How Much Does It Cost to Replace a Boiler? Full Breakdown

How Much Does It Cost to Replace a Boiler? Full Breakdown

Boiler replacement is a major capital decision for any facility, and many operators are surprised by the full scope of costs involved. Failing to budget correctly can lead to project delays, operational disruptions, or hidden expenses during installation. Whether due to system aging, capacity upgrades, or efficiency requirements, replacing an industrial boiler demands a clear cost breakdown to plan effectively and avoid costly surprises.

The cost to replace an industrial boiler typically ranges from $50,000 to $500,000 or more, depending on the boiler size, type (fire-tube or water-tube), pressure rating, fuel type, site conditions, and required auxiliary systems. Additional costs include removal of the old unit, site preparation, piping and electrical modifications, installation labor, commissioning, and controls integration—bringing the total replacement project cost to $100,000 to $1 million+ in many cases.

Understanding the individual cost elements of a boiler replacement helps plant managers and engineers make informed decisions, prepare accurate budgets, and ensure long-term return on investment.

What Factors Most Affect the Cost of Replacing an Industrial Boiler?

Replacing an industrial boiler is not just a line-item cost—it’s a multifactor engineering and logistical investment. Many operators are caught off guard by cost overruns because they overlook the true drivers behind the final price. From specification upgrades and fuel changes to compliance retrofits and crane access, each detail can dramatically impact your budget. Without proper planning, you risk exceeding your capital budget, delaying production, or failing regulatory inspections.

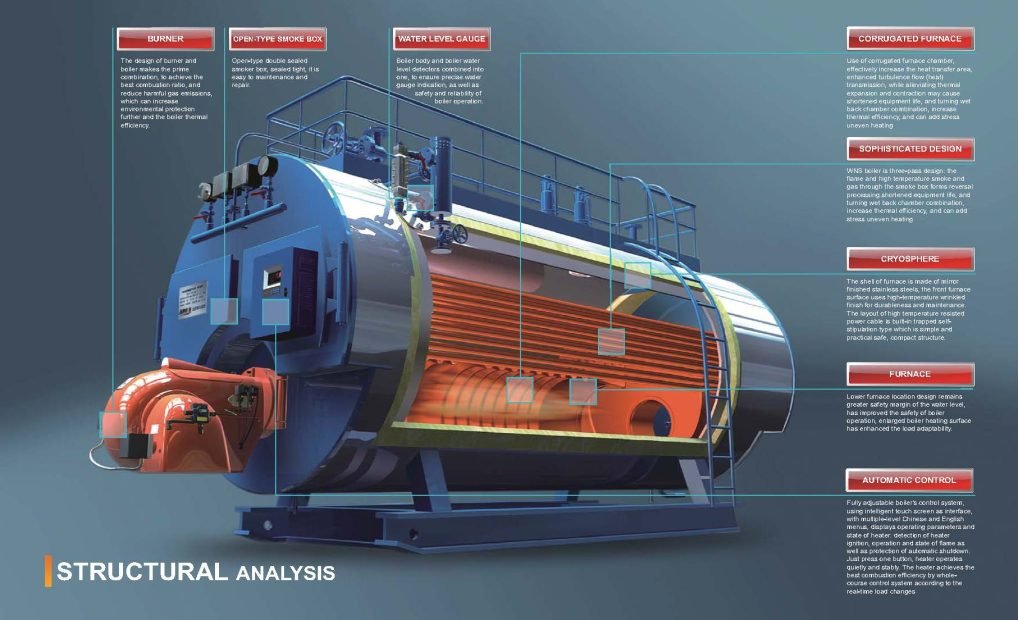

The most significant factors affecting the cost of replacing an industrial boiler include boiler capacity, pressure rating, fuel type, system complexity, site accessibility, emissions and code compliance, auxiliary equipment upgrades, and installation logistics. Together, these determine not just equipment cost but also engineering, integration, and commissioning expenses.

Understanding and planning for each cost driver is critical to an efficient, compliant, and cost-effective boiler upgrade.

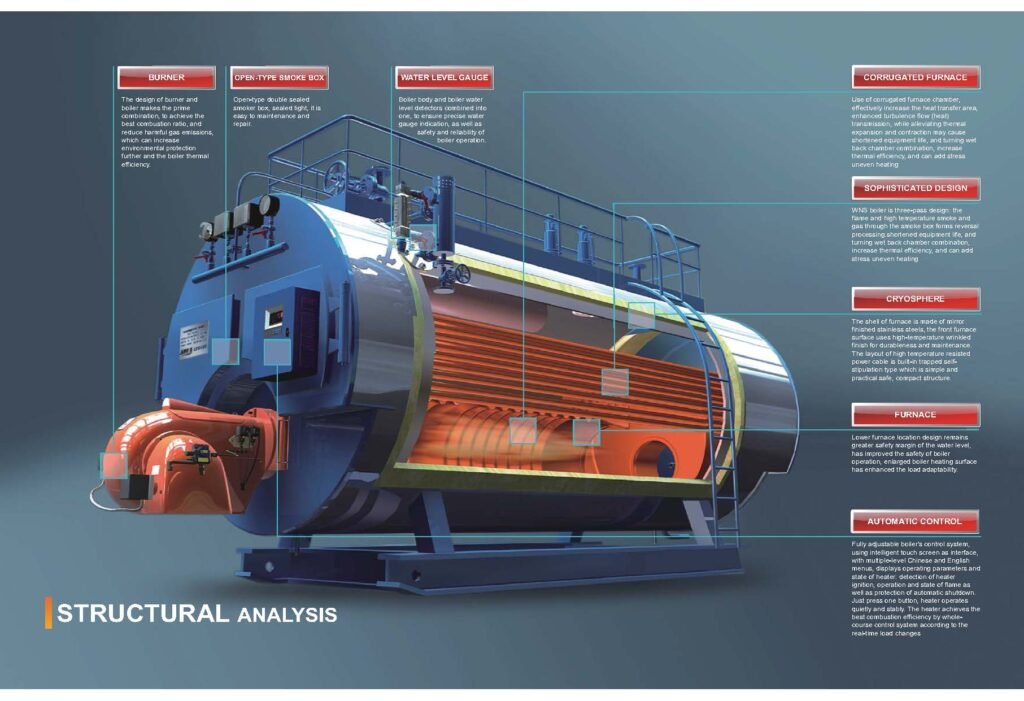

The capacity, pressure rating, and fuel type are major cost drivers when replacing an industrial boiler.True

These elements define the boiler’s physical size, material requirements, and burner design—directly impacting equipment and installation costs.

Replacing a boiler only involves the equipment cost and not any additional systems or compliance upgrades.False

Boiler replacement typically requires reevaluating emissions systems, control panels, piping, and foundation, significantly adding to the total project cost.

🔧 Major Cost Factors in Boiler Replacement Projects

| Cost Factor | How It Affects Pricing |

|---|---|

| Capacity (TPH or MW) | Larger units require more materials, bigger foundations, and stronger support |

| Pressure Rating (bar) | High-pressure boilers need thicker shells, certified welding, and advanced safety systems |

| Fuel Type (gas, oil, biomass) | Determines burner type, emissions controls, and possibly new fuel handling systems |

| Boiler Type (water-tube, fire-tube, HRSG) | Water-tube and HRSGs are costlier but needed for high output applications |

| Emissions Compliance (EPA, EU, CPCB) | May require SCR, baghouse, CEMS, low-NOx burners, driving costs significantly |

| Space Constraints & Site Access | Tight areas may require crane lifts, modularization, or off-hour work, increasing labor |

| Utility Upgrades (steam piping, stack) | A new boiler may require matching auxiliaries like economizers, stack resizing, feed tanks |

| Control & Instrumentation | Upgrading from manual to PLC/SCADA adds substantial automation and wiring cost |

| Code & Certification | ASME Section I, IBR, PED, and third-party inspections increase both equipment and documentation cost |

| Installation & Commissioning | Labor, crane rental, rigging, and commissioning engineering account for 25–40% of total cost |

| Shutdown & Downtime Impact | Cost of lost production or plant outages must be included in total financial planning |

💰 Cost Range by Boiler Type and Size (Approximate)

| Boiler Type | Capacity | Typical Installed Cost Range (USD) |

|---|---|---|

| Fire-tube (basic) | 5–10 TPH | $200,000 – $450,000 |

| Water-tube (standard) | 15–50 TPH | $600,000 – $2.5 million |

| HRSG (gas turbine) | 20–150 TPH | $1.5 million – $5+ million |

| Biomass boiler | 10–40 TPH | $1.0 million – $4.0 million |

| Supercritical/Ultra HP | 100+ TPH | $4 million – $10+ million |

These figures include equipment, controls, installation, commissioning, but not extended downtime or utility relocation.

📊 Cost Influence Breakdown (By Percentage of Total Project Cost)

| Category | Percentage of Total Cost |

|---|---|

| Boiler Equipment (core unit) | 35–45% |

| Installation & Rigging | 15–25% |

| Emissions & Compliance Gear | 10–20% |

| Controls & Instrumentation | 10–15% |

| Foundation & Structural Work | 5–10% |

| Engineering & Design | 5–10% |

| Contingency & Misc. | 5–10% |

🏗️ Installation Considerations That Add Cost

| Installation Condition | Impact on Cost |

|---|---|

| Confined Site Access | May require crane lifts or night work |

| Old Boiler Demolition | Requires safe dismantling, asbestos removal |

| Utility Tie-Ins | New headers, pumps, blowdown systems |

| Stack Modification | May need resizing or retrofitting with dampers |

| Insulation and Cladding | New thermal protection and weatherproofing |

| Testing & Flushing | Hydrostatic testing, blowdown piping, flushing |

| Third-Party Inspections | Required for ASME/IBR codes |

📍 Real-World Boiler Replacement Example (Mid-Sized Textile Plant)

| Old Boiler | Fire-tube, 8 TPH, 9 bar, gas-fired |

|---|---|

| New Boiler | Water-tube, 15 TPH, 15 bar, dual-fuel (gas/oil) |

| Upgrade Requirements | – New deaerator & feedwater tank – Stack extension – PLC control panel – Dual-fuel burner – SCADA integration |

| Project Cost | ~$1.3 million USD |

| Downtime Duration | 9 days (including testing) |

| Payback Period | 3.8 years (via fuel savings and reduced maintenance) |

Cost isn’t just about buying a boiler—it’s a full project involving site, systems, safety, and scheduling.

🔐 Compliance-Driven Cost Adders

| Regulatory Driver | Cost Implication |

|---|---|

| ASME Section I or PED | Adds design, NDT, documentation, and certification cost |

| Low-NOx Emissions Mandate | Requires advanced burners, FGR, or SCR system |

| CEMS Installation | Adds analyzers, data acquisition, calibration devices |

| State/Local Pressure Vessel Laws | May require state-approved third-party inspectors |

| Insurance Risk Audit Requirements | Requires documentation of safety valves, shutdown logic |

Conclusion

Replacing an industrial boiler involves far more than swapping out equipment. The true cost is shaped by technical specifications, site conditions, regulatory mandates, and integration complexity. Smart planning involves a full cost-benefit analysis that includes not just equipment, but auxiliaries, downtime, compliance, and future flexibility. Understanding these variables early ensures a reliable, compliant, and cost-controlled boiler investment.

How Much Does Boiler Removal, Disposal, and Site Preparation Typically Cost?

Before you install a new industrial boiler, you must deal with the removal and disposal of the old system—and properly prepare the site for the incoming unit. Many facilities underestimate these “pre-installation” costs, which can vary wildly based on the size, location, and age of the boiler. Issues like asbestos insulation, limited crane access, embedded concrete mounts, or pipe rerouting can dramatically inflate your timeline and budget. Without proper planning, removal and site prep can consume up to 30% of your boiler project cost.

Boiler removal, disposal, and site preparation typically cost between $25,000 and $150,000, depending on boiler size, site complexity, accessibility, hazardous materials, and structural modifications. Key contributors include cutting and rigging labor, crane rental, debris hauling, hazardous waste handling, and foundation work.

These operations are essential and often regulated by safety, environmental, and structural codes.

Boiler removal and site preparation can significantly impact total project cost.True

These early-phase tasks often involve specialized labor, crane services, hazardous material disposal, and foundation modifications—all of which require planning and budget allocation.

Old boilers can usually be removed at no cost by selling them as scrap metal.False

While scrap value may offset costs slightly, professional removal requires skilled labor, equipment, and often regulated hazardous material handling, which far outweigh scrap returns.

🧾 Breakdown of Typical Removal & Site Prep Costs

| Cost Component | Typical Range (USD) | What It Includes |

|---|---|---|

| Cutting & Demolition Labor | $5,000 – $25,000 | Pipe cutting, torching, vessel detachment, rigging |

| Crane & Rigging Equipment | $7,500 – $40,000 | Crane rental, rigging crew, lift planning, safety supervision |

| Disposal & Hauling | $2,000 – $10,000 | Transport of boiler shell, debris disposal, permits |

| Asbestos Abatement (if needed) | $5,000 – $35,000+ | Removal of asbestos insulation, regulated containment and testing |

| Structural Demolition/Access | $3,000 – $15,000 | Wall cuts, roof hatches, floor reinforcement |

| Foundation/Anchor Removal | $2,000 – $10,000 | Removal of old concrete bases, anchor bolts, floor repairs |

| Utility Disconnect & Rerouting | $3,000 – $15,000 | Steam header disconnection, gas/electric/water lines rerouted |

| Permit & Inspection Fees | $500 – $2,500 | City, fire marshal, environmental department, OSHA coordination |

In tight spaces or older plants, total removal and prep costs can exceed $150,000, especially if the boiler was originally built into the structure.

📊 Total Cost Ranges by Boiler Size and Complexity

| Boiler Size | Site Complexity | Estimated Removal & Prep Cost |

|---|---|---|

| <5 TPH (compact) | Easy access, modern site | $20,000 – $40,000 |

| 5–15 TPH | Moderate piping and space | $40,000 – $75,000 |

| 15–50 TPH | Crowded site, crane required | $75,000 – $120,000 |

| >50 TPH or HRSG | Built-in or retrofit removal | $100,000 – $200,000+ |

Sites with roof lifts, nighttime restrictions, or hazardous material remediation will always trend toward the higher end of cost ranges.

🏗️ Real-World Example: Boiler Decommissioning & Prep

| Facility | Details |

|---|---|

| Industry | Food processing plant |

| Old Boiler | 10 TPH fire-tube, 9 bar, oil-fired |

| Challenges | Confined access, asbestos insulation, no roof hatch |

| Scope of Work | – Cut old headers and stack- Remove firebrick and anchor- Crane lift through temporary roof opening- Asbestos removal |

| Total Removal Cost | $92,000 |

| Duration | 5 days |

In this project, asbestos handling and structural access were the largest cost drivers.

🔐 Compliance Considerations Affecting Cost

| Regulatory Area | Cost Impact |

|---|---|

| Asbestos or Lead Paint | Increases labor time and adds abatement licensing costs |

| Confined Space Entry (OSHA) | Requires air monitoring, rescue plans, added PPE |

| Crane Lift Permits | Public roadway use may require city permitting and traffic control |

| Environmental Regulations | Certain boiler removals must include soil or emissions testing |

| Noise or After-Hours Work | May need union approvals or overtime crews |

📉 Can Scrap Value Offset Costs?

| Component | Approx. Scrap Value (USD) | Realistic Recovery |

|---|---|---|

| Boiler shell (10–20 tons steel) | $1,500 – $4,000 | Limited—requires cut-down, transport |

| Copper/Brass fittings | $100 – $300 | Often corroded or unrecoverable |

| Tubes, pumps, burners | $500 – $1,000 total | May be obsolete or cost-prohibitive to remove cleanly |

While some vendors offer “scrap-for-credit” models, they rarely exceed 5–10% of actual removal cost.

✅ Site Preparation Activities for New Boiler Installation

| Prep Task | Why It’s Needed |

|---|---|

| Foundation assessment | New unit may need deeper or wider pad |

| Utility planning | Ensure gas, water, steam, and electrical feeds align |

| Floor reinforcement | Especially for heavy water-tube or HRSG units |

| Stack alignment | May need resizing, new breeching |

| Drainage and blowdown setup | Proper slope and discharge planning |

| Access path clearing | Equipment must reach final install position |

Conclusion

Boiler removal, disposal, and site preparation represent a critical and potentially costly phase of an industrial boiler replacement project. From cutting and rigging to hazardous waste handling and foundation prep, these tasks demand specialized skills, equipment, and regulatory compliance. Accurately estimating these costs—and integrating them early into your project plan—will ensure a smooth transition, safe operation, and budget certainty when installing your new boiler system.

What Installation and Commissioning Costs Should Be Expected During Boiler Replacement?

Replacing an industrial boiler is not just about the unit cost—installation and commissioning often account for 30–50% of the total project cost. These stages involve mechanical setup, electrical integration, safety checks, and live performance testing, all of which require specialized personnel and equipment. Many facility managers overlook these “soft” costs and later face budget overruns or delays in plant startup. Without precise planning and coordination, you risk regulatory violations, process disruptions, or unsafe operation.

Typical installation and commissioning costs during boiler replacement range from $50,000 to $500,000, depending on boiler size, fuel system complexity, site constraints, control integration, and code compliance requirements. Costs scale with the unit’s capacity (TPH), operating pressure, and auxiliary systems like feedwater, blowdown, and emissions controls.

Properly estimating these costs is essential for budgeting, safety, and a successful handover.

Boiler installation and commissioning can cost as much or more than the boiler equipment itself.True

High-capacity industrial systems require skilled labor, crane logistics, electrical work, compliance inspections, and live testing—all of which can match or exceed equipment cost depending on complexity.

Boiler commissioning only involves switching the boiler on and requires minimal budget.False

Commissioning is a detailed process including hydrostatic testing, burner tuning, safety checks, and control calibration—all of which require engineering labor and time.

🧾 Typical Installation & Commissioning Cost Breakdown

| Activity | Cost Range (USD) | Includes |

|---|---|---|

| Rigging & Setting in Place | $10,000 – $80,000 | Crane rental, labor, positioning, lifting permits |

| Steam, Water, Gas Piping | $15,000 – $150,000 | Welding, insulation, header tie-ins, valves |

| Electrical Hookup | $5,000 – $50,000 | Panels, VFDs, motor starters, field wiring |

| Control System Integration | $10,000 – $75,000 | PLC/SCADA connection, signal testing, programming |

| Stack/Breeching Connection | $5,000 – $40,000 | Ductwork welding, expansion joints, damper installation |

| Insulation & Lagging | $3,000 – $20,000 | Thermal wrap, sheet metal cladding |

| Hydrostatic Testing | $1,000 – $5,000 | Pressure test for leaks, code documentation |

| Burner Setup & Tuning | $3,000 – $15,000 | Combustion adjustment, O₂ trim, emissions tuning |

| Safety Device Testing | $2,000 – $10,000 | Valve lift checks, interlock verification, sensor calibration |

| Training & Handover | $2,000 – $15,000 | Operator training, manuals, certification |

| Third-Party Inspections | $1,000 – $10,000 | State/insurance inspections, ASME/IBR sign-off |

These figures are project-dependent. Larger, high-pressure water-tube or HRSG boilers with emissions systems and automation will push costs to the higher end.

📊 Cost Ranges by Boiler Size

| Boiler Capacity | Total Installation & Commissioning Estimate |

|---|---|

| <5 TPH | $50,000 – $100,000 |

| 5–15 TPH | $100,000 – $250,000 |

| 15–40 TPH | $200,000 – $400,000 |

| >40 TPH or HRSG | $400,000 – $750,000+ |

High-pressure (above 20 bar) or dual-fuel systems increase control and safety complexity, raising total commissioning costs.

🏗️ Key Factors That Influence Installation Costs

| Factor | How It Affects Cost |

|---|---|

| Boiler Size and Weight | Larger units need bigger cranes, more riggers, heavier foundations |

| Fuel System Type | Dual-fuel or oil systems need additional pumps, valves, flame scanners |

| Existing vs. New Foundation | Retrofitting may require cutting, anchoring, or casting new bases |

| Utility Tie-in Distance | Long pipe or conduit runs increase labor and material |

| Site Access | Confined spaces need custom rigging or night work |

| Automation & Controls | PLC/SCADA integration adds software programming, loop testing |

| Code Requirements | ASME, IBR, PED, or UL codes may demand inspection points and extra sensors |

🔍 Real-World Case Study: 10 TPH Boiler Commissioning

| Project Scope | Cost Breakdown (USD) |

|---|---|

| Steam piping tie-in to main header | $35,000 |

| Natural gas line rerouting + valve train | $18,000 |

| Electrical wiring for motor/pump/control | $12,000 |

| Burner setup and O₂ trim | $4,000 |

| Stack and breeching connection | $7,500 |

| Safety system loop testing | $3,500 |

| Operator training and certification | $2,000 |

| Total | $82,000 |

Commissioning duration: 5 days, with 2 engineers, 1 burner technician, and 1 safety officer.

🔐 Regulatory-Driven Commissioning Tasks

| Compliance Requirement | Task |

|---|---|

| ASME Section I or IV | Hydrotest, valve setting, pressure relief documentation |

| NFPA 85 | Flame failure testing, scanner alignment, purge sequence |

| EPA Title V / EU IED | Initial NOx/CO/SOx tuning and stack sampling |

| CEMS Setup (if needed) | Calibration, data acquisition validation |

| Operator Certification | Regional licensing, hands-on training |

🧠 Commissioning Scope: More Than Just “Startup”

| Phase | Description |

|---|---|

| Pre-start Checks | Water level, gas pressure, control wiring, purge |

| Ignition and Ramp-Up | Burner startup, modulation, flame monitoring |

| Performance Testing | Load cycling, steam pressure/flow stability checks |

| Interlock Testing | Fuel cutoff, high-pressure shutdown, level alarms |

| Efficiency Optimization | O₂ trim tuning, feedwater control |

| Training & Documentation | SOPs, troubleshooting guides, service handoff |

Proper commissioning ensures not just safety but optimal fuel efficiency and emission compliance.

Conclusion

Installation and commissioning are complex, multi-discipline processes involving mechanical, electrical, automation, safety, and regulatory elements. Costs can range from $50,000 for small, skid-mounted boilers to over $500,000 for large industrial or power plant units, depending on fuel system complexity, site layout, automation level, and local compliance codes. Planning early and engaging expert commissioning teams is essential to ensure safe startup, legal operation, and maximum performance from day one.

How Do Control Systems, Auxiliaries, and Integration Affect Total Boiler Replacement Cost?

When planning for boiler replacement, many facility managers budget only for the main pressure vessel. But the true cost lies in everything connected to it—especially modern control systems, auxiliary equipment, and the often-overlooked integration with your plant’s infrastructure. Failing to account for these systems can double your expected costs and delay commissioning. These components are essential for safe operation, fuel efficiency, emissions compliance, and full automation, making them non-negotiable for most industrial applications.

Control systems, auxiliaries (such as feedwater tanks, economizers, blowdown separators), and plant integration can account for 40%–70% of total industrial boiler replacement cost. Their impact is driven by system complexity, compliance level, automation needs, and compatibility with existing infrastructure.

Without them, a boiler cannot run efficiently, safely, or legally in regulated industrial settings.

Boiler controls, auxiliaries, and integration costs can exceed the boiler equipment cost itself.True

In modern industrial systems, automation, energy recovery units, and emission-control auxiliaries are mandatory, adding significant cost beyond the pressure vessel.

You can reuse old auxiliaries and controls without affecting the new boiler’s performance or safety.False

Old components may not match the flow, pressure, temperature, or code requirements of new systems, and often lead to failure or compliance risks.

🧾 Cost Contribution of Controls, Auxiliaries, and Integration

| Component | Typical Cost Range (USD) | Function |

|---|---|---|

| Boiler Control System (PLC/SCADA) | $15,000 – $120,000 | Safety interlocks, modulating burner, system diagnostics |

| Burner Management System (BMS) | $10,000 – $80,000 | Monitors flame, purge cycle, fuel valve logic |

| Deaerator + Feedwater Tank | $25,000 – $150,000 | Removes O₂/CO₂ from water, maintains pressure/feed quality |

| Feedwater Pumps (VFD included) | $10,000 – $45,000 | Delivers high-pressure water with flow control |

| Economizer (heat recovery) | $20,000 – $100,000 | Preheats feedwater using flue gas, improving efficiency |

| Blowdown Separator/Heat Recovery | $5,000 – $30,000 | Safely removes solids, recovers flash steam |

| Stack/Breeching & Dampers | $5,000 – $50,000 | Connects boiler to chimney, controls flue flow |

| Instrumentation & Sensors | $10,000 – $40,000 | Temp, pressure, flow, O₂, TDS, pH, and safety data |

| Wiring & Electrical Integration | $10,000 – $60,000 | Cable trays, terminations, panels, and compliance grounding |

| Piping Integration (steam/water/gas) | $20,000 – $150,000 | Interconnects all utilities, insulation included |

📊 Share of Total Project Cost

| System Element | % of Total Boiler Replacement Cost |

|---|---|

| Main Boiler Unit | 30%–40% |

| Controls & Automation | 10%–20% |

| Auxiliaries (pumps, tanks, economizer) | 20%–30% |

| Integration & Commissioning | 15%–25% |

| Regulatory Compliance/Testing | 5%–10% |

On a $1.5 million boiler project, you may spend $600,000–$1.0 million on non-boiler equipment and services.

🧠 Why You Can’t Ignore These Components

| Component | Impact if Skipped or Underdesigned |

|---|---|

| Control Panel | No burner modulation, unsafe startup, loss of efficiency |

| BMS | Fails regulatory inspection, cannot detect flame faults |

| Deaerator | Tube corrosion from oxygen ingress, reduces boiler life |

| Economizer | Fuel cost 5–10% higher over boiler lifespan |

| Blowdown Heat Recovery | Energy loss, scalding hazard, high water treatment cost |

| Instrumentation | No real-time control, risk of dry fire or overpressure |

These systems aren’t optional in any regulated industrial boiler setup—they’re essential to operation, performance, and compliance.

🧩 Integration Challenges That Add Cost

| Challenge | Cost Implication |

|---|---|

| Mismatched Piping Sizes | New headers, reducers, or retrofitting needed |

| Legacy Control Systems | May not talk to modern PLCs, requires full rewiring |

| Non-code-compliant Valves/Fittings | Must be replaced to meet ASME/IBR/PED standards |

| Space Constraints | May require compact custom-fabricated auxiliaries |

| Fuel System Conversion (e.g., from oil to gas) | New gas train, purge blower, and sensors required |

🏗️ Case Study Example: 20 TPH Water-Tube Boiler Replacement

| Cost Component | Cost (USD) |

|---|---|

| Boiler Unit | $550,000 |

| PLC + Burner Management System | $70,000 |

| Deaerator + Feed System | $110,000 |

| Economizer + Flue Piping | $85,000 |

| Electrical/Instrumentation | $45,000 |

| Integration Labor & Piping | $125,000 |

| Commissioning | $35,000 |

| Total Cost | $1.02 million |

In this project, auxiliaries and integration accounted for 46% of the total project budget.

🔐 Compliance and Safety Requirements Driving Costs

| Standard/Code | Required Component |

|---|---|

| ASME Section I | Certified safety valves, level indicators |

| NFPA 85 | Flame scanners, BMS with lockout logic |

| EPA or CPCB Emissions | O₂ analyzers, modulating burner, economizer |

| OSHA/IEC 61511 | Safety interlocks, SIL-rated devices |

| ISO 13849-1 (EU Plants) | Redundant controls, fault diagnostics |

Conclusion

Controls, auxiliaries, and plant integration are not just accessories—they are essential to the safe, legal, and efficient operation of your new boiler. These systems define long-term O&M costs, emissions performance, and the boiler’s ability to respond to process demands. Expect them to contribute 40–70% of the total cost depending on how advanced your system must be. Skimping here results in higher fuel bills, downtime, or failed inspections—costing far more in the long run.

What Cost-Saving Options Exist When Replacing an Industrial Boiler?

Replacing an industrial boiler often triggers concern over capital expenditure. From pressure vessel pricing to commissioning and auxiliary integration, costs can climb rapidly—often exceeding $1 million. But many facilities overlook strategic options that can significantly reduce both upfront and lifecycle expenses. Poor planning or over-specifying capacity can lead to wasted capital, underperformance, and higher fuel bills. Instead, optimized design, modularization, equipment reuse, and strategic scheduling can reduce total replacement costs by 15–40% without compromising performance.

Cost-saving options during industrial boiler replacement include right-sizing the unit, reusing compliant auxiliaries, selecting modular or skid-mounted systems, choosing efficient control strategies, exploring fuel flexibility, and timing the replacement during low production or seasonal shutdown periods. Smart design and expert consultation can dramatically reduce both capital and operational costs.

Strategically applying these measures can convert your boiler project from a cost burden to a long-term asset with strong ROI.

Replacing an industrial boiler always requires a full system rebuild with new equipment.False

Depending on condition and compatibility, auxiliary systems like feedwater tanks, stacks, or economizers can often be reused or upgraded, saving substantial costs.

Modular or skid-mounted boiler systems can reduce installation and commissioning costs.True

Pre-assembled boiler packages minimize on-site labor, reduce downtime, and simplify integration, lowering total installed cost.

💸 Key Cost-Saving Strategies During Boiler Replacement

| Strategy | Description | Estimated Savings |

|---|---|---|

| Right-Size the Boiler | Match steam capacity to actual load + margin, not worst-case | 10%–20% savings on CAPEX |

| Use Modular / Skid-Mounted Systems | Reduces installation time, labor, and crane costs | 15%–30% reduction in install cost |

| Refurbish or Retain Auxiliaries | Reuse existing economizer, pumps, or tanks if compliant | $50k–$300k saved |

| Install During Off-Season | Avoids overtime or production loss | 5%–10% total project cost |

| Choose Dual-Fuel or Lower-Cost Fuel | Increases fuel flexibility, improves long-term savings | 10%–30% OPEX savings/year |

| Simplify Controls Where Applicable | Choose manual or semi-auto for low-duty applications | $10k–$75k saved on controls |

| Pre-Engineer Integration Plan | Avoid rework, size mismatches, foundation errors | 5%–15% install budget buffer |

| Negotiate Extended Warranty or Service | Reduces unplanned O&M costs over time | $25k–$100k over 5 years |

🔧 Table: Elements That Can Often Be Reused

| Component | Reusability Potential | Condition |

|---|---|---|

| Economizer | High (if pressure/temp match) | Inspect for scaling, weld integrity |

| Deaerator Tank | Moderate | Test for corrosion, flow match |

| Feedwater Pumps | Moderate | Must match new head and flow requirements |

| Stack/Ducting | High if location unchanged | Check for ID, draft, and corrosion |

| Control Wiring/Conduits | Low–Moderate | Must meet electrical code and PLC integration |

| Steam Piping Headers | Moderate | Valid if pressure and size compatible |

Equipment under 10–15 years old and meeting ASME/IBR/PED code may be inspected and reused safely with minor refurbishment.

🏗️ Case Study: Smart Replacement Strategy

| Project Scope | Savings Strategy Applied | Savings Achieved |

|---|---|---|

| 10 TPH boiler for food processing plant | Reused economizer and feed tank Installed skid-mounted dual-fuel boiler Scheduled during summer shutdown | $185,000 off estimated $1.1M project |

The integration-friendly layout and off-season labor planning helped avoid process downtime and excess installation cost.

🧠 Design-Driven Savings Tactics

| Design Decision | Cost Impact |

|---|---|

| Avoid Overspecification | Extra capacity adds unnecessary material and emissions gear |

| Minimize Steam Pressure | Lower pressure = thinner shell, cheaper safety valves |

| Pre-wire & Pre-pipe Components | Reduces site work, risk of delays |

| Use Plug-and-Play Controls | Reduces commissioning time |

| Incorporate Heat Recovery from Day One | Avoids retrofitting costs and permits later |

📊 Cost Reduction Potential by Approach

| Cost-Saving Area | Potential Budget Reduction |

|---|---|

| Design Optimization | 10%–20% |

| Component Reuse | 5%–15% |

| Modularization | 10%–30% |

| Installation Scheduling | 5%–10% |

| Simplified Automation | 5%–15% |

🛠️ Vendors & Services That Help Lower Costs

| Service | How It Helps |

|---|---|

| Boiler Audit / Sizing Consultant | Ensures right capacity, avoids overspending |

| Control System Integration Expert | Avoids unnecessary rewiring or logic duplication |

| Turnkey Boiler Providers | Bundle auxiliary systems for better pricing |

| Reconditioned Equipment Vendors | Offer certified, tested used auxiliaries with warranty |

| Energy Efficiency Consultant | Design to minimize lifetime fuel spend |

Conclusion

Replacing an industrial boiler doesn’t have to break the bank. By focusing on right-sizing, modularization, smart scheduling, and reusing compliant auxiliaries, you can shave 15–40% off total costs without sacrificing performance or reliability. Each facility is different, so a site-specific audit is critical to uncovering hidden reuse potential and integration efficiencies. These strategies not only reduce upfront expenses but also position your system for long-term operational savings through energy efficiency and minimal downtime.

How Can Lifecycle Cost Analysis Help Justify Boiler Replacement Investment?

Replacing an aging industrial boiler often triggers budget scrutiny—especially when capital costs can exceed $1 million. However, focusing only on upfront costs obscures the bigger financial picture. Older boilers are typically fuel-inefficient, require frequent maintenance, and can rack up emissions penalties or lost production from unplanned downtime. Lifecycle Cost Analysis (LCCA) quantifies the total cost of ownership over the system’s life, revealing how a new boiler can actually save money—even if the initial price is high. Without it, you risk making short-term decisions that drain long-term resources.

Lifecycle cost analysis (LCCA) justifies boiler replacement by comparing the total cost of ownership of a new system—including capital, fuel, maintenance, downtime, and emissions—against continued operation of an old boiler. It highlights how savings from efficiency gains, reliability, and compliance can outweigh upfront investment, resulting in better ROI and lower long-term costs.

A well-executed LCCA often shows that delaying replacement costs more than acting early.

Lifecycle cost analysis helps determine the most cost-effective boiler over its entire lifespan.True

By evaluating capital, operating, maintenance, and disposal costs, LCCA identifies the boiler system with the lowest total cost of ownership—not just the lowest purchase price.

Choosing the boiler with the lowest upfront price always results in the lowest overall cost.False

Lower-cost boilers often consume more fuel, require more maintenance, and have shorter lives—raising long-term costs compared to higher-efficiency alternatives.

📊 Key Elements in Boiler Lifecycle Cost Analysis (LCCA)

| Cost Category | Description | Typical Duration |

|---|---|---|

| CAPEX (Capital Cost) | Boiler unit, controls, auxiliaries, installation | Year 0 |

| Fuel Costs (OPEX) | Cost of fuel over 10–30 years, based on efficiency rating | Year 1–20+ |

| Maintenance Costs | Annual servicing, repairs, spare parts | Ongoing |

| Downtime/Lost Production | Cost of shutdowns due to failure or inefficiency | Ongoing |

| Emissions Compliance | Cost of pollution control, penalties, permit compliance | Year 1–20+ |

| Disposal & Decommissioning | Removal, disposal, and environmental remediation | Final Year (end of life) |

💰 Sample Lifecycle Cost Comparison: Old vs. New Boiler

| Cost Item (over 20 years) | Old Boiler (75% eff.) | New Boiler (89% eff.) |

|---|---|---|

| Fuel Cost (natural gas) | $5,200,000 | $4,300,000 |

| Annual Maintenance | $40,000 × 20 = $800,000 | $20,000 × 20 = $400,000 |

| Unplanned Downtime Losses | $500,000 | $100,000 |

| Emissions Penalties/Upgrades | $200,000 | $50,000 |

| Initial Boiler Cost | Already depreciated | $850,000 |

| Total Lifecycle Cost | $6.7 million | $5.7 million |

Savings Over Lifecycle: $1,000,000, despite the new boiler’s upfront cost.

🧠 How LCCA Supports Decision-Making

| LCCA Function | Decision Impact |

|---|---|

| Highlights long-term fuel savings | Justifies higher-efficiency (condensing or heat recovery) systems |

| Shows downtime cost of aging boilers | Supports reliability and automation investment |

| Quantifies emissions penalties avoided | Helps budget for clean energy or fuel-switching |

| Compares vendors over full lifecycle | Prevents short-term cost bias |

| Identifies maintenance trend savings | Guides spare parts and service planning |

🧮 Example LCCA Formula (Simplified)

LCC = C + (∑ (O&M + Fuel + Downtime + Emissions) / (1 + i)^n ) + E

Where:

C = Capital cost

O&M = Annual operation and maintenance cost

i = Discount rate (inflation or opportunity cost)

n = Number of years

E = End-of-life disposal cost

This formula is often run using Excel or LCCA-specific software to simulate real cost curves.

📈 Chart: Typical Lifecycle Cost Distribution for a 20-Year Boiler System

| Cost Component | % of Total Lifecycle Cost |

|---|---|

| Fuel | 65%–75% |

| Maintenance & Downtime | 10%–20% |

| Capital Equipment | 10%–15% |

| Emissions Compliance | 5%–10% |

Fuel efficiency alone dominates total ownership cost, making it a high-leverage factor in LCCA.

🔍 Hidden Costs Avoided Through LCCA

| Hidden Cost | LCCA Advantage |

|---|---|

| Unscheduled Boiler Shutdown | Accounts for lost production + emergency repairs |

| Parts Obsolescence | Projects upgrade cost when older parts become unavailable |

| Fuel Price Volatility | Models ROI under various energy price scenarios |

| Emissions Regulation Changes | Incorporates possible future emissions surcharges |

| Plant Expansion Requirements | Anticipates future steam demand to avoid under-sizing |

✅ When to Use LCCA for Boiler Decisions

| Use Case | Why It Helps |

|---|---|

| Deciding to repair vs. replace | Quantifies long-term cost of keeping inefficient systems |

| Choosing between boiler types | Compares fire-tube vs. water-tube vs. electric over time |

| Fuel-switching decision (oil to gas) | Measures breakeven point for gas conversion investment |

| Evaluating dual-fuel vs. single-fuel | Determines ROI for redundancy vs. initial cost |

| Planning for ESG or decarbonization | Models cost of emissions avoidance and cleaner systems |

Conclusion

Lifecycle Cost Analysis is a powerful financial tool that turns your boiler replacement decision from a capital expenditure into a long-term cost optimization strategy. Rather than asking “what’s the cheapest boiler now,” LCCA answers “which boiler will cost the least over 20 years?” In nearly every scenario, the more efficient, reliable, and compliant system pays for itself through lower fuel use, less downtime, and improved performance. When properly calculated, LCCA is your strongest argument for upgrading before failures—or fuel bills—force the issue.

🔍 Conclusion

Replacing an industrial boiler is a multi-faceted investment involving equipment, labor, engineering, and system upgrades. With total costs ranging from $100,000 to over $1 million, careful planning and accurate budgeting are essential to maximize efficiency, compliance, and reliability.

📞 Contact Us

💡 Need an accurate cost estimate for your boiler replacement project? We provide site assessments, system design, project costing, and turnkey replacement services for industrial boilers of all sizes.

🔹 Let us help you replace your boiler with confidence—on time, on budget, and built to perform. 🔧🔥📈✅

FAQ

How much does it cost to replace a commercial or industrial boiler?

The total cost to replace a boiler depends on its size, type, and complexity of installation:

Commercial boiler replacement: $20,000–$100,000

Industrial boiler replacement: $100,000–$500,000+

High-capacity or custom boilers: Up to $1 million or more

This includes boiler cost, old system removal, piping adjustments, and labor fees. Prices may vary depending on local labor rates and site access.

What factors influence the cost of boiler replacement?

Key cost factors include:

Boiler size and capacity (BTU/hr or HP)

Fuel type (natural gas, oil, biomass, electric)

Boiler type (fire-tube, water-tube, condensing)

Efficiency rating and emissions compliance

Structural or foundation modifications

Control systems and integration

Permits and inspections

Custom configurations and high-efficiency upgrades can significantly increase costs.

What is included in a typical boiler replacement quote?

A full boiler replacement quote generally includes:

New boiler unit cost

Removal and disposal of old boiler

Installation labor (mechanical and electrical)

Piping and system integration

Start-up and commissioning

Compliance testing and certifications

Optional extended warranties or service contracts

Always request a detailed breakdown to understand what’s covered.

Is it cheaper to replace or repair an old boiler?

Repairing may be more cost-effective for minor issues or boilers under 10 years old. However, replacement is often more economical if:

Repairs exceed 40–50% of the boiler’s value

Efficiency is outdated, leading to high energy bills

Replacement parts are scarce or obsolete

The boiler has exceeded its typical lifespan (15–30 years)

Modern replacements can offer up to 30% better energy efficiency.

How can I reduce boiler replacement costs?

Cost-saving tips include:

Scheduling during the off-season (lower labor demand)

Choosing a standardized model over custom design

Reusing existing piping or infrastructure when compatible

Applying for energy efficiency incentives or rebates

Bundling replacement with preventive maintenance contracts

Partnering with a reputable EPC contractor can also avoid hidden costs.

References

Powerhouse – Boiler Replacement & Cost Planning – https://www.powerhouse.com

Cleaver-Brooks – Boiler Upgrade and Replacement Services – https://www.cleaverbrooks.com

Hurst Boiler – Equipment Replacement Estimates – https://www.hurstboiler.com

Miura Boiler – Retrofit and Modernization Cost Guide – https://www.miuraboiler.com

Thermodyne Boilers – Cost of Replacing Industrial Boilers – https://www.thermodyneboilers.com

Spirax Sarco – Boiler System Upgrades – https://www.spiraxsarco.com

BioEnergy Consult – Cost-Effective Boiler Replacement Tips – https://www.bioenergyconsult.com

EPA – Boiler Emissions & Upgrade Considerations – https://www.epa.gov

IEA – Boiler Modernization & Energy Efficiency Trends – https://www.iea.org

ASHRAE – Boiler Replacement Guidelines – https://www.ashrae.org

Wade Zhang

How Much Does It Cost to Replace a Boiler? Full Breakdown Read More »

-1024x768.jpg)

-scaled-r3gfus8l0p2gl106z0ksl6rqq0kqjrbuwda948iv2c.jpg)