As industries face growing pressure to reduce carbon emissions and fuel costs, many facilities are exploring fuel conversions for existing boilers. Switching from coal or oil to biomass or gas firing offers improved efficiency, cleaner emissions, and regulatory compliance. But conversion isn’t always straightforward—it involves careful technical, structural, and economic evaluation to determine feasibility.

Yes, it is possible to convert an existing boiler to biomass or gas firing, but it depends on the boiler’s original design, age, condition, and compatibility with new combustion systems. Gas conversions (natural gas, LNG, LPG) are often simpler and more cost-effective, requiring burner replacement and control upgrades. Biomass conversions are more complex due to differences in combustion properties, moisture content, fuel feeding, and ash handling, often requiring major furnace modifications, grate redesign, and emissions controls. A professional feasibility study is essential before proceeding.

Below is a detailed breakdown of what to consider before converting your boiler.

What Types of Boilers Are Most Suitable for Fuel Conversion to Biomass or Gas?

As energy costs rise and emission standards tighten, many industries are switching from coal or oil to cleaner fuels like biomass or natural gas. But not every boiler can handle this transition easily. Some boiler types are better suited for conversion, while others may require major redesigns—or may not be viable at all. Understanding which boiler systems are most compatible with biomass or gas fuel helps companies plan efficient, low-risk upgrades that reduce fuel costs and improve compliance.

Boilers most suitable for fuel conversion to biomass or gas include water tube boilers, hybrid biomass-gas boilers, and modern fire tube boilers with flexible burner configurations. These systems offer structural compatibility, adaptable combustion chambers, and proven retrofit success.

Choosing the right boiler type for conversion saves time, avoids engineering problems, and ensures stable performance with the new fuel. Let’s take a closer look at which systems are ideal and why.

Water tube boilers are well-suited for conversion to biomass or gas fuels.True

Their large combustion chambers, high heat transfer rates, and flexible design allow for effective retrofitting to alternative fuel sources.

Boiler Types and Their Suitability for Fuel Conversion

| Boiler Type | Biomass Conversion | Gas Conversion | Why It’s Suitable or Not |

|---|---|---|---|

| Water Tube Boiler | ✅ Excellent | ✅ Excellent | Large furnace area, strong pressure ratings, and modular designs |

| Fire Tube Boiler | ⚠️ Limited (for biomass) | ✅ Good | Gas burners retrofit easily; biomass limited by space/furnace design |

| Chain Grate Boiler | ✅ Good | ❌ Poor | Already solid-fuel-based, ideal for biomass but hard to convert to gas |

| Fluidized Bed Boiler | ✅ Excellent (for biomass) | ⚠️ Moderate | Designed for solid fuels; gas use requires careful modification |

| Package Boiler (Oil/Coal) | ⚠️ Costly for biomass | ✅ Good | Compact design works well with gas burners; biomass needs major mods |

Key Factors That Influence Boiler Conversion Feasibility

Combustion Chamber Size and Shape

Biomass requires more space to burn properly due to lower energy density. Water tube and fluidized bed boilers have large chambers ideal for this. Gas, by contrast, works with smaller chambers and can often use premix burners.Burner Compatibility

Fire tube and package boilers can often switch to gas simply by installing new burners. Water tube boilers may need tuning but are still compatible.Fuel Feed Systems

Biomass needs augers, hoppers, and air distribution systems. Chain grate and fluidized bed boilers are pre-designed for solid fuel flow.Ash and Moisture Handling

Biomass produces ash and often has high moisture. Boilers that allow ash removal and moisture control—like chain grate or fluidized bed types—are better suited.Emission Compliance

Gas-fired conversions usually improve emissions, making them easier to permit. Biomass conversions may require filters or scrubbers.

Pro Tip: Always do a feasibility study or fuel conversion audit before starting any retrofit project. It ensures you pick the right boiler, avoid hidden costs, and meet compliance standards.

Switching fuels can cut costs and lower your carbon footprint—but only if your boiler type is up to the task.

What Structural and System Modifications Are Needed for Gas or Biomass Retrofits?

Switching your industrial boiler to run on gas or biomass can lead to lower fuel costs, reduced emissions, and better compliance with modern energy standards. But it’s not as simple as swapping the fuel. Retrofitting a boiler for gas or biomass requires careful structural and system modifications to ensure safe, efficient, and long-lasting performance. Failing to make these changes correctly can lead to combustion problems, equipment damage, or even serious safety risks. In this guide, we explain what structural and system upgrades are typically needed to support a successful fuel conversion.

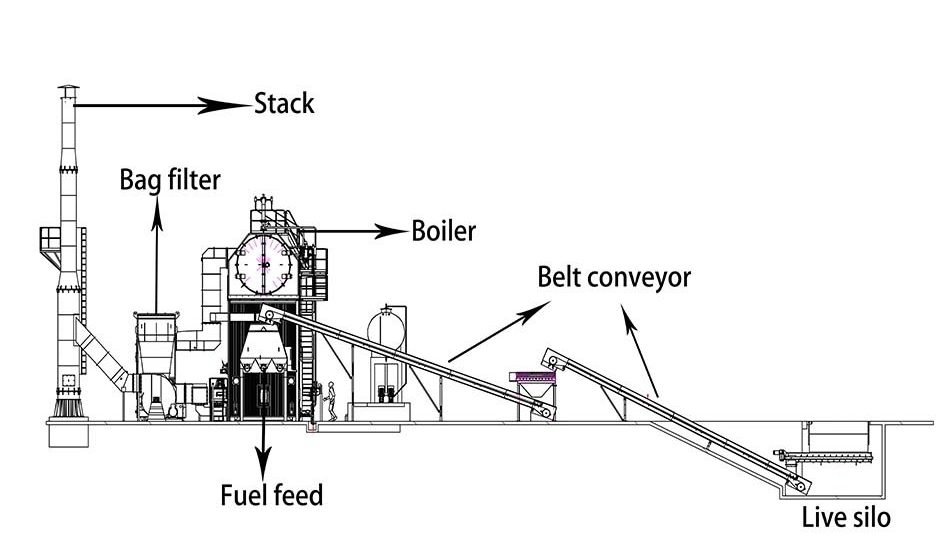

Retrofitting a boiler to use gas or biomass fuel often requires modifications to the combustion chamber, burner system, fuel feed or piping setup, control systems, emission handling, and ash or condensate removal systems. Structural reinforcements may also be needed to support heavier biomass equipment or to meet new code requirements.

Each retrofit is unique, but understanding the key upgrade areas helps plant managers plan for cost, time, and system compatibility.

Retrofitting a boiler to burn biomass or gas requires changes to both mechanical and control systems.True

These fuels have different combustion characteristics and flow requirements, so boilers must be physically and digitally adjusted to handle them properly.

Key Modifications Required for Biomass or Gas Boiler Retrofits

| System Area | Modifications for Gas Retrofit | Modifications for Biomass Retrofit |

|---|---|---|

| Combustion Chamber | Re-sizing or lining changes to optimize flame geometry | Enlarged or reinforced to handle slower, larger biomass burn |

| Burner System | New gas burner installation (low NOx or premix types) | Removal of oil/coal burners, install biomass grate or stoker |

| Fuel Supply System | Gas pipeline installation, regulators, safety shutoff valves | Hopper, auger conveyors, fuel feed motors, moisture control |

| Flue and Stack | May need corrosion-resistant materials for gas condensates | Larger ash handling and draft adjustments for biomass exhaust |

| Emission Controls | Adjust air/fuel ratio via O₂ sensors, optional NOx control | Add cyclones, bag filters, or ESP to control ash and PM |

| Control System (PLC/HMI) | Retune combustion controls, flame monitoring, interlocks | Add biomass feed rate control, flue temp sensors, flame cams |

| Ash or Condensate System | Add drain traps or neutralizers for condensate | Install ash conveyors, storage bins, and discharge controls |

| Structural Supports | Usually minor (gas gear is lightweight) | May require heavy-duty base for feeders, silos, and stokers |

Other Important Considerations

Safety Upgrades: Gas systems need explosion-proof valves, leak detectors, and pressure cutoffs. Biomass systems require spark arrestors, flame sensors, and over-temperature alarms.

Energy Management Integration: Retrofitted systems should connect to a central energy or SCADA system to track performance and fuel savings.

Regulatory Compliance: New fuel types often require updated environmental permits, especially for particulate or NOx emissions.

Downtime Planning: Depending on the extent of modifications, the retrofit could take 2–8 weeks, so plan accordingly.

Example: Fire Tube Boiler Converted to Gas

| Before Retrofit | After Retrofit |

|---|---|

| Oil burner with mechanical linkage | Fully modulating low-NOx gas burner installed |

| Manual draft control | Digital O₂ trim added |

| No condensate trap | Stainless condensate neutralizer added |

| Basic analog controls | PLC and touchscreen HMI installed |

Final Word

Successful biomass or gas retrofits require more than just changing the fuel source. They involve coordinated upgrades across mechanical, electrical, and control systems. Done correctly, these modifications can extend boiler life, improve energy efficiency, and help meet sustainability goals.

How Does Fuel Conversion Affect Thermal Efficiency, Emissions, and Operational Control?

Many companies switch from coal or oil to gas or biomass to lower costs and meet emission regulations—but what does this really mean for your boiler’s performance? Understanding how fuel conversion impacts thermal efficiency, emissions, and operational control helps you make smarter energy decisions and avoid costly surprises. In this article, we explain these three key areas in simple terms.

Fuel conversion can improve thermal efficiency (especially with natural gas), reduce harmful emissions like SOx and NOx, and enhance operational control through modern burners and automation. Biomass can lower emissions but may slightly reduce efficiency without proper design.

Choosing the right fuel doesn’t just affect your energy bill—it changes how your system runs day to day. Here’s what you can expect.

Switching from coal to gas improves boiler thermal efficiency and reduces emissions.True

Natural gas burns cleaner and more completely than coal, improving efficiency and lowering pollutants like CO₂, SOx, and particulates.

Key Impacts of Fuel Conversion

| Category | Gas Conversion | Biomass Conversion |

|---|---|---|

| Thermal Efficiency | ✅ Improves 3–8% due to cleaner, hotter combustion | ⚠️ May drop slightly due to lower fuel energy |

| Emissions | ✅ Major reductions in CO₂, NOx, SOx, and particulates | ✅ Lower CO₂ (net-zero), but more ash or PM |

| Operational Control | ✅ Enhanced via modern modulating gas burners | ⚠️ Requires precise feed and air control systems |

Conclusion:

Fuel conversion can deliver major gains—but results vary by fuel type and boiler design. Gas typically boosts efficiency and simplifies control. Biomass offers green benefits but needs proper system tuning.

What Are the Regulatory and Safety Considerations in Boiler Fuel Switching?

Switching an industrial boiler from oil or coal to gas or biomass may seem like a smart move for cost savings or environmental goals—but it also brings new regulatory and safety responsibilities. If you overlook compliance rules or skip safety upgrades, your project could face legal penalties, shutdowns, or even accidents. Understanding what authorities require and what safety systems must be updated is key to a smooth and safe fuel switch.

Fuel switching requires compliance with environmental permits, boiler code standards, fire safety regulations, and local utility rules. You must also upgrade safety systems like fuel shutoff valves, gas detectors, flame monitoring, and emissions controls to match the new fuel type.

Whether converting to natural gas or biomass, boiler systems must meet new expectations. These include emission limits, combustion controls, and risk prevention measures.

Switching boiler fuel without updating safety systems can violate code and increase explosion risks.True

Different fuels have unique combustion characteristics and hazards. Codes require proper safety devices to match the fuel used.

Key Regulatory and Safety Considerations

| Area | Consideration |

|---|---|

| Environmental Compliance | Update air permits for new emission profiles (NOx, CO, particulates) |

| Boiler Code Standards | Must meet ASME, NFPA, or EN codes for new burner and fuel system |

| Fire Safety Requirements | Install fuel shutoff valves, flame safeguards, gas leak detectors |

| Utility Regulations | Coordinate with gas suppliers or biomass authorities for supply approval |

| Operator Certification | Train staff on new fuel handling procedures and safety protocols |

| Inspection & Reporting | May require post-conversion safety inspections and documentation |

Tip: Always consult with local environmental and safety agencies before starting a conversion. Early planning avoids delays or penalties.

In short, switching boiler fuel is not just a technical project—it’s a compliance and safety challenge. But with proper planning and expert help, it can be done safely and legally.

How Do the Conversion Costs Compare to Full Boiler Replacement?

If you’re looking to switch from coal or oil to natural gas or biomass, you may wonder: is it better to convert the existing boiler or just buy a new one? Both options offer benefits, but the costs—upfront and long-term—can be very different. Making the wrong choice could lead to budget overruns, hidden upgrades, or poor system performance. In this article, we compare the true costs of fuel conversion versus full boiler replacement, so you can decide what’s best for your operation.

Fuel conversion typically costs 40–70% less than full boiler replacement. While retrofitting saves money and time, new boiler installations may offer higher efficiency, better long-term reliability, and easier compliance with modern codes. The right choice depends on the age, condition, and design of your current boiler.

Let’s break down the numbers and trade-offs, so you get the best return on your investment.

Boiler fuel conversion is generally more cost-effective than replacing the entire boiler system.True

Retrofitting allows you to reuse most of the existing boiler structure and systems, significantly reducing material and labor costs.

Cost Comparison: Retrofit vs Replacement

| Category | Fuel Conversion (Retrofit) | Full Boiler Replacement |

|---|---|---|

| Upfront Cost Range | $50,000 – $300,000 | $250,000 – $1,000,000+ |

| Installation Time | 2 – 8 weeks | 8 – 16 weeks |

| Downtime Required | Minimal (can phase-in during shutdown) | Longer (plant shutdown may be required) |

| New Control Systems | Upgrade existing where needed | Included in new system |

| Fuel Efficiency Gain | Moderate (2–8%) | High (up to 15–20%) |

| Compliance Level | May require additional retrofits | Fully code-compliant out of the box |

| Return on Investment (ROI) | 1–3 years | 5–10 years |

Key Considerations for Choosing Retrofit or Replacement

Boiler Age: If your boiler is under 20 years old and structurally sound, retrofitting is often the better value.

Fuel Flexibility: Modern replacement boilers are designed to switch between gas, biomass, or even hydrogen blends.

Space Limitations: Retrofitting fits into your current plant layout; replacements may require rework of piping and exhaust systems.

Emission Targets: If your plant has strict carbon or NOx goals, newer boilers often achieve lower emissions with less effort.

Example:

A mid-sized manufacturing plant converted its 15-year-old coal-fired water tube boiler to natural gas.

Retrofit cost: $180,000

Time to complete: 6 weeks

Fuel cost savings: $90,000/year

ROI: Just 2 years

By contrast, replacing the unit would have cost $650,000 and taken 14 weeks of downtime.

Final Word

If your boiler is in decent condition, fuel conversion offers major savings and faster ROI. But if it’s outdated, inefficient, or near failure, a new boiler may be a smarter long-term investment.

What Steps Are Involved in Assessing the Feasibility of a Boiler Fuel Conversion?

Switching an industrial boiler from oil or coal to natural gas or biomass can cut fuel costs and emissions—but it’s not a plug-and-play change. Before moving forward, it’s critical to conduct a feasibility assessment. This helps determine if your current boiler is compatible, what upgrades are needed, and whether the investment makes sense. Skipping this step can lead to unexpected costs, safety issues, or compliance failures. In this article, we outline the essential steps to assess whether your boiler is a good candidate for fuel conversion.

A boiler fuel conversion feasibility assessment involves: (1) evaluating boiler condition, (2) analyzing fuel compatibility, (3) checking structural and control systems, (4) estimating upgrade requirements and costs, and (5) reviewing regulatory and safety compliance. These steps ensure technical fit, cost-effectiveness, and code approval.

A detailed assessment helps you avoid guesswork, uncover hidden risks, and build a confident case for conversion or replacement.

A fuel conversion feasibility study is essential to determine if an existing boiler can safely switch fuels.True

This evaluation checks system compatibility, engineering requirements, and cost-benefit ratios to avoid performance or compliance issues.

Step-by-Step Feasibility Assessment Process

| Step | Purpose |

|---|---|

| 1. Boiler Age & Condition Check | Inspects pressure vessel, furnace, and components for long-term usability |

| 2. Fuel Compatibility Review | Compares burner type, chamber size, and design with new fuel properties |

| 3. Structural & Control System Audit | Assesses controls, piping, feed systems, sensors, and emissions gear |

| 4. Cost Estimate & ROI Analysis | Calculates upgrade costs, expected savings, and return on investment |

| 5. Regulatory Review | Identifies permits, environmental standards, and code requirements |

| 6. Utility and Infrastructure Check | Confirms fuel availability, gas line size, or biomass storage capacity |

| 7. Safety Risk Assessment | Evaluates explosion risk, ventilation, shutdown protocols, and alarms |

| 8. Conversion Plan Development | Outlines timeline, installation plan, and contingency measures |

Key Questions to Ask During Assessment

Is the boiler structurally sound and under 25 years old?

Can the combustion chamber handle the new fuel’s heat release?

Will the retrofit meet new NOx, SOx, or CO₂ targets?

Is your site ready for new fuel delivery systems (e.g., gas line or biomass silo)?

How quickly will the fuel savings cover the conversion costs?

Tip: Involve a certified boiler specialist or OEM engineer during the assessment for technical accuracy and safety assurance.

Final Word

Fuel conversion can be a great move—but only if your boiler is a good fit. A proper feasibility study gives you the data to make a smart, safe, and cost-effective decision.

🔍 Conclusion

Converting an existing boiler to gas or biomass firing is technically possible and often financially advantageous, especially when fuel savings, emissions compliance, and carbon reduction goals are considered. However, each case must be evaluated individually—taking into account engineering constraints, fuel properties, and long-term performance requirements.

📞 Contact Us

💡 Considering a fuel switch for your industrial boiler? We offer technical feasibility studies, conversion engineering, and ROI analysis for gas and biomass retrofit projects.

🔹 Let us help you transition your boiler to a cleaner, more sustainable fuel source. 🌱🔥🔧✅

FAQ

Can an existing boiler be converted to use biomass or gas fuel?

Yes, many industrial boilers can be converted from coal or oil to biomass or gas, but feasibility depends on:

Boiler type (water-tube and fire-tube designs vary in adaptability)

Age and condition of the boiler

Combustion system configuration

Space for fuel handling systems (especially for biomass)

Regulatory compliance and emissions limits

A professional retrofit assessment is required to confirm viability.

What modifications are needed to convert a boiler to biomass firing?

Converting to biomass typically requires:

Installing fuel storage silos and conveyors or augers

Modifying or replacing the burner and grate systems

Upgrading the combustion chamber to handle ash and variable fuel quality

Enhancing emissions control systems (particulate filters, scrubbers)

Adjusting the control and feedwater systems to accommodate new heat profiles

What’s involved in converting a boiler to natural gas?

A gas conversion is often more straightforward than biomass. It typically includes:

Burner replacement or modification

Installing gas supply lines and pressure regulation systems

Updating combustion controls and flame safeguards

Boiler tuning for optimum air-to-fuel ratio and efficiency

Ensuring compliance with NOx and CO emissions limits

Is it cost-effective to retrofit instead of replacing the boiler?

It can be, especially if:

The boiler shell and pressure parts are still in good condition

The plant has fuel cost advantages (e.g., local biomass availability)

There are incentives or grants for renewable fuel upgrades

However, in older or heavily worn boilers, replacement may be more economical long-term.

Are there any regulatory or permitting concerns when converting boiler fuels?

Yes. You may need:

Air emissions permit revisions

Fuel handling and safety compliance upgrades

Environmental impact assessments (especially for biomass)

Compliance with local fire codes and NFPA standards

Consult local environmental and building authorities before initiating any retrofit project.

References

EPA Guide to Boiler Fuel Switching and Emissions Compliance – https://www.epa.gov

DOE Industrial Boiler Retrofit Handbook – https://www.energy.gov

Biomass Fuel Conversion Case Studies – IEA Bioenergy – https://www.ieabioenergy.com

Gas Conversion Burner Technology Overview – https://www.sciencedirect.com

NFPA Combustion Safety Code for Fuel Conversions – https://www.nfpa.org

Industrial Boiler Retrofitting Economics – ResearchGate – https://www.researchgate.net

Biomass Storage and Feeding Design Guidelines – https://www.bioenergyconsult.com

Emission Standards for Industrial Boilers – https://www.iso.org

Gas Supply Infrastructure and Safety Rules – https://www.osha.gov

Retrofitting vs. Replacing Industrial Boilers – Trustpilot Reviews – https://www.trustpilot.com