What’s Inside an Industrial Steam Boiler? Key Parts Explained

What’s Inside an Industrial Steam Boiler? Key Parts Explained

Industrial steam boilers are high-efficiency thermal systems used to generate pressurized steam for applications such as power generation, chemical processing, food sterilization, and textile manufacturing. While they may look like a simple tank from the outside, internally they consist of complex, interdependent systems designed for maximum heat transfer, safe operation, and fuel efficiency.

An industrial steam boiler typically contains a pressure vessel, furnace (combustion chamber), burner assembly, steam drum or headers, heat exchanger tubes, water feed system, blowdown system, control panel, safety valves, and flue gas handling equipment. These components work together to convert fuel energy (gas, oil, biomass, or coal) into usable steam while ensuring pressure regulation, efficient combustion, and emission control.

Let’s explore the core components that make up a complete industrial steam boiler system.

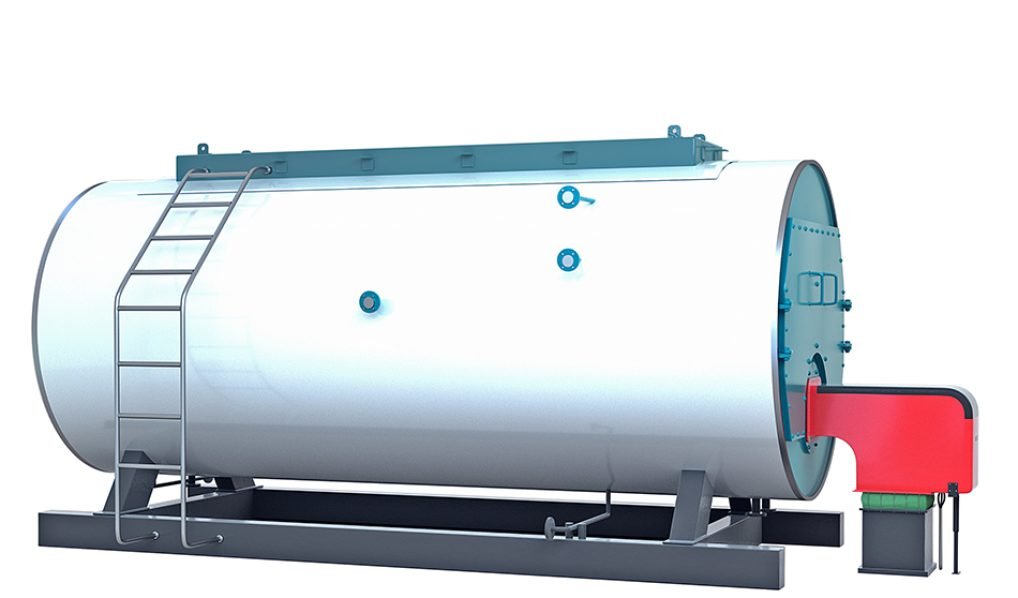

What Is the Function of the Pressure Vessel in a Steam Boiler?

In every steam boiler system, the pressure vessel is the core component where heat energy is transferred to water under pressure to generate steam. This part of the boiler must withstand extreme temperature and pressure conditions safely and reliably over long periods. The consequences of failure—ranging from efficiency losses to catastrophic explosion risks—make understanding its structure and function absolutely critical. Whether in a power station, chemical plant, or food factory, the pressure vessel plays a central role in steam generation and safety.

The pressure vessel in a steam boiler serves as the sealed chamber where water is heated and steam is generated under pressure; it is designed to safely contain high-temperature and high-pressure fluids, providing the necessary environment for efficient phase transformation from water to steam.

It is the structural heart of the boiler, designed to strict engineering codes to ensure safety, efficiency, and long-term durability.

The pressure vessel holds water and steam at high pressure for safe energy transfer in a boiler.True

Its purpose is to contain the phase change from water to steam under controlled pressure and temperature.

The pressure vessel is not important to steam boiler operation.False

The pressure vessel is a critical component that defines the function and safety of any steam boiler system.

Components and Functions of a Steam Boiler Pressure Vessel

| Part | Function |

|---|---|

| Shell or Drum | Primary container for water and steam |

| Water Space | Lower part where water absorbs heat |

| Steam Space | Upper section where steam accumulates |

| Tubes (fire-tube or water-tube) | Facilitate heat transfer from combustion gases |

| End Plates / Heads | Seal the vessel ends; must resist internal pressure |

| Nozzles and Openings | Entry/exit points for steam, feedwater, and safety devices |

| Safety Valves | Release excess pressure to prevent rupture |

| Manholes / Inspection Ports | Allow maintenance access without compromising vessel integrity |

In fire-tube boilers, the pressure vessel contains the tubes through which hot gases pass.

In water-tube boilers, the pressure vessel contains steam drums and headers, while water circulates in external tubes.

Thermodynamic Role of the Pressure Vessel

Maintains pressure typically ranging from 7 to 200 bar, depending on the boiler type.

Supports the phase change: Liquid water absorbs heat → becomes saturated steam → optionally superheated.

Stores and stabilizes pressure fluctuations during load variations.

Allows latent heat accumulation to sustain steam delivery under dynamic load.

Typical Operating Parameters by Boiler Type

| Boiler Type | Pressure Vessel Pressure Range | Steam Temperature | Function in Vessel |

|---|---|---|---|

| Fire-Tube Boiler | 7–20 bar | 170–220°C | Hot gases pass through tubes in shell |

| Water-Tube (Subcritical) | 30–170 bar | 300–540°C | Water in tubes, steam in drum |

| Supercritical Boiler | >221 bar | >540°C | No steam drum; entire system acts as pressure vessel |

Design Codes: Pressure vessels in boilers are regulated by standards such as ASME Section I, EN 12952, and PED 2014/68/EU, ensuring safe design and fabrication.

Cross-Sectional Diagram: Pressure Vessel Components

| Label | Description |

|---|---|

| A – Shell | Outer steel body rated for pressure |

| B – Water Line | Normal level during operation |

| C – Steam Space | Area above water line where steam collects |

| D – Tube Bundle | Internal tubes (fire-tube or water-tube) for heat transfer |

| E – Safety Valve Mount | Pressure relief to avoid explosion |

| F – Manhole | Access for internal inspection and cleaning |

Pressure Vessel Safety Design Features

| Feature | Purpose |

|---|---|

| Material Thickness | Designed based on internal pressure formula (ASME/EN) |

| Stress Relieving | Heat-treated to remove welding-induced stress |

| Hydrostatic Testing | Pressure tested 1.5× design pressure before commissioning |

| Radiographic/X-ray Inspection | Checks for weld defects in shell and heads |

| Corrosion Allowance | Extra thickness or coatings for long-term durability |

Case Study: Power Plant Boiler Drum Failure Analysis

Problem: A thermal power plant experienced fluctuating steam pressure and eventual tube rupture.

Findings:

Internal scale build-up in the pressure vessel disrupted heat transfer.

Safety valve set point drifted above design pressure.

Operating pressure exceeded material limit intermittently.

Solution:

Immediate descaling and chemical cleaning.

Recalibration of safety valve and drum pressure sensors.

Upgrade to ASME Section I-compliant reinforced shell.

Result: Restored safe operations and 4% improvement in thermal output.

Pressure Vessel Monitoring for Efficiency and Safety

| Monitoring Tool | Parameter Tracked | Purpose |

|---|---|---|

| Pressure Transmitter | Steam drum internal pressure | Ensures operation within limits |

| Level Transmitter | Water level in vessel | Avoids low/high water risks |

| Temperature Sensor | Steam temperature | Indicates superheating or overloading |

| Ultrasonic Thickness Gauge | Shell wall thickness (offline) | Detects corrosion or wear |

| Acoustic Emission Detector | Crack or stress signature | Early warning of structural failure |

Summary: Why the Pressure Vessel Is Indispensable

| Benefit | Explanation |

|---|---|

| Steam Generation | Converts water to steam under controlled pressure |

| Pressure Stabilization | Ensures safe and consistent energy output |

| Structural Integrity | Contains high-pressure water/steam mixture |

| Heat Transfer Facilitation | Supports energy absorption from combustion |

| Compliance and Inspection | Meets mandatory regulatory safety codes |

Conclusion

The pressure vessel is the backbone of every steam boiler. It is the chamber where thermal energy becomes mechanical power in the form of pressurized steam. From withstanding extreme internal forces to supporting efficient heat transfer and safe energy storage, the pressure vessel’s design, monitoring, and maintenance are critical for operational success. Whether you’re running a small industrial boiler or a 1,000 MW power plant, the vessel’s performance directly affects boiler efficiency, safety, and longevity.

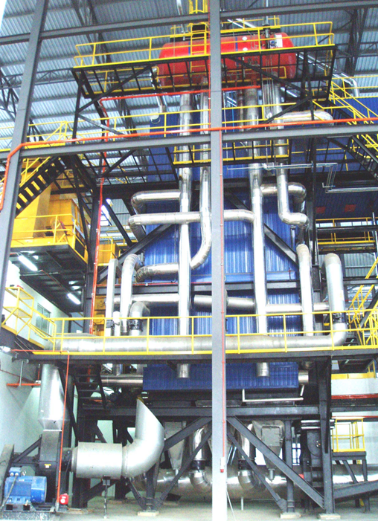

How Does the Burner and Furnace Generate Heat from Various Fuel Sources?

The burner and furnace are the heart of the boiler system, where chemical energy stored in fuels—such as natural gas, coal, oil, or biomass—is converted into thermal energy through controlled combustion. This intense heat is then transferred to water via radiation and convection, forming high-pressure steam for power generation or industrial processes. The design and behavior of the burner and furnace vary greatly depending on the fuel type, combustion method, flame control, and emissions strategy. Choosing the right combination ensures high combustion efficiency, stable operation, and regulatory compliance.

The burner delivers and mixes fuel with combustion air, while the furnace provides the high-temperature environment where ignition and complete combustion occur; together, they generate heat by oxidizing the fuel, converting chemical energy into thermal energy used to produce steam.

Each fuel type—gas, oil, coal, or biomass—requires a specialized burner-furnace system to ensure optimal combustion, low emissions, and safe thermal delivery.

Burners and furnaces convert the chemical energy of fuels into heat through controlled combustion.True

The burner mixes fuel and air for ignition, and the furnace holds the flame and allows heat transfer.

All fuels can use the same burner and furnace without adjustment.False

Different fuels require customized burners and furnace designs due to varying combustion characteristics and physical forms.

1. Burner Function: Fuel Injection + Air Mixing + Ignition

| Burner Role | Function |

|---|---|

| Fuel Atomization / Injection | Introduces gas, oil, or pulverized solid into furnace |

| Primary Air Mixing | Delivers oxygen for combustion |

| Ignition Initiation | Starts combustion via spark, pilot, or hot surface |

| Flame Shaping & Control | Controls flame size, shape, stability |

| Safety Shutdown Capability | Shuts down during flame loss or excess pressure |

Burners are classified based on the fuel type:

Gas Burners: Use pressure-jet or premix design

Oil Burners: Use atomizing nozzles or steam-assisted injection

Coal Burners: Use pulverized coal + air injection

Biomass Burners: Use stoker, fluidized bed, or rotary grate systems

2. Furnace Function: Heat Holding + Radiation + Convection

| Furnace Role | Function |

|---|---|

| Combustion Chamber | Contains flame and radiant heat zone |

| Refractory / Insulation | Prevents heat loss and supports high-temperature zones |

| Gas Flow Management | Directs flue gas to tubes or superheater |

| Residence Time Control | Ensures complete combustion of volatile matter |

| Ash and Slag Management | Collects unburned solids (for solid fuels) |

The shape, volume, and material of the furnace are tuned based on the fuel used. High-ash fuels like coal and biomass require slag-resistant materials and large volumes for burnout.

3. Combustion Mechanisms by Fuel Type

| Fuel Type | Combustion Process in Burner/Furnace | Flame Characteristics |

|---|---|---|

| Natural Gas | Mixed with air → ignited in premix or diffusion flame → fast, clean combustion | Short, blue or orange flame |

| Fuel Oil | Atomized into fine mist → mixed with heated air → burns in suspended droplet form | Yellow luminous flame |

| Pulverized Coal | Fine coal blown with air → ignited by pilot → burns in suspension in radiant zone | Long, luminous flame with sparks |

| Biomass (Chips, RDF) | Solid fuel spread over grate or fluidized with air → burns as char or gasifies | Volatile, unstable flame (orange) |

4. Typical Furnace Temperature and Combustion Efficiency

| Fuel | Furnace Temp (°C) | Combustion Efficiency (%) | Special Considerations |

|---|---|---|---|

| Natural Gas | 1,000–1,400°C | 98–99% | Minimal ash or residue |

| Fuel Oil | 1,100–1,500°C | 96–98% | Requires preheating and atomization |

| Pulverized Coal | 1,300–1,700°C | 94–97% | Needs fine grind (60–70% <75 μm) |

| Biomass (wet) | 800–1,200°C | 85–92% | Moisture affects ignition & flame quality |

Higher temperatures in the furnace zone lead to better heat transfer but increase NOₓ emissions unless controlled.

5. Burner Configurations for Different Applications

| Application | Burner Type Used | Design Feature |

|---|---|---|

| Power Plant (Gas) | Low-NOₓ gas burners | Premixed flame with staged air |

| Coal-Fired Boiler | Tangential or swirl burners | Creates vortex for complete combustion |

| Industrial Oil Boiler | Pressure jet burner | Atomizes fuel at nozzle under high pressure |

| Biomass Steam Plant | Moving grate or bubbling bed burner | Handles variable size and moisture of solid fuel |

6. Emission Control at Burner/Furnace Level

| Emission | Control at Combustion Zone |

|---|---|

| NOₓ | Low-NOₓ burner, flue gas recirculation |

| SO₂ | Fuel selection (e.g., low sulfur coal/oil) |

| CO | Proper air-fuel mixing, staged combustion |

| PM (Dust) | Furnace temperature, fuel preparation |

Combustion efficiency and NOx emissions are heavily influenced by burner design.True

Burner air-fuel mixing, flame temperature, and staging determine the rate of complete combustion and formation of nitrogen oxides.

7. Burner-Furnace Matching Diagram by Fuel

| Fuel Type | Burner Type | Furnace Design | Automation Level |

|---|---|---|---|

| Natural Gas | Premix / Pressure Jet | Small, compact radiant zone | High (instant response) |

| Fuel Oil | Atomizing burner | Larger for droplet burnout | Medium to high |

| Pulverized Coal | Swirl / Tangential jet | Large radiant + convection | Medium (requires tuning) |

| Biomass (solid) | Grate / Fluidized bed burner | Voluminous, high residence | Medium (moisture responsive) |

8. Real-World Case: Burner Retrofit for Efficiency

Industry: Textile mill

Old Burner: Pressure-jet oil burner, 88% efficiency

New Burner: Dual-fuel gas + oil low-NOₓ burner

Upgrade Result:

Efficiency increased to 92.5%

NOₓ reduced by 60%

Fuel savings of $36,000/year

Conclusion

The burner and furnace work in tandem to perform one of the most critical processes in a boiler: heat generation through fuel combustion. While the burner precisely injects and mixes fuel and air, the furnace retains the high-temperature flame and directs the resulting thermal energy to the water walls or tubes. Each fuel type—whether gaseous, liquid, or solid—requires tailored burner geometry, airflow design, and furnace volume to ensure efficient and clean combustion. Optimizing these systems for your fuel and process needs can dramatically improve thermal efficiency, fuel economy, and emissions compliance.

What Are Heat Exchanger Tubes, and How Do They Facilitate Energy Transfer?

In any thermal process—whether in a power boiler, chemical reactor, or HVAC unit—heat exchangers play a central role by allowing energy to move from one fluid to another without mixing them. At the heart of most heat exchangers are tubes, which separate and guide the fluids while maximizing the surface area for energy transfer. These heat exchanger tubes must withstand high temperatures, pressures, and corrosion while delivering efficient, safe, and long-lasting performance. In industrial boilers, they are critical for turning combustion energy into usable steam or hot water.

Heat exchanger tubes are cylindrical components used in boiler and process equipment to separate and transfer thermal energy between two fluids—typically hot gases and water or steam—by providing a large surface area across which heat can flow efficiently via conduction, convection, and sometimes radiation.

Their design, material, and arrangement determine the heat exchanger’s capacity, efficiency, and durability in high-temperature environments.

Heat exchanger tubes are responsible for transferring heat between two separate fluids in a boiler.True

They act as the thermal conduit, allowing energy to pass from hot combustion gases to water or steam without mixing the fluids.

Heat exchanger tubes mix water and flue gas to exchange heat.False

The tubes separate the fluids and transfer heat through solid surfaces, not by mixing.

1. Where Are Heat Exchanger Tubes Used?

| Application | Type of Heat Exchanger | Tubes Carry | Heat Source |

|---|---|---|---|

| Fire-Tube Boiler | Fire-tube | Hot gases | Combustion flame |

| Water-Tube Boiler | Water-tube | Water/steam | Gases outside tubes |

| Economizer | Tubular bundle | Feedwater | Flue gas |

| Superheater/Reheater | U-tube or straight tube | Steam | High-temp flue gas |

| Shell and Tube HX | Tube bundle inside shell | Process fluid | Utility steam/hot oil |

| Air Preheater (Tubular) | Tube bundles (sometimes) | Air | Hot flue gas |

2. How Heat Exchanger Tubes Transfer Heat

The thermal energy transfer occurs in three stages:

Convection (Fluid → Tube Wall):

Hot fluid (e.g., flue gas or steam) transfers energy to the inside/outside wall of the tube.

Conduction (Through Tube Wall):

Heat flows through the metal wall of the tube by conduction.

Convection (Tube Wall → Cooler Fluid):

Cooler fluid on the opposite side absorbs the energy from the tube wall.

| Energy Transfer Mode | Mechanism | Equation (Simplified) |

|---|---|---|

| Conduction | Through tube wall | q = k × A × (T₁–T₂)/d |

| Convection | Fluid-tube interface | q = h × A × ΔT |

| Overall Transfer | Combined rate | q = U × A × ΔTₘ |

Where:

q= heat transfer rate (W)k= thermal conductivity (W/m·K)A= surface area of tubes (m²)h= convective heat transfer coefficient (W/m²·K)U= overall heat transfer coefficientΔTₘ= log mean temperature difference

3. Tube Types and Arrangements

| Tube Arrangement | Typical Use | Characteristics |

|---|---|---|

| Straight Tubes | Water-tube boilers, superheaters | Simple to fabricate and clean |

| U-Tubes | Economizers, process HX | Compact, handles expansion stress |

| Helical / Spiral Tubes | Waste heat recovery units | Increases surface area in limited space |

| Fin Tubes | Air preheaters, economizers | Enhanced surface area for gas side |

| Bundled Arrays | Shell & tube HX | Higher heat exchange density |

Most high-efficiency boilers use staggered tube arrays to promote turbulence on the gas/fluid side and increase heat transfer rates.

4. Materials Used for Heat Exchanger Tubes

| Material | Common Use | Why It’s Chosen |

|---|---|---|

| Carbon Steel | General-purpose boilers | Affordable, good strength, moderate corrosion resistance |

| Alloy Steel (e.g., SA213 T11, T22) | Power boilers, superheaters | High temperature/pressure resistance |

| Stainless Steel (304, 316) | Food, pharma, marine HX | Excellent corrosion resistance |

| Inconel / Hastelloy | High-temp waste heat recovery | Exceptional oxidation and acid resistance |

| Copper/Brass | HVAC and small heat exchangers | High thermal conductivity, corrosion resistance |

Alloy steels like SA213 T22 are commonly used in boiler heat exchanger tubes for high-temperature resistance.True

These materials withstand creep and oxidation under prolonged high-temperature operation.

5. Key Design Parameters of Heat Exchanger Tubes

| Parameter | Typical Range | Effect on Performance |

|---|---|---|

| Outer Diameter (OD) | 12.7–76.2 mm (0.5–3 inches) | Affects surface area and fluid velocity |

| Wall Thickness (Gauge/Sch) | 16–10 gauge or Sch 20–Sch 80 | Impacts pressure capacity and conduction resistance |

| Length | 1–12 meters (can vary) | Determines heat surface availability |

| Surface Finish | Smooth, ribbed, or finned | Affects fluid turbulence and fouling resistance |

| Pitch (Tube Spacing) | 1.25–1.5 × OD | Influences flow distribution and cleaning access |

6. Heat Transfer Efficiency Enhancement Techniques

| Technique | Purpose |

|---|---|

| Finned Tubes | Increase surface area on gas side |

| Tube Turbulators | Create turbulence to disrupt laminar flow |

| Water Treatment | Prevent internal scaling and fouling |

| Regular Soot Blowing | Maintain clean external tube surfaces |

| Baffle Design Optimization | Guides flow for better tube contact |

7. Heat Exchanger Tube Failure Modes (and Solutions)

| Failure Mode | Cause | Prevention |

|---|---|---|

| Erosion/Corrosion | High-velocity water + dissolved O₂ | Deaeration, better material, inhibitors |

| Scaling/Fouling | Hard water or ash deposition | Water softening, sootblowing |

| Stress Corrosion Cracking | Temperature + chloride or acid | Alloy selection, pH control |

| Creep Failure | Long-term high temp operation | Use of Cr-Mo alloys like SA213 T91 |

| Pitting/Localized Corrosion | Poor water quality | Better chemical dosing, passivation |

Real-World Example: Water-Tube Boiler Upgrade

Application: Chemical Plant Steam Boiler

Previous Tubes: Carbon steel SA192 (max 400°C)

Problem: Tube scaling, low efficiency, early creep

Upgrade: Replaced with SA213 T22 alloy steel tubes

Result:

Increased boiler outlet temp from 410°C to 520°C

Extended tube life by 2×

Reduced fuel use by 6% (due to better heat transfer)

Conclusion

Heat exchanger tubes are vital components in the thermal systems of boilers, condensers, economizers, and process heat exchangers. They enable the efficient transfer of heat between two fluids by maximizing surface area while preventing direct contact between them. Their material, geometry, and arrangement dictate the efficiency, durability, and pressure-handling capacity of the overall system. Understanding their function and optimizing their design is key to improving boiler efficiency, reliability, and lifecycle cost.

What Roles Do the Steam Drum, Headers, and Water Circulation Systems Play?

In a water-tube steam boiler, particularly in power generation and high-pressure industrial boilers, three critical components—steam drum, headers, and the water circulation system—work together to manage the flow, phase separation, and pressure integrity of the boiler’s internal fluid cycle. These elements form the backbone of boiler operation, directly influencing steam quality, heat transfer efficiency, and the safety of high-pressure systems. Without proper design and coordination among these elements, the boiler cannot maintain stable and efficient operation.

The steam drum separates steam from water, the headers distribute water and collect steam among the tubes, and the water circulation system ensures continuous fluid movement through the heated and unheated zones, maintaining proper heat transfer, steam production, and pressure balance in the boiler.

This synergy ensures stable steam output, effective phase separation, and safe operation across a wide range of loads and temperatures.

Steam drums separate steam and water in water-tube boilers, enabling high-quality dry steam output.True

Steam drums collect steam from riser tubes and use gravity, baffles, and cyclones to separate it from water.

Headers are not necessary in large boiler systems.False

Headers are essential for distributing water and steam between tubes and controlling flow balance.

1. Steam Drum: The Core Steam-Water Separator

Primary Functions:

Phase Separation: Separates saturated steam from the water-steam mixture.

Steam Storage: Maintains a reserve of steam to meet load fluctuations.

Water Level Management: Ensures enough water volume to feed evaporation tubes.

Chemical Dosing: Injects chemicals to control scale, corrosion, and carryover.

Blowdown Point: Removes sludge and impurities from the system.

Key Features:

| Component | Purpose |

|---|---|

| Cyclone Separators | Mechanical separation of water droplets |

| Scrubber Baffles | Reduce moisture carryover into steam line |

| Feedwater Nozzle | Even distribution of feedwater |

| Water Level Indicators | For manual and automatic control |

| Safety Valves | Protect drum from overpressure |

A typical subcritical boiler steam drum operates at 60–170 bar pressure and stores steam at temperatures between 300–540°C.

2. Headers: Distribution and Collection Junctions

What Are Headers?

Headers are large, pressurized manifolds that collect or distribute water or steam between the steam drum and the network of water tubes. They are strategically located at various boiler zones, including furnace walls, superheaters, and economizers.

Types of Headers:

| Header Type | Function | Location |

|---|---|---|

| Water Distribution Header | Sends water from downcomers to risers | Bottom of furnace wall |

| Steam Collection Header | Collects steam from risers | Top of furnace wall or roof |

| Intermediate Headers | Balance flow in multi-pass units | Between tube banks |

| Superheater Headers | Handle high-temperature steam | Superheater outlet section |

Headers are designed for equal flow distribution, structural support, and pressure integrity at temperatures up to 600°C or more in high-efficiency boilers.

3. Water Circulation System: Driving Thermal Flow

The water circulation system in boilers can be natural, assisted, or forced depending on pressure, temperature, and load requirements.

| Circulation Type | Driving Force | Used In |

|---|---|---|

| Natural Circulation | Density difference between hot risers and cool downcomers | Subcritical boilers (<180 bar) |

| Forced Circulation | External pumps drive flow | High-pressure or compact units |

| Once-Through Flow | No recirculation (fluid exits once) | Supercritical boilers (>221 bar) |

Circulation Loop in Natural Boilers:

Downcomers carry cool, dense water from steam drum to waterwall headers.

Waterwall Tubes absorb radiant heat from the furnace and heat the water.

Risers carry hot water/steam mixture back up to the steam drum.

Steam Drum separates and delivers dry steam to superheater or process line.

This loop ensures uniform heating, avoids hot spots, and maintains stable boiling conditions.

Water Circulation System Diagram (Natural Circulation):

[Steam Drum]

↑ ↓

[Risers] [Downcomers]

↑ ↓

[Waterwall Headers]

↓ ↑

[Furnace Tube Panels]

4. Integration of Steam Drum, Headers, and Circulation

| Component | Connected To | Key Role |

|---|---|---|

| Steam Drum | Risers, downcomers, SH inlet | Separates steam, stores water |

| Riser Tubes | Waterwall headers → Steam drum | Deliver hot water-steam mix to drum |

| Downcomer Tubes | Steam drum → bottom headers | Feed cool water to furnace wall tubes |

| Waterwall Headers | Downcomers ↔ Furnace tubes | Supply and collect fluid for waterwall heating |

| Superheater Headers | Steam drum outlet → process | Deliver dry, high-temp steam downstream |

5. Material and Design Considerations

| Component | Material | Design Pressure Range | Thermal Stress Considerations |

|---|---|---|---|

| Steam Drum | Alloy steel (SA516, SA302) | 60–250 bar | Thermal expansion, pressure retention |

| Headers | Cr-Mo Alloy (T11, T22, T91) | Up to 300 bar | Must tolerate cyclic stresses |

| Downcomers/Risers | Seamless alloy steel | Based on load configuration | Must prevent flow reversal or stagnation |

Downcomers feed cool water to furnace tubes while risers return steam-water mixtures to the steam drum.True

This circulation creates a natural loop that facilitates continuous heat absorption and phase change.

6. Monitoring and Control of Circulation System

| Parameter | Sensor/Device | Purpose |

|---|---|---|

| Drum Level | Differential pressure probe | Maintain water-steam interface |

| Drum Pressure | Pressure transmitter | Monitor operating pressure |

| Steam Purity | Silica/Na analyzers | Prevent turbine damage from contaminants |

| Flow in Downcomers | Ultrasonic/magnetic flowmeter | Detect blockage or stagnation |

| Tube Temperature | Thermocouples | Prevent overheating and creep damage |

7. Real-World Performance Case: Power Plant Retrofit

Situation: A 300 MW subcritical coal-fired boiler was experiencing drum pressure fluctuations and steam wetness.

Issues Identified:

Uneven riser flow due to header imbalance

Improper drum water level control

Excess carryover of moisture to superheater

Solutions Implemented:

Rebalanced steam headers and added internal baffles

Installed modern level control system

Upgraded separators in the drum

Result:

Steam purity improved from 96% to 99.7%

Efficiency gain of 2.8%

Avoided turbine blade fouling

Conclusion

The steam drum, headers, and circulation system form the circulatory and respiratory system of a water-tube boiler. The steam drum acts as the separation and storage center; the headers serve as fluid junctions; and the circulation system maintains steady phase change and uniform heat absorption. A well-designed and balanced system ensures stable steam production, high purity, and prolonged tube and component life. In high-pressure power boilers and process units alike, their function is both structural and thermodynamic.

How Do Control Systems and Safety Valves Protect Boiler Operation?

In high-pressure steam boilers, safe and stable operation hinges not only on good mechanical design but also on robust control systems and safety devices. From sudden load surges to fuel feed errors or water level loss, boilers face a range of hazards. If not managed instantly, these issues can lead to thermal failure, pressure vessel rupture, or explosion. That’s why every modern boiler is equipped with intelligent automation systems, instrumentation, and mechanical safety valves designed to anticipate, detect, and correct dangerous situations before they escalate.

Control systems regulate fuel, air, water, and steam parameters in real time to maintain safe operating conditions, while safety valves act as mechanical fail-safes that automatically release excess pressure to prevent overpressure and explosion.

Together, these systems form the foundation of boiler safety, ensuring reliable steam generation under all conditions.

Control systems and safety valves are essential for safe boiler operation.True

Control systems manage boiler inputs automatically, while safety valves provide emergency pressure relief if system limits are exceeded.

Boilers can operate safely without control systems or pressure relief devices.False

Without these protections, the risk of overheating, pressure surges, and catastrophic failure increases dramatically.

1. Boiler Control System: The Brain of Safe Operation

Modern boilers are governed by PLC- or DCS-based control systems that automate essential operating parameters. These systems use sensors, actuators, and logic programs to constantly monitor and adjust the boiler’s behavior.

Key Functions:

| Function | Monitored/Controlled Parameter | Purpose |

|---|---|---|

| Combustion Control | Fuel and air flow | Maintain efficient and safe flame |

| Water Level Control | Drum or shell water level | Prevent low/high water incidents |

| Pressure Control | Steam pressure | Match load demand without overshooting |

| Feedwater Control | Flow rate and inlet pressure | Ensure continuous water supply |

| Oxygen Trim | Flue gas O₂ levels | Optimize combustion and prevent CO formation |

| Alarm and Interlock | All critical parameters | Initiate shutdown if limits are breached |

Typical Control System Components:

| Device | Function |

|---|---|

| PLC/DCS Controller | Executes logic, receives sensor data |

| HMI (Human-Machine Interface) | Operator interaction and alerts |

| Actuators (valves, dampers) | Adjust fuel, water, and air flows |

| Sensors (temperature, pressure, flow) | Provide real-time data |

| Alarm Modules | Notify operators of abnormal events |

2. Safety Valves: Mechanical Guardians of Pressure Limits

Safety valves (or relief valves) are spring-loaded devices mounted on steam drums, headers, or superheaters. They are not dependent on control systems and operate purely on pressure physics to vent steam when set limits are exceeded.

Steam Safety Valve Operation:

When system pressure exceeds the valve’s set pressure, the internal spring is compressed.

The valve pops open, releasing steam rapidly to reduce pressure.

Once the pressure falls below the reseating point, the valve closes.

Key Parameters:

| Parameter | Typical Range | Description |

|---|---|---|

| Set Pressure | 10–200 bar | Valve opens at this pressure |

| Blowdown Pressure | 2–4% below set point | Valve reseats at this pressure |

| Capacity | Sized in kg/hr or TPH | Must handle worst-case steam generation rate |

| Certification | ASME, EN, PED, IBR | Verified by 3rd-party testing and stamping |

3. Combined Protection System: How They Work Together

| Scenario | Control System Action | Safety Valve Role |

|---|---|---|

| Sudden Steam Demand Drop | Reduce fuel/air input to maintain pressure | Vent if pressure spike occurs |

| Water Level Too Low | Trigger alarm, stop burner, initiate feedwater | Prevent dry firing |

| Fuel Supply Surge | Throttle fuel flow, adjust air/fuel ratio | Backup venting if overpressure results |

| Sensor Failure | Interlock shuts down system safely | Final protection if system logic fails |

In many high-integrity boiler setups, redundant safety valves, emergency shutdown solenoids, and multiple control loops are used to comply with SIL (Safety Integrity Level) standards.

4. Real-Time Monitoring Parameters

| Control Variable | Typical Sensor Type | Boiler Location |

|---|---|---|

| Steam Pressure | Pressure transmitter | Steam drum or outlet header |

| Water Level | DP transmitter or conductivity probe | Steam drum |

| Fuel Flow | Mass flow meter or orifice plate | Fuel inlet line |

| Air Flow | Vortex/thermal flow meter | Combustion air duct |

| Flue Gas Oxygen | Zirconia O₂ analyzer | Stack or flue gas exit |

Safety valves operate independently of the boiler’s electrical control system.True

They are mechanical devices designed to function even in the event of a power failure or system crash.

5. Control & Safety Interlock Examples

| Interlock Condition | System Response |

|---|---|

| Low water level alarm | Shut off fuel valve, stop burner |

| High steam pressure | Close damper, modulate fuel, or trip burner |

| Flame failure (burner) | Shutdown fuel valves, activate purge cycle |

| Feedwater pump failure | Alarm, engage standby pump or stop firing |

| High flue gas temperature | Warn of tube fouling or incomplete combustion |

6. Regular Testing and Calibration

| Device | Recommended Frequency | Why It Matters |

|---|---|---|

| Safety Valves | Every 12–24 months (code required) | Ensures set pressure and reseating reliability |

| Pressure Transmitters | Quarterly or semi-annually | Avoids false readings or missed trips |

| Water Level Probes | Monthly | Prevent false alarms or dry firing |

| PLC System Logic | Annually or after updates | Confirm response sequences and shutdowns |

| Alarm Systems | Monthly | Verify audible/visible alerts work properly |

7. Case Study: Control Failure vs. Safety Valve Action

Scenario: Power boiler at 120 bar suffered PLC logic error; control system failed to reduce firing rate during a drop in load.

System Response:

Steam pressure surged from 118 bar to 129 bar in 3 seconds.

Control system failed to respond due to software bug.

Primary and secondary safety valves activated at 130 bar.Outcome:

Safety valves released steam for 7 seconds, reducing pressure to 117 bar.

No equipment damage. Control system later patched.

Lesson: Mechanical safety valves provide fail-safe backup to digital control systems in any scenario.

Conclusion

A steam boiler’s safety and reliability depend on intelligent control systems working in tandem with mechanical safety devices. Controls ensure stable and optimized operation under normal conditions by managing fuel, air, water, and steam. Safety valves stand as the final line of defense, protecting the system from overpressure even if sensors or software fail. Together, they form a comprehensive protection architecture that keeps boiler operations safe, efficient, and compliant with global standards.

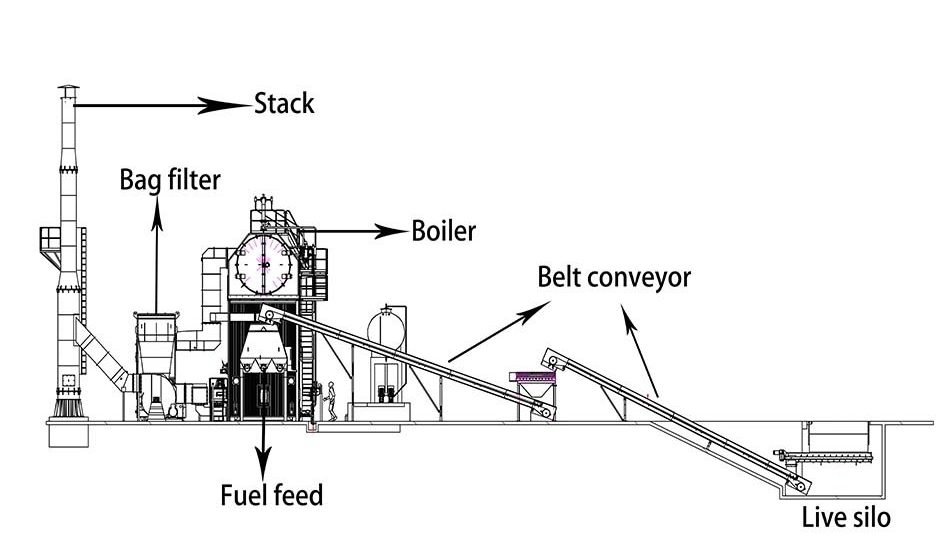

What Auxiliary Systems Manage Feedwater, Blowdown, and Flue Gas Emissions?

In a high-performance boiler system, the core functions—steam generation and heat transfer—rely heavily on several auxiliary systems to maintain water purity, pressure stability, and emission compliance. These support systems manage critical operations such as feedwater delivery and conditioning, boiler blowdown, and flue gas treatment. Without them, boilers would suffer from corrosion, scaling, thermal inefficiency, or environmental violations. Whether in a power plant or a process facility, these auxiliary units are essential for safe, clean, and continuous boiler operation.

Feedwater systems regulate and purify water entering the boiler, blowdown systems remove concentrated impurities to protect internal components, and flue gas emission systems control pollutants like NOₓ, SO₂, and particulates before releasing combustion gases to the atmosphere.

Together, these systems enable long-term reliability, operational safety, and environmental compliance of steam boiler installations.

Auxiliary systems like feedwater conditioning and blowdown are essential to protect boiler tubes from scale and corrosion.True

These systems manage water purity and remove dissolved solids and gases that can damage the boiler.

Flue gas emissions can be released without treatment in modern boiler systems.False

Environmental laws require boilers to include filtration and chemical systems to reduce air pollution before flue gas discharge.

1. Feedwater System: Supplying Clean, Pressurized Water

Objectives:

Deliver high-purity water at the required pressure and temperature

Remove dissolved oxygen, CO₂, and hardness-causing minerals

Maintain continuous and stable water level in the steam drum

Components:

| Feedwater Equipment | Function |

|---|---|

| Deaerator | Removes oxygen and CO₂ using steam stripping |

| Feedwater Pump (BFP) | Pressurizes water (30–250 bar, depending on boiler) |

| Low-Pressure Heater (LPH) | Recovers heat from steam condensate return |

| High-Pressure Heater (HPH) | Heats feedwater using extraction steam |

| Control Valve | Regulates flow based on drum level sensors |

| Make-up Water Treatment | Softens or demineralizes raw water |

High-pressure boilers typically use multistage centrifugal pumps and thermally conditioned feedwater to avoid shocking boiler tubes.

2. Blowdown System: Managing Solids and Concentration

Purpose:

Prevent buildup of dissolved solids, sludge, and corrosion products in the boiler

Maintain appropriate Total Dissolved Solids (TDS) to avoid foaming, scaling, and carryover

Types of Blowdown:

| Blowdown Type | Method | When It Occurs |

|---|---|---|

| Continuous Blowdown | Small, constant flow from drum | Maintains TDS balance during operation |

| Intermittent Blowdown | Manual or automatic valve opening | Performed periodically to remove sludge |

Blowdown Equipment:

| Component | Function |

|---|---|

| Blowdown Valve | Controls discharge of water and solids |

| Blowdown Tank / Separator | Reduces pressure and temperature of blowdown |

| Flash Tank | Recovers flash steam for reuse |

| Cooling Water Injection | Cools discharge before sewer or treatment entry |

Regulatory codes like ASME and EN require controlled blowdown temperature (typically <60°C at discharge) to protect plumbing and the environment.

3. Flue Gas Emissions System: Pollution Control & Heat Recovery

Purpose:

Remove air pollutants before stack release

Recover waste heat to improve system efficiency

Meet emission regulations (e.g., NOₓ, SO₂, CO, PM, Hg)

Major Equipment:

| Component | Function |

|---|---|

| Economizer | Recovers heat from flue gas to preheat feedwater |

| Air Preheater (APH) | Heats combustion air using flue gas |

| Cyclone Separator | Removes coarse particulates from flue gas |

| Baghouse / Fabric Filter | Captures fine particles (PM2.5, ash) |

| Electrostatic Precipitator (ESP) | Electrically charges and collects dust |

| SCR (Selective Catalytic Reduction) | Reduces NOₓ using ammonia or urea |

| FGD (Flue Gas Desulfurization) | Removes SO₂ via limestone slurry or seawater |

| ID Fan | Maintains negative draft in furnace |

| Stack / Chimney | Releases treated flue gas to atmosphere |

Emission Standards for Large Boilers:

| Pollutant | Typical Limit (mg/Nm³) | Control Method |

|---|---|---|

| NOₓ | 100–200 | Low-NOₓ burner, SCR |

| SO₂ | 200–400 | FGD scrubber (wet/dry) |

| Particulates | <50 | Baghouse, ESP |

| CO | <100 | Combustion tuning |

SCR systems reduce NOₓ emissions in boilers by injecting ammonia or urea into flue gas.True

The injected reagent reacts with NOₓ over a catalyst bed to convert it into nitrogen and water.

4. Integration Flow Chart: Auxiliary Systems in Boiler Cycle

[Make-up Water] → [Water Softener] → [Deaerator] → [Feed Pump] → [Boiler Drum]

↓ ↓

[Blowdown] ← [TDS Control] [Steam Generation]

↓ ↓

[Blowdown Separator] [Flue Gas Flow]

↓ ↓

[Condensate Cooling] → [Economizer → ESP → Stack]

→ [SCR / FGD if needed]

5. Monitoring and Automation

| System | Key Sensors / Instruments | Control Logic |

|---|---|---|

| Feedwater | Flow meter, pressure sensor, conductivity | Regulates drum level and oxygen removal |

| Blowdown | TDS analyzer, temperature probe | Opens valves based on concentration setpoints |

| Emission | NOₓ analyzer, opacity monitor, SO₂ sensor | Adjusts reagent flow and triggers alarms |

Many auxiliary systems are integrated into the main boiler DCS or PLC system for real-time coordination and alarms.

6. Real Case Example: Power Plant Auxiliary System Optimization

Problem: A 500 MW coal-fired plant experienced high TDS in the boiler, wet steam carryover, and NOₓ emission non-compliance.

Solution:

Upgraded to automated continuous blowdown with conductivity sensors

Installed new economizer and dual-stage SCR system

Integrated feedwater oxygen sensor into deaerator loop

Results:

Reduced blowdown rate by 40%, saving water and heat

Steam quality increased to 99.6% dryness

NOₓ reduced from 350 to 160 mg/Nm³ (within regulatory limits)

Conclusion

The feedwater system, blowdown system, and flue gas emission controls are vital auxiliary subsystems that protect a boiler’s core functions from chemical damage, thermal loss, and environmental penalties. They are as essential as the boiler itself. Ensuring these systems are properly sized, monitored, and maintained is key to achieving long-term boiler efficiency, steam quality, and compliance with global emission standards.

🔍 Conclusion

An industrial steam boiler is a precision-engineered system made up of several key components that together ensure safe, reliable, and efficient steam production. Understanding what’s inside helps operators maintain performance, improve efficiency, and plan maintenance for long-term operational success.

📞 Contact Us

💡 Need a complete steam boiler system or component consultation? We offer technical audits, system design, spare parts sourcing, and lifecycle support for industrial steam boiler operations.

🔹 Let us help you build and manage a steam boiler system that delivers safe, reliable output. ♨️💨📊✅

FAQ

What are the main components of an industrial steam boiler?

An industrial steam boiler consists of several critical parts that work together to generate steam:

Burner – Mixes fuel and air to ignite combustion

Combustion chamber – Area where fuel burns to produce heat

Boiler drum – Collects and separates steam and water

Heat exchanger or tubes – Transfers heat from combustion gases to water

Economizer – Recovers residual heat from exhaust gases

Feedwater system – Supplies treated water to the boiler

Steam outlet – Directs steam to the system or process

Controls and sensors – Monitor temperature, pressure, and safety

Each part plays a vital role in steam generation and system efficiency.

What is the function of the boiler drum?

The boiler drum acts as a separator, collecting both steam and water. It ensures that:

Steam rises to the top and exits to the distribution system

Water returns to the tubes for reheating

Pressure remains stable during operation

It’s essential for phase separation, pressure regulation, and maintaining safe operations.

What type of burner is used in industrial steam boilers?

Common types include:

Gas burners – High-efficiency, low-emission, used with natural gas

Oil burners – Often used in dual-fuel systems

Combination burners – Allow switching between fuels based on availability and cost

Low-NOx burners – Designed to reduce nitrogen oxide emissions

Burner selection impacts fuel efficiency, emission control, and combustion stability.

How does heat transfer happen in a steam boiler?

Heat is transferred through the heat exchanger tubes inside the boiler:

Flue gases from combustion travel around or through the tubes

Water inside the tubes absorbs the heat

As water temperature increases, it turns into steam

Efficient heat transfer is crucial for fuel economy and boiler output

Boilers are designed with fire-tube or water-tube configurations to optimize this process.

Why are sensors and control systems important in a steam boiler?

Sensors and controls monitor:

Pressure

Temperature

Water levels

Flame detection

Fuel-to-air ratios

These systems help prevent accidents, maintain performance, and optimize fuel use. Modern boilers use digital control panels and SCADA systems for real-time monitoring and automation.

References

ASME Boiler & Pressure Vessel Code – https://www.asme.org

Cleaver-Brooks Boiler Systems – https://www.cleaverbrooks.com

Spirax Sarco – Steam Boiler Components Explained – https://www.spiraxsarco.com

Thermodyne Engineering – Boiler Working Principles – https://www.thermodyneboilers.com

EPA Industrial Steam Boilers Guide – https://www.epa.gov

Powerhouse Boiler Equipment – Parts & Systems – https://www.powerhouse.com

Hurst Boiler Technical Specs – https://www.hurstboiler.com

Indeck Industrial Boiler Design – https://www.indeck.com

Industrial Boiler Inspection Best Practices – https://www.bioenergyconsult.com

Boiler Room Guide – Cleaver-Brooks – https://www.cleaverbrooks.com/boiler-room-guide

Wade Zhang

What’s Inside an Industrial Steam Boiler? Key Parts Explained Read More »

-scaled.jpg)