How to Improve the Efficiency of Industrial Gas-Fired Boilers?

How to Improve the Efficiency of Industrial Gas-Fired Boilers?

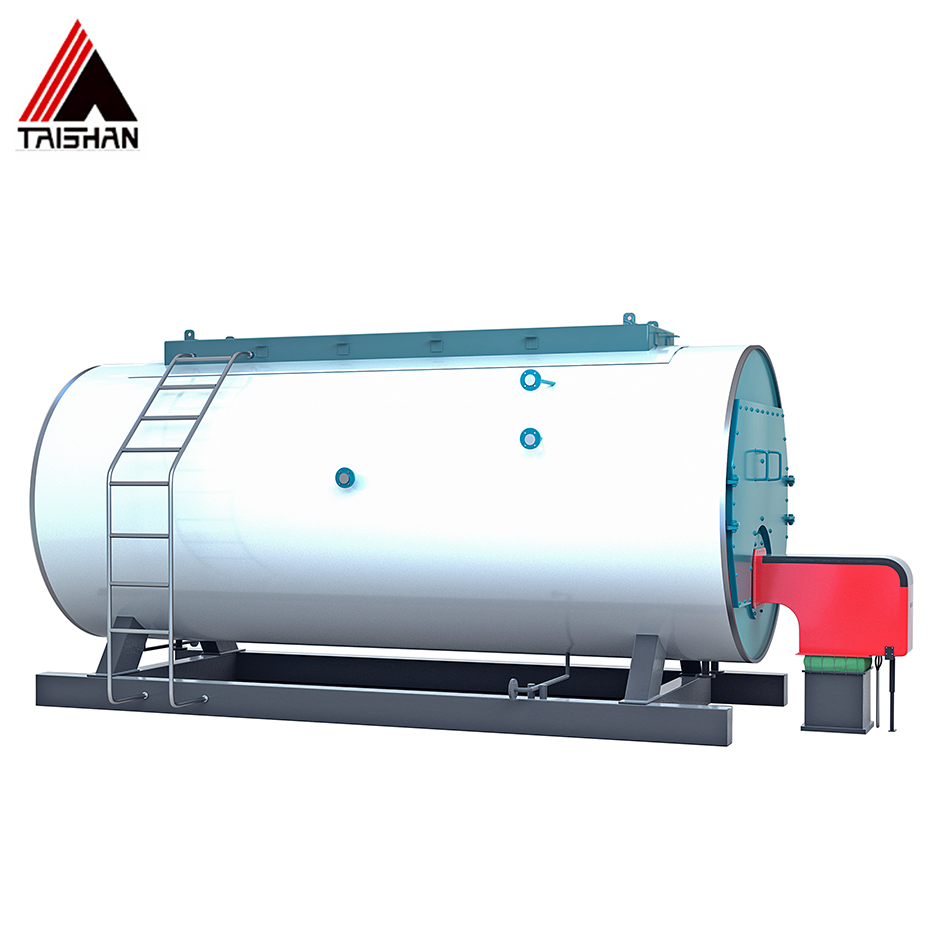

Industrial gas-fired boilers are popular due to their clean combustion, high reliability, and flexible applications. However, even well-designed boilers can waste energy if they are not optimized, resulting in higher fuel bills, unnecessary emissions, and reduced service life. Without efficiency improvements, plants risk losing their competitive edge in terms of cost and sustainability.

The efficiency of industrial gas-fired boilers can be improved by optimizing combustion with oxygen trim controls, installing economizers and condensing heat exchangers, maintaining proper insulation, reducing excess air, implementing feedwater preheating, and using advanced digital monitoring and automation. Regular burner tuning, water treatment, and preventive maintenance further ensure sustained efficiency and reliability.

By applying these measures, businesses can significantly cut fuel consumption, lower emissions, and maximize lifecycle performance of their boilers.

How Does Combustion Optimization Improve the Efficiency of Gas-Fired Boilers?

Even though natural gas is one of the cleanest and most efficient boiler fuels, many gas-fired systems still operate below their potential. The main culprit is improper combustion settings—too much excess air, uneven burner performance, or poor flame stability. This leads to wasted fuel, higher emissions, and unnecessary operating costs.

Combustion optimization improves the efficiency of gas-fired boilers by precisely controlling the fuel-air ratio, ensuring complete combustion, minimizing excess air, and maintaining stable flame conditions. Advanced controls and real-time monitoring reduce stack losses, prevent unburned fuel, and increase efficiency by 2–4%, lowering fuel costs and emissions.

In practice, combustion optimization means that instead of running the boiler with a wide safety margin of excess air, the system dynamically adjusts conditions to achieve the ideal balance between efficiency and safety.

Adding more excess air always improves combustion efficiency in gas-fired boilers.False

Excess air beyond the optimal range carries heat away in the flue gases, reducing efficiency.

Combustion optimization can reduce natural gas consumption by 2–4% in boilers.True

By fine-tuning the air-fuel ratio and burner performance, fuel use is reduced without compromising safety.

1. Fuel-Air Ratio Control

Natural gas requires a precise stoichiometric ratio for clean combustion.

Too little air → CO formation, incomplete combustion.

Too much air → heat loss through flue gases.

Automated O₂ trim control maintains efficiency within ±0.5% of the target.

| Condition | Excess Air (%) | Flue Gas Temp (°C) | Boiler Efficiency (%) |

|---|---|---|---|

| Poorly tuned | 25% | 240 | 86 |

| Optimized | 10–15% | 180 | 89–90 |

2. Burner Tuning and Maintenance

Ensures flame stability and uniform mixing.

Prevents cold spots and reduces NOx formation.

Regular burner calibration can improve efficiency by 1–2%.

3. Real-Time Monitoring and Controls

O₂ analyzers and CO sensors provide continuous feedback.

Automated control loops adjust dampers and gas valves.

AI-driven systems predict optimal conditions under varying loads.

4. Secondary Benefits

Reduced Emissions: Lower CO, CO₂, and NOx output.

Operational Flexibility: Stable operation at low loads.

Safety Improvements: Automatic shutdowns for unsafe conditions.

Lower Maintenance: Cleaner combustion reduces fouling.

5. Case Study Example

A 20 TPH industrial gas-fired boiler implemented combustion optimization with O₂ trim controls and burner tuning:

Baseline efficiency: 87%

Post-optimization efficiency: 90.5%

Annual fuel savings: $120,000

Payback period: 8 months

Conclusion

Combustion optimization is one of the most cost-effective upgrades for gas-fired boilers. By fine-tuning the air-fuel ratio and using modern automation systems, plants can achieve 2–4% efficiency gains, reduce emissions, and lower O&M costs with minimal investment.

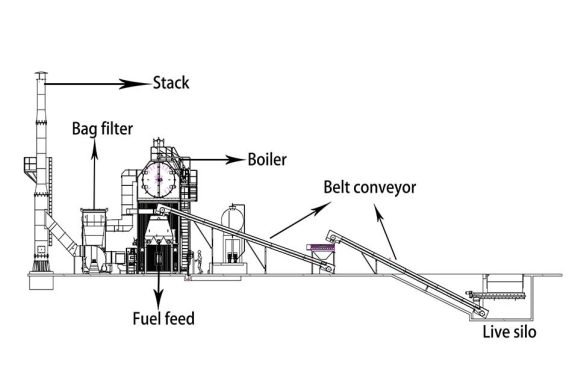

What Role Do Economizers and Condensing Technology Play in Heat Recovery?

One of the biggest energy losses in boilers comes from hot flue gases vented into the atmosphere. Without heat recovery, 15–20% of fuel energy can be wasted. To counter this, two technologies—economizers and condensing heat exchangers—are widely applied to capture and reuse waste heat, directly boosting efficiency and lowering fuel costs.

Economizers and condensing technology improve heat recovery by extracting energy from flue gases and transferring it to boiler feedwater or return water. Economizers typically raise feedwater temperature, reducing fuel consumption, while condensing units capture latent heat from water vapor in flue gases. Together, they can increase boiler efficiency by 5–10% for economizers and up to 15% when condensing is applied, making them essential for high-efficiency gas-fired boilers.

This means that what was once considered “lost energy” can now be recycled into the system, turning waste into savings.

Condensing boilers are only slightly more efficient than conventional boilers.False

Condensing technology can boost efficiency up to 98% by recovering latent heat, compared to 85–90% for conventional boilers.

Economizers reduce fuel consumption by preheating boiler feedwater.True

By raising feedwater temperature with flue gas heat, economizers cut fuel demand and improve system efficiency.

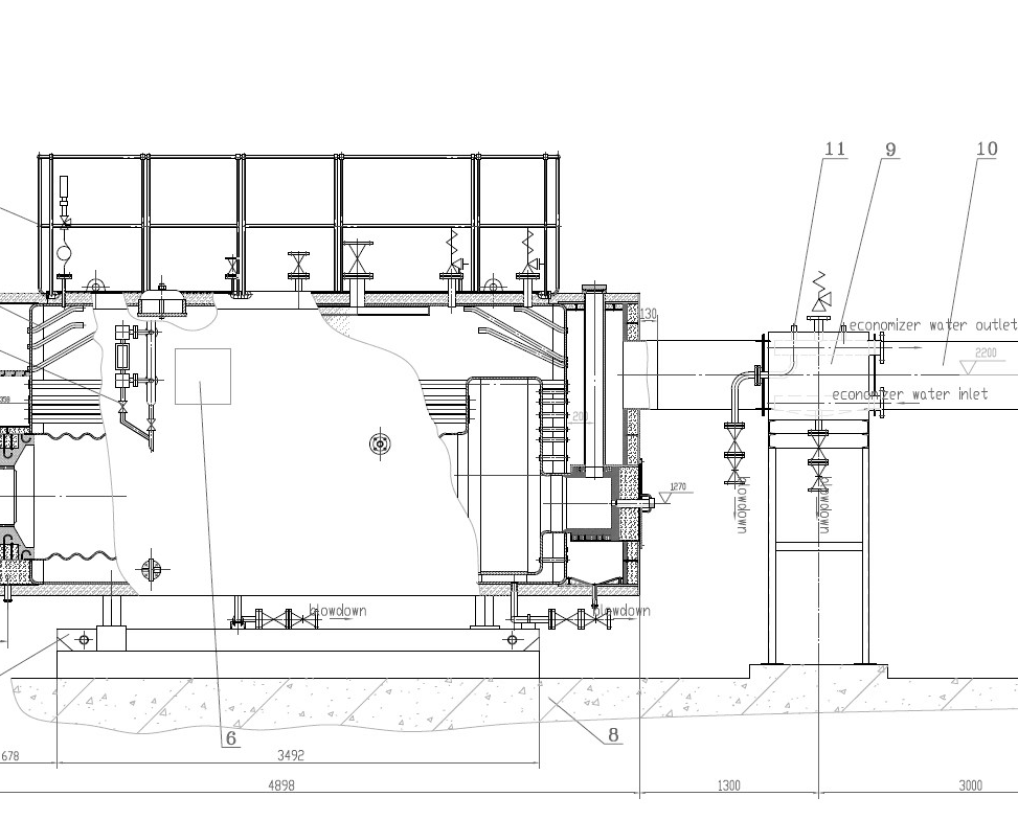

1. Economizers – Sensible Heat Recovery

Located in the flue gas path before the stack.

Transfer heat from flue gases to boiler feedwater.

Commonly raise feedwater temperature by 20–40°C.

Efficiency gain: 3–6% fuel savings.

| Parameter | Without Economizer | With Economizer |

|---|---|---|

| Feedwater Temp (°C) | 80 | 120 |

| Boiler Efficiency (%) | 87 | 91 |

| Gas Consumption (per ton steam) | 70 Nm³ | 66 Nm³ |

2. Condensing Technology – Latent Heat Recovery

Flue gas contains water vapor formed during combustion.

In condensing boilers, flue gas is cooled below the dew point (~55°C).

This releases latent heat of vaporization, which is recovered to preheat return water.

Efficiency gain: 8–12% fuel savings (can reach 98% total efficiency).

| Condition | Flue Gas Temp (°C) | Boiler Efficiency (%) |

|---|---|---|

| Non-condensing | 180 | 88–90 |

| Condensing | 50–60 | 95–98 |

3. Combined Benefits

Economizers recover sensible heat → good for all boiler types.

Condensing units recover latent heat → most effective with low return water temperatures (<55°C).

Combining both ensures maximum flue gas heat utilization.

4. Case Example

A 10 TPH natural gas boiler retrofitted with economizer and condensing heat exchanger:

Baseline efficiency: 88%

After economizer: 92%

After condensing recovery: 97%

Annual fuel savings: $150,000

Payback period: 12–15 months

5. Secondary Advantages

Reduced Emissions: Lower CO₂ per ton of steam.

Extended Equipment Life: Lower flue gas temperatures reduce thermal stress.

Improved Return on Investment: Fuel savings pay back investment quickly.

Conclusion

Economizers and condensing technology are cornerstones of modern boiler efficiency. By recovering both sensible and latent heat from flue gases, plants can cut fuel costs, achieve efficiencies close to 98%, and reduce environmental impact.

Why Is Controlling Excess Air Essential for Maximizing Fuel Efficiency?

One of the most common hidden causes of energy waste in boilers is improper excess air control. Operators often add more combustion air “just to be safe,” but too much air sends valuable heat straight out the stack. On the other hand, too little air leads to incomplete combustion, unburned fuel, and higher CO emissions. Balancing excess air is therefore critical to fuel efficiency and clean operation.

Controlling excess air is essential for maximizing fuel efficiency because the right air-to-fuel ratio ensures complete combustion with minimal heat loss in flue gases. Optimal excess air reduces fuel waste, lowers stack temperature, cuts emissions, and improves boiler efficiency by 2–5%, while preventing unsafe incomplete combustion.

This means that fine-tuning combustion air is one of the simplest yet most impactful steps to reduce operating costs and emissions.

More excess air always improves combustion efficiency.False

While some excess air is required, too much increases flue gas losses and lowers efficiency.

Controlling excess air can improve boiler efficiency by 2–5%.True

Optimized combustion reduces stack losses and fuel waste, raising efficiency without compromising safety.

1. The Role of Excess Air in Combustion

Theoretical Air: Minimum air required for complete combustion.

Excess Air: Extra air supplied above theoretical to ensure safety.

Too Little Air: Incomplete combustion → CO, soot, and unburned fuel.

Too Much Air: Heat carried away by nitrogen and unused oxygen → efficiency loss.

2. Efficiency Impact of Excess Air

| Excess Air (%) | Flue Gas O₂ (%) | Flue Gas Temp (°C) | Boiler Efficiency (%) |

|---|---|---|---|

| 5 | 1 | 165 | 91.5 |

| 15 (Optimal) | 3 | 180 | 89.5 |

| 30 | 6 | 220 | 86.5 |

| 50 | 10 | 280 | 82.5 |

Observation: Efficiency drops by ~9% when excess air rises from 15% to 50%.

3. Methods to Control Excess Air

O₂ Trim Control Systems: Continuously adjust dampers and valves based on flue gas oxygen.

CO Monitoring: Ensures complete combustion without too much excess air.

Burner Tuning: Calibrating for load conditions to maintain balance.

Real-Time Automation: AI-based systems predict optimal air-fuel ratios under variable loads.

4. Case Example

A 20 TPH natural gas-fired boiler reduced average excess air from 35% to 15% after installing O₂ trim control:

Efficiency gain: +3.2%

Annual gas savings: $95,000

Payback period: 10 months

5. Secondary Benefits

Lower Emissions: Reduced CO₂ per unit steam and lower NOx due to optimized flame.

Stable Flame: Prevents blow-off and improves low-load operation.

Extended Equipment Life: Lower flue gas temperatures reduce tube stress.

Conclusion

Excess air is both necessary and potentially wasteful—it must be controlled precisely. Optimizing excess air ensures complete combustion at maximum efficiency, typically saving 2–5% in fuel use and delivering rapid ROI.

How Can Feedwater Preheating and Water Treatment Enhance Boiler Performance?

A major share of boiler inefficiency and maintenance costs comes from cold, untreated feedwater. Supplying a boiler with low-temperature or poor-quality water forces the system to burn more fuel, accelerates scaling and corrosion, and shortens equipment lifespan. Addressing these issues through feedwater preheating and proper water treatment significantly improves efficiency, reliability, and operating cost control.

Feedwater preheating improves boiler performance by raising the inlet water temperature, reducing fuel demand, and lowering thermal shock risk, while water treatment ensures purity, preventing scaling, corrosion, and fouling. Together, they enhance efficiency by 3–8%, extend boiler life, and reduce downtime and maintenance costs.

In other words, preheating reduces energy waste, while water treatment ensures the system remains clean and stable for long-term operation.

Cold feedwater increases boiler efficiency because more heat is absorbed.False

Cold feedwater requires more fuel to heat, increases stack losses, and causes thermal stress in boiler tubes.

Proper feedwater treatment prevents scaling and corrosion, maintaining efficiency.True

Water treatment removes hardness, oxygen, and impurities, preventing deposits that reduce heat transfer and raise fuel use.

1. Feedwater Preheating

Uses economizers, deaerators, or heat exchangers to raise water temperature before entering the boiler.

Typical feedwater temperature rise: 30–60°C.

Benefits:

Fuel Savings: Every 6°C rise in feedwater temp saves ~1% fuel.

Reduced Thermal Shock: Prevents stress cracking of boiler tubes.

Oxygen Removal: Deaerators strip dissolved gases, protecting metal surfaces.

| Parameter | Without Preheating | With Preheating (Deaerator) |

|---|---|---|

| Feedwater Temp (°C) | 40 | 105 |

| Boiler Efficiency (%) | 86 | 91 |

| Fuel Use (per ton steam) | 72 Nm³ | 67 Nm³ |

2. Water Treatment

Prevents deposits and corrosion that lower efficiency and reliability.

Common methods:

Softening: Removes calcium & magnesium hardness to stop scale.

Deaeration & Oxygen Scavengers: Prevent oxygen corrosion.

Filtration/RO Systems: Remove solids, silica, and organics.

pH Control: Maintains optimal alkalinity to protect tubes.

| Problem | Cause | Impact on Efficiency | Treatment |

|---|---|---|---|

| Scale (CaCO₃) | Hardness salts | 1 mm scale → 2–3% fuel loss | Water softener, blowdown |

| Corrosion | Dissolved O₂/CO₂ | Tube leaks, downtime | Deaerator, scavengers |

| Fouling | Suspended solids | Blocked flow, overheating | Filtration, RO |

3. Combined Effect

Efficiency Improvement: 3–8% fuel savings.

Extended Lifespan: Up to 20–30% longer boiler service life.

Reduced Maintenance: Less downtime from leaks and cleanings.

Stable Operation: Consistent steam pressure and temperature.

4. Case Example

A 15 TPH oil-fired boiler integrated with a deaerator and softener system:

Efficiency increase: +4.5%

Annual fuel savings: $120,000

Payback: 1.2 years

Reduced tube replacement by 70% over 5 years.

Conclusion

Feedwater preheating and water treatment work hand in hand: one improves thermal efficiency, the other ensures clean, reliable operation. Together, they are among the most cost-effective efficiency upgrades for any steam boiler system.

What Maintenance and Burner Tuning Practices Sustain High Efficiency?

Even the most advanced steam boiler cannot sustain high efficiency without consistent maintenance and burner tuning. Over time, deposits on heat-transfer surfaces, misaligned burners, and drifting control settings all reduce combustion quality and raise fuel consumption. In fact, a poorly maintained boiler can lose 5–10% efficiency within just one year of neglect. The good news: systematic care and fine-tuned burners restore peak performance and prevent costly inefficiencies.

Regular maintenance and burner tuning sustain high efficiency by ensuring optimal combustion, preventing fouling, minimizing excess air, and maintaining stable flame performance. Proper practices include routine cleaning, calibration of air-fuel ratios, flue gas analysis, and real-time control adjustments, which together can save 2–7% in fuel costs annually.

This makes maintenance not just a compliance activity, but a profitability strategy for any boiler owner.

Boiler efficiency remains stable without maintenance.False

Efficiency degrades rapidly from fouling, misalignment, and control drift; maintenance is essential to sustain performance.

Burner tuning improves efficiency by reducing excess air and ensuring complete combustion.True

Proper air-fuel calibration reduces stack losses and increases boiler fuel-to-steam efficiency.

1. Maintenance Practices for High Efficiency

Tube & Surface Cleaning: Remove scale and soot; just 1 mm of scale can increase fuel use by 2–3%.

Blowdown Management: Prevents solids buildup and maintains water chemistry.

Feedwater Equipment Care: Inspect deaerators, softeners, and pumps to avoid oxygen corrosion and scaling.

Leak Detection: Steam, air, and fuel leaks waste energy and create unsafe conditions.

Insulation Checks: Repair damaged lagging to minimize radiant heat losses.

| Maintenance Task | Frequency | Efficiency Impact |

|---|---|---|

| Tube cleaning | Quarterly–Biannual | +2–4% |

| Blowdown testing | Weekly | Stable efficiency |

| Burner inspection | Monthly | +1–2% |

| Flue gas analysis | Semiannual | +1–3% |

2. Burner Tuning for Optimal Combustion

Air-Fuel Ratio Adjustment: Ensure complete combustion with minimal excess air (usually 10–15%).

Flame Stability Testing: Avoid flame impingement or blow-off at varying loads.

O₂ and CO Monitoring: Use flue gas analyzers for precise calibration.

Load-Based Control: Implement O₂ trim and variable-speed fans for efficiency at part load.

| Excess Air (%) | Boiler Efficiency (%) | CO Emissions (ppm) |

|---|---|---|

| 5 (Too Low) | 87 | 300+ (Unsafe) |

| 15 (Optimal) | 91 | <50 |

| 40 (Too High) | 85 | <10 but high stack loss |

3. Advanced Tools for Sustained Tuning

Digital Combustion Analyzers → Measure O₂, CO₂, CO, and stack temp.

O₂ Trim Systems → Automatic real-time correction for changing conditions.

Variable Frequency Drives (VFDs) → Optimize fan energy use.

Predictive Maintenance Software → Detects combustion drift before it impacts efficiency.

4. Case Example

A 20 TPH natural gas boiler introduced quarterly burner tuning and digital O₂ trim:

Baseline efficiency: 88%

After program: 92% sustained

Annual fuel savings: $140,000

Payback on instrumentation: 8 months

5. Secondary Benefits

Lower CO₂ emissions per ton of steam.

Extended tube and burner life.

Fewer unplanned shutdowns due to stable combustion.

Conclusion

High efficiency is not just achieved at commissioning—it must be sustained with maintenance and burner tuning. These practices protect against performance drift, ensure stable combustion, and deliver significant cost savings over the boiler’s lifecycle.

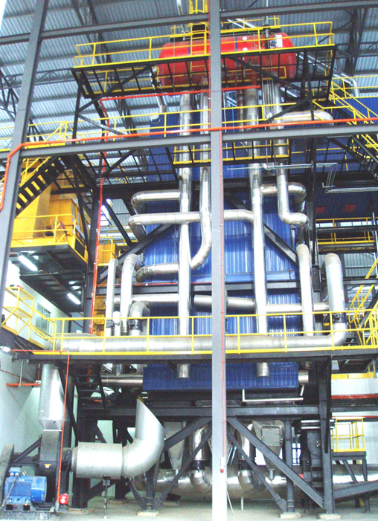

How Does Digital Monitoring and Automation Improve Long-Term Efficiency Management?

Traditional boiler operation relied heavily on manual adjustments, operator experience, and scheduled checks. While effective to a degree, this approach leaves efficiency vulnerable to drift, unnoticed faults, and unoptimized combustion. In contrast, digital monitoring and automation systems now allow plant operators to track, analyze, and control boiler performance in real time, ensuring sustained high efficiency and reliability over the boiler’s entire lifecycle.

Digital monitoring and automation improve long-term efficiency management by providing real-time data on fuel, air, steam, and water flows, automatically optimizing combustion, and detecting inefficiencies before they escalate. By integrating smart sensors, O₂ trim controls, predictive maintenance, and remote dashboards, plants can sustain 2–8% higher efficiency, reduce downtime, and extend boiler lifespan.

This means that efficiency management shifts from reactive to proactive, enabling cost savings and improved compliance.

Automation mainly benefits operator convenience but has little effect on efficiency.False

Automation directly improves efficiency by continuously optimizing combustion and load response, reducing fuel losses.

Digital monitoring reduces unplanned downtime by detecting issues early.True

Sensors and predictive algorithms flag anomalies before they cause breakdowns, avoiding costly shutdowns.

1. Real-Time Performance Tracking

Sensors monitor steam output, O₂ levels, fuel use, flue gas temperature, and water chemistry.

Dashboards display KPIs such as efficiency %, specific fuel consumption, and emissions.

Immediate Alerts notify operators of deviations from setpoints.

| Parameter | Manual Operation | Digital Monitoring |

|---|---|---|

| Data Frequency | Once per shift | Continuous (seconds) |

| Efficiency Drift Detection | Delayed (weeks) | Instant |

| Operator Action | Reactive | Proactive |

2. Automated Combustion Control

O₂ Trim Systems → adjust air-fuel ratio in real time.

Variable Speed Drives (VSDs) → optimize fan and pump energy use.

Load-Adaptive Burners → modulate to maintain stable flame at partial load.

AI Algorithms → predict optimal setpoints based on fuel type, demand, and weather.

3. Predictive Maintenance

Vibration and Temperature Monitoring → early warning of mechanical wear.

Fouling Detection Algorithms → alert when scaling or soot reduces heat transfer.

Anomaly Detection → identifies irregularities in gas composition or efficiency before failure.

4. Case Example

A 30 TPH gas-fired boiler integrated with IoT-based monitoring and automation:

Baseline efficiency: 88% (manual operation)

Post-digitalization: 93% sustained

Downtime reduction: 40% fewer outages

Annual savings: $250,000

Payback: <18 months

5. Secondary Benefits

Regulatory Compliance: Automated reporting of emissions and efficiency.

Operator Training: Dashboards simplify complex data into actionable insights.

Scalability: Centralized monitoring across multiple boilers or sites.

Conclusion

Digital monitoring and automation are no longer optional—they are essential tools for long-term efficiency management. By combining real-time visibility with automated optimization and predictive analytics, plants can achieve higher, more consistent efficiency while reducing maintenance and fuel costs.

🔍 Conclusion

Improving the efficiency of industrial gas-fired boilers requires a combination of design upgrades, operational optimization, and proactive maintenance. Facilities that adopt these best practices benefit from lower energy costs, better reliability, and compliance with environmental standards.

📞 Contact Us

💡 Looking to maximize the efficiency of your gas-fired boiler system? We offer energy audits, retrofitting solutions, and turnkey efficiency upgrades tailored to industrial gas boilers.

🔹 Contact us today to improve your gas-fired boiler efficiency and reduce operating costs. 🔥📊✅

FAQ

How can the efficiency of an industrial gas-fired boiler be improved?

Efficiency improvements can be achieved through:

Combustion tuning – Optimize the air-to-fuel ratio for complete combustion.

Economizers – Recover flue gas heat to preheat feedwater.

Condensing technology – Capture latent heat for up to 95% efficiency.

Proper insulation – Reduce radiation and convection losses.

Blowdown heat recovery – Reuse heat from boiler blowdown water.

Real-time monitoring – Use sensors and controls for automatic adjustments.

Why is combustion tuning important for gas-fired boilers?

Gas boilers perform best when the air-fuel mixture is balanced:

Too much air → heat loss through excess flue gas.

Too little air → incomplete combustion, soot buildup, and CO emissions.

Regular tuning ensures stable flames, low emissions, and maximum fuel efficiency.

How does waste heat recovery improve efficiency?

Installing economizers and condensing heat exchangers allows plants to capture waste heat from flue gases.

Economizers increase feedwater temperature, reducing fuel use.

Condensing systems recover latent heat from water vapor, pushing efficiency beyond 90%.

These systems typically improve efficiency by 5–10%.

What maintenance practices help sustain high efficiency?

Daily checks – Monitor water levels, pressures, and fuel flow.

Regular cleaning – Prevent scaling, fouling, and soot formation.

Burner inspection – Ensure proper flame shape and stability.

Leak detection – Check steam traps, valves, and piping for energy losses.

Preventive maintenance avoids hidden losses that reduce efficiency over time.

Can automation improve gas-fired boiler efficiency?

Yes. Modern PLC and IoT-based controls optimize performance by:

Adjusting burners and dampers in real time.

Monitoring O₂ and CO₂ levels for precise combustion.

Predicting failures and scheduling preventive maintenance.

Automation can improve boiler efficiency by 5–8% while reducing downtime.

References

U.S. Department of Energy – Energy Efficiency for Boilers – https://www.energy.gov

ASME – Gas Boiler Performance Guidelines – https://www.asme.org

Spirax Sarco – Boiler Efficiency and Heat Recovery – https://www.spiraxsarco.com

Forbes Marshall – Gas-Fired Boiler Optimization – https://www.forbesmarshall.com

Cleaver-Brooks – Condensing and High-Efficiency Boilers – https://www.cleaverbrooks.com

Babcock & Wilcox – Industrial Boiler Efficiency Solutions – https://www.babcock.com

Engineering Toolbox – Combustion Efficiency Data – https://www.engineeringtoolbox.com

ScienceDirect – Boiler Heat Recovery Studies – https://www.sciencedirect.com

ResearchGate – Industrial Boiler Optimization Case Studies – https://www.researchgate.net

IEA – Fuel Efficiency and Industrial Energy Use – https://www.iea.org

Wade Zhang

How to Improve the Efficiency of Industrial Gas-Fired Boilers? Read More »

-scaled.jpg)