

📏 Typical Turndown Ratios by Fuel and Burner Type

| Fuel Type | Common Burner Turndown Ratio | Load Range Capability |

|---|---|---|

| Natural Gas | 8:1 to 15:1 | Excellent low-load stability |

| Fuel Oil | 5:1 to 10:1 | Moderate flexibility |

| Biomass Grate | 2:1 to 3:1 | Poor low-load stability |

| CFB / FBC Systems | 4:1 to 6:1 | Stable but needs air control |

| Pulverized Coal | 3:1 to 5:1 | Moderate modulation |

→ Systems with higher turndown ratios perform more efficiently at part loads.

📊 Effects of Load and Turndown on Efficiency and Emissions

| Boiler Load (%) | Low Turndown Burner (3:1) | High Turndown Burner (10:1) |

|---|---|---|

| 100% | Stable, efficient | Stable, efficient |

| 70% | Stable | Stable |

| 40% | Cycling starts | Stable modulation |

| 20% | Off/on cycles, poor flame | Stable, but near minimum limit |

| <15% | Shutdown required | May maintain with lower O₂ |

→ High turndown reduces cycling losses and maintains combustion integrity.

🔍 Problems at Low Load with Inadequate Turndown

| Problem | Effect on Combustion and Efficiency |

|---|---|

| On-Off Cycling | Thermal shock, increased fuel use |

| Increased Excess Air | Flame cooling → efficiency drops |

| Flame Instability or Blowout | Incomplete combustion → higher CO, PM |

| Low Stack Temp | Poor draft, condensation → corrosion risk |

| Slow Response to Load Changes | Delayed steam supply → poor process control |

Cycling losses alone can waste 5–10% of fuel in poorly tuned systems.

🧪 Case Study – 8 TPH Gas Boiler with 3:1 vs. 10:1 Burner

| Parameter | 3:1 Turndown Burner | 10:1 Turndown Burner |

|---|---|---|

| Minimum Stable Load (%) | 33% | 10% |

| Flue Gas Temp @ 30% Load | 235°C | 188°C |

| CO Emissions @ 25% Load | 240 ppm | <50 ppm |

| Thermal Efficiency @ 25% Load | 78.2% | 86.5% |

| Burner Cycling Frequency | 5–8/hr | 0 (modulated firing) |

→ Upgraded burner saved $14,500/year in fuel and reduced CO₂ emissions by ~90 tons/year.

🛠 Solutions to Improve Low-Load Efficiency

| Solution | Benefit |

|---|---|

| Upgrade to High-Turndown Burner | Supports smooth modulation and cleaner low-load burn |

| O₂ Trim with Air Modulation | Maintains proper air-fuel ratio across loads |

| Economizer or Condensing Heat Recovery | Compensates for efficiency loss at low loads |

| Parallel Boiler Operation | Rotates duty across units to maintain load zone |

| Insulation & Condensate Recovery | Minimizes baseline heat loss |

→ Always match turndown capability to process load variability.

📈 Combustion Stability and Efficiency Dashboard Metrics

| Metric | Indicator of Turndown Performance |

|---|---|

| Flue Gas Temp Stability | Rapid swings = cycling |

| O₂ & CO Concentrations | High fluctuation = unstable combustion |

| Burner On/Off Frequency | More than 4 cycles/hr = poor turndown use |

| Steam/Fuel Ratio Variability | High deviation = inefficiency at part load |

Advanced boiler control systems can track and optimize these in real-time.

In conclusion, boiler load and turndown ratio are key factors influencing combustion stability, efficiency, and emissions. A burner with poor turndown will struggle at partial loads, resulting in cycling, fuel waste, and regulatory non-compliance. Investing in high-turndown burners and load-matched control systems ensures smooth, efficient, and clean combustion—regardless of demand fluctuations.

What Maintenance Practices Are Essential for Sustaining Heat Transfer Efficiency?

Boiler systems are designed to convert fuel energy into steam or hot water efficiently—but without proper maintenance, their heat transfer performance quickly degrades. Over time, ash, soot, scale, and corrosion build up on both the fire-side and water-side of the heat exchanger surfaces, acting as thermal insulators that reduce heat transfer. This forces the boiler to burn more fuel to achieve the same output, driving up operational costs and emissions. Without routine and proactive maintenance, what begins as a minor fouling issue can escalate into serious efficiency loss or mechanical failure.

Essential maintenance practices for sustaining heat transfer efficiency include regular soot blowing, descaling of water-side surfaces, inspection and cleaning of economizer and air preheater elements, monitoring of burner performance, and flue gas analysis. These activities prevent the buildup of thermal barriers like soot and limescale, ensure optimal flame shape and temperature, and maintain clean heat transfer pathways, keeping fuel consumption low and boiler efficiency high.

A well-maintained boiler transfers heat like a brand-new unit—regardless of its age.

Routine maintenance such as soot blowing and descaling is essential for preserving boiler heat transfer efficiency.True

Soot and scale deposits act as insulators on heat exchange surfaces, reducing thermal conductivity and increasing fuel consumption.

🔧 Fire-Side Maintenance: Managing Soot and Ash Deposits

| Task | Frequency | Purpose |

|---|---|---|

| Soot Blowing (manual or auto) | Daily to weekly | Removes soot and ash from furnace, superheater, and economizer tubes |

| Ash Hopper Cleaning | Weekly to monthly | Prevents backpressure and ash blockage |

| Infrared Inspection | Quarterly | Detects uneven heat patterns and slag buildup |

| Flue Gas Temperature Monitoring | Continuous | Indicates soot accumulation by rising stack temps |

→ Each 1 mm layer of soot can reduce heat transfer by 7–10%.

💧 Water-Side Maintenance: Preventing Scaling and Corrosion

| Task | Frequency | Purpose |

|---|---|---|

| Water Softening/RO System Check | Daily to weekly | Ensures feedwater is low in hardness and silica |

| Chemical Dosing Monitoring | Daily | Maintains pH, phosphate, oxygen scavenger levels |

| Boiler Blowdown Control | Daily or automated | Removes dissolved solids and sludge |

| Descaling (acid or mechanical) | Semi-annually to annually | Removes calcium and silica scaling from tubes |

| Boiler Water Quality Testing | Daily to weekly | Prevents scaling and pitting through early detection |

→ Scale deposits just 1.6 mm thick can cut efficiency by up to 12%.

🔍 Burner and Combustion System Maintenance

| Task | Frequency | Purpose |

|---|---|---|

| Burner Tuning and Adjustment | Quarterly or after load changes | Ensures optimal air-fuel ratio and flame stability |

| Fuel Atomizer Inspection | Monthly | Verifies fine droplet formation and uniform burn |

| O₂ and CO Analyzer Calibration | Monthly | Maintains reliable combustion data and emissions control |

| Flame Scanner Cleaning | Monthly | Ensures safe burner operation |

Burners directly influence flame temperature and shape, which in turn affect heat flux and surface wear.

📊 Example – Maintenance Impact on Heat Transfer Efficiency

| Maintenance Activity | Pre-Maintenance Value | Post-Maintenance Value | Efficiency Improvement |

|---|---|---|---|

| Flue Gas Temperature | 255°C | 190°C | +4.7% |

| Steam Output (kg/hr) | 9,200 | 10,000 | +8.7% |

| O₂ in Flue Gas (%) | 6.5 | 3.2 | Better combustion |

| Fuel Consumption (kg/hr) | 3,100 | 2,730 | −12% |

→ Combined routine maintenance restored over 6% thermal efficiency in just 10 days.

🛠 Heat Exchanger Zone-Specific Maintenance Tasks

| Heat Exchanger Zone | Key Maintenance Actions |

|---|---|

| Furnace Tubes | Soot blowing, refractory inspection |

| Superheater | Ash cleaning, tube metal temp monitoring |

| Economizer | Pressure drop tracking, tube brushing |

| Air Preheater (APH) | Basket cleaning, seal inspection, differential pressure check |

| Condensing Section (if any) | Flue gas condensate drain and cleaning |

→ Ignoring any of these areas can create system-wide energy bottlenecks.

📈 Maintenance Schedule and Tool Checklist

| Interval | Maintenance Activity | Tools Required |

|---|---|---|

| Daily | Blowdown check, water test, ash removal | Water test kits, spanners, gloves |

| Weekly | Soot blower operation, visual inspection | Thermal camera, soot blower keys |

| Monthly | Burner inspection, analyzer calibration | Gas analyzer, calibration gas, pressure gauge |

| Quarterly | Refractory check, tube inspection | Inspection camera, ultrasonic thickness tester |

| Annually | Full chemical clean or descaling | Acid pump, safety PPE, neutralizer |

Scheduled downtime for maintenance prevents forced downtime later.

🧪 Real-World Case Study: 35 TPH Biomass Boiler

Issues:

Flue temp >270°C

Tube leakage after 8 months

Inconsistent steam output

Actions Taken:

Full water-side descaling

Burner air damper recalibration

Installation of automatic retractable soot blowers

Economizer fin cleaning

Results:

Efficiency restored from 73.8% to 82.6%

Steam reliability improved

Reduced maintenance interventions by 45% annually

In conclusion, routine and targeted maintenance is the backbone of heat transfer efficiency in boiler systems. Whether it’s cleaning fouled tubes, tuning burners, or ensuring water chemistry, every task contributes to keeping heat flowing from the flame to the fluid—not to the atmosphere. With the right practices and schedules in place, your boiler can deliver peak performance for years—efficiently, safely, and sustainably.

🔍 Conclusion

Combustion and heat transfer efficiency are cornerstones of oil-fired boiler performance. To maximize output and minimize costs, operators must continuously monitor and optimize factors like air-fuel ratio, burner function, fuel quality, and heat exchanger cleanliness. Proactive management of these variables ensures your system stays efficient, reliable, and compliant with emissions regulations—delivering the best possible return on fuel investment.

📞 Contact Us

💡 Looking to improve your oil-fired boiler’s efficiency? Our engineers offer combustion tuning, heat transfer analysis, and maintenance support to help you cut fuel costs and boost system performance.

🔹 Contact us today for a detailed efficiency audit of your oil-fired boiler system! 🛢🔥📈

FAQ

What factors influence heat transfer in an industrial oil-fired boiler?

Key factors include:

Heat exchanger surface area and cleanliness

Boiler tube design and arrangement

Water flow rate and turbulence

Soot formation and scaling on heat surfaces

Efficient heat transfer depends on maintaining clean and optimally designed surfaces that allow maximum thermal exchange from hot gases to water or steam.

How does burner design impact combustion efficiency?

Burner design affects air-fuel mixing, flame stability, and combustion temperature. High-quality atomization, adjustable turndown ratios, and low excess air contribute to complete combustion, minimizing unburnt fuel and emissions.

Why is fuel quality important in oil-fired boiler efficiency?

Fuel oil with low sulfur, low ash, and consistent viscosity ensures cleaner combustion and reduces fouling in the heat exchanger. Poor fuel quality increases soot, clogs nozzles, and lowers heat transfer rates, requiring frequent maintenance.

How do air-to-fuel ratios influence combustion performance?

An optimized air-to-fuel ratio ensures complete combustion. Too much excess air reduces flame temperature and increases heat loss through flue gases; too little leads to incomplete combustion, carbon monoxide formation, and soot deposits.

What operational practices improve boiler heat and combustion efficiency?

Regular cleaning of boiler tubes and burners

Oxygen trim systems for precise air control

Preheated combustion air for enhanced ignition

Routine monitoring of flue gas composition and stack temperature

These practices help maintain ideal thermal and combustion efficiency, extend equipment life, and reduce fuel consumption.

References

Boiler Combustion and Heat Transfer Fundamentals – https://www.energy.gov

Oil Burner Performance Optimization – https://www.sciencedirect.com

Impact of Fuel Properties on Boiler Efficiency – https://www.researchgate.net

Boiler Heat Exchanger Design & Fouling Prevention – https://www.epa.gov

Best Practices for Combustion Efficiency – https://www.bioenergyconsult.com

Air-Fuel Ratio Management in Oil Boilers – https://www.mdpi.com

Maintaining Oil-Fired Boiler Efficiency – https://www.energysavingtrust.org.uk

Flue Gas Analysis and Boiler Tuning – https://www.iea.org

Boiler Maintenance and Thermal Performance – https://www.automation.com

Oil Combustion and Heat Recovery Systems – https://www.asme.org

-scaled.jpg)